oh btw, I wouldn't consider companies who do everything in house better or so.

It just changes the whole business you're running all together.

There are some extremely good production and engineering houses out there.

With many many years of experience. Very hard to beat that.

There is a lot more involved than plain physics and engineering in the whole process.

Something people often forget.

It just changes the whole business you're running all together.

There are some extremely good production and engineering houses out there.

With many many years of experience. Very hard to beat that.

There is a lot more involved than plain physics and engineering in the whole process.

Something people often forget.

What b-force is saying makes sense. I have no (zero) insight into driver manufacturing, but I do have a lot of experience in the manufacture of other technologically advanced products.

For many manufacturers, their main technological expertise, and their most important intellectual property, is the knowledge of how to build their product. thousands or millions of identical units, efficiently built and quality controlled. Their other expertise is marketing: knowing what the customers want at every price level, how their products fit relative to the competition. The design of a new product happens infrequently, so they can not really maintain a full product design/development staff.

j.

For many manufacturers, their main technological expertise, and their most important intellectual property, is the knowledge of how to build their product. thousands or millions of identical units, efficiently built and quality controlled. Their other expertise is marketing: knowing what the customers want at every price level, how their products fit relative to the competition. The design of a new product happens infrequently, so they can not really maintain a full product design/development staff.

j.

Quite tr UE. We see new speaker line each 15 years maybe. Seas Prestige and Scan Speak Revelator are 15-20 years old.What b-force is saying makes sense. I have no (zero) insight into driver manufacturing, but I do have a lot of experience in the manufacture of other technologically advanced products.

For many manufacturers, their main technological expertise, and their most important intellectual property, is the knowledge of how to build their product. thousands or millions of identical units, efficiently built and quality controlled. Their other expertise is marketing: knowing what the customers want at every price level, how their products fit relative to the competition. The design of a new product happens infrequently, so they can not really maintain a full product design/development staff.

j.

And this is still fastinating to me that we Cannon beat it with modern tools and sell for 50% of the price.

I do realizacji though that DIY speaker market is extremely small

Don't forget, developing something is not the same as manufacturing something.

Simple example;

I can decide to make an active loudspeaker cabinet.

Am I gonna manufacture ALL the parts in house?

So cabinet making, manufacturing the speakers (even the drivers), manufacturing the electronics etc.

In that case a big part of my business is being a manufacturer company.

In that scenario one needs manufacture machines, assembly lines, people who buy the materials etc.

And most importantly, if something goes wrong (in any way), you're fully responsible for everything.

Or am I gonna outsource parts, get the speakers from a certain brand, the amplifiers from a certain brand etc?

It that case I only do the end assembly myself. (even that you can outsource).

The 3rd party manufactures are responsible when things go wrong (from a technical point of course).

You only have a handful of people for end-assembly and can fully focus of developing.

A similar scenario can be made with loudspeakers.

I consult quite some start-up or small businesses and a big portion of them take the wrong turn when they have to scale up.

Making your own stuff from scratch all sounds amazing on paper, in reality it's a big mess and can of worms.

Simple example;

I can decide to make an active loudspeaker cabinet.

Am I gonna manufacture ALL the parts in house?

So cabinet making, manufacturing the speakers (even the drivers), manufacturing the electronics etc.

In that case a big part of my business is being a manufacturer company.

In that scenario one needs manufacture machines, assembly lines, people who buy the materials etc.

And most importantly, if something goes wrong (in any way), you're fully responsible for everything.

Or am I gonna outsource parts, get the speakers from a certain brand, the amplifiers from a certain brand etc?

It that case I only do the end assembly myself. (even that you can outsource).

The 3rd party manufactures are responsible when things go wrong (from a technical point of course).

You only have a handful of people for end-assembly and can fully focus of developing.

A similar scenario can be made with loudspeakers.

I consult quite some start-up or small businesses and a big portion of them take the wrong turn when they have to scale up.

Making your own stuff from scratch all sounds amazing on paper, in reality it's a big mess and can of worms.

Speaking of measurements Puri Wave | HiFiCompass - anything to show yet? This looks like it could be very promising

Clue one, on a baffle that wide (8-10") the loss of SPL is about 6dB from 500Hz down to 100Hz; at those respective wavelengths causes the sound to transition from 2Pi to 4Pi. In addition, there is usually an additional peak of about 2dB around 1Khz.

Nearfield measurements not only remove the room reflections, it also eliminates baffle diffraction, so the baffle step at lower frequencies is not shown.

Troel's merged responses do not show that he's taken this in account.

Nearfield measurements not only remove the room reflections, it also eliminates baffle diffraction, so the baffle step at lower frequencies is not shown.

Troel's merged responses do not show that he's taken this in account.

Member

Joined 2003

This is really unfortunate for an otherwise high end speaker. Top of the line components, great cabinetry, and then mediocre acoustic design.

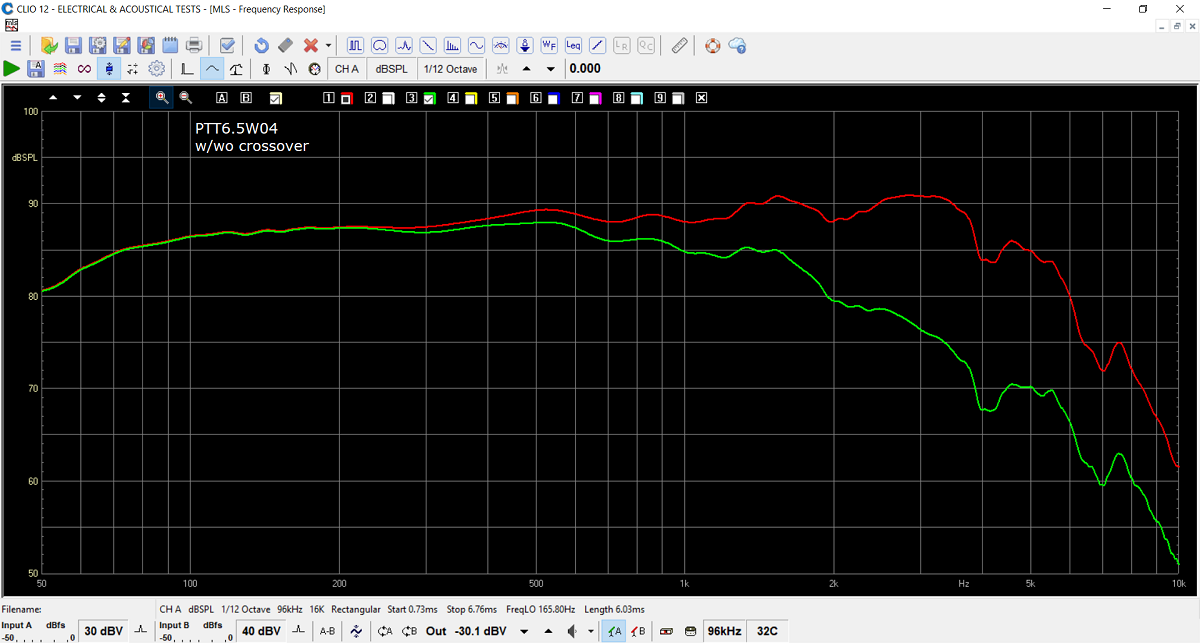

Here is what Troels has put forth as driver response in cabinet without crossover:

For a comparison, simply trace the manufacturer data, apply diffraction simulation and box model to get an idea of what to expect. The mid-bass deficiency is obvious, and the attached image shows exactly this, Troels measurement in orange, and something resembling what you should expect of an in-cabinet measurement is in green.

Here is what Troels has put forth as driver response in cabinet without crossover:

For a comparison, simply trace the manufacturer data, apply diffraction simulation and box model to get an idea of what to expect. The mid-bass deficiency is obvious, and the attached image shows exactly this, Troels measurement in orange, and something resembling what you should expect of an in-cabinet measurement is in green.

Attachments

Often that seems to be the case in a lot of designs.This is really unfortunate for an otherwise high end speaker. Top of the line components, great cabinetry, and then mediocre acoustic design.

To be very clear, I am NOT talking about Troels, but just a general observation with peoples speaker designs.

Often they don't even bother measuring off-axis response for example.

I don't really know how Troels measures his loudspeakers, it's kind of strange that there doesn't seem to be any bafflestep indeed?

That being said, in passive filters one can sometimes get away with a 2nd order filter that does kind of do a bafflestep at the same time.

Tracing manufacture data (hoping it has been measured in inf baffle) is a very handy trick yes.

I do it quite often to get a very rough sense how a certain speaker will perform on a certain baffle.

The bafflestep itself is pretty predictable.

One only has to be careful with diffraction, which is a lot more difficult to model.

(in many cases close to impossible)

Member

Joined 2003

Clue one, on a baffle that wide (8-10") the loss of SPL is about 6dB from 500Hz down to 100Hz; at those respective wavelengths causes the sound to transition from 2Pi to 4Pi. In addition, there is usually an additional peak of about 2dB around 1Khz.

Nearfield measurements not only remove the room reflections, it also eliminates baffle diffraction, so the baffle step at lower frequencies is not shown.

Troel's merged responses do not show that he's taken this in account.

I know why you say that but is there really such a thing as 4pi in a living room? Presumably there is a back wall that must provide some reinforcement at LF albeit with a somewhat more complex frequency response (ripples maybe).

I have wondered about that but don’t have the resources to measure it.

So have I and often the terms are very onerous for revealling anything publicly. Not just for audio gear, but in general.I had to sign quite some NDA's over the years.

I know why you say that but is there really such a thing as 4pi in a living room? Presumably there is a back wall that must provide some reinforcement at LF albeit with a somewhat more complex frequency response (ripples maybe).

I have wondered about that but don’t have the resources to measure it.

In loudspeaker system design there’s a few tradeoffs.

You could do full baffle step compensation design which gives a truer reflection of how the speaker itself performs eg. Outdoors without reflections, or in an anechoic chamber.

The problem with this, is that a typical room, where speakers are close to boundaries, there’s fluctuations in the low end that can give it a muddy thick tone, for lack of a better adjective.

On the other hand, you could do a no baffle step compensation design, the speaker can sound very thin in the bass. Now you have to play around with placement and move the speaker closer towards the front wall to get a boost in the low end. But then you compromise on the midrange clarity due to early reflections.

A better compromise is slightly less than full baffle step. Sometimes people call this “4dB of baffle step” (6dB being “full”) but it’s not a precise term. The point is you tailor it so that the speaker’s natural response combines with your target room so that you get an neutral response from the midrange through to the mid bass. That, too, is not foolproof, because everyone has different rooms and place their speakers differently.

Modern active designs have switches which allow for adjustment of frequencies below about 200Hz; which allow for variable compensation and thus flexibility in placement.

But even better is when this is combined with in-room EQ.

I would argue that rooms are never optimal for sound anyway, so perfectly flat speakers will invariably need processing regardless, albeit hopefully less.

Affordable microphones and modern DSP and software really has made this easier. Eg. Acourate, Dirac.

Troels’ strength is his experience and prolific number of designs for all sizes.

But at the crossover frequency I don’t see a problem.

Last edited:

With this Troels design in particular, there absolutely is "some" BSC from a shallow filter rolloff, but probably not enough.

To me this isn't bafflestep compensation proper but just him compensating for a high frequency rise in the woofers response. This is something the PTT6.5 exhibits mildly anyway.

Yes you could say the end effect is that it gives the speaker a mild amount of effective BSC but this is more a matter of circumstance rather than by design.

In Troels' original measurements he's clearly neglected to take into consideration the effects of baffle step. If he had added in these effects, as you have in your graphs above, then I would say it was by conscious design and decision. In other words he was aware of the phenomena, had taken it into account in his measurements, and has then chosen, specifically, to only apply 0.5-1dB of BSC. But this is not the case.

- Home

- Loudspeakers

- Multi-Way

- Some speaker driver measurements...