unless I have missed something?

Yes, Q is always set by the ratio of damping to mass reactance. Higher mass or stiffness makes the damping component less in proportion. Q will rise.

Read the paper, Harwood gives curves that are exactly on point. (Thanks Lojzek!)

All damping materials possess different absorption spectra, depending on their material's properties (density, viscosity, mass, etc.) What not many of us know, is the mechanism of conversion. What happens to the absorbed energy??

Simple rule of physics: due to the mechanical excitation of mechanical parts inside of the damping material -friction- it is converted to heat.... While the rise in temperature is minimal within the material itself, it is measurable with sophisticated equipment, simply speaking the temperature inside of the box raises proportionally with the power fed into your speakers.

The problem is, that various materials have different absorption spectrum, so there is no universally applicable method or material exists that can dampen (or completely eliminate) those resonances over the full critical range (usually a few hundred Hertz to 2-3 kHz).

Also -as it is pointed out in several replies before- simple mechanical methods like crossbracing can do very little in this regard, they can only increase and spread the spectra of the resonances toward higher frequencies, so you will have more resonance points with reduced energy... don't forget, energy cannot vanish, only transform.

Simple rule of physics: due to the mechanical excitation of mechanical parts inside of the damping material -friction- it is converted to heat.... While the rise in temperature is minimal within the material itself, it is measurable with sophisticated equipment, simply speaking the temperature inside of the box raises proportionally with the power fed into your speakers.

The problem is, that various materials have different absorption spectrum, so there is no universally applicable method or material exists that can dampen (or completely eliminate) those resonances over the full critical range (usually a few hundred Hertz to 2-3 kHz).

Also -as it is pointed out in several replies before- simple mechanical methods like crossbracing can do very little in this regard, they can only increase and spread the spectra of the resonances toward higher frequencies, so you will have more resonance points with reduced energy... don't forget, energy cannot vanish, only transform.

Last edited:

I hope I am not getting very boring with my musings on this subject, but I've experimented a lot in this area...

Some practical advice. Get an accelerometer (cheapest ones are the piezoelectric types- do some Googling....) to measure the main panel resonances on your box panels. (You can use them with your favoured measurement software by replacing the microphone with the accelerometer).

When you apply any kind of damping to the walls, consider an important fact: the resonance frequency will lower with the damping applied, so you must select a material that will be effective at the combined-LOWERED frequency, not on the original one...

This means quite a few trial-and error- type of measurements, but in return you will have a cleaner, less coloured sounding speaker.

Some practical advice. Get an accelerometer (cheapest ones are the piezoelectric types- do some Googling....) to measure the main panel resonances on your box panels. (You can use them with your favoured measurement software by replacing the microphone with the accelerometer).

When you apply any kind of damping to the walls, consider an important fact: the resonance frequency will lower with the damping applied, so you must select a material that will be effective at the combined-LOWERED frequency, not on the original one...

This means quite a few trial-and error- type of measurements, but in return you will have a cleaner, less coloured sounding speaker.

To quote: "For plywoods the value of Q for the fundamental mode is appreciably greater than for the higher modes". But this is probably not the point because it is the damping material and not the wood that is providing most of the damping. The plots showing the relative response of the cabinet also suggest this: the response at higher frequencies is smaller than that at lower frequencies for the same level of input.Yes, Q is always set by the ratio of damping to mass reactance. Higher mass or stiffness makes the damping component less in proportion. Q will rise.

Read the paper, Harwood gives curves that are exactly on point. (Thanks Lojzek!)

Damping material will dissipate more energy at higher frequencies and so BBC designs need more damping material than more conventional designs to dissipate the same amount of energy. However, the BBC also shows a plot for the audibility threshold of panel resonances showing that low frequency resonances are more difficult to perceive.

Am I still missing something?

Damping material will dissipate more energy at higher frequencies and so BBC designs need more damping material than more conventional designs to dissipate the same amount of energy. However, the BBC also shows a plot for the audibility threshold of panel resonances showing that low frequency resonances are more difficult to perceive.

Am I still missing something?

Yes.

I'm not sure that damping material will damp more at high frequencies. Empirical evidence isn't supporting that, so I certainly wouldn't want to generalize. As to BBC designs needing more damping than others, I don't understand that. If low frequency resonances are more difficult to perceive then we should be pushing resonances down, right? So thinner floppier walls should help? Or mass from damping rather than mass from a rigid material.

Look at figure 14 as it is exactly on point. Doubling a wall thickness pushes resonances upwards. The damping is less effective as the mass reactance has increased while the damping quantity has not changed. Resonances go from below the perception threshold to above.

Yes, making the walls thicker raised the peak level of the resonances, resulting in a poorer cabinet performance.

I hope I am not getting very boring with my musings on this subject, but I've experimented a lot in this area...

Some practical advice. Get an accelerometer (cheapest ones are the piezoelectric types- do some Googling....) to measure the main panel resonances on your box panels. (You can use them with your favoured measurement software by replacing the microphone with the accelerometer).

When you apply any kind of damping to the walls, consider an important fact: the resonance frequency will lower with the damping applied, so you must select a material that will be effective at the combined-LOWERED frequency, not on the original one...

This means quite a few trial-and error- type of measurements, but in return you will have a cleaner, less coloured sounding speaker.

So you are saying that if I drop resonances by 20% the damping will go from effective to ineffective? That seems surprising frequency selective. How do you explain that?

Read the paper, Harwood gives curves that are exactly on point. (Thanks Lojzek!)

Thank you David and others too, for all your contribution of making possible for the

truth to come out! Only good and great people can do that.

So you are saying that if I drop resonances by 20% the damping will go from effective to ineffective? That seems surprising frequency selective. How do you explain that?

What I am trying to say, is this: Let's say the side panels have a strong resonance mode at 800 Hz. So you glue a bitumenous damping sheet to them. Then the side wall- damping sheet combo will (still) have a -hopefully reduced amount- of resonance at a lower (say 750 Hz) frequency due to the mass increase of the panels. Now with some experimenting of the position and shape of the damping sheets you can "tune" the whole thing to be the most effective in reducing THAT frequency (750 Hz). Of course you can increase or decrease the mass (thickness) of the sheets too, but in this case you must re-tune it to the altered frequency. As I said it is a kind of trial-and-error game....

It is basically a mechanically tuned notch filter analogous to the electrical ones used in driver response peak removal.

I know it can be done, because I did this already several times with rather good results

For the hardcore ones: If you have enough time and patience, you can measure the resonance's nodal points on the panel with the accelerometer -draw a map of them- and place the absorbing pads right on the spot, this way their effect is even better than the one of a full sheet.

What I am trying to say, is this: Let's say the side panels have a strong resonance mode at 800 Hz. So you glue a bitumenous damping sheet to them. Then the side wall- damping sheet combo will (still) have a -hopefully reduced amount- of resonance at a lower (say 750 Hz) frequency due to the mass increase of the panels. Now with some experimenting of the position and shape of the damping sheets you can "tune" the whole thing to be the most effective in reducing THAT frequency (750 Hz). Of course you can increase or decrease the mass (thickness) of the sheets too, but in this case you must re-tune it to the altered frequency. As I said it is a kind of trial-and-error game....

It is basically a mechanically tuned notch filter analogous to the electrical ones used in driver response peak removal.

I know it can be done, because I did this already several times with rather good results

I know people have used tuned resonators to kill an existing cabinet resonance. Somebody was selling a unit a few years back that was a mass on a cantilever that vibrated at some frequency. Some internal damping ate up the energy and the cabinet vibration reduced, as long as the resonator was a reasonable match to the cabinet resonance.

But we are talking about simply adding a loss mechanism, the damping sheets or Bitumen pads. They are just a gooey lossy mass which resists bending waves. I don't see that any particular tuning effort is then required. They really should have a loss that, if not frequency invariant, should only change slowly with frequency.

A bit like shock absorbers on your car. The have no tuned frequency aspect, they just create friction force in proportion to velocity. The mass and spring rate sets the resonance frequency and the shock just kills the Q of it.

David

But we are talking about simply adding a loss mechanism, the damping sheets or Bitumen pads. They are just a gooey lossy mass which resists bending waves.

I'd suggest looking into Butyl instead of Bitumen pads... Not really a great difference at steady temperatures in homes but Butyl stays elastic at lower temperatures and will also withstand higher temperatures than Bitumen and won't smell like asphalt

Most of the CLD pads for automotive use are Butyl based today. Not sure if the advantages of Butyl come into play in the home environment but with a reflex port and say, a fireplace nearby I'd go for the Butyl based products

I have listened to a "kit" Ls3/5a from the time and it is a remarkably neutral speaker. It has severe limitations in SPL, however.

I think one could do much better nowadays using less expensive modern drivers in a not-much bigger" cabinet. Look to the monitor designs from Behringer and M-Audio.

I think one could do much better nowadays using less expensive modern drivers in a not-much bigger" cabinet. Look to the monitor designs from Behringer and M-Audio.

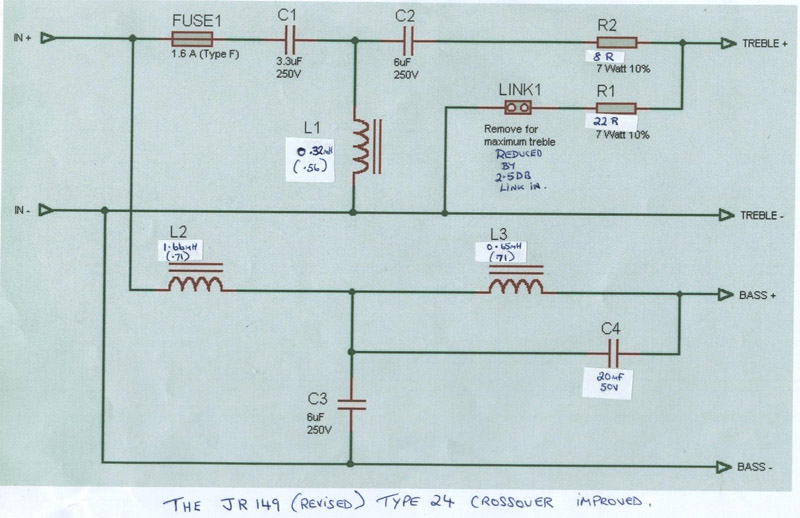

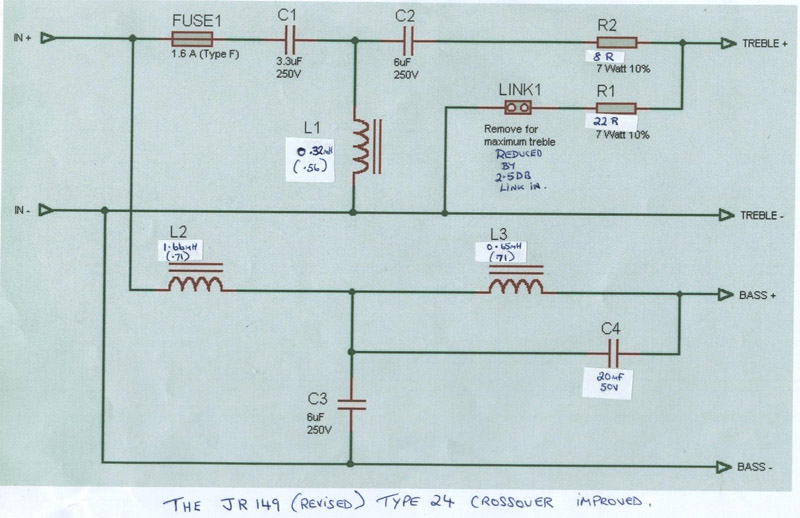

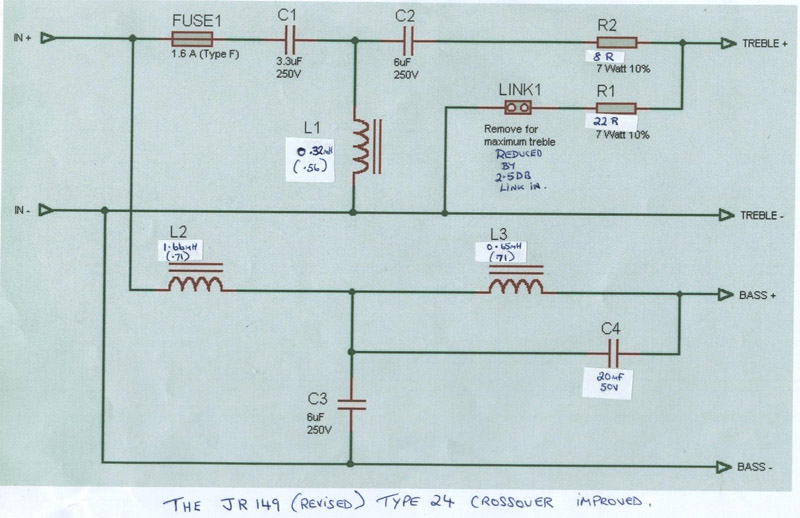

The JR149 used the B110 and T27 in an aluminum cylinder. It had somewhat more internal volume than the LS3/5A, had less extreme baffle-step compensation in its crossover, and therefore had somewhat better dynamics than the LS3/5A which can sound kind of constricted in that department.

An externally hosted image should be here but it was not working when we last tested it.

The JR149 used the B110 and T27 in an aluminum cylinder. It had somewhat more internal volume than the LS3/5A, had less extreme baffle-step compensation in its crossover, and therefore had somewhat better dynamics than the LS3/5A which can sound kind of constricted in that department.

An externally hosted image should be here but it was not working when we last tested it.

That is interesting. I suspect we tend to overlook the fact that these BBC derived designs designs are 18dB/octave BW3. Third Order Butterworth has a more integrated sound than even order Linkwitz Riley and better dispersion and energy at crossover. It's quite hard and unfamiliar to model because of the 90 degree phase difference required. Interestingly, you can flip the tweeter phase on BW3 and it still works. You merely change the upwards or downwards lobing and the group delay with tweeter polarity.

In short, it sounds different. I won't say it sounds BETTER than LR4, but probably works well with 5" bextrene or polycone bass because there is a good overlap between the drivers even at a high 3.5kHz crossover point. For all that, I don't see why you need ancient drivers to implement it.

The BBC approach to thin-walled cabinets and damping is a thing of great subtlety IMO. It's quite, er, low fat.

Last edited:

Ah yes, the JR149. I believe that it was actually conceived as an "improved" LS3/5A. About 10 litres, made of aluminium, cylindrical, heavily damped with thick acoustic foam and with fibre disks at the top & bottom deformed internally by means of a steel rod - presumably to further avoid reflections (LINK).

I am still puzzled that Falcon Acoustics once advocated a 50% increase in cabinet volume but don't seem interested in pursuing that route with their new and very expensive speaker - or as an alternative?

I am also puzzled as to why the BBC didn't simply move the baffle forward in order to avoid reflections from the cabinet edge rather than using felt strips?

I have tried to make sense of the BBC paper on speaker design and must admit that it went well above my head. As to resonance and thin damped panels as opposed to thicker panels, I suspect that MDF was not in common use when that paper was written? Clearly there must be "some" crossover point where a thicker panel will resonate less than a thin damped panel? I believe that the early R&D versions of what was to become the LS3/5A used thinner ply?Don't fall into the trap of assuming that a thicker cabinet would be an improvement. Read the BBC published paper by Harwood where he shows that thinner walls with heavier damping (a greater damping to mass ratio) is the only way to reduce cabinet resonances. <snip>

I believe that Kef produced an enhanced B110, the SP1228? As to the T27 not being a very good tweeter, it (and the B110) certainly seem to have popped up in a great many speakers back in the day. I believe that the only thing(s) that came close to it in popularity were the Celestion HF1300 & HF2000 combined!<snip> The B110 SP1003 was good but not especially consistent. The T27 is not a very good tweeter <snip>

Interesting point about cabinet volume, certainly the JR149 had greater volume and a very interesting (low reflection) cylindrical cabinet shape.<snip> More cabinet volume would help and attention to cabinet diffraction would improve system response smoothness, especially if a grille isn't required.

I am still puzzled that Falcon Acoustics once advocated a 50% increase in cabinet volume but don't seem interested in pursuing that route with their new and very expensive speaker - or as an alternative?

I am also puzzled as to why the BBC didn't simply move the baffle forward in order to avoid reflections from the cabinet edge rather than using felt strips?

I think you're making it more difficult than it is. Thin-walled cabinet construction relies on lightness, rigidity and some panel damping:

http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html#post3234256

For a modern equivalent, I'd look at Eekel's Mini here:

Eekels' Mini

Seems to tick most of the boxes. Especially third order butterworth and small midrange driver.

http://www.diyaudio.com/forums/multi-way/223174-interesting-read-i-found-lossy-cabinet-designs-harbeth.html#post3234256

For a modern equivalent, I'd look at Eekel's Mini here:

Eekels' Mini

Seems to tick most of the boxes. Especially third order butterworth and small midrange driver.

Hi,

There are two versions of the JR149. The later one used

completely different drivers to the B110 and T27.

rgds, sreten.

3rd order BW x/o slopes were popular back in the day you

implemented the slopes electrically ignoring acoustic issues.

They are no longer popular because they are worse than what is.

There are two versions of the JR149. The later one used

completely different drivers to the B110 and T27.

rgds, sreten.

3rd order BW x/o slopes were popular back in the day you

implemented the slopes electrically ignoring acoustic issues.

They are no longer popular because they are worse than what is.

Last edited:

JR149 variants. Audax drive units, wasn't it? There are no acoustic issues with BW3 as it goes. It's just a design choice which works well if the drivers have good overlap as 5" and 1" do. It certainly sounds different from LR2 and LR4. It has different strengths, particularly in even power delivery. A modern example would be Joachim Gerhard's small Anima.

All quite irrelevant really. What we're talking about is the midrange strengths of a small speaker with a small midbass unit. And no real bass worth mentioning.

Very nice in a small room, but you'd probably want a three-way in a serious living room. All speakers are a compromise. There isn't even a perfect tweeter, either. You get what you get with mylar, metal, soft dome or ring radiators or cone types.

So you shouldn't live in the past IMO. Or think that any design was perfect. Competently executed though, whatever you do here will sound like a good small speaker.

Might have a go myself soon.

An externally hosted image should be here but it was not working when we last tested it.

All quite irrelevant really. What we're talking about is the midrange strengths of a small speaker with a small midbass unit. And no real bass worth mentioning.

Very nice in a small room, but you'd probably want a three-way in a serious living room. All speakers are a compromise. There isn't even a perfect tweeter, either. You get what you get with mylar, metal, soft dome or ring radiators or cone types.

So you shouldn't live in the past IMO. Or think that any design was perfect. Competently executed though, whatever you do here will sound like a good small speaker.

Might have a go myself soon.

Last edited:

Getting to the original posters question, I really don't recommend trying to design an xover from scratch for the B110. I did (mating it to a Scanspeak 9300 in a JR149 cabinet) and the driver has really quite bad break up characteristics (you can see break up issues on the impedance plot even), and its response above 1 kHz is pretty non uniform over angle.

I've designed many xovers from scratch and this was the hardest driver I ever worked with. Took me months and many many hours of measure, sim, build, listen, try again, to get a satisfactory outcome.

For the T27s, I eventually just gave my pair away: poor power handling, and again too hard to work with.

If you're fixated on these drivers, save yourself allot of time and find a design you like the sound of and go with that.

I've designed many xovers from scratch and this was the hardest driver I ever worked with. Took me months and many many hours of measure, sim, build, listen, try again, to get a satisfactory outcome.

For the T27s, I eventually just gave my pair away: poor power handling, and again too hard to work with.

If you're fixated on these drivers, save yourself allot of time and find a design you like the sound of and go with that.

- Home

- Loudspeakers

- Multi-Way

- Can one build a better (non) LS3/5A speaker based on T27s & B110s?