Hans-

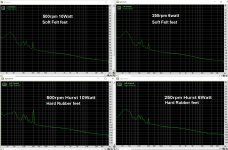

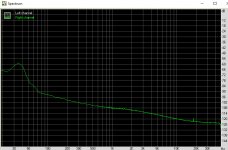

Thanks for the follow up data. It's strange that the biggest response is at 200 Hz (on the 500 RPM motor); normally, the primary response due to cogging is at Fr x 2 or 100 Hz in this case. Perhaps it is due to the driving currents being matched exactly to 90°?

Your data would seem to still support my conclusion that the vibration is proportional to the power and not the number of poles, at least at the primary frequency of cogging (100Hz). Although the 500RPM motor is not 4.4 dB higher (10W/6W), it is higher by a couple of dB. On the 250 RPM motor, the 200Hz response is lower than the primary fr (as expected), not sure why it is so much higher on the 500 RPM motor. It might warrant further investigation?

Thanks for the follow up data. It's strange that the biggest response is at 200 Hz (on the 500 RPM motor); normally, the primary response due to cogging is at Fr x 2 or 100 Hz in this case. Perhaps it is due to the driving currents being matched exactly to 90°?

Your data would seem to still support my conclusion that the vibration is proportional to the power and not the number of poles, at least at the primary frequency of cogging (100Hz). Although the 500RPM motor is not 4.4 dB higher (10W/6W), it is higher by a couple of dB. On the 250 RPM motor, the 200Hz response is lower than the primary fr (as expected), not sure why it is so much higher on the 500 RPM motor. It might warrant further investigation?

I followed your advice and tried several changes.

Picture below shows what happens when changing the 4 feet under the motor housing from the standard hard rubber to soft felt.

For the 250rpm motor the difference is not too different, but for the 500rpm motor the 200Hz component went down to a level only 3dB above the 250rpm motor, a huge step.

I also recorded the noise with motor off, and as you can see, the peak at 25Hz, is caused by the environment.

Doing the same test late at night, this peak will drop 25dB.

Hans

Picture below shows what happens when changing the 4 feet under the motor housing from the standard hard rubber to soft felt.

For the 250rpm motor the difference is not too different, but for the 500rpm motor the 200Hz component went down to a level only 3dB above the 250rpm motor, a huge step.

I also recorded the noise with motor off, and as you can see, the peak at 25Hz, is caused by the environment.

Doing the same test late at night, this peak will drop 25dB.

Hans

Attachments

.....the peak at 25Hz, is caused by the environment. .... Doing the same test late at night, this peak will drop 25dB.

I once recorded a pipe-organ, that I did not know well, and selected my rig to be flat below 32Hz. Stone church, in a small city, with a major highway not too far.

The church seemed quiet. But analyzing my tracks, I had huge content below 40Hz, even to 10Hz. Isolating a no-organ no-crowd moment and boosting it, it was clearly trucks on the highway. Sometimes hardly any. Single truck rise and fall at just the rate I would expect (I drove that road daily). Clumps of trucks.

This was clearly distinct from most of the organ tones. These bounced with the beat and most were >50Hz. One odd piece *started* with a sustained low-low tone near 32Hz, which at first made me think I had a technical problem, but it cut abruptly as the music shifted and I realized it was just a composer's technique.

FWIW-- I mastered with steep 45Hz high-pass on all but the one track where I cut <30Hz. Getting rid of the subsonics really cleaned-up the pitch.

Reviving an old thread. My old VPI Scout had a 600rpm Hurst motor. When I upgraded to the VPI Prime, it of course has the 300rpm Hurst motor. I felt no vibrations with the former motor pod, but do with the latter motor pod. Hence, to try to reduce this vibration noise, I recently went to the SOTA Eclipse package for the Prime, which includes a BLDC motor. My measurements via AnalogMagik concur with Bill's, and the sound improvements are noticeable.

vpiforum.com • View topic - VPI/Hurst motor vs SOTA BLDC motor (or silience is bliss)

Thanks Bill for some great products and DIY contributions.

vpiforum.com • View topic - VPI/Hurst motor vs SOTA BLDC motor (or silience is bliss)

Thanks Bill for some great products and DIY contributions.

Last edited:

I am glad for your positive experience Edw, it’s in line with my experience with my BLDC Rim drive and Condor controller.

It will be fun to see VPI’s BLDC proposal, they have passionately argued against BLDC motors. It will be fun Too, to see the controller they will use, although I suspect that it will be a copy of Bill’s design.

It will be fun to see VPI’s BLDC proposal, they have passionately argued against BLDC motors. It will be fun Too, to see the controller they will use, although I suspect that it will be a copy of Bill’s design.

Hello,

After trying to get in touch with Teres to see if it would be an option to use their rimdrive for my partly diy and being left with no answer i come across this thread.

I already asked Pyramid in a personal message about using the Sota total eclipse package and he said it could be done if it will be possible to get the Sota unit with a bigger pulley so i wrote an email to Sota to find out if it is possible.

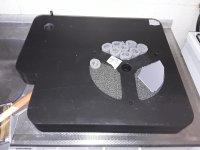

My turntable is in fact a standard Scheu set up with a larger diameter platter to create more flywheel effect.

the string will run on the upper part where most of the inverted bearing is but where the diameter is still bigger than usual.

The Scheu unit is attached with nylon bolts two two pieces of pom material which are partly filled with lead shot.

The Scheu motor unit stands on top of the pom plate. When using the Sota motor unit i can make a circular housing, ( filled with lead shot or just a big '' chunk of lead) and decouple it from the pom by using one of the products in the link. I thought they would be hard to find but i found out Mouser is selling them. O think it will be possible to create a motor housing with the right weight and with the right dampers it will function very well.

Greetings, Eduard

P.s maybe it can be possible to machine a rim identical to the one used by Teres ( the rubber ring is a well available product in the USA)

Greetings, eduard

After trying to get in touch with Teres to see if it would be an option to use their rimdrive for my partly diy and being left with no answer i come across this thread.

I already asked Pyramid in a personal message about using the Sota total eclipse package and he said it could be done if it will be possible to get the Sota unit with a bigger pulley so i wrote an email to Sota to find out if it is possible.

My turntable is in fact a standard Scheu set up with a larger diameter platter to create more flywheel effect.

the string will run on the upper part where most of the inverted bearing is but where the diameter is still bigger than usual.

The Scheu unit is attached with nylon bolts two two pieces of pom material which are partly filled with lead shot.

The Scheu motor unit stands on top of the pom plate. When using the Sota motor unit i can make a circular housing, ( filled with lead shot or just a big '' chunk of lead) and decouple it from the pom by using one of the products in the link. I thought they would be hard to find but i found out Mouser is selling them. O think it will be possible to create a motor housing with the right weight and with the right dampers it will function very well.

Greetings, Eduard

P.s maybe it can be possible to machine a rim identical to the one used by Teres ( the rubber ring is a well available product in the USA)

Greetings, eduard

Attachments

I am glad for your positive experience Edw, it’s in line with my experience with my BLDC Rim drive and Condor controller.

It will be fun to see VPI’s BLDC proposal, they have passionately argued against BLDC motors. It will be fun Too, to see the controller they will use, although I suspect that it will be a copy of Bill’s design.

Yes, it will be interesting to see what VPI comes up with. They also posted pics of the updated ADS controller with a rpm readout.

BTW, rim drive, condor motor, and in Greece - I don't suppose your initials are S.K.?

Yes, it will be interesting to see what VPI comes up with. They also posted pics of the updated ADS controller with a rpm readout.

BTW, rim drive, condor motor, and in Greece - I don't suppose your initials are S.K.?

That’s right Edw

I am very pleased with my BLDC rim drive Edw.

It has nothing to do with the noisy and vibrating Hurst Motors. My Avenger reference‘s performance, dimensionality, detail, dynamics, accuracy and timing has reached unbelievable levels.

At my case the performance was further improved with the high biased Class AB amplifier and the linear power supply both made a very noticeable sound difference.

Surprisingly I have experienced the same improvement at my Brinkmann Balance. The tube Ront power supply made a very noticeable sound improvement.

Also By replacing the RIM drive flywheel with a center belt pulley I am converting the drive into a belt one within seconds. But I prefer the sound of the rim drive.

I know that a number of Avenger reference users are looking to convert their rim drives into BLDC too

I totally agree with your statement ....silence is bliss....

Can’t thank enough Bill Carlin....

It has nothing to do with the noisy and vibrating Hurst Motors. My Avenger reference‘s performance, dimensionality, detail, dynamics, accuracy and timing has reached unbelievable levels.

At my case the performance was further improved with the high biased Class AB amplifier and the linear power supply both made a very noticeable sound difference.

Surprisingly I have experienced the same improvement at my Brinkmann Balance. The tube Ront power supply made a very noticeable sound improvement.

Also By replacing the RIM drive flywheel with a center belt pulley I am converting the drive into a belt one within seconds. But I prefer the sound of the rim drive.

I know that a number of Avenger reference users are looking to convert their rim drives into BLDC too

I totally agree with your statement ....silence is bliss....

Can’t thank enough Bill Carlin....

Last edited:

SK,

Congrats. Must sound incredible now. Ive been looking for a single motor rim drive that would fit my Prime, but they are so very rare.

Sometime ago BRF was selling one.

Get in contact with him

Hello,

Rim drive sounds like a nice option if you can find the right rim. Maybe this one?

Lenco refurbish and restore - Audio Creative Shop

And you will have to change the speed from the motor which could be difficult.

Greetings, Eduard

Rim drive sounds like a nice option if you can find the right rim. Maybe this one?

Lenco refurbish and restore - Audio Creative Shop

And you will have to change the speed from the motor which could be difficult.

Greetings, Eduard

Hello,

It is sold by the company that also sells the DDDAC and the Groovemaster arm.

Me too, i dont know if it will work on my turntable because as far as i know you will need a motor with more rpm.

And of course there the problem of attaching the rim to the motor.

The VPI rim drive is to big and just plain ugly.

The Teres Verus is probably obsolete.

So i am curious if Sota can deliver me the total Eclipse package with another diameter pulley.

Greetings, Eduard

It is sold by the company that also sells the DDDAC and the Groovemaster arm.

Me too, i dont know if it will work on my turntable because as far as i know you will need a motor with more rpm.

And of course there the problem of attaching the rim to the motor.

The VPI rim drive is to big and just plain ugly.

The Teres Verus is probably obsolete.

So i am curious if Sota can deliver me the total Eclipse package with another diameter pulley.

Greetings, Eduard

- Home

- Source & Line

- Analogue Source

- Hurst Motors: 300 RPM vs 600 RPM--Upgrade or Myth?