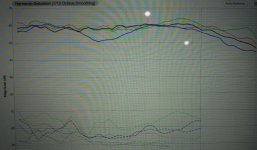

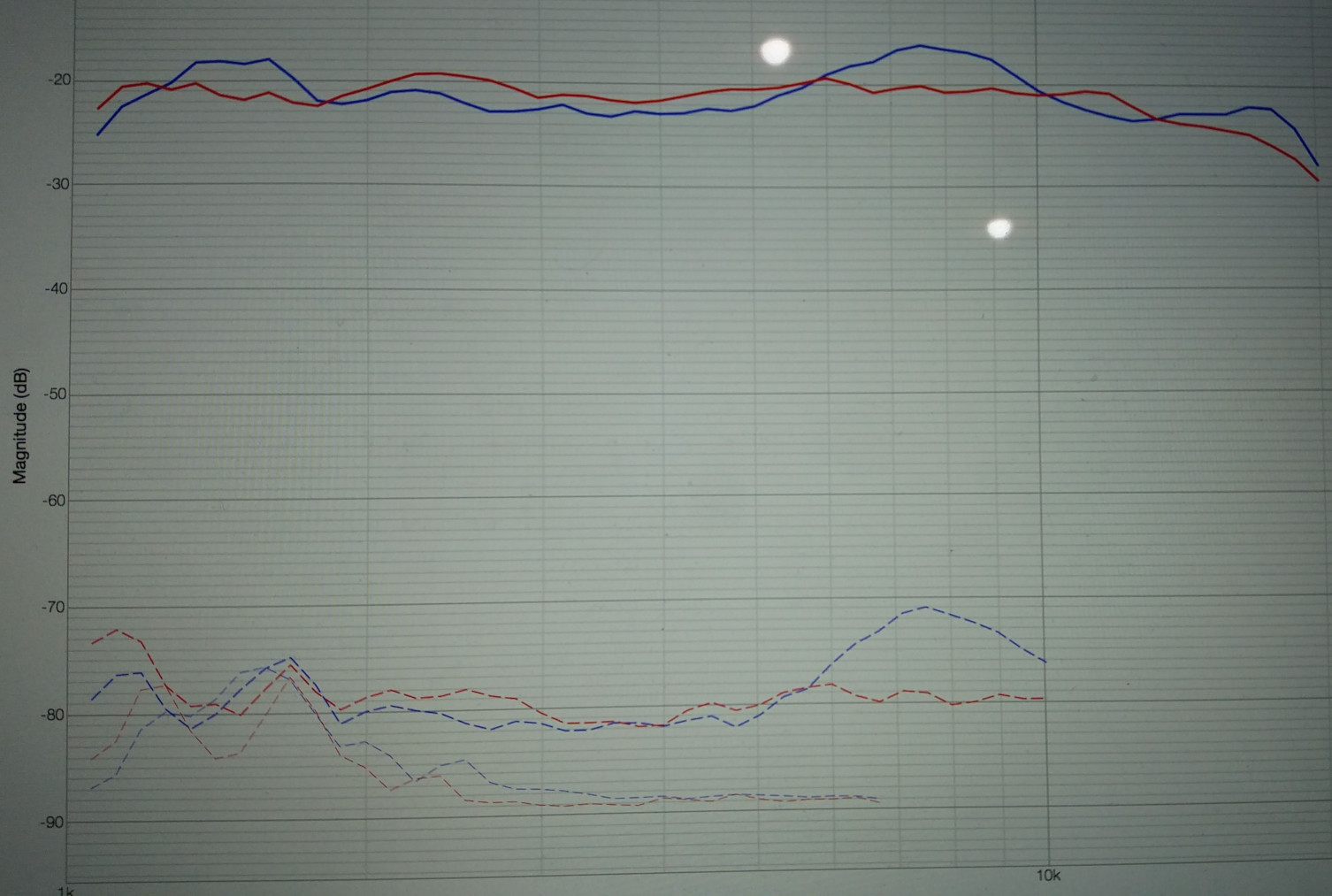

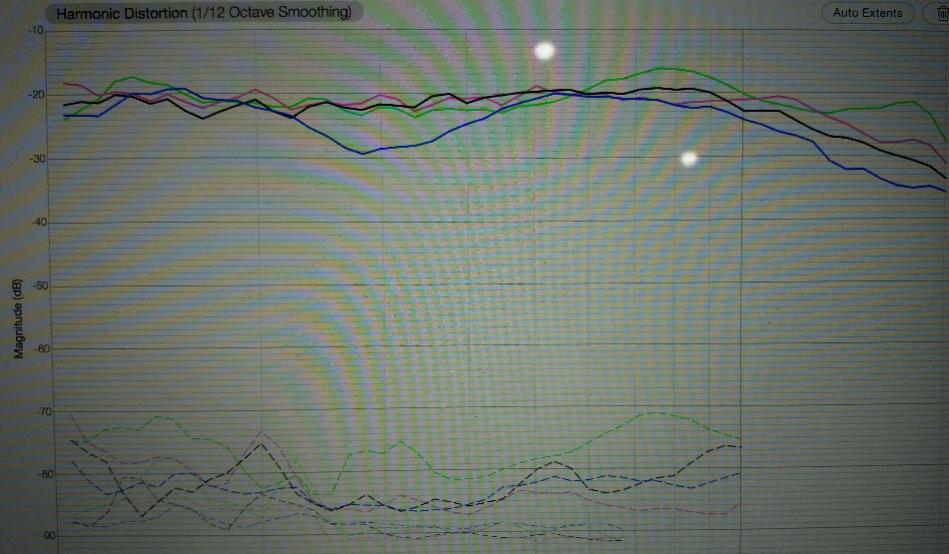

TPL 150 in dipole the 2º harmonic distortion drops 20dB, but have a big peak in the 8kHz range frequency response.

You can see in this tread:

https://www.diyaudio.com/forums/multi-way/142015-baffle-dipole-beyma-tpl-150-a-9.html#post1993491

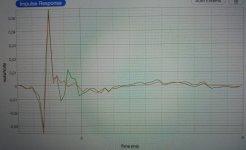

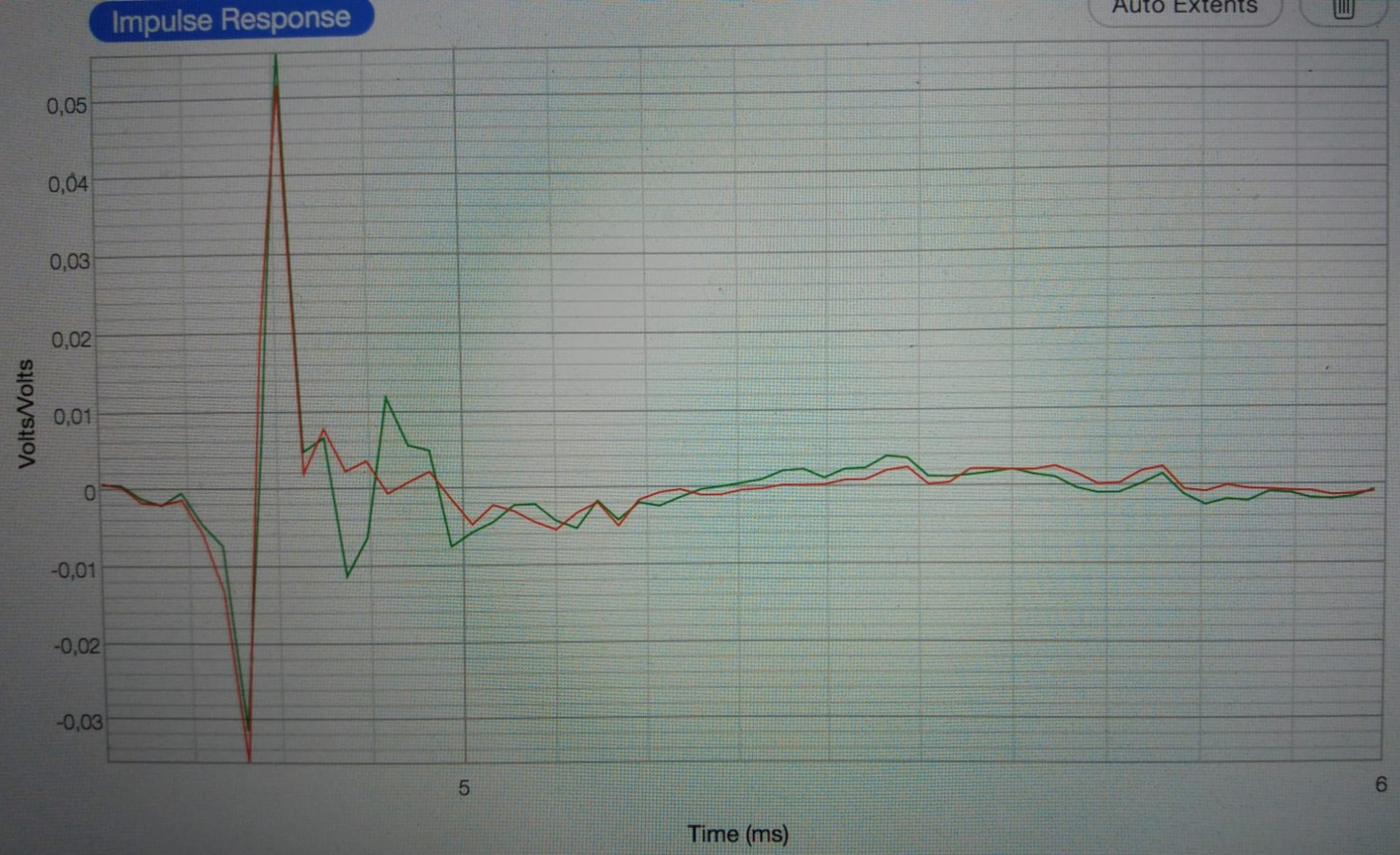

You can see in the green impulse response a double oscillation. The period coincides approximately with 8 Khz. peak.

8 Khz. Wavelength 4,3 cm. Time period 0,13 ms.

A notch filter R // L // C in series corrects the 8 Khz peak response, but not these small impulse oscillations, in addition you have a peak in the impedance just at 8 Khz.

Acustical 8 Khz notch filter can corrects these small oscillations. You can see in red impulse with acustical filter. And the 8 Khz peak also in red in frequency response, in addition you don't have an 8 Khz peak in the impedance. And better harmonic distortion

I am going to summarize the steps that I have taken to obtain it.

The first clue is 1,1 cm. the 1/4 of the 8 Khz. Wavelength.

TPL-150 impulse response.

Green only dipole. Red with acustical notch filter.

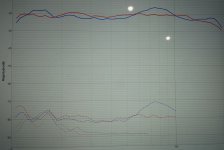

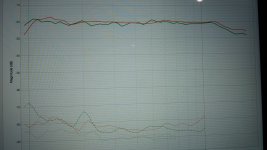

TPL-150 frequency response

Green only dipole. Red with acustical notch filter.

You can see in this tread:

https://www.diyaudio.com/forums/multi-way/142015-baffle-dipole-beyma-tpl-150-a-9.html#post1993491

You can see in the green impulse response a double oscillation. The period coincides approximately with 8 Khz. peak.

8 Khz. Wavelength 4,3 cm. Time period 0,13 ms.

A notch filter R // L // C in series corrects the 8 Khz peak response, but not these small impulse oscillations, in addition you have a peak in the impedance just at 8 Khz.

Acustical 8 Khz notch filter can corrects these small oscillations. You can see in red impulse with acustical filter. And the 8 Khz peak also in red in frequency response, in addition you don't have an 8 Khz peak in the impedance. And better harmonic distortion

I am going to summarize the steps that I have taken to obtain it.

The first clue is 1,1 cm. the 1/4 of the 8 Khz. Wavelength.

TPL-150 impulse response.

Green only dipole. Red with acustical notch filter.

TPL-150 frequency response

Green only dipole. Red with acustical notch filter.

Attachments

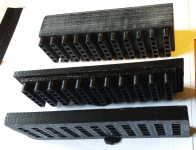

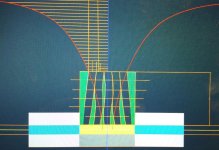

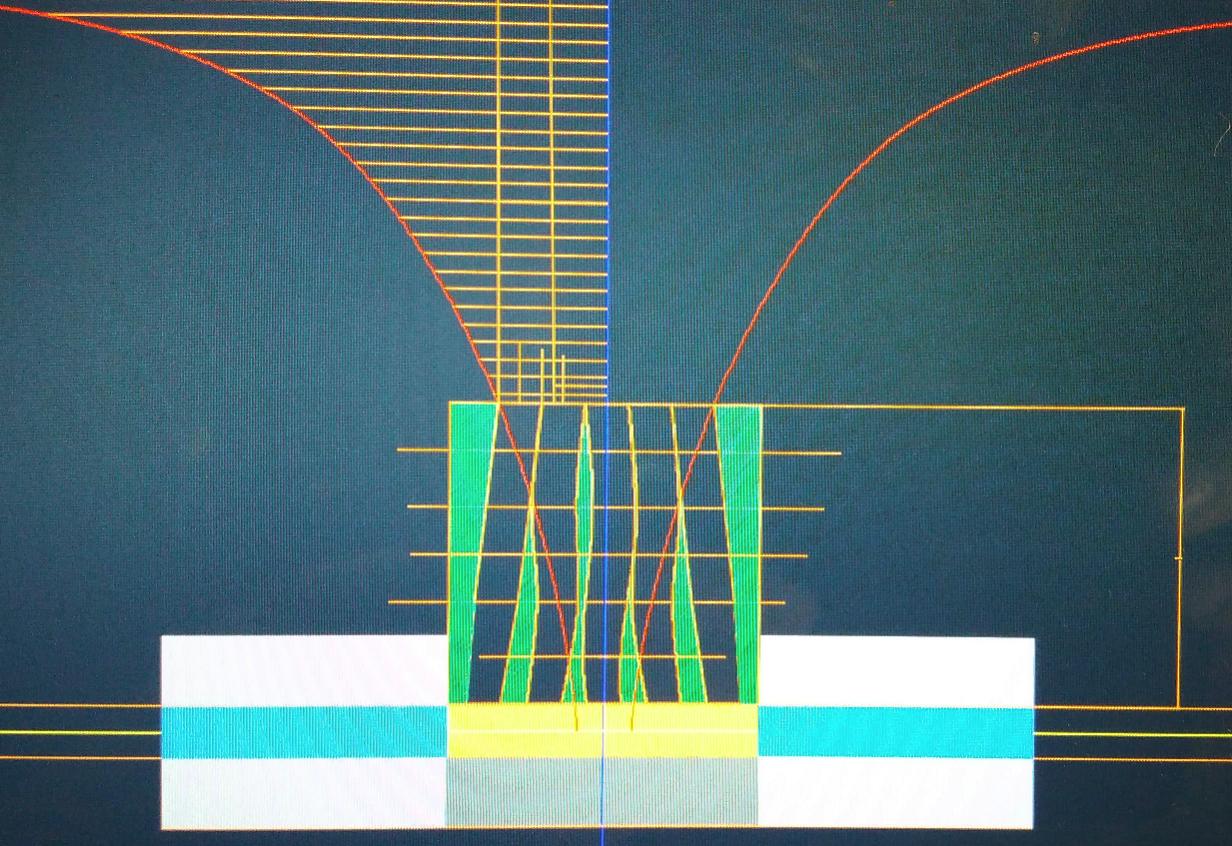

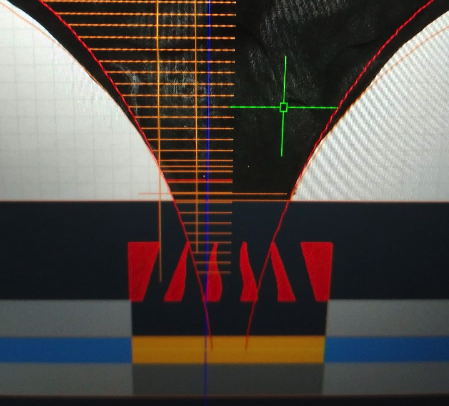

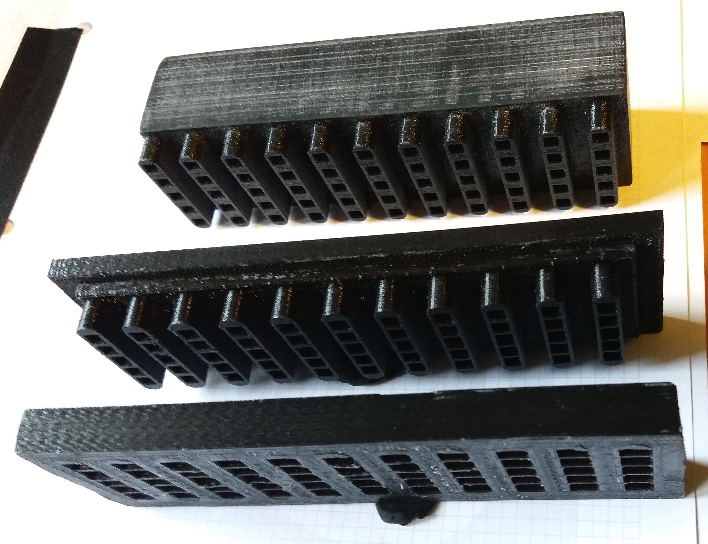

I had made many 1,1 x 12 cm sheets. Of aluminum, cardboard, plastic, was

other:

Silicone mold to make polyester filter.Obtained with piece manufactured manually in wax

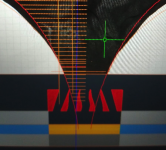

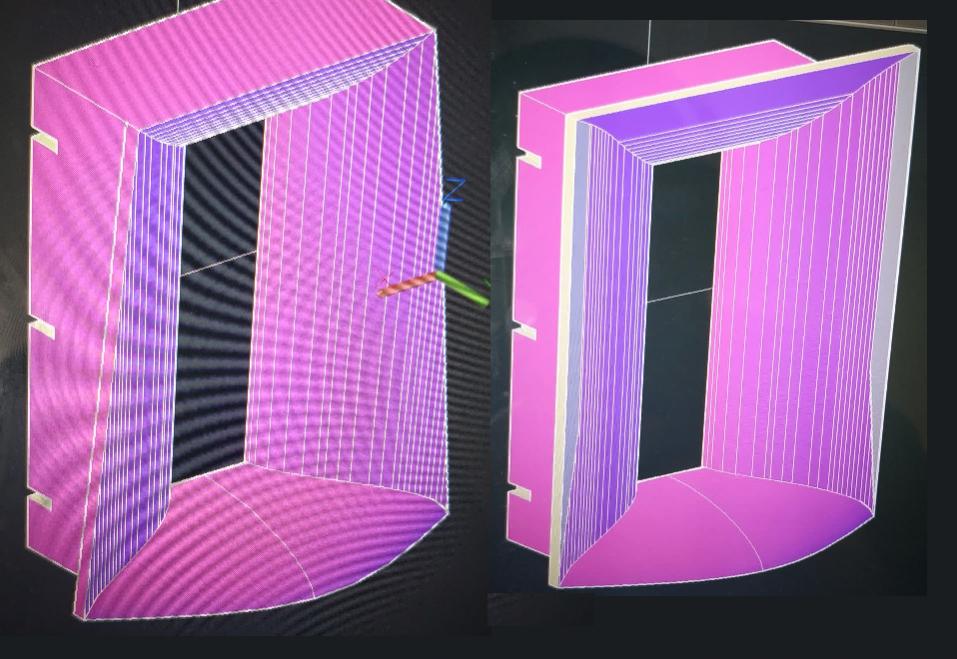

I discovered that they did not work. You need to oppose acoustic resistance. And I did this by placing a horn in front and reducing the 3.5 x 12cm section of the tweeter to 2.5 x 12cm at the throat of the horn.

First horns.

other:

Silicone mold to make polyester filter.Obtained with piece manufactured manually in wax

I discovered that they did not work. You need to oppose acoustic resistance. And I did this by placing a horn in front and reducing the 3.5 x 12cm section of the tweeter to 2.5 x 12cm at the throat of the horn.

First horns.

Profile of different filters.

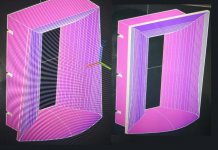

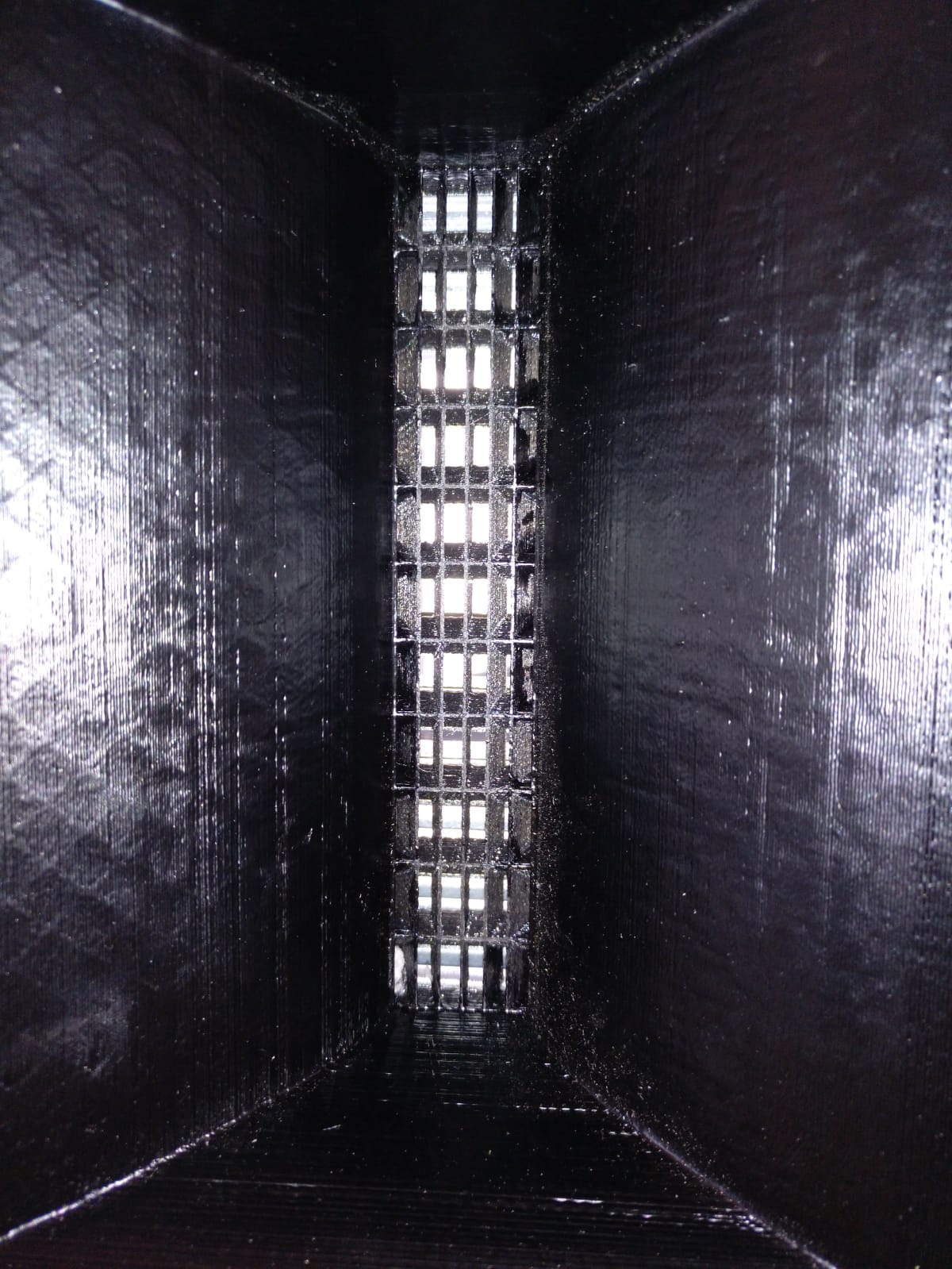

Different filters in 3D printer.

Different measures of each one.

Different horns.

Filter detail

Different filters in 3D printer.

Different measures of each one.

Different horns.

Filter detail

Attachments

I agree. It's interesting to note that part of your filter resemble what Oscar Heil did with the focus plates of the original big heil AMT. Both sides (vertical) of the plates narrowed the throat. This mass loading, around 8k, reduces the diaphragms energy on the edges toward the center as the frequency goes up ... this according to his patent. Your filters additional structure show further smoothing of the response using technique not available in 1974. nice.

US3832499A - Electro-acoustic transducer

- Google Patents

An earlier patent of his eluded to how the depth of the pleats influenced the upper frequency efficiency to around 10-15k. Which sort of explains the roll off these diaphragms exhibit.

US3832499A - Electro-acoustic transducer

- Google Patents

An earlier patent of his eluded to how the depth of the pleats influenced the upper frequency efficiency to around 10-15k. Which sort of explains the roll off these diaphragms exhibit.

Last edited:

Exact. The more I have worked on this, the more I have admired and understood the work of the AMT speaker. I find it admirable.

What would have been capable with a 3D printer? 🙂)

What would have been capable with a 3D printer? 🙂)

Last edited:

This is really glorious stuff. I have a pair of TPL-150H and I'm thinking of removing the back cover - but I am dreading the loss of impulse control and the 8kHz peak. It would be nice to have your files (designs) for the 3d printing.

Last edited:

I came to the same conclusions with the TPL150 back cover. It raises the 3rd order THD along with that nasty bump at 8k, which I suspect they did to artificially lift the top end. Some thicher medium density wool felt gets rid of it and really cleans up the entire FR. Most closed back planars (as well as alot of other HF drivers in general) suffer from inadequate rewr chamber design.

This is the notch filter for the TPL150's Beyma trumpet. Without rear camera or with rear camera with a volume 10 times greater and little acoustic filling.

Red without rear camera and without filter. Blue with acoustic notch filter and without rear camera.

Last edited:

This is really glorious stuff. I have a pair of TPL-150H and I'm thinking of removing the back cover - but I am dreading the loss of impulse control and the 8kHz peak. It would be nice to have your files (designs) for the 3d printing.

Send me a private message with your mail please.

I came to the same conclusions with the TPL150 back cover. It raises the 3rd order THD along with that nasty bump at 8k, which I suspect they did to artificially lift the top end. Some thicher medium density wool felt gets rid of it and really cleans up the entire FR. Most closed back planars (as well as alot of other HF drivers in general) suffer from inadequate rewr chamber design.

So you are saying that I should not only remove the thick felt, but use a larger chamber with "thicker medium density wool felt" on the back?

Something like this: Grauer Wollfilz ? The description has its weight at ± 0,32-0,40 g /cm³ - which may be too high? Should I try to find 0,20-0.25 g /cm³?

Maybe with the rear also closing a bit like a wedge to avoid direct reflections going back, as I read elsewhere?

Roberto

Last edited:

Unfortunately, the images are not showing.This is the notch filter for the TPL150's Beyma trumpet.

Could you please check them? Thank you!

So you are saying that I should not only remove the thick felt, but use a larger chamber with "thicker medium density wool felt" on the back?

Something like this: Grauer Wollfilz ? The description has its weight at ± 0,32-0,40 g /cm³ - which may be too high? Should I try to find 0,20-0.25 g /cm³?

Maybe with the rear also closing a bit like a wedge to avoid direct reflections going back, as I read elsewhere?

Roberto

It works in dipole, without rear camera. And also if you put a large rear camera. I have tried one about 10 times larger than Beyma's and stuffed with polyester wool. And it works too. I don't know if that one you put is good.

Unfortunately, the images are not showing.

Could you please check them? Thank you!

I'm not sure that you can put links to other websites. If it can't, I apologize to the administrators and delete it. I have problems to put images in this forum and a lot of difficulty to express myself fluently.

Perhaps if you read my interventions with the google translator on this page you can see more images.

TPL-150 NOTCH

I wanted to write something similar here in English.

Luis,

Saludos desde Argentina!

This is great stuff. I don't know how I missed the original thread a year ago!

I'm also using TPL-150H in dipole and really liking it. I have it with Beyma waveguide in the front and DIY foam waveguide (prototype) of similar dimensions in the back. I use digital xo and room correction so the peak at 7-8kHz is taken care of by DSP, but anything that can be done to correct it physically at origin and avoid needing digital correction is a good development. I can absolutely agree that OB or big space behind reduces distortion/sounds better.

I'm thinking of testing it in dipole but without waveguides, crossing over to mids at 1.7-2kHz with steep slopes. What are your thoughts?

Saludos,

Horacio

Saludos desde Argentina!

This is great stuff. I don't know how I missed the original thread a year ago!

I'm also using TPL-150H in dipole and really liking it. I have it with Beyma waveguide in the front and DIY foam waveguide (prototype) of similar dimensions in the back. I use digital xo and room correction so the peak at 7-8kHz is taken care of by DSP, but anything that can be done to correct it physically at origin and avoid needing digital correction is a good development. I can absolutely agree that OB or big space behind reduces distortion/sounds better.

I'm thinking of testing it in dipole but without waveguides, crossing over to mids at 1.7-2kHz with steep slopes. What are your thoughts?

Saludos,

Horacio

Last edited:

You can put TPL-150 without horn and without filter notch, and correct 8000 Hz response with DSP without problems.

If you mean to use my notch filter without horn, it won't work. It only works if you use a horn.

The Beyma waveguide is constant directivity, but without the coloration that these types of trumpets usually have. It has little coloration. Mine tractrix horn or "bi-eliptical horn" sound better in my opinion. It has no coloration.

If you mean to use my notch filter without horn, it won't work. It only works if you use a horn.

The Beyma waveguide is constant directivity, but without the coloration that these types of trumpets usually have. It has little coloration. Mine tractrix horn or "bi-eliptical horn" sound better in my opinion. It has no coloration.

You can put TPL-150 without horn and without filter notch, and correct 8000 Hz response with DSP without problems.

If you mean to use my notch filter without horn, it won't work. It only works if you use a horn.

The Beyma waveguide is constant directivity, but without the coloration that these types of trumpets usually have. It has little coloration. Mine tractrix horn or "bi-eliptical horn" sound better in my opinion. It has no coloration.

The Beyma waveguide is made of Aluminium and it has some resonance. Do you think that dampening it would help? Like gluing bitumen sheets to its external surface (on the back of course)?

- Home

- Loudspeakers

- Multi-Way

- Acoustical notch filter for TPL-150