Don‘t overestimate the word „stand-by“… it’s just that ss-board standing by, waiting for your finger to push the button…

Having it running first certainly is a good path to follow, except that you‘ll be dis-/ assembling that beast a few more times. (Well and I actually wrecked my WLS this way)

Re: SS being able to handle the inrush current—as I have understood, there’s the relays which switch from softstart to full throttle, and more importantly, the resistors or in Mark’s jig the thermistors that handle the current-spike, these must be able to sustain the peak.

Then, on the store’s board, there’s some capacitor which regulate the timing, how Mark’s handles it I don‘t remember.

I am pretty sure all of the mentioned jigs are easily able to handle the inrush current of your PSU…

Last sentence, I think so too. And the space saver of all time is CL-60. Though I’d really like a soldered solution. Alternatively the allready finished softstart boards, there will be room for them.

Regarding the cap on the stores boards, that will be the part that MIGHT need changing. But maybe not. I do believe it will work fine as is, but no math to support that assumption. That it works for Russels BA-3, is encouraging as long as he used the stock cap value?

Hi Andy,

I was planning like you to have an oversized power supply, "soft-starting" with 2 CL-60. I thought like you, to replace it (one day), until I checked I think Amtherm's guide on choosing thermistors. Mark Johnson has some nice links to start with researching in his thread about the soft start, google will you find more.

To make it short: the CL-60 can't handle your amount of capacitance. And there is the likelihood that it might fail shorted: not so nice.

A bigger one is the Amtherm MS32 50006-L. Please compare the datasheets and read about how to calculate soft starts. 0.8F is quite a lot, to second poseidonsvoice's opinion.

I didn't want to slow down you, but this is meant just for your safety.

Enjoy building!

Best regards,

Matthias

I was planning like you to have an oversized power supply, "soft-starting" with 2 CL-60. I thought like you, to replace it (one day), until I checked I think Amtherm's guide on choosing thermistors. Mark Johnson has some nice links to start with researching in his thread about the soft start, google will you find more.

To make it short: the CL-60 can't handle your amount of capacitance. And there is the likelihood that it might fail shorted: not so nice.

A bigger one is the Amtherm MS32 50006-L. Please compare the datasheets and read about how to calculate soft starts. 0.8F is quite a lot, to second poseidonsvoice's opinion.

I didn't want to slow down you, but this is meant just for your safety.

Enjoy building!

Best regards,

Matthias

No on the separate power supply. I was going to, but converted a couple of amps into switchable mono blocks, but have since returned them to 2 stereo amps.I read about that board, Russel. Seems really nice. I am kinda thinking keeping it as simple *** possible just for now, and perhaps employing the fancy stuff later. I saw one of Marka circuits, prolly the one you are referring to, also had 12v remote switch on functionality. Really nice.

Did you once make an external PSU?

That would save all the space worries, and perhaps reduce risk of inductors magnetically coupling with tranny and circuitry and so on... then I could put the 100kuFs in the amp case. Have been contemplating it, but dunno if it is worth the extra cost and work at this point.

Would need some umbilicals and dc entries and outputs, and also a careful gnd routing scheme.

Pointers appreciated.

Cheers,

Andy

Keeping it simple is a great idea. Makes it easier to get right the first time, and easy to diagnose if something goes wrong. Then, once its as it should be you can play and will know if the play is the problem.

Russellc

What will really pay off in my opinion is spending a few hours thinking of how you can make the modules, e.g. the power supply and the output stage as easy as possible dismountable.

So, if you then one day have to repair something or you want so try another output stage, you don't have to dismount first you whole chassis -- in my first build I had to do this.

There are lots of good builds here, but like always in life, you have to know beforehand to understand when you see it.

To the softstarts:

Here on diyaudio are plenty recommendations. I've looked arround, also on other homepages, and made a list what I wanted, and then checked which design is the best for my needs. Therefore I boiled it down to 4:

The SST03 softstart from Sjöström audio (a helpful and kind member here):

This one was my first softstart, I ordered a beautiful PCB from Per Anders, and everything is perfectly documented and worked from the first power-on until today. Works with two relais and resistors.

2nd: FdW's softstart

Frans de Witt FdW is also a member here, and one of the best amplifier designers on this planet, Joachim Gerhard praised him a lot when I was reading in Joachim's MTT thread.

* As my time is limited, I skipped this one, because it lacks a documentation. It is for people with more time or knowledge, and for sure a very refined soft start with some gimmicks in its pockets. Soft Start / Missing Cycle Detector / On-Off Mute Controller

3rd:

Soft as a feather pillow from XRK971:

*Easy to get, good documentation

And 4th:

Mark Johnson's softstart

*Good documentation, Gerber files to order you PCBs

For me Mark Johnson's softstart won, I ordered the PCB, I hope this week the parts will follow.

Some criteria:

* Relais or solid state to do the switching?

* Can I use a low current switch at the front (has a plus to not route a power cable from the back to the front and back)

* How much energy can be switched reliable? (E = 0,5 * U² * C)

* Does the PCB fit into my chassis?

* insert your criteria here

By the way I checked the costs for shipping a PCB to Norway. Shipping got so expensive, why? Maybe ordering at a Chinese fab is more interesting for you. But if you prefer to receive a PCB from me, I can sent it to you for 17,50€ with tracking or 14€ without.

Edit:

I forgot the best:

BA3 is identical to the F4, which is until now my favorite FirstWatt amp!

Have fun,

Matthias

So, if you then one day have to repair something or you want so try another output stage, you don't have to dismount first you whole chassis -- in my first build I had to do this.

There are lots of good builds here, but like always in life, you have to know beforehand to understand when you see it.

To the softstarts:

Here on diyaudio are plenty recommendations. I've looked arround, also on other homepages, and made a list what I wanted, and then checked which design is the best for my needs. Therefore I boiled it down to 4:

The SST03 softstart from Sjöström audio (a helpful and kind member here):

This one was my first softstart, I ordered a beautiful PCB from Per Anders, and everything is perfectly documented and worked from the first power-on until today. Works with two relais and resistors.

2nd: FdW's softstart

Frans de Witt FdW is also a member here, and one of the best amplifier designers on this planet, Joachim Gerhard praised him a lot when I was reading in Joachim's MTT thread.

* As my time is limited, I skipped this one, because it lacks a documentation. It is for people with more time or knowledge, and for sure a very refined soft start with some gimmicks in its pockets. Soft Start / Missing Cycle Detector / On-Off Mute Controller

3rd:

Soft as a feather pillow from XRK971:

*Easy to get, good documentation

And 4th:

Mark Johnson's softstart

*Good documentation, Gerber files to order you PCBs

For me Mark Johnson's softstart won, I ordered the PCB, I hope this week the parts will follow.

Some criteria:

* Relais or solid state to do the switching?

* Can I use a low current switch at the front (has a plus to not route a power cable from the back to the front and back)

* How much energy can be switched reliable? (E = 0,5 * U² * C)

* Does the PCB fit into my chassis?

* insert your criteria here

By the way I checked the costs for shipping a PCB to Norway. Shipping got so expensive, why? Maybe ordering at a Chinese fab is more interesting for you. But if you prefer to receive a PCB from me, I can sent it to you for 17,50€ with tracking or 14€ without.

Edit:

I forgot the best:

BA3 is identical to the F4, which is until now my favorite FirstWatt amp!

Have fun,

Matthias

Re: Soft start

For what it's worth, another data point regarding soft starting:

I have a dual-mono PSU, 400 VA transformer, 264,000 uF.

So, together 2x 400 VA transformer, 528 mF capacitance. That's not 0.8F, but still a good 0.5F.

I have run this PSU for my F4 and SissySIT so far.

I am using just a single CL-60 for the whole amp. 230V mains, 2A mains fuse.

Works perfectly for more than 2 years now.

Regards, Claas

For what it's worth, another data point regarding soft starting:

I have a dual-mono PSU, 400 VA transformer, 264,000 uF.

So, together 2x 400 VA transformer, 528 mF capacitance. That's not 0.8F, but still a good 0.5F.

I have run this PSU for my F4 and SissySIT so far.

I am using just a single CL-60 for the whole amp. 230V mains, 2A mains fuse.

Works perfectly for more than 2 years now.

Regards, Claas

Attachments

That is very, very good news, Claas. Thank you for sharing both your experience and the pic of a beautiful amp. Kudos!

I was actually contemplating doing the connections under the trannies up front, just like you. If so I was planning on using two CL-60s, one per PSU/channel.

I was under the impression that I have to use one fuse per mono PSU, and have parts for that. But it does complicate things a tad. Could you please share your view on the subject?

Regards,

Andy

I was actually contemplating doing the connections under the trannies up front, just like you. If so I was planning on using two CL-60s, one per PSU/channel.

I was under the impression that I have to use one fuse per mono PSU, and have parts for that. But it does complicate things a tad. Could you please share your view on the subject?

Regards,

Andy

Hi Andy,

- on the CL-60: I purposefully used just one CL-60, so that it has enough current running through it when the amp is operating in steady-state (about 1 A). That way, it heats up properly and has less voltage loss. If the one CL-60 wouldn't withstand the inrush current, I would use one per transformer ...

- regarding the fuses: for ease-of-use purposes, I use the one fuse that the IEC inlet caters for. I like my fuses close-rated; if a fuse blows every couple months on switch-on, I consider it correctly sized .

.

However, in addition to that, I have two more fuses, between distribution block and transformers (everything mounted on a small perf board between the two transformers).

Zen Mod always advises to fuse each mono PSU side separately, and I agree that it provides better protection to the components in the case of a short in one of the channels. I don't remember exactly, but I think I have 1.6A fuses for the two mono sides.

It would be a pain to change these for the occasional fuse-blow, because I would have to open up the amp. So I choose for my "primary" fuse in the IEC inlet a closer-rated 2A one, so that that one would blow on inrush. Has worked perfectly the last two years so far

Regards, Claas

- on the CL-60: I purposefully used just one CL-60, so that it has enough current running through it when the amp is operating in steady-state (about 1 A). That way, it heats up properly and has less voltage loss. If the one CL-60 wouldn't withstand the inrush current, I would use one per transformer ...

- regarding the fuses: for ease-of-use purposes, I use the one fuse that the IEC inlet caters for. I like my fuses close-rated; if a fuse blows every couple months on switch-on, I consider it correctly sized

However, in addition to that, I have two more fuses, between distribution block and transformers (everything mounted on a small perf board between the two transformers).

Zen Mod always advises to fuse each mono PSU side separately, and I agree that it provides better protection to the components in the case of a short in one of the channels. I don't remember exactly, but I think I have 1.6A fuses for the two mono sides.

It would be a pain to change these for the occasional fuse-blow, because I would have to open up the amp. So I choose for my "primary" fuse in the IEC inlet a closer-rated 2A one, so that that one would blow on inrush. Has worked perfectly the last two years so far

Regards, Claas

For what it's worth, another data point regarding soft starting:

I have a dual-mono PSU, 400 VA transformer, 264,000 uF.

So, together 2x 400 VA transformer, 528 mF capacitance. That's not 0.8F, but still a good 0.5F.

I have run this PSU for my F4 and SissySIT so far.

I am using just a single CL-60 for the whole amp. 230V mains, 2A mains fuse.

Works perfectly for more than 2 years now.

Regards, Claas

Explained mounting technique for those trannies would also be lovely. I have rise panels, but prolly need to weld the bolt to their underside. Plus they take up space. Would love to avoid them.

Regards,

Andy

Hi Andy,

- on the CL-60: I purposefully used just one CL-60, so that it has enough current running through it when the amp is operating in steady-state (about 1 A). That way, it heats up properly and has less voltage loss. If the one CL-60 wouldn't withstand the inrush current, I would use one per transformer ...

- regarding the fuses: for ease-of-use purposes, I use the one fuse that the IEC inlet caters for. I like my fuses close-rated; if a fuse blows every couple months on switch-on, I consider it correctly sized.

However, in addition to that, I have two more fuses, between distribution block and transformers (everything mounted on a small perf board between the two transformers).

Zen Mod always advises to fuse each mono PSU side separately, and I agree that it provides better protection to the components in the case of a short in one of the channels. I don't remember exactly, but I think I have 1.6A fuses for the two mono sides.

It would be a pain to change these for the occasional fuse-blow, because I would have to open up the amp. So I choose for my "primary" fuse in the IEC inlet a closer-rated 2A one, so that that one would blow on inrush. Has worked perfectly the last two years so far

Regards, Claas

Lovely, really lovely. I am on the lookout for such perfboards or the likes, as I want to solder as much as possible. Avoiding distribution blocks completely, is also sort of a goal since we are dealing with 230Vac. Kinda feels.... safer, guaranteed reliable.

I have i my boxes Littelfuse panelmount fuses, plan was to put them in the rear panel. I do have long primary wires, so with a bit of luck I can make my connections all down by the inlet. But doing them by the chassis front has it’s advantages too. Like less wire chaos right under the inlet, and also the front end which will be at the back.

Did you cut that perfboard yourself or did it come in that size?

BTW: my steady state will be approx 1 amp as well. Like the idea of letting the thermistor work.

Regards,

Andy

Last edited:

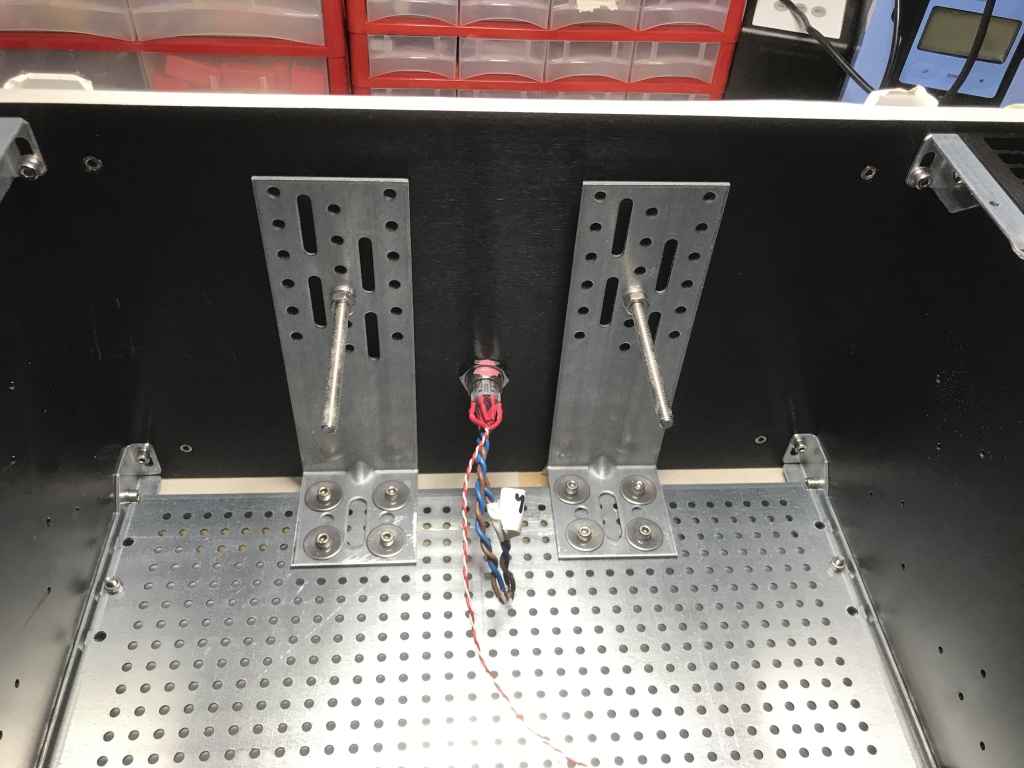

OK, last one before going to bed ...

Steel angles from Bauhaus (local hardware store). Not attached to front panel. Transformers are Toroidy audio grade, they come with resin-filled center with just a bore. Neoprene sheets on "top" and "bottom" of transformer; using the mounting disk that comes with the transformer. To give it a bit more stability, I wedge a piece of neoprene between the angle iron and the front panel, and between the transformer and the bottom plate - gives some tension on the angle iron.

Regards, Claas

Steel angles from Bauhaus (local hardware store). Not attached to front panel. Transformers are Toroidy audio grade, they come with resin-filled center with just a bore. Neoprene sheets on "top" and "bottom" of transformer; using the mounting disk that comes with the transformer. To give it a bit more stability, I wedge a piece of neoprene between the angle iron and the front panel, and between the transformer and the bottom plate - gives some tension on the angle iron.

Regards, Claas

Attachments

No on the separate power supply. I was going to, but converted a couple of amps into switchable mono blocks, but have since returned them to 2 stereo amps.

Keeping it simple is a great idea. Makes it easier to get right the first time, and easy to diagnose if something goes wrong. Then, once its as it should be you can play and will know if the play is the problem.

Russellc

Hear, hear. You are so right, so right. At this point, doing a P2P PSU for the first time, and dual mono, is in itself not the easiest and simplest ways to go. So might be a very good idea not to complicate it any further.

OK, last one before going to bed ...

Steel angles from Bauhaus (local hardware store). Not attached to front panel. Transformers are Toroidy audio grade, they come with resin-filled center with just a bore. Neoprene sheets on "top" and "bottom" of transformer; using the mounting disk that comes with the transformer. To give it a bit more stability, I wedge a piece of neoprene between the angle iron and the front panel, and between the transformer and the bottom plate - gives some tension on the angle iron.

Regards, Claas

Hah! Really really nice. I actually think I have some suitable angles from the local hardware shop. If not, we too have Bauhaus. Jeez, why complicate matters. KISS should be my slogan, got burnt many times allready complicating things.

I believe I will do just that!

Going to bed too. Good night!

PS: After sleep, I would love a link to that front panel switch

- Home

- Amplifiers

- Pass Labs

- BA-3 revisited