I’ve been following all the tham and roar threads on swedish audio forums where you (circlomanen) and Martinsson are participating/leading.

The HROAR has cought my attention for one the described sq, but not the leaset for its ease of build.

Would a peerless xls10 work i the HROAR version for 10” woof?

The HROAR has cought my attention for one the described sq, but not the leaset for its ease of build.

Would a peerless xls10 work i the HROAR version for 10” woof?

http://www.loudspeakerdatabase.com/Peerless/XLS-P830452

The Peerless XLS-P830452 is not a very suitable driver for a HROAR type of design. It would be usable with some DSP, but I guess it would sound quite resonant and "burkig" in swedish. It could probably be quite ok with some heavyhanded DSP and use of damping wool, but there are probably better designs for that driver. The HROAR design seems to prefer the typical 12 inch pro drivers. Low mms, high(ish) Fs, lots of BL, low Qts etc etc. B&C 12PS100 or 12TBX100 are two good candidates.

one complaint about the (conventional) roar, mechanical noise of the drivers especially it seems when they’re sitting at velocity max for the upstream quarter wave path and all that air makes a swishing sound(hard to explain since it’s going much faster than ‘swish’

But no matter what anyone says these things spank ‘ Paraflex ‘ on the bottom end or at least have the potential to depending how you lay them out I guess? I just finished dialing in a roar in a vehicle where the pairflex was removed And is going directly in Monday’s trash(after hearing the roar in alll its potential )

But no matter what anyone says these things spank ‘ Paraflex ‘ on the bottom end or at least have the potential to depending how you lay them out I guess? I just finished dialing in a roar in a vehicle where the pairflex was removed And is going directly in Monday’s trash(after hearing the roar in alll its potential )

I don't want to denigrate other designs (except for bassreflex), but one aspect that is as overlooked as it is misunderstood about the ROAR or other 8th order QW series bandpass designs is the positive feedback and substantial increase in virtual Bl that is a large part of the high power response that does not show up in Hornresp-sims. ROAR designs does not thermally or acoustically compress in the same way as many other designs do - and this is very apparent in the midbass where the positive feedback is most pronounced. They just seem to get louder and louder in an almost slightly exponential way until the voilcoil catastrophically fails and the output instantly vanishes. We have been pushing insane amounts of power into several different HROAR and ROAR designs, and if you are lucky you feel a smell of burned voicecoil a few seconds before the driver is destroyed.

This character does add a sense of abundant power that only increases with power level and is very strange for those used to bass reflex or other Helmholtz based designs. Many describe them as getting more and more powerful, tactile and punchy with increasing powerlevels - all the way up to a catastrophic driver fail. And this seems to follow a slight exponential curve, which is kind of the hallmark of positive feedback. But the effect is more pronounced then I could imagine before actually building one and testing it with some real power (Powersoft K10 powering a single B&C 12PS100).

This character does add a sense of abundant power that only increases with power level and is very strange for those used to bass reflex or other Helmholtz based designs. Many describe them as getting more and more powerful, tactile and punchy with increasing powerlevels - all the way up to a catastrophic driver fail. And this seems to follow a slight exponential curve, which is kind of the hallmark of positive feedback. But the effect is more pronounced then I could imagine before actually building one and testing it with some real power (Powersoft K10 powering a single B&C 12PS100).

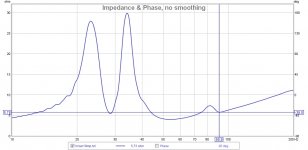

If you trade the high efficiency of the ROAR for an extended bandwidth, but you stick with the QW based series 8th order BP, you end up with a strange looking simulated beast. It does need lots of DSP and some careful use of damping to tame the response to something suitable for indoor use.

Max Spl for 150 watt and 12.5 + 12.5 mm xmax.

Add anywhere from 3 dB to 20 dB of spl depending on the room gain profile of your listing space. This is simulated in 1.0 Pi (along a wall - not corner loaded).

https://www.diyaudio.com/community/threads/tp12ll34-duality-and-positive-feedback.344958/

It is the non expanding - extended bandwidth - version of the ROAR as described in the link above. In this case the box would be 1500 mm tall (if standing upright).

The Peerless XLS10 is a sub driver and is better suited for this kind of enclosure.

That's a characteristic of well-designed bandpass systems, particularly those with good out-of-band noise rejection (which can be difficult to achieve with vents that are large enough to minimize vent compression effects). The limited passband reduces or removes HD, so there's less audible notification that the driver's limits are being exceeded. Unfortunately, they might not dump heat as well as other designs because of the location of the driver in the box. The ROAR (and TH designs) are probably better at dumping heat than other BP designs though, for the same reason.They just seem to get louder and louder in an almost slightly exponential way until the voilcoil catastrophically fails and the output instantly vanishes.

To protect the BP subwoofer currently in use in my brother's bar, I wired a simple protection circuit in series with it. Basically two PTCs and a resistor. If one PTC was triggered, the input to the driver would be reduced by about 2.5dB around where power utilization would be highest. The second PTC basically cut almost all power to the driver if it was really overdriven. It's been a few years now and it's still operating successfully.

Thanks for the pointers. I have the xls 10 on hand, thats why I wanted to use it.View attachment 1092056

http://www.loudspeakerdatabase.com/Peerless/XLS-P830452

The Peerless XLS-P830452 is not a very suitable driver for a HROAR type of design. It would be usable with some DSP, but I guess it would sound quite resonant and "burkig" in swedish. It could probably be quite ok with some heavyhanded DSP and use of damping wool, but there are probably better designs for that driver. The HROAR design seems to prefer the typical 12 inch pro drivers. Low mms, high(ish) Fs, lots of BL, low Qts etc etc. B&C 12PS100 or 12TBX100 are two good candidates.

But I will source a new suitable driver for the HROAR design insted.

I do not want to go much bigger then 8~10” so that the box wont petrude in to the room to much.

The HROAR will compliment the low end of a pair of Stage Accompany ps44 monitors (93db/w 1m, 8 Ohm ) power to the HROAR will be 170w @ 4 Ohm and 2x40 w 8 Ohm for the Stage Accompanys ( James loudspeaker a2.1 amp). I do not have any DSP on hand just the xo in the James loudspeaker amp.

Room is about 42 sq meters.

Will a 8” in HROAR keep up with the Stage Accompany monitors in those circumstances.

Last edited:

Indeed, the front chamber is an acoustic low pass filter same for a horn.That's a characteristic of well-designed bandpass systems, particularly those with good out-of-band noise rejection (which can be difficult to achieve with vents that are large enough to minimize vent compression effects). The limited passband reduces or removes HD, so there's less audible notification that the driver's limits are being exceeded. Unfortunately, they might not dump heat as well as other designs because of the location of the driver in the box.

stinky voice coils (new) are a fact! this is stupid fun! (need to verify the sim detsils

and real)

https://www.skaraudio.com/products/skv2-4500-1d-monoblock-subwoofer-car-amplifier

and real)

https://www.skaraudio.com/products/skv2-4500-1d-monoblock-subwoofer-car-amplifier

Attachments

Last edited:

I do not want to go much bigger then 8~10”

I do not have any DSP on hand just the xo in the James loudspeaker amp.

The HROAR design tends to become very peaky and resonant with smaller drivers. I will see what I can do, but it might take a few days. It is often difficult to find solid data on small car audio bass drivers, and 8 inch pro drivers are often more mid or mid-bass with Fs at around 60 - 90 Hz.

The B&C 12PS100 does give a fairly flat response down to 35 Hz or so in a reasonably compact enclosure. It will protrude at least 45 - 50 cm into the room from the wall. A B&C 8FG51 is not really suitable for a HROAR type of enclosure.

The HROAR design tends to become very peaky and resonant with smaller drivers. I will see what I can do, but it might take a few days. It is often difficult to find solid data on small car audio bass drivers, and 8 inch pro drivers are often more mid or mid-bass with Fs at around 60 - 90 Hz.

The B&C 12PS100 does give a fairly flat response down to 35 Hz or so in a reasonably compact enclosure. It will protrude at least 45 - 50 cm into the room from the wall. A B&C 8FG51 is not really suitable for a HROAR type of enclosure.

View attachment 1092612 View attachment 1092611

I see, I might go for a larger driver then but that want happen very soon due to lack of space. Please don’t waist your time on modeling for smaller (8”-10”) drivers if they tend to behave a little wild.

I will try to repair a humming Sunfire sub I have sitting around and try of it Will satisfy.

To bad that I can’t find any T/S of the drive unit in it. It really seem to be of the typical car audio woofer type, small VAS, big big magnet and heavy stiff cone. Maybe it could have been used in a HROAR, but without the T/S there us ni way to know I guess.

The thing that sucks about that tyight VAS is that the only way to get that smoother response is to get really scary skinny (small csa) on your upstream resonator section?I see, I might go for a larger driver then but that want happen very soon due to lack of space. Please don’t waist your time on modeling for smaller (8”-10”) drivers if they tend to behave a little wild.

I will try to repair a humming Sunfire sub I have sitting around and try of it Will satisfy.

To bad that I can’t find any T/S of the drive unit in it. It really seem to be of the typical car audio woofer type, small VAS, big big magnet and heavy stiff cone. Maybe it could have been used in a HROAR, but without the T/S there us ni way to know I guess.

Maybe circlomenin can elaborate on this 🙏🏻but it makes me very apprehensive and/or I would push this further instead of using the parallel version (A modified Paraflex that works much better, than -most- paraflex because it’s lined up appropriately instead of so awkwardAt random. (The type C Paraflex is the only one that seems to almost hold a perfect alignment and offset entry from both points in a variety of different ways you can simulated using either parallel endpoints or advanced centerline or reality as measured and built cabinet thankfully

Those endpoints or initial reflection from the driver location(and then back again hypothetically or as one would see if this was an actual thermal acoustic motor that was relying on that) seem to very much matter in all of this and it shows up in simulation as well

Outgoing wave and returning reflection overlapping at certain frequencies at the same exact time the driver is making the same pressurized or rarefy and this all becomes a pendulum swing and synchronicity if you look at it that way and the results speak for them selves?

you don’t get any funny buzzes or beat frequency type weirdness or whatever description you want to use as extra resonances and phenomen like that and all kinds of funky junk that very much becomes present in these if that scenario doesn’t seem to fit?

it might be why they sometimes have a bad reputation by those who didn’t take the time to experiment with them long enough to figure them out and just assume they’re all junk because of that? Those are the same people who just use simple base reflex or sealed boxes anyhow so the argument is pointless and only relevant to those of us who want to look at these things here and why they’re so interesting and when comparing and contrasting to suck a couple other things we see there is a commonality in what’s going on and it’s either wide bandwith(offset driver tapped qw pipe @ 0349) or it’s wide band with and super loud(A nicely lined up to 70/90 with 30 offset Paraflex) or it’s a little bit of both and some type of lower tune bias , if wanted, to go along with it(?) (roar??)

Last edited:

When wanting us to critique HR sims please Export the file for us to (down) load. TIAdoes this look reasonable? using the l26ro4y

- Home

- Loudspeakers

- Subwoofers

- ROAR with Helmholtz front resonator