Hi all-

I am excited to report I have finally found and purchased a pair of Beveridge electrostatic speakers. I am NOT excited to report they are in rough shape and do not currently run; they need significant work. So let's start a conversation, shall we? I'm happy to hear from anyone who's been there and done that.

They are model 2SW-1 but the separate woofers are gone. The amps need a significant amount of work, time & money to fix. Before I do all that I first want to verify the health of the ESL elements, to the extent possible anyway. So let's start with them.

I have not opened the cabinets yet but the capacitance measured at the banana plugs is ~2,500pF from stator-to-stator, and it's one-half that from the membrane to any stator (~1,300pF). Both cabinets measure the same; I take that as a hopeful sign.

So... what do you think? What testing and inspections should I be doing here? Any input is most welcome, these are unique in many ways and I could easily be missing some important detail (or several ).

).

Many thanks.

I am excited to report I have finally found and purchased a pair of Beveridge electrostatic speakers. I am NOT excited to report they are in rough shape and do not currently run; they need significant work. So let's start a conversation, shall we? I'm happy to hear from anyone who's been there and done that.

They are model 2SW-1 but the separate woofers are gone. The amps need a significant amount of work, time & money to fix. Before I do all that I first want to verify the health of the ESL elements, to the extent possible anyway. So let's start with them.

I have not opened the cabinets yet but the capacitance measured at the banana plugs is ~2,500pF from stator-to-stator, and it's one-half that from the membrane to any stator (~1,300pF). Both cabinets measure the same; I take that as a hopeful sign.

So... what do you think? What testing and inspections should I be doing here? Any input is most welcome, these are unique in many ways and I could easily be missing some important detail (or several

Many thanks.

Last edited:

Congratulations on the Beveridges

Still amazing speakers after all these years. I have Model IIIs that I have modified to run with pure tube direct drive amps

While the electrostatic elements are fragile with careful handling they will slide out and should be vacuumed. I know that Rick Beveridge used compressed air - I would be careful to avoid that. You likely have lots of remnants from the foam grilles in the stators.

The aluminized film should not be peeling and you should not be able to see straight through it. Otherwise it cannot be tensioned with heat if it is sagging. It should be ok.

The stator elements will be very brittle.. be careful . there may be some missing. This was likely done at the factory as they were pulled from molds or if there were hot spots

The amps will have to be completely serviced with new sockets and new components. The transformer is a weak link but hopefully you are lucky.

Nice find,

Still amazing speakers after all these years. I have Model IIIs that I have modified to run with pure tube direct drive amps

While the electrostatic elements are fragile with careful handling they will slide out and should be vacuumed. I know that Rick Beveridge used compressed air - I would be careful to avoid that. You likely have lots of remnants from the foam grilles in the stators.

The aluminized film should not be peeling and you should not be able to see straight through it. Otherwise it cannot be tensioned with heat if it is sagging. It should be ok.

The stator elements will be very brittle.. be careful . there may be some missing. This was likely done at the factory as they were pulled from molds or if there were hot spots

The amps will have to be completely serviced with new sockets and new components. The transformer is a weak link but hopefully you are lucky.

Nice find,

Attachments

Actually RM made the initial amp and then I took it further and built my own version

Sadly RM has just passed away- what a loss. I will be making another amp with some further thoughts. Right now I am working on a preamp and have a tape pre in line as well.

Without Roger's work I really could not have cracked some of the issues I was having and now have an outstanding DD amp that many feel is a fabulous pairing with the Beveridges. I am very pleased with it.

I don't know who would take that on today with RM gone. Curcio perhaps?

Sadly RM has just passed away- what a loss. I will be making another amp with some further thoughts. Right now I am working on a preamp and have a tape pre in line as well.

Without Roger's work I really could not have cracked some of the issues I was having and now have an outstanding DD amp that many feel is a fabulous pairing with the Beveridges. I am very pleased with it.

I don't know who would take that on today with RM gone. Curcio perhaps?

Please keep in touch. I have a day job that keeps me busy. When I build my 3rd iteration I will let you know.

The direct drive is transformational for the model IIIs ... I think it is better than the original Beveridge amps with the SS input. Mine are all tube. and very robust.

The direct drive is transformational for the model IIIs ... I think it is better than the original Beveridge amps with the SS input. Mine are all tube. and very robust.

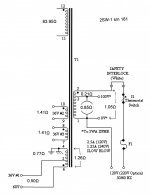

Here are the power transformer DCR values for one of my amps. All windings were disconnected and I used a 4-wire ohmmeter for these measurements. Will post the other transformer when I can.

Then I ran some AC thru it with good results. I did the usual 'creep up slowly with a Variac and a light bulb' thing. All secondaries were disconnected except for my meters. It seems to be OK; I got all the way up to 120v and it didn't blow the 0.5A fuse I had on the primary.

(What is the typical failure mode of the transformers? Or does it vary?)

Then I ran some AC thru it with good results. I did the usual 'creep up slowly with a Variac and a light bulb' thing. All secondaries were disconnected except for my meters. It seems to be OK; I got all the way up to 120v and it didn't blow the 0.5A fuse I had on the primary.

(What is the typical failure mode of the transformers? Or does it vary?)

Attachments

Last edited:

(...)there can be a short cut between this winding and other windings(...)

All my windings measure as opens to all other windings. Seems like it's OK - let's hope the second one is too.

Thank you for your input.

You can NOT measure with an ordinary multimeter... you have to use an Insulation meter that use at least 1000Volt on the output!

Like this one: 1008-221, AVO835 Multimeter digital RMS 750 VAC Megger

Like this one: 1008-221, AVO835 Multimeter digital RMS 750 VAC Megger

If you have a small crack in the insulation you will probably not find any fault with a multimeter. You have to increase the voltage close to the voltage when in use, to seen any defects. Trust me.

Íf you know of any electrician they have insulation tester, use at least 1000 volt range, preferably MORE than 1000Volt since we are talking about 1600-3200 volt.

SO a perfectly healthy transformer should withstand 5kV !! But those insulation testers is rare. I have built my own instrument from a Bias supply from a QUAD ESL 63 (5,25 kV) . WIth this arrangement i managed to find and repair a set of Beveridge speakers. It took me a while to find that issue... i worked for several weeks. I never considered the popping noise would originate from the mains transformer. Instead i swapped tubes, worked on the input stage, changed all electrolytics, and even the film caps. When i finally swapped main transformer between the working amp and the non working amp as a last attempt, i found the root cause...

Íf you know of any electrician they have insulation tester, use at least 1000 volt range, preferably MORE than 1000Volt since we are talking about 1600-3200 volt.

SO a perfectly healthy transformer should withstand 5kV !! But those insulation testers is rare. I have built my own instrument from a Bias supply from a QUAD ESL 63 (5,25 kV) . WIth this arrangement i managed to find and repair a set of Beveridge speakers. It took me a while to find that issue... i worked for several weeks. I never considered the popping noise would originate from the mains transformer. Instead i swapped tubes, worked on the input stage, changed all electrolytics, and even the film caps. When i finally swapped main transformer between the working amp and the non working amp as a last attempt, i found the root cause...

I get that the megger is the ultimate tool. No hobbyists will have one. Almost no audio service technicians will have one.

In order to get your speakers up and running you have independently tested for output on each of the windings and verified the similarity to the other transformer.

That's enough to get you going with the rebuild. Unfortunately a bad transformer with intermittent insulation breakdown will be difficult to replace. Rewinding may be possible with someone like heyboer or you can adapt and use multiple aftermarket transformers to get to where you want to go. For now you can forge ahead .

If you are set on megging the transformer.. go to a motor or transformer shop in your town and see if you can get them to do it for you. should take 5 minutes.

In order to get your speakers up and running you have independently tested for output on each of the windings and verified the similarity to the other transformer.

That's enough to get you going with the rebuild. Unfortunately a bad transformer with intermittent insulation breakdown will be difficult to replace. Rewinding may be possible with someone like heyboer or you can adapt and use multiple aftermarket transformers to get to where you want to go. For now you can forge ahead .

If you are set on megging the transformer.. go to a motor or transformer shop in your town and see if you can get them to do it for you. should take 5 minutes.

- Home

- Loudspeakers

- Planars & Exotics

- New owner of Beveridge Electrostatics!