Most of my experience is on Otari MX series machines. I recently sent the head stack from my MX-50 NII to JRF to be assessed, lapped, and realigned. The assembly had been "tweaked" by someone who clearly did not know what they were doing and both the erase and replay heads were out of alignment. There was just enough wear I decided lapping the heads was a good idea. Thrilled with the result. (I don't have either the patience or proper tools to do it myself.)

JRF has OEM Panasonic heads in stock for Otari and Technics decks last time I knew.

The CT-F1000 is a challenge, came at an irresistible price and so far represents both a minimal investment in time and money. It clearly was not designed with serviceability in mind and is perhaps not the worst electronics I have worked on but it's not good either.

Alan, I'm replacing all of the belts, tires, had the clutch repaired so it remains serviceable in the future, replaced the switches, lubricated the motors. Everything but the clutch is here for the transport overhaul, just waiting for the clutch. I expect it to be here by the end of the week, barring a postal mishap.

I have replaced all of the electrolytics in the PSU, logic board, and servo board because these assemblies are inaccessible once the transport is back in place. I will verify that the transport and heads are OK once it's all back together, and then move on to replacing all of the rest of the electrolytics, at 42 years old I am not going to waste any time on troubleshooting until after I have replaced all of the capacitors.

I don't believe in wholesale component replacement outside of electrolytic capacitors, and will troubleshoot and replace only what is required. Once that is done I will need to determine then whether I am going to move to the next step and calibrate the playback, record, and dolby electronics or give up on the deck.

JRF has OEM Panasonic heads in stock for Otari and Technics decks last time I knew.

The CT-F1000 is a challenge, came at an irresistible price and so far represents both a minimal investment in time and money. It clearly was not designed with serviceability in mind and is perhaps not the worst electronics I have worked on but it's not good either.

Alan, I'm replacing all of the belts, tires, had the clutch repaired so it remains serviceable in the future, replaced the switches, lubricated the motors. Everything but the clutch is here for the transport overhaul, just waiting for the clutch. I expect it to be here by the end of the week, barring a postal mishap.

I have replaced all of the electrolytics in the PSU, logic board, and servo board because these assemblies are inaccessible once the transport is back in place. I will verify that the transport and heads are OK once it's all back together, and then move on to replacing all of the rest of the electrolytics, at 42 years old I am not going to waste any time on troubleshooting until after I have replaced all of the capacitors.

I don't believe in wholesale component replacement outside of electrolytic capacitors, and will troubleshoot and replace only what is required. Once that is done I will need to determine then whether I am going to move to the next step and calibrate the playback, record, and dolby electronics or give up on the deck.

JRF has OEM Panasonic heads in stock for Otari and Technics decks last time I knew.

Yes, I was on their site and noted that.

Got a roundabout cost to share so I can alert the customer?

The heads have moderate wear, and operate fine, but the 2 track play head plays with low audio on right channel.

I've confirmed that it needs probable replacement.

I've already re-capped the entire audio board, lubed and adjusted the mechs, she runs beautiful.

Best to talk to John French, I don't have a ball park. I've bought good used and relapped Panasonic heads for around $130 each, but the new ones will be more.

John responds pretty quickly to his email.

JRF Magnetics

John responds pretty quickly to his email.

JRF Magnetics

I'm curious about the dual capstans. I assume they are there to maintain tension for the tape/head gap, and to prevent snagging and bunching.. Is there a risk of overtension if they don't remain synchronised, can differently worn pinch rollers cause that? What if one has a dent in it and the tape slips, could this introduce slack.. does one run faster under slip through a clutch?

No slip clutches, and the pinch rollers don't determine the tension or speed - that's determined entirely by the diameter of the individual capstans and/or the pulley/flywheel driving them. (+ motor speed, pulley ratios and belt thickness) The pinch roller's job is just to force the tape tightly against the capstan.

I'm pretty sure in the Pioneer it's all determined by the ratio of the pulley diameters. The supply capstan runs ever so slightly slower than the one on the take up side. Any slippage is likely across the capstans and to avoid damaging the tape would have to be minute.

The purported advantages are more constant tape tension across the heads and slightly better speed stability. Since this was an expensive 3 head machine and there is not room for the tensioners typically found on better R2R (not to mention the opposing torque applied by the supply side reel motor) this is the solution they came up with. Reel to reel decks both auto reverse and not also showed up in this time frame with dual capstan drives. (There are high performance R2R drives sans pinch rollers as well - not the cheesy rim drive found on cheap portables of the early 1960s)

I'm pretty sure in the Pioneer it's all determined by the ratio of the pulley diameters. The supply capstan runs ever so slightly slower than the one on the take up side. Any slippage is likely across the capstans and to avoid damaging the tape would have to be minute.

The purported advantages are more constant tape tension across the heads and slightly better speed stability. Since this was an expensive 3 head machine and there is not room for the tensioners typically found on better R2R (not to mention the opposing torque applied by the supply side reel motor) this is the solution they came up with. Reel to reel decks both auto reverse and not also showed up in this time frame with dual capstan drives. (There are high performance R2R drives sans pinch rollers as well - not the cheesy rim drive found on cheap portables of the early 1960s)

You didn't specify which measurement you are using.

WFGUI 8 I believe it was DIN, but my SONY MHC5900 dual plastic parts deck also re-belted & re-capstaned rubbers measured under .02

Last edited:

Best to talk to John French, I don't have a ball park. I've bought good used and relapped Panasonic heads for around $130 each, but the new ones will be more.

John responds pretty quickly to his email.

JRF Magnetics

I spoke with John today on the phone, and Cookie his wife.

Nice people.

I got a quote and options, and an OK from the customer to ship the head block out to JRF.

In time, I'll have that 1500 running great again.

Attachments

Last edited by a moderator:

Looking good! I could not believe how much better that deck sounded with a properly sorted out head stack. I have a stack with SAKI 2 track heads on another machine which I always thought was superior to the stock heads, after the tune up much less sure about that.. Your customer will be pleased.

Your customer will be pleased.

That's exactly why he keeps bringing me his, as he says - "High End Audio"

LOL!

McIntosh amps....

Dual 701 turntable....

AR LST speakers....

His buddy brings me his Akai Pro 1000 rtr deck...(a major headache that was)

McIntosh amps...

APT Holman preamp....

It keeps me "off the streets" and out of trouble....LOL!

I'm basically retired now, but these guys keep bringing me stuff!

That's a very good number, almost too good to be true.

Sorry. I meant .2 not .02

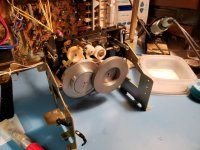

Well tonight was the perfect storm, all the parts needed to fix the transport have arrived at this point.

I slowly and carefully dismantled a few more components to change the idler tire (wrong tire!), but I was able to lubricate the sintered bronze bearing which needed it.

I installed a new tire on the FF/RWD clutch, then installed it. I then installed the capstans and added 3 belts which need to be installed before things are bolted back together, then I installed the rear chassis plate with capstan motor and solenoid. Using a special tool I installed the counter belt first, then the capstan belt and finally the take up reel drive belt.

I added the FF/RWD motor and cassette well lamp...

FF and play seem to work OK, RWD is a bit of a mixed bag and I'm not quite clear as to what the exact problem is - everything is buried. There is a tension setting I can change perhaps without dismantling the transport again.

It actually sounds OK excluding the intermittent switch issues which I will address next..

Not the complete nightmare to work on I was led to believe, but this no deck for the inexperienced or faint of heart. It would not be a lot of fun to work on either if you were on the clock. I'm also concerned about the mechanical bits and motors, none of this is nearly as robust as the Otaris R2R I habitually work on. I am not sure how much further I am going to go once I sort out the RWD issue (if it can be fixed)

I slowly and carefully dismantled a few more components to change the idler tire (wrong tire!), but I was able to lubricate the sintered bronze bearing which needed it.

I installed a new tire on the FF/RWD clutch, then installed it. I then installed the capstans and added 3 belts which need to be installed before things are bolted back together, then I installed the rear chassis plate with capstan motor and solenoid. Using a special tool I installed the counter belt first, then the capstan belt and finally the take up reel drive belt.

I added the FF/RWD motor and cassette well lamp...

FF and play seem to work OK, RWD is a bit of a mixed bag and I'm not quite clear as to what the exact problem is - everything is buried. There is a tension setting I can change perhaps without dismantling the transport again.

It actually sounds OK excluding the intermittent switch issues which I will address next..

Not the complete nightmare to work on I was led to believe, but this no deck for the inexperienced or faint of heart. It would not be a lot of fun to work on either if you were on the clock. I'm also concerned about the mechanical bits and motors, none of this is nearly as robust as the Otaris R2R I habitually work on. I am not sure how much further I am going to go once I sort out the RWD issue (if it can be fixed)

Attachments

-

20200924_212649.jpg142.8 KB · Views: 131

20200924_212649.jpg142.8 KB · Views: 131 -

20200924_204610.jpg204.8 KB · Views: 120

20200924_204610.jpg204.8 KB · Views: 120 -

20200924_200325.jpg210.1 KB · Views: 127

20200924_200325.jpg210.1 KB · Views: 127 -

20200924_195231.jpg175.1 KB · Views: 118

20200924_195231.jpg175.1 KB · Views: 118 -

20200924_193700.jpg194.1 KB · Views: 112

20200924_193700.jpg194.1 KB · Views: 112 -

20200924_192359.jpg175.3 KB · Views: 183

20200924_192359.jpg175.3 KB · Views: 183 -

20200924_191551.jpg145.9 KB · Views: 174

20200924_191551.jpg145.9 KB · Views: 174 -

20200924_190941.jpg161.1 KB · Views: 182

20200924_190941.jpg161.1 KB · Views: 182 -

20200924_185525.jpg159.8 KB · Views: 186

20200924_185525.jpg159.8 KB · Views: 186 -

20200924_181109.jpg69.3 KB · Views: 190

20200924_181109.jpg69.3 KB · Views: 190

I never liked it when they started making assemblies out of that "recycled milk bottle plastic" stuff.

Over time, it sometimes deteriorates, gets brittle, cracks or warps from stress.

Like that spring hooked to that elbow lever in the cassette mech above.

Press-fit gears and pulleys crack, you know the deal.

Then it's a pain to diagnose and repair.

But, ya know, cheapening happens.

Well, I sent out the RS-1500 head block today, called and alerted Connie that it's on its way (UPS).

I'll be glad to finish up THAT job.

Over time, it sometimes deteriorates, gets brittle, cracks or warps from stress.

Like that spring hooked to that elbow lever in the cassette mech above.

Press-fit gears and pulleys crack, you know the deal.

Then it's a pain to diagnose and repair.

But, ya know, cheapening happens.

Well, I sent out the RS-1500 head block today, called and alerted Connie that it's on its way (UPS).

I'll be glad to finish up THAT job.

Last edited:

I have a CT-F1250 which had similar problems with the transport.

It sounds terrible! Very dull sound! Cannot see any wear on the heads. Suspecting there may be some bad caps in the circuit.

The plan is to feed some signal to it and trace it with a scope. Task for long cold winter evenings

How was the sound from your unit?

Hi. Sorry, but the head of the CT-F1250 was prone to this fault, fault that consists in only playing low or very low frequencies.

I don't know the reason, but the only way to repair this fault is to replace the head.

Well tonight was the perfect storm, all the parts needed to fix the transport have arrived at this point.

I slowly and carefully dismantled a few more components to change the idler tire (wrong tire!), but I was able to lubricate the sintered bronze bearing which needed it.

I installed a new tire on the FF/RWD clutch, then installed it. I then installed the capstans and added 3 belts which need to be installed before things are bolted back together, then I installed the rear chassis plate with capstan motor and solenoid. Using a special tool I installed the counter belt first, then the capstan belt and finally the take up reel drive belt.

I added the FF/RWD motor and cassette well lamp...

FF and play seem to work OK, RWD is a bit of a mixed bag and I'm not quite clear as to what the exact problem is - everything is buried. There is a tension setting I can change perhaps without dismantling the transport again.

It actually sounds OK excluding the intermittent switch issues which I will address next..

Not the complete nightmare to work on I was led to believe, but this no deck for the inexperienced or faint of heart. It would not be a lot of fun to work on either if you were on the clock. I'm also concerned about the mechanical bits and motors, none of this is nearly as robust as the Otaris R2R I habitually work on. I am not sure how much further I am going to go once I sort out the RWD issue (if it can be fixed)

Did you check the capstan seat?

Old cassete decks need new head and new pinch roller,if capstan seat is ok

Attachments

Last edited:

Yup, capstan seats are fine, and so are the heads. The pinch rollers are serviceable short term, but will only be replaced if I sort out the other issues. I've reached a reasonable spending limit until I am sure this thing is going to continue to run. I need to do some more work to the FF/RWD components.

I never liked it when they started making assemblies out of that "recycled milk bottle plastic" stuff.

Over time, it sometimes deteriorates, gets brittle, cracks or warps from stress.

Like that spring hooked to that elbow lever in the cassette mech above.

Press-fit gears and pulleys crack, you know the deal.

Then it's a pain to diagnose and repair.

But, ya know, cheapening happens.

Well, I sent out the RS-1500 head block today, called and alerted Connie that it's on its way (UPS).

I'll be glad to finish up THAT job.

Yeah I am facing the plastic reality right now. I have had the transport apart 3 times since I last posted. I have resolved the noise problems and also lost an irreplaceable spring and had to make a "substitute" - I figure it is in orbit somewhere because while I fortunately found everything else I was not able to find the spring.

I've ordered a selection of springs one of which should fit in the hub assembly it launched from.

Seriously anyone contemplating working on one of these decks disassemble take up and supply hub assemblies in a plastic bag!

Cookie and John are great. I will be sending them more head assemblies in the future as I settle on the long term decks I will keep. (I currently own 4, 1 has gone to a new home, but at this point I still own it.) Most likely those decks will be just the two MX-50s I own.. (Not to be confused with MX-5050 series)

OK, here is the brutal truth about rehabbing a 42 year old high end cassette deck - it's a colossal waste of time and possibly money. I have about $100 into this project in total so far and the end result is a deck that works, sort of..

I've had it apart at least 3 more times since I last posted trying to resolve noise problems [successful] and really poor rewind performance in the last few yards of tape [completely resistant to any reasonable solution].

I own a rather well equipped machine shop, but have not acquired the skills to put all of that machinery to good use. So.... I am going to attempt to make bronze pulleys and a few other components to install in some locations with the intention of replacing all of the pulleys to start and eventually all moving parts including all of the clutches.

So I am now in the odd position of needing to recap most of the replay electronics to determine whether this is even worth the effort. (It may be if I learn something along the way about using all of those tools I invested in.)

Last night I was pretty convinced I was throwing in the towel and purchasing either a later Sony ES or Nakamichi machine.

Strangely enough the models I am most interested in have escalated a lot in price since August when I started thinking about this.

There are no spare parts for these machines other than belts and tires. (WJOE best source for what is available). Literally every single component in mine that is a press fit onto a shaft has split, and that's in addition to the notorious clutch problem. There are 2 other clutches built into the hub drive assemblies which I suspect will also fail in time.

I'm going to make a best effort to really fix this machine over time, but will try to put rather more time (learning opportunity) than money into this project.

I'm pretty sure there is a Sony TC-KA3ES or KA5ES in my future as I am curious about what was achieved during the cassette's last gasp.

I've had it apart at least 3 more times since I last posted trying to resolve noise problems [successful] and really poor rewind performance in the last few yards of tape [completely resistant to any reasonable solution].

I own a rather well equipped machine shop, but have not acquired the skills to put all of that machinery to good use. So.... I am going to attempt to make bronze pulleys and a few other components to install in some locations with the intention of replacing all of the pulleys to start and eventually all moving parts including all of the clutches.

So I am now in the odd position of needing to recap most of the replay electronics to determine whether this is even worth the effort. (It may be if I learn something along the way about using all of those tools I invested in.)

Last night I was pretty convinced I was throwing in the towel and purchasing either a later Sony ES or Nakamichi machine.

Strangely enough the models I am most interested in have escalated a lot in price since August when I started thinking about this.

There are no spare parts for these machines other than belts and tires. (WJOE best source for what is available). Literally every single component in mine that is a press fit onto a shaft has split, and that's in addition to the notorious clutch problem. There are 2 other clutches built into the hub drive assemblies which I suspect will also fail in time.

I'm going to make a best effort to really fix this machine over time, but will try to put rather more time (learning opportunity) than money into this project.

I'm pretty sure there is a Sony TC-KA3ES or KA5ES in my future as I am curious about what was achieved during the cassette's last gasp.

- Home

- Source & Line

- Analogue Source

- So you think you want to play with tape: The Pioneer CT-F1000 3 Head Cassette Deck