I got a set of Wharfedale Diamond 10.1 speakers and after seeing the review of the 10.2 from AudioExcite (www.audioexcite.com Wharfedale Diamond 10.2 review part 1, and also I think he's Gornir from this forum) I decided to have a crack at mine.

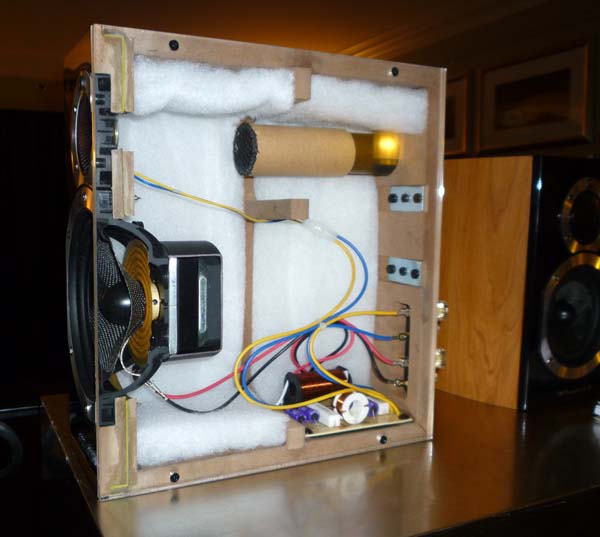

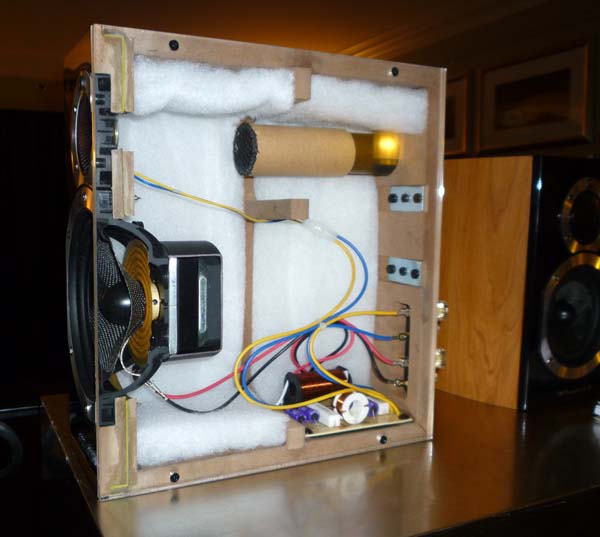

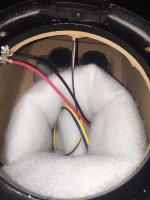

After I took off the midwoofer I found the same crap job with the wool. Just packed in there, not even a remote attention to detail like gluing it to the walls or anything like that.

As you can see in this picture:

Also the crossover was mounted vertically above the speaker connectors, not horizontally like the picture (this doesn't matter).

Further in the back there's a second piece of wool that's mounted the same way, just shoved in there.

Seams are not sealed, actually there's space between some parts inside. I also see a sort of metal pin protruding in the bottom. Maybe some structural thing that went the wrong way?

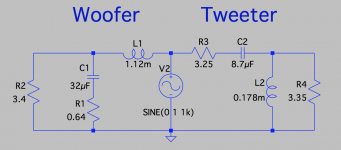

Second order crossover with two parallel 15uF capacitors for the low side. The high side has one 8.2uF cap. All caps are 50V rated, 105 degrees C and what I find curious is that even thou the 15uF caps are almost twice the capacitance of the 8.2uF one, they are twice as small. They seem from the same series and the only value different is the actual capacitance. Weird how they are smaller than the 8.2uF one.

Their ESR measured about 0.13R for the two 15uF in parallel (I guess 0.26R for each?) and 0.14R for the 8.2uF cap.

The actual capacitance measured 32uF for the two 15uF parallel ones and 8.7uF for the other.

Resistors measured 0.64R for the 0.68R rated one. The other resistor (rated 3.3R) measured 3.2R.

Inductors are 1.12mH and 0.178mH.

I also attached a schematic for the crossover. Tweeter has an air core inductor while the midwoofer has a metal core one.

Mid woofer measured a Re of 3.4R and tweeter 3.35R.

While the speakers look real nice on the outside, there's no attention to detail on the inside.

I'm going to seal the seams on the inside with filler and I'd replace the components on the crossover, especially the caps/resistors.

I don't know if it's worth messing with the metal core inductor. It's riveted on the board and I'm not sure if it would help the overall quality of the sound.

What do you say? Worth to replace with an air core one?

I'm not so sure on my inductance meter. It might not be super accurate but it gives a rough idea I guess.

As I see on Audio Excite site there's a more complicated mod for the tweeter section but I don't know if I'll go there yet, maybe later.

Upon reassembly I noticed that the insulating pad that sits between the crossover and speaker wall has a sticky side that doesn't have the protecting pad taken off.

I did that myself and sticked it to the wall of the speaker.

The wool doesn't go all the way around the wall. It's shorter so there's nothing covering the top side of the speaker. It is also bigger in width so I have to fold it. The same for the one in the back.

I need to take measurements and replace the wool with something better and correct size.

I am really disappointed with the attention to detail inside these units.

Wharfedale lost my trust completely with this.

Although the units sound and look really good I really don't like the way they treated the insides of this unit.

After I took off the midwoofer I found the same crap job with the wool. Just packed in there, not even a remote attention to detail like gluing it to the walls or anything like that.

As you can see in this picture:

Also the crossover was mounted vertically above the speaker connectors, not horizontally like the picture (this doesn't matter).

Further in the back there's a second piece of wool that's mounted the same way, just shoved in there.

Seams are not sealed, actually there's space between some parts inside. I also see a sort of metal pin protruding in the bottom. Maybe some structural thing that went the wrong way?

Second order crossover with two parallel 15uF capacitors for the low side. The high side has one 8.2uF cap. All caps are 50V rated, 105 degrees C and what I find curious is that even thou the 15uF caps are almost twice the capacitance of the 8.2uF one, they are twice as small. They seem from the same series and the only value different is the actual capacitance. Weird how they are smaller than the 8.2uF one.

Their ESR measured about 0.13R for the two 15uF in parallel (I guess 0.26R for each?) and 0.14R for the 8.2uF cap.

The actual capacitance measured 32uF for the two 15uF parallel ones and 8.7uF for the other.

Resistors measured 0.64R for the 0.68R rated one. The other resistor (rated 3.3R) measured 3.2R.

Inductors are 1.12mH and 0.178mH.

I also attached a schematic for the crossover. Tweeter has an air core inductor while the midwoofer has a metal core one.

Mid woofer measured a Re of 3.4R and tweeter 3.35R.

While the speakers look real nice on the outside, there's no attention to detail on the inside.

I'm going to seal the seams on the inside with filler and I'd replace the components on the crossover, especially the caps/resistors.

I don't know if it's worth messing with the metal core inductor. It's riveted on the board and I'm not sure if it would help the overall quality of the sound.

What do you say? Worth to replace with an air core one?

I'm not so sure on my inductance meter. It might not be super accurate but it gives a rough idea I guess.

As I see on Audio Excite site there's a more complicated mod for the tweeter section but I don't know if I'll go there yet, maybe later.

Upon reassembly I noticed that the insulating pad that sits between the crossover and speaker wall has a sticky side that doesn't have the protecting pad taken off.

I did that myself and sticked it to the wall of the speaker.

The wool doesn't go all the way around the wall. It's shorter so there's nothing covering the top side of the speaker. It is also bigger in width so I have to fold it. The same for the one in the back.

I need to take measurements and replace the wool with something better and correct size.

I am really disappointed with the attention to detail inside these units.

Wharfedale lost my trust completely with this.

Although the units sound and look really good I really don't like the way they treated the insides of this unit.

Attachments

-

IMG_2723.JPG178.2 KB · Views: 1,437

IMG_2723.JPG178.2 KB · Views: 1,437 -

IMG_2749.JPG180 KB · Views: 619

IMG_2749.JPG180 KB · Views: 619 -

IMG_2747.JPG122 KB · Views: 586

IMG_2747.JPG122 KB · Views: 586 -

IMG_2746.JPG145.5 KB · Views: 617

IMG_2746.JPG145.5 KB · Views: 617 -

IMG_2745.JPG186.3 KB · Views: 625

IMG_2745.JPG186.3 KB · Views: 625 -

IMG_2739.JPG156.1 KB · Views: 621

IMG_2739.JPG156.1 KB · Views: 621 -

IMG_2735.JPG172.8 KB · Views: 679

IMG_2735.JPG172.8 KB · Views: 679 -

IMG_2732.JPG160.8 KB · Views: 1,548

IMG_2732.JPG160.8 KB · Views: 1,548 -

IMG_2726.JPG178.9 KB · Views: 1,476

IMG_2726.JPG178.9 KB · Views: 1,476 -

IMG_2725.JPG182.7 KB · Views: 1,710

IMG_2725.JPG182.7 KB · Views: 1,710

I'm not looking to turn it into something it isn't going to be anyway

I'd like just to properly seal the inside, stick the wool to the walls and maybe replace the caps/resistors since it wouldn't be something expensive. I guess 20 bucks for all parts isn't that much.

As I said, I really like the way it sounds. It would just make me feel fuzzy inside knowing I've sealed the inside and the wool is sitting nice Right now it's covering the ports and looks like a poor job.

Right now it's covering the ports and looks like a poor job.

I'd like just to properly seal the inside, stick the wool to the walls and maybe replace the caps/resistors since it wouldn't be something expensive. I guess 20 bucks for all parts isn't that much.

As I said, I really like the way it sounds. It would just make me feel fuzzy inside knowing I've sealed the inside and the wool is sitting nice

You could upgrade the wire and check parts express for better ports. Ive never heard good things about iron core inductors. I dont know much about crossovers but if the core saturates it wont have the same value until its not saturated so it cant perform as well as an air core.

I finally went bi-amp with these speakers.

I removed the crossover completely and installed good ol' wire instead.

I got an active crossover (4th order LR) and used the same crossover frequency of 1.8KHz or so.

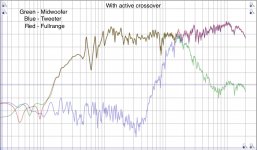

I also made some measurements on them before and after using REW with a Scarlett 2i4 audio card and a T.Bone MM1 measurement microphone.

I put each speaker in turn in the middle of the room at about 60cm from the floor and the microphone on axis at about 50cm distance from the speaker.

I made a full range test and then on each driver separately. I added all 3 measurements in one picture overlaid.

The microphone is not calibrated, I just used it to get an idea on what's happening. I might have had the highs a bit louder on the bi-amped one. Actually they were at the same level as the low pass. The passive crossover attenuates the highs a few db.

I removed the crossover completely and installed good ol' wire instead.

I got an active crossover (4th order LR) and used the same crossover frequency of 1.8KHz or so.

I also made some measurements on them before and after using REW with a Scarlett 2i4 audio card and a T.Bone MM1 measurement microphone.

I put each speaker in turn in the middle of the room at about 60cm from the floor and the microphone on axis at about 50cm distance from the speaker.

I made a full range test and then on each driver separately. I added all 3 measurements in one picture overlaid.

The microphone is not calibrated, I just used it to get an idea on what's happening. I might have had the highs a bit louder on the bi-amped one. Actually they were at the same level as the low pass. The passive crossover attenuates the highs a few db.

Attachments

It usually pays to recap. You can get 33 uF and 15 uF polypropylene capacitors at very reasonable cost at Parts Express.

I will caution about replacing the 1.12 mH laminated coil. Modern laminated coil are very linear and have high power rating (low distortion), and it has the advantage of lower resistance. You need to match the coil resistance if you want to use air core coil, which means very large wire gauge (thus very expensive) air coil. Depending on what Wharfedale used originally, the air coil may need to be gauge 14 or even 12 wire. And it is unlikely to hear any improvement.

The wool stuffing is properly there for cabinet wall damping. I am not sure that gluing them makes any difference.

I agree with shaun that "there is very little you can do to this speaker to improve it. It has been value engineered to the nth degree". To keep the cost down, they did a good job optimizing the system design to allow use of low cost speaker drivers. Be really careful in your mod. But do not allow my opinion to discourage you. It is fun to undertake such a project. Your listening is the final test.

I will caution about replacing the 1.12 mH laminated coil. Modern laminated coil are very linear and have high power rating (low distortion), and it has the advantage of lower resistance. You need to match the coil resistance if you want to use air core coil, which means very large wire gauge (thus very expensive) air coil. Depending on what Wharfedale used originally, the air coil may need to be gauge 14 or even 12 wire. And it is unlikely to hear any improvement.

The wool stuffing is properly there for cabinet wall damping. I am not sure that gluing them makes any difference.

I agree with shaun that "there is very little you can do to this speaker to improve it. It has been value engineered to the nth degree". To keep the cost down, they did a good job optimizing the system design to allow use of low cost speaker drivers. Be really careful in your mod. But do not allow my opinion to discourage you. It is fun to undertake such a project. Your listening is the final test.

Last edited:

I have since gone with bi-amping them with an active crossover and a 4 channel Marantz amplifier. Beats the passive crossover approach hands down!

The right way to go. You can't match the performance of an active crossover with a passive one. I saw the improvement you made. How would you describe the difference in sound?

I want clarify my comment on the damping material. The cutaway picture shows the proper way that it was done. It does not need to be glued down, but it needs to be lined up against the cabinet walls. In a vented box design, volume stuffing the cabinet has very little benefit.

Volume filling a reflex box

Hi,

Glueing stuffing to the walls will do squat.

It's simply not necessary, or useful.

rgds, sreten

Agreed. I don't see anything wrong with the design at all. Superfluous naysaying. Speakers built to a price point that actually give you a lot for your money.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Inside the Wharfedale Diamond 10.1