Aesthetics are driving a lot of this, but they are also trying to optimize the acoustics within the form factor of interest.

I think the plan is still to use a Dayton Audio LW150-4, which is a low-profile 6 inch woofer (post #34). System resonance should be around 60 Hz. Combined with on-wall mounting, the bass will likely be respectable.

I think the plan is still to use a Dayton Audio LW150-4, which is a low-profile 6 inch woofer (post #34). System resonance should be around 60 Hz. Combined with on-wall mounting, the bass will likely be respectable.

From Ikea Symfonisk Picture Frame Speaker reviews:

"I’ve already said that it’s not, strictly speaking, a picture frame - at 60mm - the frame is fairly thick, so will jut out of the wall. That makes it more obvious that this is more than it seems"

"Despite Ikea calling it a picture frame, this is unmistakably a speaker to anyone who looks at it. It doesn’t hide in your home at all ... "

"Great sound, but as a Picture Frame it fails"

"I’ve already said that it’s not, strictly speaking, a picture frame - at 60mm - the frame is fairly thick, so will jut out of the wall. That makes it more obvious that this is more than it seems"

"Despite Ikea calling it a picture frame, this is unmistakably a speaker to anyone who looks at it. It doesn’t hide in your home at all ... "

"Great sound, but as a Picture Frame it fails"

I've seen varying opinions about standard silicone (the kind with acetic acid) in speaker boxes. Some fear damage to speaker components due to outgassing. Water based/latex or urethane glues and caulks are typically preferred inside cabinets.

Another thing to consider is the difficulty of removing the driver if you glue it into the cabinet. For driver flanges, I typically use an easily compressed, thin weatherstrip to seal them. There are also rope caulks available for this application. You really don't need extreme measures here, and drivers can be quite hard to remove even with basic gasketing, so I'd be careful with this aspect.

https://www.parts-express.com/speak...aker-grill-cloth/Speaker-Gasketing-Tape-Caulk

Gluing the back of the driver to the rear cabinet wall seems a little tougher to do in an easily reversed way. Some ideas that aren't well thought out:

1) apply the glue through holes in the back panel that can be drilled out to remove most of the glue when necessary

2) use a 2-sided tape that has poor high temperature performance so you can pop the enclosure in a 200-ish °F oven to weaken the adhesive when needed

3) use a small sub-panel that glues/tapes to the speaker. This can fit from the inside of the box into a recess in the rear panel where you screw the two panels together. This seems like the best of these options.

Another thing to consider is the difficulty of removing the driver if you glue it into the cabinet. For driver flanges, I typically use an easily compressed, thin weatherstrip to seal them. There are also rope caulks available for this application. You really don't need extreme measures here, and drivers can be quite hard to remove even with basic gasketing, so I'd be careful with this aspect.

https://www.parts-express.com/speak...aker-grill-cloth/Speaker-Gasketing-Tape-Caulk

Gluing the back of the driver to the rear cabinet wall seems a little tougher to do in an easily reversed way. Some ideas that aren't well thought out:

1) apply the glue through holes in the back panel that can be drilled out to remove most of the glue when necessary

2) use a 2-sided tape that has poor high temperature performance so you can pop the enclosure in a 200-ish °F oven to weaken the adhesive when needed

3) use a small sub-panel that glues/tapes to the speaker. This can fit from the inside of the box into a recess in the rear panel where you screw the two panels together. This seems like the best of these options.

I think I will just use water dissolved wood glue and included driver sealsI've seen varying opinions about standard silicone (the kind with acetic acid) in speaker boxes. Some fear damage to speaker components due to outgassing. Water based/latex or urethane glues and caulks are typically preferred inside cabinets.

Another thing to consider is the difficulty of removing the driver if you glue it into the cabinet. For driver flanges, I typically use an easily compressed, thin weatherstrip to seal them. There are also rope caulks available for this application. You really don't need extreme measures here, and drivers can be quite hard to remove even with basic gasketing, so I'd be careful with this aspect.

https://www.parts-express.com/speak...aker-grill-cloth/Speaker-Gasketing-Tape-Caulk

Gluing the back of the driver to the rear cabinet wall seems a little tougher to do in an easily reversed way. Some ideas that aren't well thought out:

1) apply the glue through holes in the back panel that can be drilled out to remove most of the glue when necessary

2) use a 2-sided tape that has poor high temperature performance so you can pop the enclosure in a 200-ish °F oven to weaken the adhesive when needed

3) use a small sub-panel that glues/tapes to the speaker. This can fit from the inside of the box into a recess in the rear panel where you screw the two panels together. This seems like the best of these options.

Hi Mattstat,

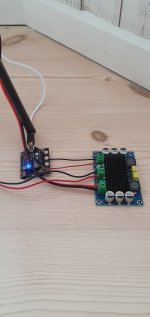

Long time no see. Just want to tell you that this little TPA3116D2 amplifier board solved all my distortion problems 😁 Paired with a small versatile Tinysine Broadcomm based BT module with AptX HD, TWS and Partymode.

Your freind,

Ole

Long time no see. Just want to tell you that this little TPA3116D2 amplifier board solved all my distortion problems 😁 Paired with a small versatile Tinysine Broadcomm based BT module with AptX HD, TWS and Partymode.

Your freind,

Ole

Attachments

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Thin backplate material for 24" x 24" 3-way speaker