Hoooold up. Different power through a field coil will result in different effective motor strength, inductance, and other factors. I would expect wider bandwidth generally with lower coil current, certainly less damping at Fs and very likely a lower inductance.

That's not snake oil. Superiority of field coil may be more debatable.

Original field coil speakers have been around since the 1930's, having the coil used as a choke in the power supply, and as a hum-reducing system in those antique tube radios.

It's nothing "new", obviously.

And yes, the strength of the magnetic field depends on the power applied to it.

But alas, someone, somewhere, deamt up the idea to market these things again, and professes to claim all sorts of reasons to buy them.

Mostly to attract the buyers with "something different" to play with.

A marketing exec once told me a story....

"if you give a child a set of blocks, those toys made of wood with letters and numbers on them, the child will be fascinated by them, naturally.

And not having the knowledge or knowing the background or reasons of them, will be amused.

The company has now profited from the purchase, and the parents are satisfied to keep the child "busy".

All is well.

The same thing goes for marketing something that the public is not aware of in the current era, be it an old design or whatever."

Like today, how many people (perhaps millenials) are aware that field coil speakers are "old school" devices from the 1930's?

To them, it's something new and wonderful - made that way by marketing hype.

So, out of curiosity, they buy those things, believing whatever claims made will gain them satisfaction.

And the company profits...

It's all BS to me, listen, I've been around for 66 years, seen it all by now, and serviced people's broken audio/video stuff professionally for at least 45 years.

That's why I sit back and laugh at all the "claims," "trends," and goofy marketing going on these days.

Original field coil speakers have been around since the 1930's, having the coil used as a choke in the power supply

I’ll have to snap a pic of th elate-30s one i have downstairs on my table as an example.

But alas, someone, somewhere, deamt up the idea to market these things again

Alas, historically they went away because fixed magnets became much less expensive. FC have their theoretical advantages, the only pair i ever heard were very flawed (but i doubt it was the FC). As a frugal-phile(tm) the huge price make sit unlikely i will have more pairs to play with. I’ll live vicariously with DJN.

dave

Original field coil speakers have been around since the 1930's, having the coil used as a choke in the power supply, and as a hum-reducing system in those antique tube radios.

It's nothing "new", obviously. And yes, the strength of the magnetic field depends on the power applied to it...

The more magnet strength the better. Sure, you can post a hocus-pocus sim showing an exception, but maybe you need to re-think how sims work and why their "answer" isn't always peak SQ. Ditto for the "benefits" of lowering the supply to a field coil if that is an option on your speakers.

Field coils disappeared 50 years before it became feasible to deliver big low-ripple DC currents using solid-state circuits. Times have changed.

With a field coil, you have flexibility in various ways and the potential for making great magnets. While I am no fan of the ancient cone driver concept, a field coil makes a lot of sense to me.

B.

Last edited:

Home depot PVC sheets. very well damped. Someone needs to try this stuff. 1/4, 1/2, 3/4 " available

This might interest you Issues in speaker design - 2 The KEF midrange is mentioned at the end, a magnet clamping method was used to mount itKEF was also the company that grommet mounted the midrange in the 105 to isolate it from the box. Measured good, but didn’t sound as good as removing the grommets and properly tightening the bolts. I am always suspicios of suff that KEF “measures” into existance.

Home depot PVC sheets. very well damped. Someone needs to try this stuff. 1/4, 1/2, 3/4 " available

Use it as the middle layer in a CLD type application?

Or are you proposing to use it to line the inner walls, like bitumen or sound deadening materials?

Fun with materials

Picture about 43:16: YouTube

Youtube: World's Second Best Speakers!The whole video is worth the time but 26:00 to about 45:00 is on this subject. CLD for the win.

An externally hosted image should be here but it was not working when we last tested it.

Picture about 43:16: YouTube

Last edited:

Use it as the middle layer in a CLD type application?

Or are you proposing to use it to line the inner walls, like bitumen or sound deadening materials?

I was thinking making the entire cab out of it. Its a rigid dense and heavy "board". There may be an issue with its structural properties, im not sure. It may "flow" over time and strain??

Maybe will need some structure in the form of braces inside made of wood?

Not sure what to do BUT it is much better damped than any wood and would love to see what can be done with it.

This is all great discussion but I am taking a chance on the drivers already so I'll stick to Birch plywood well braced and veneered with bamboo. The PVC looks good but it is not sold here in Albuquerque.

Also, I run 4 subwoofers to handle the low end and don't listen really loud anymore so the braced plywood should work just fine for my situation.

Also, I run 4 subwoofers to handle the low end and don't listen really loud anymore so the braced plywood should work just fine for my situation.

I wonder if there is anything I can use that I can pick up at the hardware store. Silicone? Elastomeric caulk?

Last edited by a moderator:

Red Spade Audio: RSA HE2 in progress

Red Spade Audio: Waveguide damping

-> bitumen rubber - Google Search

-> -> Google Images too.

Red Spade Audio: Waveguide damping

-> bitumen rubber - Google Search

-> -> Google Images too.

Last edited:

No Rez 24"x27" Sheet

An externally hosted image should be here but it was not working when we last tested it.

A Whitepaper: The Audibility Of Cabinet Panel Resonances and Pat. Pend. Method Of Reduction Of Audible Coloration - Dagogo

You know, sandwich with materials of different density and stiffness / rigidity.

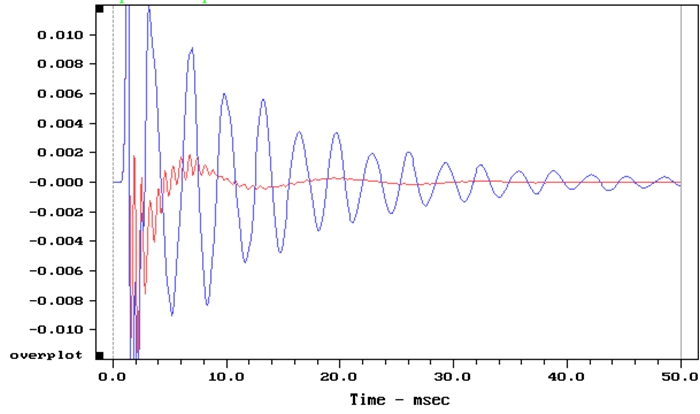

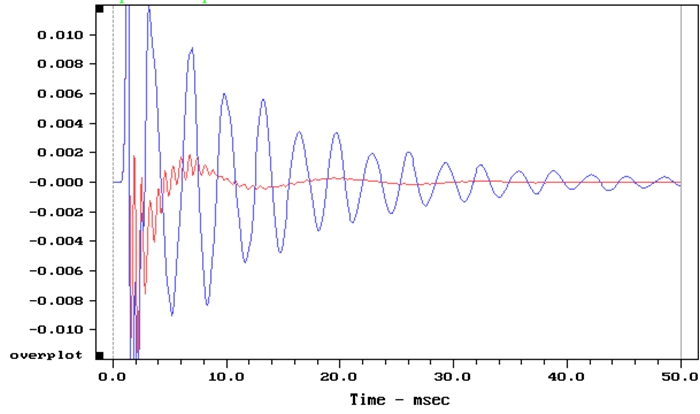

#1. Comparison of Damped Vs. Undamped Baffles

(Graph courtesy of A. Jones, TAD laboratory)

You know, sandwich with materials of different density and stiffness / rigidity.

Last edited:

I wonder if there is anything I can use that I can pick up at the hardware store. Silicone? Elastomeric caulk?

There is a material used to dampen cars for car audio call Dynamat.....I think. I've used that in the past when using thin walled cabinets. It sticks on and does well.

Might not be sold in your area but the car audio shops will know.

I'm starting a new full range speaker project and want to know what is better for cabinets MDF or good plywood.

I would recommend MDF, but not the conventional inch thick stuff people generally use.

Instead I would suggest an inner layer of 1/2 inch MDF with a thin layer of rubberized adhesive with an outer layer of 3/8 inch MDF. The result is a piece of 2 layer MDF board with virtually no acoustic properties at all.

Way back in the late 1970s I did this on my own DIY speakers and the outcome was surprisingly good. The idea seems reborn in several papers and videos with companies who are now touting it for their own idea.

The principle behind this is explained here...

YouTube

Well damn, looks like I'll be ordering a bucket of Decidamp! I was put off by the idea of making then cutting constrained layered boards but with the Decidamp you put the boards on after the cabinet is built. I like that.

- Home

- Loudspeakers

- Multi-Way

- Is MDF or plywood better for speaker cabinets?