My Proposition

I want to adapt this project to fit within my woodworking skills and tools, I like the drivers we chose but the main issue for me was the TD15Xs, they need a large, very large cabinet to breath, 150-250L will take some serious space.

So the rational decision for me was to sacrifice the sensitivity to a smaller volume, this will also make the project much easier to build and wife friendly. The woofers I chose to replace the TD15Xs is BMS 12N630, not easy to obtain but so is the AE drivers, I already purchased the BMS drivers ( thanks to Heathkit ) and I will continue the project with same TD8Ms and HF107 as before, Also bought a new table saw! I wanted to start a new thread since I’m not following the TXL criteria anymore, but I decided to continue here as this is not that far off as the original plan. I hope I still have your support.

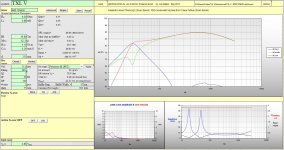

I started the project with some basic calculations, the major change aside the woofer, is that I decided to make Mid-Tweeter cabinet separated from the Bass cabinet, With this approach it’s easier to manage/avoid the standing waves in the cabinet (initial design shows that it will push the standing waves to ~270Hz) and also this will make the build much easier with smaller cuts, lighter weight, and overall easier to manage. The Bass cabinet will be around 83L, after driver displacement and the port volume and the bracing it will be around 75L with two 3” ports tuned to 30Hz.

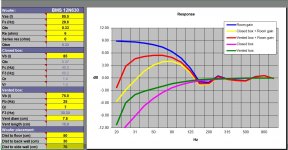

The bass cabinet will sit on a stand and the woofer will be about 45cm above the floor, I ran a simulation with Roy Allison room gain formula spreadsheet and based on intended cabinet size and my room ( the distance from the walls and the floor) we are looking at 5-6db gain in bass region area, which when add it to the cabinet simulation data, we will get around 90db sensitivity, After building the prototype we can confirm this.

I wanted to have something to show before coming back to this thread, I already built the prototype, the cabinet drawing is attached, the bass cabinet is about 75 liters, braced, the rear and side walls are covered with felt with extra 3-4 inches of mineral wool on bottom and top and one inch on the sides, I measured the cabinet respond with different stuffing, I felt that with that much going on inside the cabinet the driver might not be able to breath, anyhow long story short, I end up with only 2 inch mineral wool on the bottom and 1 inch on top and the sides, and still didn’t measured much noticeable difference in standing waves leaking from the port ( I will attach all the measurements ).

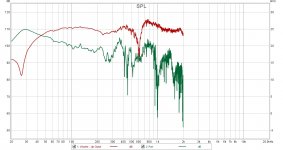

I placed the mic 1 inch away from the woofer and for the port I placed the mic by the opening of the port, the measurements show that the cabinet behaved as expected, I'm happy with it !

The Mid+CD cabinet is the same, it has felt on the walls, 1 inch mineral wool all around and some polyester fiber (50%).

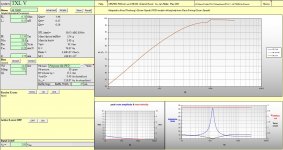

After doing some measurements in the garage to make sure everything is as expected, I moved the cabinet to my living room, where it will be placed and listened to and did some 1m and 0.5 m measurements separately for each driver (different heights).

The final measurement is the mic placed between LF and Mid drivers 1m and 0.5m away, as you see in the results, the bass gained about 6db as predicted by Roy Allison room gain formula, the spl is not calibrated, but comparing the bass response to the mid response (which should be around 94db) the bass is shy just a few db.

So of course at this point I couldn’t help myself and I attached to the speaker to miniDSP and start playing around, I started with 250hz LR2 crossed between LF/Mid and went from there, after some time listening to some music, I prefer to lower the mid -6db, to me this is a sweet spot, any higher would abit bass shy and lower would be bass heavy, but it may change later.

As for the crossover, I end up with 350Hz LR4 for the woofer and 350Hz LR2 highpass for the mid, I like the 250Hz but I feel on some vocals (like Tom Waits) crossing at 250 sometimes sound a little bassy and heavy, so for now I prefer 350Hz LR4+LR2.

I want to adapt this project to fit within my woodworking skills and tools, I like the drivers we chose but the main issue for me was the TD15Xs, they need a large, very large cabinet to breath, 150-250L will take some serious space.

So the rational decision for me was to sacrifice the sensitivity to a smaller volume, this will also make the project much easier to build and wife friendly. The woofers I chose to replace the TD15Xs is BMS 12N630, not easy to obtain but so is the AE drivers, I already purchased the BMS drivers ( thanks to Heathkit ) and I will continue the project with same TD8Ms and HF107 as before, Also bought a new table saw! I wanted to start a new thread since I’m not following the TXL criteria anymore, but I decided to continue here as this is not that far off as the original plan. I hope I still have your support.

I started the project with some basic calculations, the major change aside the woofer, is that I decided to make Mid-Tweeter cabinet separated from the Bass cabinet, With this approach it’s easier to manage/avoid the standing waves in the cabinet (initial design shows that it will push the standing waves to ~270Hz) and also this will make the build much easier with smaller cuts, lighter weight, and overall easier to manage. The Bass cabinet will be around 83L, after driver displacement and the port volume and the bracing it will be around 75L with two 3” ports tuned to 30Hz.

The bass cabinet will sit on a stand and the woofer will be about 45cm above the floor, I ran a simulation with Roy Allison room gain formula spreadsheet and based on intended cabinet size and my room ( the distance from the walls and the floor) we are looking at 5-6db gain in bass region area, which when add it to the cabinet simulation data, we will get around 90db sensitivity, After building the prototype we can confirm this.

I wanted to have something to show before coming back to this thread, I already built the prototype, the cabinet drawing is attached, the bass cabinet is about 75 liters, braced, the rear and side walls are covered with felt with extra 3-4 inches of mineral wool on bottom and top and one inch on the sides, I measured the cabinet respond with different stuffing, I felt that with that much going on inside the cabinet the driver might not be able to breath, anyhow long story short, I end up with only 2 inch mineral wool on the bottom and 1 inch on top and the sides, and still didn’t measured much noticeable difference in standing waves leaking from the port ( I will attach all the measurements ).

I placed the mic 1 inch away from the woofer and for the port I placed the mic by the opening of the port, the measurements show that the cabinet behaved as expected, I'm happy with it !

The Mid+CD cabinet is the same, it has felt on the walls, 1 inch mineral wool all around and some polyester fiber (50%).

After doing some measurements in the garage to make sure everything is as expected, I moved the cabinet to my living room, where it will be placed and listened to and did some 1m and 0.5 m measurements separately for each driver (different heights).

The final measurement is the mic placed between LF and Mid drivers 1m and 0.5m away, as you see in the results, the bass gained about 6db as predicted by Roy Allison room gain formula, the spl is not calibrated, but comparing the bass response to the mid response (which should be around 94db) the bass is shy just a few db.

So of course at this point I couldn’t help myself and I attached to the speaker to miniDSP and start playing around, I started with 250hz LR2 crossed between LF/Mid and went from there, after some time listening to some music, I prefer to lower the mid -6db, to me this is a sweet spot, any higher would abit bass shy and lower would be bass heavy, but it may change later.

As for the crossover, I end up with 350Hz LR4 for the woofer and 350Hz LR2 highpass for the mid, I like the 250Hz but I feel on some vocals (like Tom Waits) crossing at 250 sometimes sound a little bassy and heavy, so for now I prefer 350Hz LR4+LR2.

Attachments

Last edited:

I will not continue this project with TD15X anymore, it is not happening...

I want to adapt this project to fit within my woodworking skills and tools, I like the drivers we chose but the main issue for me was the TD15Xs, they need a large, very large cabinet to breath, 150-250L will take some serious space.

So the rational decision for me was to sacrifice the sensitivity to a smaller volume, this will also make the project much easier to build and wife friendly. The woofers I chose to replace the TD15Xs is BMS 12N630, not easy to obtain but so is the AE drivers, I already purchased the BMS drivers ( thanks to Heathkit )...

Sometimes it's hard to change plans when things don't work out easily, but it's better not to stick to a plan that does not work.

Why did you choose the BMS 12N630? The sensitivity calculated from the datasheet TSP is about 85 dB/2.83V/4pi. I don't think it would meet the design goals for the Open Source Tower project.

If you want to go with a 12" woofer, take a look at the 12" woofers we considered for the Monkey Coffin (the BMS 12N630 was not one of them). Or just build the OSMC in a larger "tower" box, which would allow you to extend lower cut-off frequency 😀

hi mbrennwa, good to have you here

yes the 12N630 does not have the advertised 96db sensitivity, this driver has been mentioned here before but we passed on it since it didn't met the criteria, based on posted TS and measured TS (by me) the sensitivity is around 89.5 db. but as I mentioned before, based on the intended cabinet size and room placement we can gain 6 db boost in bass region which will compensate the baffle loss and will bring back the sensitivity to ~90db (see attachment)

attached is an up close measurement of the woofer and the port, for the second measurement I placed the mic in the room aiming between woofer and the mid 1m away and measured the signals separately , this confirm that we got bass boost, the signal from the woofer is a few db shy from the mid which should be around 94db. decreasing the mid signal by -6, -5db with LR4/LR2 xover will make a nice transition between two. and I have to say the TD8M is a very sweet sounding midrange.

yes the 12N630 does not have the advertised 96db sensitivity, this driver has been mentioned here before but we passed on it since it didn't met the criteria, based on posted TS and measured TS (by me) the sensitivity is around 89.5 db. but as I mentioned before, based on the intended cabinet size and room placement we can gain 6 db boost in bass region which will compensate the baffle loss and will bring back the sensitivity to ~90db (see attachment)

attached is an up close measurement of the woofer and the port, for the second measurement I placed the mic in the room aiming between woofer and the mid 1m away and measured the signals separately , this confirm that we got bass boost, the signal from the woofer is a few db shy from the mid which should be around 94db. decreasing the mid signal by -6, -5db with LR4/LR2 xover will make a nice transition between two. and I have to say the TD8M is a very sweet sounding midrange.

Attachments

-

LF+MID - 1m in room - LR4+LR2 350 -6.jpg120 KB · Views: 165

LF+MID - 1m in room - LR4+LR2 350 -6.jpg120 KB · Views: 165 -

12N630 + Port - Up CLose.jpg132.1 KB · Views: 160

12N630 + Port - Up CLose.jpg132.1 KB · Views: 160 -

BMS 12N630 - SS Sim.JPG202.7 KB · Views: 149

BMS 12N630 - SS Sim.JPG202.7 KB · Views: 149 -

AE TD8M - SS Sim.JPG152.9 KB · Views: 158

AE TD8M - SS Sim.JPG152.9 KB · Views: 158 -

BMS 12N630 Room Sim.JPG131.3 KB · Views: 149

BMS 12N630 Room Sim.JPG131.3 KB · Views: 149 -

BoxNote - Standing Waves - 12N630.JPG91.1 KB · Views: 199

BoxNote - Standing Waves - 12N630.JPG91.1 KB · Views: 199 -

LF=MD - 1m in room - LR4+LR2 250 overlay.jpg149.1 KB · Views: 149

LF=MD - 1m in room - LR4+LR2 250 overlay.jpg149.1 KB · Views: 149

Last edited:

yes the 12N630 does not have the advertised 96db sensitivity, this driver has been mentioned here before but we passed on it since it didn't met the criteria, based on posted TS and measured TS (by me) the sensitivity is around 89.5 db.

Can you post the measured TSP here? How did you do the break-in? Some woofers take a long time to settle. Remember that the sensitivity is proportional to fs^3, so getting fs stable is important to get the sensitivity right.

attached is an up close measurement of the woofer and the port, for the second measurement I placed the mic in the room aiming between woofer and the mid 1m away and measured the signals separately...

What was the drive voltage of this measurement?

You can count on a bit of room gain if the speaker is crammed to a wall or into a corner of the room. Is this really what this speaker is about?

Also, don't forget about the baffle step. While this will not be relevant at deep bass frequencies, it will be important from 100 Hz and up. The woofer filter will need to compensate for the baffle step, so you'll loose some more SPL there.

Just for comparison, it was tough to achieve 92 dB/2.83 V sensitivity with the Monkey Coffin, which also uses a 12" woofer, but one with much higher fs and therefore higher efficiency.

Last edited:

Can you post the measured TSP here? How did you do the break-in? Some woofers take a long time to settle.

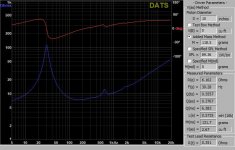

the DATS measurement is attached, the woofers have some 10Hrs break in, the TS is pretty close to manufacturer data.

haven't measure it. will do in later tests.What was the drive voltage of this measurement?

You can count on a bit of room gain if the speaker is crammed to a wall or into a corner of the room. Is this really what this speaker is about?

Also, don't forget about the baffle step. While this will not be relevant at deep bass frequencies, it will be important from 100 Hz and up. The woofer filter will need to compensate for the baffle step, so you'll loose some more SPL there.

Just for comparison, it was tough to achieve 92 dB/2.83 V sensitivity with the Monkey Coffin, which also uses a 12" woofer, but one with much higher fs and therefore higher efficiency.

the speaker is not crammed in a corner, it is 30cm from the back wall and 70cm from the sides, again this is based on my room placement.

As I mentioned I had to sacrifice some sensitivity to smaller box, there might be someone that don't have space problem and can build the TXL as planned, but BMS works in my case and if you feel this does not follow the TXL criteria I can start another thread.

Attachments

the DATS measurement is attached, the woofers have some 10Hrs break in, the TS is pretty close to manufacturer data.

Ok, here is the sensitivity calculation (see here):

fs=30.28; Vas=2.67*28.3/1000; c=343;Qes=0.376; Re=6.162; n0 = 112.1+10*log10(4*pi*fs^3*Vas/c^3/Qes)+10*log10(8/Re)

n0 = 85.633

===> Sensitivity n0 = 85.6 dB/2.83Vrms @ 1m / 4pi

This is way too low to meet the target sensitivity of the Tower XL. The physics simply don't allow small box, deep bass and high sensitivity at the same time.

As I mentioned I had to sacrifice some sensitivity to smaller box, there might be someone that don't have space problem and can build the TXL as planned, but BMS works in my case and if you feel this does not follow the TXL criteria I can start another thread.

If you decide to continue the Tower XL as planned, someone will have build and test prototypes. The original poll indicated that the Tower XL format was the most preferred type of speaker. Sooo... would anyone who voted for the Tower XL go for it?

Ok, here is the sensitivity calculation (see here):

fs=30.28; Vas=2.67*28.3/1000; c=343;Qes=0.376; Re=6.162; n0 = 112.1+10*log10(4*pi*fs^3*Vas/c^3/Qes)+10*log10(8/Re)

n0 = 85.633

===> Sensitivity n0 = 85.6 dB/2.83Vrms @ 1m / 4pi

thanks for clarification mbrennwa,

Troel has similar approach in his Fusion design which uses the same BMS driver, I followed his documentation, if his approach using Roy Allison Bass and Room formula is accurate, we should have enough room gain to compensate that and bring the sensitivity to close to 89-90, as Troel also claimed, but without calibrated SPL meter it is hard to measure, I may get a SPL meter, any advice on measuring the SPL and sensitivity ?

If you decide to continue the Tower XL as planned, someone will have build and test prototypes...

it is such a shame, the beautiful TD15X drivers are just sitting in their box for now.

Last edited:

Hi Aatto

A big misunderstanding concerning sensitivity here.

The Tower XL sensitivity was specified to be minimum 90 dB /2.83Vrms/1m in a 4pi domain.

Placing that Tower XL in a 2 pi environment (on a flat floor) SPL at 2.83Vrms/1m will become 6 dB higher or 96 dB. Because the 2pi domain is half the 4 pi domain, it is as simple as that.

Placing the speaker in a room, the domain is even less than a 2pi domain because of ceiling and walls and the SPL will even be more than 96 dB.

The BMS 12N630 has a sensititvity of 90.5dB/2.83Vrms/1m on infinite baffle ( = 2pi domain).

So in a 4pi domain you can make a flat SPL speaker with a 84.5 dB /2.83Vrms/1m sensitivity.

IMO the replacement of the AE by the BMS is not a correct decision w.r.t. the specification of the Tower XL, where people have voted for.

A big misunderstanding concerning sensitivity here.

The Tower XL sensitivity was specified to be minimum 90 dB /2.83Vrms/1m in a 4pi domain.

Placing that Tower XL in a 2 pi environment (on a flat floor) SPL at 2.83Vrms/1m will become 6 dB higher or 96 dB. Because the 2pi domain is half the 4 pi domain, it is as simple as that.

Placing the speaker in a room, the domain is even less than a 2pi domain because of ceiling and walls and the SPL will even be more than 96 dB.

The BMS 12N630 has a sensititvity of 90.5dB/2.83Vrms/1m on infinite baffle ( = 2pi domain).

So in a 4pi domain you can make a flat SPL speaker with a 84.5 dB /2.83Vrms/1m sensitivity.

IMO the replacement of the AE by the BMS is not a correct decision w.r.t. the specification of the Tower XL, where people have voted for.

Last edited:

Hi Paul.

thanks for explanation, this clear things out.

Unfortunately I will not (can't) continue this with AE drivers for now, it will be great if someone else can pick this up from here.

thanks for explanation, this clear things out.

Unfortunately I will not (can't) continue this with AE drivers for now, it will be great if someone else can pick this up from here.

Remark that the AE TD15X can also be used in smaller basreflex cabinets, accepting some restrictions for F3, F6 and F10.

A few examples to compare. Aatto's measured AE TD15X driver model is used for the simulations.

Vb = 250 L, FB = 26 Hz, F3 = 28 Hz, F6 = 24 Hz, F10 = 21 Hz

Vb = 150 L, FB = 26 Hz, F3 = 36 Hz, F6 = 29 Hz, F10 = 23 Hz

Vb = 120 L, FB = 26 Hz, F3 = 39 Hz, F6 = 32 Hz, F10 = 25 Hz

Vb = 100 L, FB = 26 Hz, F3 = 42 Hz, F6 = 35 Hz, F10 = 27 Hz

Vb = 80 L, FB = 26 Hz, F3 = 45 Hz, F6 = 38 Hz, F10 = 30 Hz

For the smaller volumes below 150 L there is a little SPL boost in the 80 - 100 Hz region. It is maximum 1.00 dB at 80 Hz for a VB = 80 L. It can be equalized electrically.

The smaller cabinet volumes are not the ideal choice, but still possible to use, accepting the restrictions.

The system gets more and more an extended basreflex system behavior for the smaller cabinets, keeping FB = 26 Hz.

A few examples to compare. Aatto's measured AE TD15X driver model is used for the simulations.

Vb = 250 L, FB = 26 Hz, F3 = 28 Hz, F6 = 24 Hz, F10 = 21 Hz

Vb = 150 L, FB = 26 Hz, F3 = 36 Hz, F6 = 29 Hz, F10 = 23 Hz

Vb = 120 L, FB = 26 Hz, F3 = 39 Hz, F6 = 32 Hz, F10 = 25 Hz

Vb = 100 L, FB = 26 Hz, F3 = 42 Hz, F6 = 35 Hz, F10 = 27 Hz

Vb = 80 L, FB = 26 Hz, F3 = 45 Hz, F6 = 38 Hz, F10 = 30 Hz

For the smaller volumes below 150 L there is a little SPL boost in the 80 - 100 Hz region. It is maximum 1.00 dB at 80 Hz for a VB = 80 L. It can be equalized electrically.

The smaller cabinet volumes are not the ideal choice, but still possible to use, accepting the restrictions.

The system gets more and more an extended basreflex system behavior for the smaller cabinets, keeping FB = 26 Hz.

but anything smaller than 150 will also not meet the criteria and what been voted for TXL.

I m willing to work out a fair deal with anyone considering making the TXL with AE drivers.

I m willing to work out a fair deal with anyone considering making the TXL with AE drivers.

but anything smaller than 150 will also not meet the criteria and what been voted for TXL.

Overall sensitivity = 89 dB / 2.83 Vrms / 1m, according to Aatto's measurements on its AE TD15X, for all cabinet volumes.

Target specification for the Tower XL sensitivity was 92 dB.

For VB smaller than 120 L, F3 becomes higher than 40 Hz. For VB = 80 L, F3 = 45 Hz.

Target specification for the Tower XL F3 was 35 - 40 Hz.

I need your help, please!

Hi, could you design for me a passive crossover for the Faital Pro HF10AK / STH100 combo, 2500 Hz High - pass and L-Pad down to 89 db? I know nothing about CD Crossovers. I've had few dome tweeters in the past for my PHL-1130 and something was always missing regarding detail and emotion...I hope this will be the right way for me. If you cannot help me, please, point me to the right direction where I can design one myself. Many thanks for the kindness!

Put the Faital HF10AK in that STH100 and you will have an unbeatable combination, sweet beautiful highs.

Hi, could you design for me a passive crossover for the Faital Pro HF10AK / STH100 combo, 2500 Hz High - pass and L-Pad down to 89 db? I know nothing about CD Crossovers. I've had few dome tweeters in the past for my PHL-1130 and something was always missing regarding detail and emotion...I hope this will be the right way for me. If you cannot help me, please, point me to the right direction where I can design one myself. Many thanks for the kindness!

Hi, could you design for me a passive crossover for the Faital Pro HF10AK / STH100 combo, 2500 Hz High - pass and L-Pad down to 89 db?

Your best option would be to build a test baffle with the same geometry for your intended build (or just use your build if you already have it) and measure SPL curves, both on-axis and off-axis at 10° increments or so, covering at least the front hemisphere, but preferably full sphere. Do the same with your midrange or midwoofer. With this data you can design a suitable xover filter that can be expected to sound good (using Vituix CAD or a similar software tool).

If you want to take this further, it might be better to start a new thread.

Thanks for the quick answer! I thought that this particular crossover could be simulated with some Software, the same way like for conventional speakers -using the distance between drivers and the baffle dimensions. Tony Gee from Humblehomadehifi simulated perfectly the crossover for the dome tweeter - mid - bass...it was not the case to change any value. But with CD / Horn it is more difficult, I think. I'll buy the pieces, first, and then I'll try to measure them. And, maybe, apen a new thread, as you sugested.

All the best!

All the best!

- Home

- Loudspeakers

- Multi-Way

- Open Source "Tower XL"