an easier way to get rid of / massively reduce box vibrations would be to mount the drivers in an opposite push-push

It has been mentioned before, but since it is such an excelent solution not taking advantage seems silly.

Mass of the box in itself is not a metric that tells you much. A push-push box can have much less heroic construction and yet outperform a box such as the OP’s.

We did a test build with 2 x SDX10 push-push in. 15mm BB box with a set of simple cross-braces. It worked supremely well. One could pick the box up sans drivers w 2 fingers in a driver cut-out — add the woofers and 2 people are usually needed.

dave

Not opposing driverson opposite walls, opposing drivers in the same box close to each other:

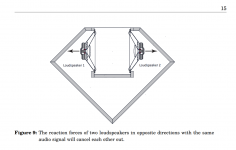

In the image (stolen from https://rmsacoustics.nl/papers/whitepaperdistortion.pdf) we have a push-push configuration. Another option is a push-pull config if we invert one driver (but keep the cone movement same as in the picture) then we will in addition to cancelling the forces also cancel even order distortion. Kind of like a push-pull amplifier, but with a speaker.

In the image (stolen from https://rmsacoustics.nl/papers/whitepaperdistortion.pdf) we have a push-push configuration. Another option is a push-pull config if we invert one driver (but keep the cone movement same as in the picture) then we will in addition to cancelling the forces also cancel even order distortion. Kind of like a push-pull amplifier, but with a speaker.

Attachments

As long as the distance between the drivers (around the outside of the box) is such that it is less than a quarter wavelength then there will be no FR issues from the driver separation.

Just design the box so the magnets are close (also aids in better driver coupling).

Note that with the configuration shown in the previous post it is hard to get good driver coupling and also a harder than necessary box to build.

dave

Just design the box so the magnets are close (also aids in better driver coupling).

Note that with the configuration shown in the previous post it is hard to get good driver coupling and also a harder than necessary box to build.

dave

Here's a video of something like the OP's bracing concept albeit on a much smaller box. Viewers can decide if it is inaudible marketing nonsense or inaudible audio purist care-taking (at least for a smaller box)?

800 Series: Cabinet bracing to the ultimate level - YouTube

B.

800 Series: Cabinet bracing to the ultimate level - YouTube

B.

Last edited:

For what it’s worth I have found that the more bracing I put into my subwoofers, the better they sound.

The last box I built was slot ported box for a monster driver, 4” p-p excursion on 2kw, and that was braced in the manner amp f your box but with triangular windows instead of rectangles.

This was all done with a router, there was a lockdown on and I had the time , and I have to say it did sound better than the previous box, which was identical in volume but not as excessively braced.

, and I have to say it did sound better than the previous box, which was identical in volume but not as excessively braced.

I think there is more to it than panel resonance, perhaps an aperiodic moment to the airflow within the box or something.

Either way, tighter, punchier and crisper bass at volume.

Looking forward to seeing the beast in wood!

The last box I built was slot ported box for a monster driver, 4” p-p excursion on 2kw, and that was braced in the manner amp f your box but with triangular windows instead of rectangles.

This was all done with a router, there was a lockdown on and I had the time

I think there is more to it than panel resonance, perhaps an aperiodic moment to the airflow within the box or something.

Either way, tighter, punchier and crisper bass at volume.

Looking forward to seeing the beast in wood!

Use this calculator:

SPL sound level to dB pressure level sound pressure sound intensity unit dB Conversion of sound pressure to sound intensity sound units levels calculating spl sound level calculation air sound units level ratio decibel Pa kPa acoustic energy power co

Once you have the pressure in pascals, then:

Convert Pascal to Psi

SPL sound level to dB pressure level sound pressure sound intensity unit dB Conversion of sound pressure to sound intensity sound units levels calculating spl sound level calculation air sound units level ratio decibel Pa kPa acoustic energy power co

Once you have the pressure in pascals, then:

Convert Pascal to Psi

I really don't know how to apply that to the inside of a ported box. Do you?

Since the surfaces in my room have no more than negligible vibration I can feel even when playing loud music, I suppose the vibration inside a ported box would be likewise negligible. Since I can't recall ever having thought of using a ported sub for HiFi since around 1964, maybe you could enlighten us.

B.

Since the surfaces in my room have no more than negligible vibration I can feel even when playing loud music, I suppose the vibration inside a ported box would be likewise negligible. Since I can't recall ever having thought of using a ported sub for HiFi since around 1964, maybe you could enlighten us.

B.

Last edited:

140 dB spl @1m is within the realm of a 21" prosound driver in a ported box, which would would equate to 200 pascals, or 0.029 psi.

I have made my 2"x12" on 16" center ceiling move more than 1" P-P @20 hz, and the stick framed interior basement walls move like jello.

Loud to you may not be loud to anyone else.

I have made my 2"x12" on 16" center ceiling move more than 1" P-P @20 hz, and the stick framed interior basement walls move like jello.

Loud to you may not be loud to anyone else.

If that's accurate....

let's look at a 5x5 inch piece of a panel (most of the panels in a box are adjacent to an edge and so are very strong). My calculator says there will be 12 oz pushing against the ¾ inch Baltic birch.

Let's have a show of hands by everybody who thinks their BB will vibrate with 12 oz pushing on it?

(I may be way off base so I hope smarter people will correct me. BTW, I suppose a sealed box is a different matter.)

B.

let's look at a 5x5 inch piece of a panel (most of the panels in a box are adjacent to an edge and so are very strong). My calculator says there will be 12 oz pushing against the ¾ inch Baltic birch.

Let's have a show of hands by everybody who thinks their BB will vibrate with 12 oz pushing on it?

(I may be way off base so I hope smarter people will correct me. BTW, I suppose a sealed box is a different matter.)

B.

Wood is not isotropic, and assuming that a 5" square is held infinitely rigid by it's edges is foolish.

3/4 BB measures out to about 18.5 mm, thinner than 3/4 MDF.

A sealed box will have less SPL output compared to a ported box. What comprises the 'P' in SPL?

In the OP's case, he has a combined weight of 814 +/- grams of moving mass being driven back and forth by 2 x 2 hp motors. Baffle stiffness will be reduced by making 2 20" diameter holes to fit the drivers in.

3/4 BB measures out to about 18.5 mm, thinner than 3/4 MDF.

A sealed box will have less SPL output compared to a ported box. What comprises the 'P' in SPL?

In the OP's case, he has a combined weight of 814 +/- grams of moving mass being driven back and forth by 2 x 2 hp motors. Baffle stiffness will be reduced by making 2 20" diameter holes to fit the drivers in.

If that's accurate....

let's look at a 5x5 inch piece of a panel (most of the panels in a box are adjacent to an edge and so are very strong). My calculator says there will be 12 oz pushing against the ¾ inch Baltic birch.

Let's have a show of hands by everybody who thinks their BB will vibrate with 12 oz pushing on it?

(I may be way off base so I hope smarter people will correct me. BTW, I suppose a sealed box is a different matter.)

B.

If you don’t have the maths you need, the best way is to build a few boxes for the same driver and have a listen.

I did just that at the suggestion of an experienced member and found the results so instructive that went back and taught myself the maths to play with it even more!

.... is foolish. ....Baffle stiffness will be reduced by making 2 20" diameter holes to fit the drivers in.

I believe you are forgetting that those 20" holes have some elaborate cast aluminum braces across them.

B.

No, I am not forgetting about the baskets. Baskets are not solid aluminum discs bolted rigidly to a perfect rebate with a backing plate to spread the force. There is a compliance usually involved (foam gasket) and rely on a small surface area of wood for the screws or t-nuts to bear down on.

If you aren't familiar with modes in panels, there are youtube videos that will help you understand what happens at various frequencies.

If you aren't familiar with modes in panels, there are youtube videos that will help you understand what happens at various frequencies.

Here's a rather extreme example of an unbraced enclosure made from sheet metal. Skip to around the 6 minute mark to watch the various modes when the driver is swept.

Will a subwoofer play well in metal casing? - YouTube

Will a subwoofer play well in metal casing? - YouTube

I believe you are forgetting that those 20" holes have some elaborate cast aluminum braces across them.

Ben, still not enuff to completely replace the losses due to the holes.

dave

...If you aren't familiar with modes in panels, there are youtube videos that will help you understand what happens at various frequencies.

If you aren't familiar with the difference between theoretical vibration modes in panels and detection in human ears, there are perception texts you could read.

I've lost track of how many times I've tried to inveigle somebody to post audibility findings or even before-and-after plots of bracing (pretty trivial effort to do that test, eh).

B.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- CNC services