Ah yes, sorry, you would have to register. I can post some relevant info and images here, if augerpro does not mind...

I just registered, but the figures still don't show. It would be great if you could present (a summary of) your findings here.

I just registered, but the figures still don't show. It would be great if you could present (a summary of) your findings here.

That's weird. I'll post relevant figures here...

What browser do you use? I normally use safari and sometimes i come across a website that doesn't work right and I have to use different browser, like Opera, chrome or firefox and also check for the browser plugins to make sure something isn't blocking the pictures. Give it a try.I just registered, but the figures still don't show. It would be great if you could present (a summary of) your findings here.

I'll have to put that waveguide on my 6600 and see for myself how this works.

So I got my adapter plates ready and put the Monacor WG300 waveguides on my ScanSpeak 6600 tweeters. I machined the WG300 to make it a few millimeters shorter so I would fit the diameter of the 6600. See photos.

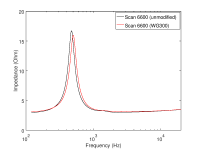

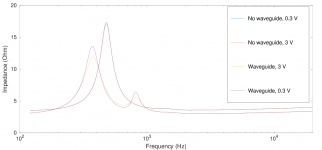

I have taken a few quick impedance measurements, which look a bit strange (no acoustic measurements yet). The curves show TWO impedance peaks (a bit like a bass-reflex system), and the size of these peaks changes a lot with different drive voltages (see attached impedance plots).

Any ideas what's going on?

Edit: note that the "no waveguide" measurements were taken from my second 6600 tweeter with the original ScanSpeak front plate installed.

Attachments

-

Revelator_6600_impedance.png38.8 KB · Views: 1,194

Revelator_6600_impedance.png38.8 KB · Views: 1,194 -

DSC08377.jpg184.9 KB · Views: 1,196

DSC08377.jpg184.9 KB · Views: 1,196 -

DSC08378.jpg174.8 KB · Views: 1,161

DSC08378.jpg174.8 KB · Views: 1,161 -

DSC08380.jpg155.5 KB · Views: 1,161

DSC08380.jpg155.5 KB · Views: 1,161 -

DSC08382.jpg190 KB · Views: 1,162

DSC08382.jpg190 KB · Views: 1,162 -

DSC08383.jpg160.7 KB · Views: 311

DSC08383.jpg160.7 KB · Views: 311 -

DSC08384.jpg158.1 KB · Views: 335

DSC08384.jpg158.1 KB · Views: 335 -

DSC08385.jpg173.2 KB · Views: 346

DSC08385.jpg173.2 KB · Views: 346 -

DSC08389.jpg318.5 KB · Views: 383

DSC08389.jpg318.5 KB · Views: 383 -

DSC08386.jpg233.7 KB · Views: 2,194

DSC08386.jpg233.7 KB · Views: 2,194

Last edited:

Problem solved. The original ScanSpeak front plate seals the three screw holes that are used to fix the plate to the tweeter, wheres the adapter plate does not. This causes air leaks from the rear chamber, resulting in the "bass reflex" behaviour. Sealing the screw holes with silicone fixed the problem.

Attachments

ScanSpeak 6600 in Monacor WG-300

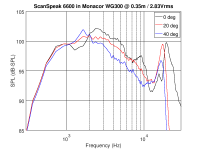

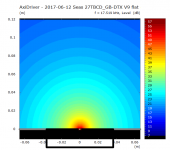

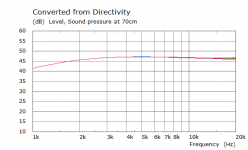

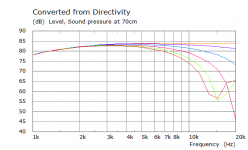

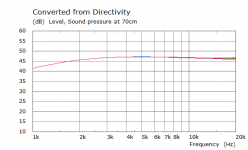

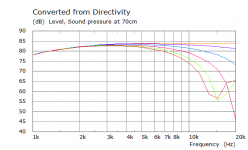

Here's a few acoustic measurements of the ScanSpeak 6600 in the WG-300 waveguide recorded at different angles. The baffle was 32cm wide, with the tweeter in the middle, 16cm from the top. The on-axis measurement shows a few wiggles, which I think are due to the baffle diffraction (note the poor tweeter position on the baffle). The off-axis response is pretty smooth up to about 15 kHz.

What are the peaks/dips at 15 kHz and above?

Why do they move to the left with increasing angle?

Here's a few acoustic measurements of the ScanSpeak 6600 in the WG-300 waveguide recorded at different angles. The baffle was 32cm wide, with the tweeter in the middle, 16cm from the top. The on-axis measurement shows a few wiggles, which I think are due to the baffle diffraction (note the poor tweeter position on the baffle). The off-axis response is pretty smooth up to about 15 kHz.

What are the peaks/dips at 15 kHz and above?

Why do they move to the left with increasing angle?

Attachments

I've never had much luck using larger domes on waveguides. 16khz is 2cm long; because of this, if the 'tip' of a radiator is more than about 5-7mm closer than the rest of the radiator, you get a dip in the response.

The dip in the response that I describe, it happens because the tip of the diaphragm is 90-180 degrees out-of-phase with the rest.

There's two ways to fix this:

1) Use a smaller dome

or

2) Use a phase plug to flatten the wavefront that's radiated off of the dome

Here's my Celestion CDX1-1425 disassembled. The phase plug takes a 29mm dome and flattens the wavefront as it exits the throat of the compression driver

Another option is to just use a ring radiator. I don't think it's a coincidence that BMS, JBL, Eminence and now B&C are selling ring radiators. They solve a ton of problems.

One thing that's going to be particularly problematic, is that this dome is quite a bit larger than 29mm when you include the surround. The spec sheet doesn't say what the diameter is, including the surround, but it appears to be close to 1.5". With a radiator that size, it's going to be challenging to make things work without a phase plug. And that's a whole 'nother can of worms, because phase plug design is not simple.

SB Acoustics SB19 is $20 and it works great on darn near every waveguide under the sun 🙂 Note how narrow the surround is.

The dip in the response that I describe, it happens because the tip of the diaphragm is 90-180 degrees out-of-phase with the rest.

There's two ways to fix this:

1) Use a smaller dome

or

2) Use a phase plug to flatten the wavefront that's radiated off of the dome

Here's my Celestion CDX1-1425 disassembled. The phase plug takes a 29mm dome and flattens the wavefront as it exits the throat of the compression driver

Another option is to just use a ring radiator. I don't think it's a coincidence that BMS, JBL, Eminence and now B&C are selling ring radiators. They solve a ton of problems.

One thing that's going to be particularly problematic, is that this dome is quite a bit larger than 29mm when you include the surround. The spec sheet doesn't say what the diameter is, including the surround, but it appears to be close to 1.5". With a radiator that size, it's going to be challenging to make things work without a phase plug. And that's a whole 'nother can of worms, because phase plug design is not simple.

An externally hosted image should be here but it was not working when we last tested it.

SB Acoustics SB19 is $20 and it works great on darn near every waveguide under the sun 🙂 Note how narrow the surround is.

Last edited:

Hi,

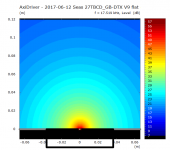

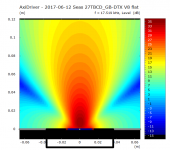

These dips are caused by the diameter of the tweeter membrane. Thy shift to lower frequencies with increasing angle because the distance from the closer edge of the membrane to the distant edge increases with increasing angle.

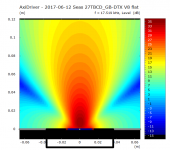

See these examples taken from the WG-Thread on the German forum.

A 1mm diameter membrane at 17.5kHz:

The respective off-axis response:

Same for a 28mm membrane (simple flat membrane here):

Off-axis response:

You see the typical dips shifting to lower frequencies with higher angles...

What's the diameter of the ScanSpeak 6600?

PS: Just see that Patrick was a bit faster...

What are the peaks/dips at 15 kHz and above?

Why do they move to the left with increasing angle?

These dips are caused by the diameter of the tweeter membrane. Thy shift to lower frequencies with increasing angle because the distance from the closer edge of the membrane to the distant edge increases with increasing angle.

See these examples taken from the WG-Thread on the German forum.

A 1mm diameter membrane at 17.5kHz:

The respective off-axis response:

Same for a 28mm membrane (simple flat membrane here):

Off-axis response:

You see the typical dips shifting to lower frequencies with higher angles...

What's the diameter of the ScanSpeak 6600?

PS: Just see that Patrick was a bit faster...

Last edited:

I don't know if you seen the results in this thread for the SB21, but THAT is nice. Great response on a waveguide AND a shorting ring which the SB19 lacks.

Yeah I need to get me some of those. I bought the SB19 for a cheap project and wound up using them over and over and over, because they're so waveguide friendly. They're cheap and low-tech but they work really well.

Yes, this measures VERY well. But what if I would like something a bit more "high end" (yes, thats difficult terminology)? What about a Scanspeak 20mm ring radiator (R2004/602000)? Or the mysterious Satori 21mm Be dome? Any other suggestions?I don't know if you seen the results in this thread for the SB21, but THAT is nice. Great response on a waveguide AND a shorting ring which the SB19 lacks.

Do you mean something like that? It is D2004 in 150mm WG.

Shamal :: Pkaudio

I think that R2004 would perform well too. I plan to measure it. Here is R2004/D2004 comparison in 120mm WG.

WG mereni :: Pkaudio

Shamal :: Pkaudio

I think that R2004 would perform well too. I plan to measure it. Here is R2004/D2004 comparison in 120mm WG.

WG mereni :: Pkaudio

But what if I would like something a bit more "high end" (yes, thats difficult terminology)? What about a Scanspeak 20mm ring radiator (R2004/602000)? Or the mysterious Satori 21mm Be dome? Any other suggestions?

Last edited:

I have very good experience with the SB26ADC for use in waveguides. The SB26ADC measures very well in terms of distortion and has good wide directivity at high frequencies (see linked datasheet). In addition, the faceplate can be removed andthe tweeter can be coupled directly to the WG throat. Though not exactly high end-priced...

If you prefer something more 'fancy', the SB26cdc should work as well. Seems tp be based on the same motor and faceplate as the SB26ADC - though I did not use it so far.

From my limited experience,

- and as already said, a small diameter membrane is preferable;

- ring radiators seem to be 'easy' to couple to WGs, as they narrow directivity at high frequencies, which minimizes possible mismatch with the WG throat (at cost of narrow directvity at high frequencies😉);

- check if the faceplate surface is flat or if it can be removed (if the tweeter is 'zwangszentriert') - a rounded faceplate might hamper good fit to the WG-throat;

- I'd avoid tweeters with large surrounds - they again hinder easy fit of tweeter and WG-throat;

- if you like to use a tweeter with faceplate, I'd use a tweeter with flat faceplate and a slightly countersinked, relatively flat dome (see discussion on the 'Step' at the WG throat within this thread) and small surround...

Personally, I actually have a close look at tweeters with concave, inverted membranes for use in WGs, like Accuton C25-6-012, old Focal tweeters or the TB 25-2234S...

May be the Transducer Lab tweeters are worth to have a closer look. However, I did not work with them so far...

Best would be to develop the WG specifically for your tweeter of choice.🙂

PS: Alexander Heißmann published quite some tweeter-WG-measurements on his homepage...

If you prefer something more 'fancy', the SB26cdc should work as well. Seems tp be based on the same motor and faceplate as the SB26ADC - though I did not use it so far.

From my limited experience,

- and as already said, a small diameter membrane is preferable;

- ring radiators seem to be 'easy' to couple to WGs, as they narrow directivity at high frequencies, which minimizes possible mismatch with the WG throat (at cost of narrow directvity at high frequencies😉);

- check if the faceplate surface is flat or if it can be removed (if the tweeter is 'zwangszentriert') - a rounded faceplate might hamper good fit to the WG-throat;

- I'd avoid tweeters with large surrounds - they again hinder easy fit of tweeter and WG-throat;

- if you like to use a tweeter with faceplate, I'd use a tweeter with flat faceplate and a slightly countersinked, relatively flat dome (see discussion on the 'Step' at the WG throat within this thread) and small surround...

Personally, I actually have a close look at tweeters with concave, inverted membranes for use in WGs, like Accuton C25-6-012, old Focal tweeters or the TB 25-2234S...

May be the Transducer Lab tweeters are worth to have a closer look. However, I did not work with them so far...

Best would be to develop the WG specifically for your tweeter of choice.🙂

PS: Alexander Heißmann published quite some tweeter-WG-measurements on his homepage...

Last edited:

Pida> thanks for those links! Some of those Scans do quite well on a waveguide. I would be open to designing something if someone wanted to donate a tweeter. Assuming my printer doesn't put the brakes on all the waveguides I'm sending him.

Mbrennwa> I think Pida and Gaga make some good suggestions. Don't disregard the SB26 family just because of price. I'm going to grab the ceramic (anodized aluminum really) SB26CDC for future measurements. Also forgot I had the fabric variant SB26STAC all this time too!

Mbrennwa> I think Pida and Gaga make some good suggestions. Don't disregard the SB26 family just because of price. I'm going to grab the ceramic (anodized aluminum really) SB26CDC for future measurements. Also forgot I had the fabric variant SB26STAC all this time too!

My favorite would be a Scanspeak 6640, but high efficiency, high impedance, and smaller diameter 🙂

No, seriously, a Scanspeak R2904/7000 ring radiator with a waveguide might be interesting for the Monkey Coffin project due to it's highish efficiency. It's still not a small diameter, but it seems ring radiators are a bit more relaxed with this.

Thoughts?

No, seriously, a Scanspeak R2904/7000 ring radiator with a waveguide might be interesting for the Monkey Coffin project due to it's highish efficiency. It's still not a small diameter, but it seems ring radiators are a bit more relaxed with this.

Thoughts?

Last edited:

Thoughts?

Well, as you ask...

As far as I understand, you defined the 3'' Volt midrange dome VM752 as midrange driver for your project. This has relatively wide directivity around the intended crossover region - obviously I'd try to aim for the same directivity for the tweeter there and keep this wide directivity to the high frequencies as far as possible.

This will not be possible with a deep waveguide or vise versa, a possible waveguide should probably only have a slight effect on directivity around the crossover region.

A ring-driver with it's inherently narrowing of directivity to high frequencies seems not the logical choice here.

Said that, I'd suggest the Bliesma T34A (or T34B if you like to go for Berillium) for your project. Directivity measurements can be found here or here for example.

This tweeter has high efficiency, wide directivity up to high frequencies and is definitely on the high-end side...😉

Use it with no or a very shallow waveguide in order not to interact with it's very good HF directivity. The WG should 'just' adjust directivity at crossover. A good development can be seen here at German DIY forum. Note: They use a Accuton C168-6-990 Cell as midrange. I could do a simulation if you really consider the Bliesma as HT.

Sorry for the slight off-topic here.

Sorry for insisting... I found Troels' tests with some of the 'large' Scanspeak tweeters in Jantzen waveguides. Most of them gave results that looked quite a bit better than mine with the Monacor WG300 (see post 167). Is it possible that the shallow Jantzen waveguide is more 'forgiving' than the deeper WG300?

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!