I like DD turntables. However, the noise issue is not simply explained with rotational speed. For example the Denon 30L has an AC motor. It also has a servo based on the tacho at 1100Hz. So there are components at 60Hz because windings hum. Also 1100Hz from the servo. But this does not translate to bad performance. The rumble figure of this deck at -78dB is comparable with some very good ones, including belt-driven. So the question is, how good is good enough? My rebuild of the Denon which touched every aspect of its operation, now performs better than my stock Sansui SR222 MkV which is belt driven.

Hi,

With the evolution of DDs the platters became continously lighter in weight.

This is due to the fact that the first regulations relied on rtectified and smoothed emf of the motor.

Due to the longer smoothing time constants the regulation was also rather slow.

Hence the inertia of the platter (mechanical time constant) had to be large also.

With the introduction of external frequency generators and Sample&Hold circuits (instead of capacitor based smoothing) the electronic time constants were reduced considerably, allowing also for much smaller mechanical time constants, hence lighter platters without(!) loosing on speed stability.

So it is to understand, that a heavy platter is of no importance at all for the speed stability of a DD with advanced regulation.

jauu

Calvin

I haven't seen many DD tables with decent bearings or heavier platters.

With the evolution of DDs the platters became continously lighter in weight.

This is due to the fact that the first regulations relied on rtectified and smoothed emf of the motor.

Due to the longer smoothing time constants the regulation was also rather slow.

Hence the inertia of the platter (mechanical time constant) had to be large also.

With the introduction of external frequency generators and Sample&Hold circuits (instead of capacitor based smoothing) the electronic time constants were reduced considerably, allowing also for much smaller mechanical time constants, hence lighter platters without(!) loosing on speed stability.

So it is to understand, that a heavy platter is of no importance at all for the speed stability of a DD with advanced regulation.

jauu

Calvin

I have little doubt that direct drive tables can sound very good, but they are in a minority compared to a good Thorens or Linn table.

Hi Chris,

Need to just make sure we are apples to apples here. Technics alone possibly made 10,000 times the number of DD turntables that Linn did at various price points from very cheap to eye wateringly expensive. comparing a full auto built down to a price to a Linn where the arm along was 5x the price of the entire competitor is of course not fair.

Now whilst I agree that all turntables have a distinct signature the great thing about 2019 is that we can measure it and work out what needs to be fettled to make it better. Hopefully in time we can work out how to repeat what Korf is doing with tonearms at home as well.

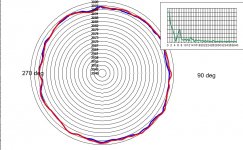

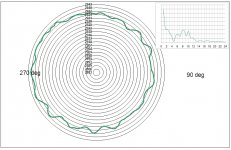

Attached are speed stabilty plots of an SL1200 vs an LP12 done on this forum. The SL is well fettled and I think the Linn needs a bit of service, but you can see there are a lot more modulation sources on the Linn. If you put those side by side the Linn would be more coloured. It might be preferable but certainly not more accurate.

What we should be looking at is how to improve ALL tables with the tools available rather than rehashing old battles

Attachments

Anatech - where to start. I well remember that Linn was playing it's punters for fools in the 70s' one upgrade after another, why weren't they all incorporated at the beginning, of course more profit.Grossly overpriced, over hyped and still is.

Long ago I realised that there are basically two types of listeners - those who love a coloured, far from neutral sound and those want as far as possible a neutral system because then more of the recorded music can be heard.

Your comment about d/d bearings is totally inaccurate, especially where the many Japanese d/d superdecks are concerned. Obviously you have no practical knowledge of the Trio/Kenwood engineering. You don't comment on the KD bearing which I gave a simplistic description of. This is advanced engineering and design way in advance of anything by Linn or Thorens - you seem to have a bible thumping mentality about these marques.

Indeed when these Japanese d/ds arrived in the west they were mercilessly attacked in the mags of the US and the UK. Only the Germans admitted to the revolutionary back to basics of direct drive. That's why the best place to look to buy one is ebay.de.

The function of a t/t is very simple to describe - it should rotate at precise speeds without noise and ideally with an indefinite life. The amount of money that is lavished on upgrades to idlers and belt drives gets quite silly. Most good d/ds are plug and play, perhaps this is what so annoys the others.

Long ago I realised that there are basically two types of listeners - those who love a coloured, far from neutral sound and those want as far as possible a neutral system because then more of the recorded music can be heard.

Your comment about d/d bearings is totally inaccurate, especially where the many Japanese d/d superdecks are concerned. Obviously you have no practical knowledge of the Trio/Kenwood engineering. You don't comment on the KD bearing which I gave a simplistic description of. This is advanced engineering and design way in advance of anything by Linn or Thorens - you seem to have a bible thumping mentality about these marques.

Indeed when these Japanese d/ds arrived in the west they were mercilessly attacked in the mags of the US and the UK. Only the Germans admitted to the revolutionary back to basics of direct drive. That's why the best place to look to buy one is ebay.de.

The function of a t/t is very simple to describe - it should rotate at precise speeds without noise and ideally with an indefinite life. The amount of money that is lavished on upgrades to idlers and belt drives gets quite silly. Most good d/ds are plug and play, perhaps this is what so annoys the others.

I will go out on a limb here to say that if the table, no matter what the drive system is, has a light platter, it probably isn't nearly as good as those tables that do have heavy platters. I'm assuming that the heavy platters are balanced and accurate for dimensions and that the bearings are up to snuff. If your DD table isn't these things, it would be best to slink out the back door without drawing attention to yourself.

-Chris

A few EMT 950 owners might argue with you there. Of course a 70kg turntable with a 200g platter is an extreme case

The function of a t/t is very simple to describe - it should rotate at precise speeds without noise and ideally with an indefinite life. The amount of money that is lavished on upgrades to idlers and belt drives gets quite silly. Most good d/ds are plug and play, perhaps this is what so annoys the others.

That is ONE function of a turntable. There are others! As I have stated, once people climb out the trenches and step into the 21st century you can actually measure this stuff and fettle your turntable to the best of its ability.

gabdx I'm going to listen to you and make a leather mat.

Tell me what leather you use; what thickness; what animal; if you wear your hair or not.

I will do it and then tell my experience.

I have also heard cork and asphalt cloth (TNT JANUS).

I have to warn you, I have no clue how to flatten the leather mat. this could be money wasted... (maybe a very flat high pressure press with steam?) All I know is that the premium mat from Pro-ject that I purchased is flat, hold the vinyl in place, I am not even using the clamp anymore, and static free.

What it did to the sound was subtle, minimal, but it helped with the click/pops. I can live happy without the mat, it is just a small plus +

There are a lot of reviews on the Internet about them, purchasers experienced exactly what I described.

I would check the Linn matt too, it seems interesting.

(btw yes project, even high line ones have poor suspensions, (they are primitive vs the Dual I had and the noresco, but at least on a good rack they are stable, and control resonances, they are costly hipsters gadgets lol.)

I know that my 1976's Technics SL1500 MKI and my 1974's Dual CS601 both easely beat the Project Debut Carbon DC i had. That project is not that bad (especially if you look at the market of modest priced turntables now), but those two sound and measure way better. The Technics is Direct Drive (from before the Quartzlock system) and the Dual belt drive. The problem is that the modest priced turntables are badly designed, and the good designed ones are way too expensive for most listerners. That's why the second hand market is so lively right now.

I think on sound both DD and BD have advantages and disadvantages, and it's all in the implementation. The bad name of DD is mainly due to the flooding of cheap dj turntables build by Harpin and sold under many brandnames (Numark, JBSystem, Reloop, Synq, ...). Those were a very bad implementation of a DD Turntable with noise from the motor and a bad tonearm. But if you look at the models of Technics or the direct drive models of VPI or some asian brands (like mentioned above), direct drive is equal good as belt drive top models.

I think on sound both DD and BD have advantages and disadvantages, and it's all in the implementation. The bad name of DD is mainly due to the flooding of cheap dj turntables build by Harpin and sold under many brandnames (Numark, JBSystem, Reloop, Synq, ...). Those were a very bad implementation of a DD Turntable with noise from the motor and a bad tonearm. But if you look at the models of Technics or the direct drive models of VPI or some asian brands (like mentioned above), direct drive is equal good as belt drive top models.

You shouldn't have modified my statement when quoting it. I typed "More motor noise coupled to the platter in dd turntables: no."

How?

How a motor, which includes the platter as its rotor, spins at 33rpm or HALF of a hertz can be audible when ALL turntables has to turn at 33rpm? I can wager you can hear noise when a motor in a belt-drive or idler drive table spins at 1800rpm which is 30HZ when not decoupled properly.

This kind of audio myth is repeated ad nauseam everywhere from all kinds of people including belt-drive turntable dealers, one of which was espousing such nonsense to show goers at an audio show recently. Nothing is perfect and all drive systems have their flaws but motor noise in well designed direct drive turntables is not one of them.

I will go out on a limb here to say that if the table, no matter what the drive system is, has a light platter, it probably isn't nearly as good as those tables that do have heavy platters. I'm assuming that the heavy platters are balanced and accurate for dimensions and that the bearings are up to snuff.

Ok, so you are saying a balanced, accuratley dimensioned platter with appropriate bearing and bushings makes a better turntable, right?

That I could agree on.

Last edited:

We need to compare apple to apple here, since the topic is about DRIVE systems, not bearing quality or platter mass, etc... Let's agree that ALL turntables have a platter, bearing, motor, and interface (belt, idler wheel, or magnetic force). Let's say we have three turntables using the SAME platter, bearing, and a motor pod consist of a 33rpm motor (which is another dd turntable), the only difference is the interface. The passive table is being driven by the active table. One is driven via a belt, one by and idler wheel, and one directly by the motor. Will that change the sound? Something to ponder.

Below are some pictures of experiments I did many years ago when I had many random tables in the house(!) by using an active platter driving a passive platter and I learned a lot from it. Each setting sounded different and each sounded quite close to the stereotypical sonic signature of the drive system but the influence of the interface is significant. My point is that all three drive systems can sound good. Despite my moniker, I used and enjoyed all three. It's all fun!

Below are some pictures of experiments I did many years ago when I had many random tables in the house(!) by using an active platter driving a passive platter and I learned a lot from it. Each setting sounded different and each sounded quite close to the stereotypical sonic signature of the drive system but the influence of the interface is significant. My point is that all three drive systems can sound good. Despite my moniker, I used and enjoyed all three. It's all fun!

Take a look at the new Technics 1000r and what a 17.4 pound platter did for vibration in comparison to the old sp-10 mk3

Do you think those long impulse trails had any effect on the needle ?

Its reasonable to see this would add a little spice to the sound

At least they did something about it and this new version looks very nice

Regards

David

Do you think those long impulse trails had any effect on the needle ?

Its reasonable to see this would add a little spice to the sound

At least they did something about it and this new version looks very nice

Regards

David

We can always look at how everyone's favorite audiophile records are made. Take a look at world famous mastering engineer Bernie Grundman's two Scully lathes and what each motor is... It's the SP-10Mk3. It uses the same motor as the SP-02M lathe motor for many mastering houses, typically replacing motors in a Neumann lathe.

Some people have $4000 cartridges on $3000 tonearms on their turntables. Against that 2400 is cheap for the total isolation it gives. But it's not DIY I will give you that.

You missed my poor man's diy Minus-K functional equivalent. Built with a hacksaw and basic hand tools:

Seismic Turntable Platform - Stops a Train

Ray K

Those photos of multi-platter monstrosities pictured here are absolutely rediculous and goofy things.

I suppose they're designed to please someone incredibly obsessed with needing to see mechanical motion in action.

They certainly don't improve the actual listening to records, which can be done with much less and reasonable designs.

I suppose they're designed to please someone incredibly obsessed with needing to see mechanical motion in action.

They certainly don't improve the actual listening to records, which can be done with much less and reasonable designs.

It's true that the budget DD implementations can have wobbly platters and poor technical specs.The bad name of DD is mainly due to the flooding of cheap dj turntables build by Harpin and sold under many brandnames (Numark, JBSystem, Reloop, Synq, ...).

However Reloop offer DJs more professional DDs which utilise 16 pole, 3 phase motors as opposed to the 8 pole, 2 phase motors of the budget models.

Torque increases from 1000 to 4500g/cm, while wow & flutter decreases from 0.15% to 0.01% WRMS in the professional models.

These look like big differences in specs to me, but I don't pretend to be an expert.

At the end of the day, as for any type of turntable, you probably get what you pay for.

Those photos of multi-platter monstrosities pictured here are absolutely rediculous and goofy things.

If people are having fun and enjoying the music then why not? You clearly haven't been over to see what Romy the cat gets up to!

- Home

- Source & Line

- Analogue Source

- Turntable DD or Belt drive. This is the question.