Thanks for your concern Joe, but I believe it is every man's (or woman's) option to practice this DIY as one self feels fit.

It is...but it is unfair to mislead people looking for enlightenment as to how to achieve a result as close as possible to a Schroeder Reference if one knows the answer.

To repeat.....the magnets are not drilled.

Well, here is a link to my version. Actually this was to demonstrate the DIY arm lifter (also using magnets), but you can shortly see the magnet assembly also.

Nice. Let's hear it play some music.

jeff

Hello gentlemen,

You may build an arm based on the general principle using one or two magnets, drill the upper magnet or use a ring magnet with a plug of sorts.... or drill the back pole plate of the upper magnet(the easiest approach), BUT, whichever hole in whatever material you end up with, make sure that that hole is just small enough to accommodate the thread of choice AND was de-burred/polished to the nth degree to avoid the thread being cut or just reduced in effective diameter.

The key to proper operation is to build in the facility to center the magnets and, just as important, the ratio of diameter to effective height/thickness of the upper magnet/pole plate.

Anodizing has no meaningful effect on the efficacy of the eddy current damping.

Good luck!

Frank

You may build an arm based on the general principle using one or two magnets, drill the upper magnet or use a ring magnet with a plug of sorts.... or drill the back pole plate of the upper magnet(the easiest approach), BUT, whichever hole in whatever material you end up with, make sure that that hole is just small enough to accommodate the thread of choice AND was de-burred/polished to the nth degree to avoid the thread being cut or just reduced in effective diameter.

The key to proper operation is to build in the facility to center the magnets and, just as important, the ratio of diameter to effective height/thickness of the upper magnet/pole plate.

Anodizing has no meaningful effect on the efficacy of the eddy current damping.

Good luck!

Frank

Nice. Let's hear it play some music.

I would if I could. But right now we are out of our home due to renovation - and no turntable of hifi here I'm afraid.

But maybe this music will do for the time being.

Piazzolla - YouTube

ANSI/ISO fit standards

Frank(Berlinta)

This question also goes out to anyone with experience in ANSI/ISO fit standards. Do you have any reference material you can point me to for pressure fitting wood to metal. I don't know if it is covered in the machinists handbook, as I do not have one at this time. Thank you

Frank(Berlinta)

This question also goes out to anyone with experience in ANSI/ISO fit standards. Do you have any reference material you can point me to for pressure fitting wood to metal. I don't know if it is covered in the machinists handbook, as I do not have one at this time. Thank you

Hi,

It depends upon the compressibility of the specific wood you're using. Anything from 0,01 to 0,03mm in excess diameter for a 10mm wooden wand or dowel is feasible.

All bets are off if you have not taken precautions to prevent the wood from reacting to changes in humidity(i.e. heat treatment, oil, laquer, resin - impregnating...)

Cheers,

Frank

It depends upon the compressibility of the specific wood you're using. Anything from 0,01 to 0,03mm in excess diameter for a 10mm wooden wand or dowel is feasible.

All bets are off if you have not taken precautions to prevent the wood from reacting to changes in humidity(i.e. heat treatment, oil, laquer, resin - impregnating...)

Cheers,

Frank

Can't edit my previous post so I will add another photo here.

Hi,

Looks really great and well done, great finish over all.

Did you encounter problem in the attraction of top and lower magnet as I did and they attract not evenly. One top magnet was leaning one side all the time.

Tks nad regartds

Adelmo

Hi Alex,

Tks for the support. My counter weigh is already center shifted one, I could correct the two surface of the magnets rotating a bit the counterweight but this great tonearm should not work like that. I would like to achieve a better attraction between the 2 mags and possibly without the need to correct with the counter weight, therefore my question.

Tks n rgds

Adelmo

Tks for the support. My counter weigh is already center shifted one, I could correct the two surface of the magnets rotating a bit the counterweight but this great tonearm should not work like that. I would like to achieve a better attraction between the 2 mags and possibly without the need to correct with the counter weight, therefore my question.

Tks n rgds

Adelmo

Wood doesn't have much hoop strength so I'd go with clearance and some adhesive if the wood is on the outside. Inside, not an issue, but remember that over time wood will likely shrink and the assembly might fall apart. Adhesive is still a good choice, flexible if possible.

Be careful with any sort of drilling or machining of neo magnets. The dust is extremely flammable and fires have been the result.

Be careful with any sort of drilling or machining of neo magnets. The dust is extremely flammable and fires have been the result.

hi Frank and everyone

I'm building a Frank schröder tonearm. my friend owns a machine shop so we got together to make a couple of arms.

I had read through everything but wish to confirm the following

the arm shaft. 10.5 inch. I intend to use carbon and balsa wood mix and intend for high compliance carts, it should be below 12grams . what is the ideal counter weight mass? and is the length ideal?

2nd what is the maximum arm height to adjust vta? or just better to make a special angled headshell to adjust vta

what is the alternative to adjust azimuth? just use a shim?

thank you in advance.

I'm building a Frank schröder tonearm. my friend owns a machine shop so we got together to make a couple of arms.

I had read through everything but wish to confirm the following

the arm shaft. 10.5 inch. I intend to use carbon and balsa wood mix and intend for high compliance carts, it should be below 12grams . what is the ideal counter weight mass? and is the length ideal?

2nd what is the maximum arm height to adjust vta? or just better to make a special angled headshell to adjust vta

what is the alternative to adjust azimuth? just use a shim?

thank you in advance.

Hi Anthony,

the arm shaft. 10.5 inch. I intend to use carbon and balsa wood mix and intend for high compliance carts, it should be below 12grams . what is the ideal counter weight mass? and is the length ideal?

There is no "ideal" mass value for a counterweight. The higher the mass of the counterweight, the lower the eff. mass of the arm. But how is anyone to know i.e. the cartridge mass? A good start for your arm would be 150gr

There is no "ideal length". There are advantages of "shorter" arms(around 9" vs 12" arms and vice versa. Check the real estate on your deck, then decide...

2nd what is the maximum arm height to adjust vta? or just better to make a special angled headshell to adjust vta

That's cartridge and turntable dependent. If your friend has a machine shop, he probably knows how to draw a rendering of the project with the deck you intend to use.

A VTA-adjustable headshell increases complexity, compromises mechanical integrity and might be a project to pursue AFTER you got the arm itself to perform satisfactorily.

what is the alternative to adjust azimuth? just use a shim?

There is no alternative to proper Azimuth alignment ;-) Using shims will work, but is decidedly unelegant and cumbersome...

Good luck!

Frank

the arm shaft. 10.5 inch. I intend to use carbon and balsa wood mix and intend for high compliance carts, it should be below 12grams . what is the ideal counter weight mass? and is the length ideal?

There is no "ideal" mass value for a counterweight. The higher the mass of the counterweight, the lower the eff. mass of the arm. But how is anyone to know i.e. the cartridge mass? A good start for your arm would be 150gr

There is no "ideal length". There are advantages of "shorter" arms(around 9" vs 12" arms and vice versa. Check the real estate on your deck, then decide...

2nd what is the maximum arm height to adjust vta? or just better to make a special angled headshell to adjust vta

That's cartridge and turntable dependent. If your friend has a machine shop, he probably knows how to draw a rendering of the project with the deck you intend to use.

A VTA-adjustable headshell increases complexity, compromises mechanical integrity and might be a project to pursue AFTER you got the arm itself to perform satisfactorily.

what is the alternative to adjust azimuth? just use a shim?

There is no alternative to proper Azimuth alignment ;-) Using shims will work, but is decidedly unelegant and cumbersome...

Good luck!

Frank

Thank You Herr Frank

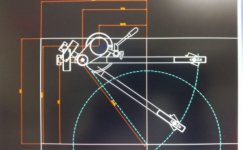

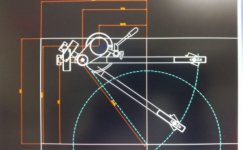

some of work in process though I cannot take any credit as I don't know how to cad. vta on the fly feature

Thank you also for all the generosity of knowledge for Diyer. I know won't be as great as original. but it sure is fun trying out new topology and making own tonearm. both first time.

some of work in process though I cannot take any credit as I don't know how to cad. vta on the fly feature

Thank you also for all the generosity of knowledge for Diyer. I know won't be as great as original. but it sure is fun trying out new topology and making own tonearm. both first time.

Hi Frank and everyone.

finally managed a pilot run, very happy with the first result

It's design with on the fly Vta and antiskate. with 10.5inch ebony tonearm

But I could not make the pivot real perpendicular and the string keep sliding. can anyone give an illustration what might work? despite that tracking is not an issue. no apparent distortion.

We are trying 5x5 mm n52 magnet, should I try a bigger magnet? also is that why the vtf changes more than normal with different platter height? inner and outer platter still have vtf variation but I have clue from previous posts.

meanwhile will enjoy them while. thinking of a small. revision.

Hi Antony,

I attempted to make a clone of the same arm, but 12 inch long. I used magnet 10mm x 5 mm. I have the problem that the top and bottom mag attract not perfectly evenly to each other.leaning in one side, so I have corrected with the counter weight. I know is by far not a perfect execution but despite it at the present I have it in use with a DL 103. Checking the cart weight with the stylus at the inner point and outer point I have a difference of 0.02 grams so there is something to improve with my next attempt. For my next attempt I shall use mag with 8 mm diameter and 6 mm thickness instead, still for a 12 inch TA.

Regarding your quoted: I could not make the pivot real perpendicular and the string keep sliding... I do not understand well.

However , what is the distance between the two magnets?

If I recall well from all the good suggestion given by Frank, he said that you can start with a clearance of a name card and from that you may decrease... Again if I recall well.

By the way, congratulations for the execution, really good one and nice looking.

Rgds

Adelmo

I attempted to make a clone of the same arm, but 12 inch long. I used magnet 10mm x 5 mm. I have the problem that the top and bottom mag attract not perfectly evenly to each other.leaning in one side, so I have corrected with the counter weight. I know is by far not a perfect execution but despite it at the present I have it in use with a DL 103. Checking the cart weight with the stylus at the inner point and outer point I have a difference of 0.02 grams so there is something to improve with my next attempt. For my next attempt I shall use mag with 8 mm diameter and 6 mm thickness instead, still for a 12 inch TA.

Regarding your quoted: I could not make the pivot real perpendicular and the string keep sliding... I do not understand well.

However , what is the distance between the two magnets?

If I recall well from all the good suggestion given by Frank, he said that you can start with a clearance of a name card and from that you may decrease... Again if I recall well.

By the way, congratulations for the execution, really good one and nice looking.

Rgds

Adelmo

Attachments

Last edited by a moderator:

hi Adelmo

what I'm saying is that the hole of the top and bottom that hold the string is not centered and the string does not hold its place very well, it will loosen with time. if someone could share a drawing. aka lacks precision my pivot due to design

I think better magnet equals better accuracy.?

BR

Anthony

what I'm saying is that the hole of the top and bottom that hold the string is not centered and the string does not hold its place very well, it will loosen with time. if someone could share a drawing. aka lacks precision my pivot due to design

I think better magnet equals better accuracy.?

BR

Anthony

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm???