Basics here.

Where is the excess current going?

How can I troubleshoot? Variac's are way out of my price range for this repair. Should I power on and see which components are getting hot? I do have a thermal IR thermometer that will point me to the hotspot. Also, when you say driver transistors, which ones are you referring to? Sorry I don't know all the terminology. I did replace the Q11 on Left and Right.

I did see a similar thread regarding the distortion light being on, and that turned out to be Q6. Although it tested OK on mine, i know when voltage is applied it can be a different story. Should I just replace that?

DIYAUDIO thread on distortion light

talk about the wind being taken out of my sails. but I gotta get back up! I do have the spare (untouched) amp running for now, but I can definitely tell the difference between that and this Jim Williams upgraded cap work!

Buy a used variac.

A variac is extremely useful for everything. You can get custom supply voltages for a project without having to buy a transformer using one you have on hand. A variac will save you money and allow much easier troubleshooting. Buy one used, a 2 ampere model is enough. You can even find 10 A models. I have a 1.75 ampere model is put in a case with volt and ammeters and socket. It is incredibly useful being on a rack panel installed on my bench. Many high school electrical classes used them, pick up a used station when they remodel if you can fine one.

I have 4 ampere, 10 and 15 ampere variacs. The larger ones are a pain and heavy. ONly used when servicing large tube power amps and some class A solid state.

I will never advise anyone to do something or buy something unless there is a very good reason to do so.

A variac is extremely useful for everything. You can get custom supply voltages for a project without having to buy a transformer using one you have on hand. A variac will save you money and allow much easier troubleshooting. Buy one used, a 2 ampere model is enough. You can even find 10 A models. I have a 1.75 ampere model is put in a case with volt and ammeters and socket. It is incredibly useful being on a rack panel installed on my bench. Many high school electrical classes used them, pick up a used station when they remodel if you can fine one.

I have 4 ampere, 10 and 15 ampere variacs. The larger ones are a pain and heavy. ONly used when servicing large tube power amps and some class A solid state.

I will never advise anyone to do something or buy something unless there is a very good reason to do so.

Question: Are these a good replacement for KSA-1381 for Q6 and Q7, just read that the OnSemi Ksa1381 are no longer available? The difference is .1 amp on the ksa vs 500ma on the MJE350G

https://www.digikey.com/en/products/detail/onsemi/MJE350G/919515

https://www.digikey.com/en/products/detail/onsemi/MJE350G/919515

Even repairing just one amplifier makes it worth getting a Variac. How much is your time worth repairing it over and over?

The "bulb tester" can only be used for the initial power up, and then must be removed for further testing.

https://www.acdcpowershack.com/prod...er-5-amp-500-watts-0-130vac-output-part-sc-5m

The "bulb tester" can only be used for the initial power up, and then must be removed for further testing.

https://www.acdcpowershack.com/prod...er-5-amp-500-watts-0-130vac-output-part-sc-5m

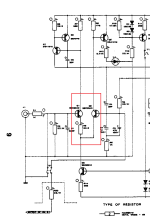

Yes, because of the DC servo, have a look at it.

I think it is a very bad way to do things. It goes against the basics.

I think it is a very bad way to do things. It goes against the basics.

bump.Question: Are these a good replacement for KSA-1381 for Q6 and Q7, just read that the OnSemi Ksa1381 are no longer available? The difference is .1 amp on the ksa vs 500ma on the MJE350G

https://www.digikey.com/en/products/detail/onsemi/MJE350G/919515

Spec sheets attached.Question: Are these a good replacement for KSA-1381 for Q6 and Q7, just read that the OnSemi Ksa1381 are no longer available? The difference is .1 amp on the ksa vs 500ma on the MJE350G

https://www.digikey.com/en/products/detail/onsemi/MJE350G/919515

Attachments

They will work. I have never used them to replace the *SC3503 and compliment.

Some important specs are not listed (I have them). Beta, Ft and capacitances.

Some important specs are not listed (I have them). Beta, Ft and capacitances.

I'd have to research that. It could be compensation for different devices. A running production change.

Adcom has new owners and moved the company. Old employees probably left a long time ago.

Adcom has new owners and moved the company. Old employees probably left a long time ago.

They will work. I have never used them to replace the *SC3503 and compliment.

Some important specs are not listed (I have them). Beta, Ft and capacitances.

MJE340/50 were the go-to VAS/predriver for +/-80V amps when the MPSU10/60 went Unobtainium and before “better” video output devices like C3503 and complements were available. Many low Cob linear video types of the day didn’t have a PNP. Good 340’s like ST run about 50 MHz fT. I’ve still got maybe 50 each of the old “SGS” labeled ones and they were the best of the bunch.

If it’s following that schematic posted earlier, C7 is a film type bypassing an electrolytic. The better the electrolytic, the less difference it will make to have it. With a modern Nichicon in that position I wouldn’t worry about C7.

Hi,

Yes. A bypass capacitor doesn't make much difference across a main filter capacitor. Local bypass is far more effective.

I used MPSW series parts for MPSU (42/92), I didn't have to try and use an MJE type. I simply have not had experience using them in this application.

Yes. A bypass capacitor doesn't make much difference across a main filter capacitor. Local bypass is far more effective.

I used MPSW series parts for MPSU (42/92), I didn't have to try and use an MJE type. I simply have not had experience using them in this application.

It’s not the main filter cap, it’s the DC block in the feedback that C7 was going around. Often used to band aid pisspoor electrolytics. Might have been needed in 1982, but not today - at least not for ones you and I would use.

MPSW42’s are long gone now too. I tried to get them years ago and struck out, so I lifetime bought C3503/A1381 for critical application where sub 20 are pF Cob is a must and 625 mA TO-92s run too hot for comfort. The Toshiba TTA/C 230V drivers would be fine here as VAS. Better than what would have been used originally. Again, too light duty as actual drivers at these voltages/currents.

MPSW42’s are long gone now too. I tried to get them years ago and struck out, so I lifetime bought C3503/A1381 for critical application where sub 20 are pF Cob is a must and 625 mA TO-92s run too hot for comfort. The Toshiba TTA/C 230V drivers would be fine here as VAS. Better than what would have been used originally. Again, too light duty as actual drivers at these voltages/currents.

Ahh, okay. I didn't bother looking at the schematic. True, today's caps are much better. I don't think the bypass does much good anyway. The damage from dielectric absorption has been done. A little cap across the mess won't fix it.

I've been playing with Poly-Aluminum in that position. They aren't bad, a solid tantalum would be horrible. A wet slug tantalum is pretty darned good (but expensive!).

The MPSW were a 1 watt dissipation, same as the MPSU "uniwatt" case (still have a couple). C3503 and A1381 I have still. Differing pinout. I have used TO-126 in place of TO-5/39 cases, and sometimes MPSU. The problem with MPSU is the smaller pads you typically see, and pinout.

Too bad they discontinued the MPSW case style.

I've been playing with Poly-Aluminum in that position. They aren't bad, a solid tantalum would be horrible. A wet slug tantalum is pretty darned good (but expensive!).

The MPSW were a 1 watt dissipation, same as the MPSU "uniwatt" case (still have a couple). C3503 and A1381 I have still. Differing pinout. I have used TO-126 in place of TO-5/39 cases, and sometimes MPSU. The problem with MPSU is the smaller pads you typically see, and pinout.

Too bad they discontinued the MPSW case style.

Buy a used variac.

A variac is extremely useful for everything. A variac will save you money and allow much easier troubleshooting. Buy one used, a 2 ampere model is enough. You can even find 10 A models.

I was able to find 142 defective parts in a 1.3 KW amp by using a 1500 watt room heater element (bad tipover switch) in series with the AC input. Price, free. The 60 w bulb in the dim bulb box was not big enough to allow the input op amps to have adequate +- supply voltages to operate. The heater element had convenient .250 flag male terminals, which worked well the .250 flag terminals the amp used for AC input. Insulated female dorman terminals from the auto supply, crimped on 2 wires, a useful and relatively shock safe current restrictor for finding shorting parts in an amp. Vce <1 in the linear parts of the amp, fail. Vbe<.7, fail. Also shorted and open diodes, resistors, open capacitors, show up as stupid DC voltages. Do not use 2 probes in 2 hands to measure voltages across components, Use an alligator clip lead on DVM black input to the analog ground, a pamona grabber on the red input to the DVM. Take 2 voltages across a component and subtract in your head to find the voltage across.Even repairing just one amplifier makes it worth getting a Variac. How much is your time worth repairing it over and over?

After the DC voltages look okay, you can trace music from an FM radio or CD player through the amp. I found a dead DDT transconductance amp, and a flaky factory sourced solder joint on the input op amp socket, causing channel A to whang to 180 VDC on the speaker output every time the solder joint let go. Previous pro techs had just labled the amp "DO NOT USE CHANNEL A".

This amp was engineered for repair. You could reverse the two input driver boards to put either one on top for component level debug. Not all amps are designed for repair access without a pricey extender board or somesuch.

Last edited:

Hi indianajo,

You can pull up countless "workarounds" to having the proper equipment. All I'm going to say is, just don't mess around. Do it right. Some situations require a differing soft start method, but every single situation like that requires skill to recognise for starters. Meaning the tech who isn't is already out of their depth. It takes some skill to know when something is beyond you .. and honesty with yourself. Ego is the biggest block to doing a good job.

I trained technicians for decades. Recommended procedures exist for extremely good reasons. Even being able to efficiently find the fault is a very good reason. So why fight it?

A truly good technician does have the proper, recommended equipment and knows how to use them. They invested money and time and guess what? It does pay off. I have yet to see even one very good technician that doesn't work this way.

What else can I say?

You can pull up countless "workarounds" to having the proper equipment. All I'm going to say is, just don't mess around. Do it right. Some situations require a differing soft start method, but every single situation like that requires skill to recognise for starters. Meaning the tech who isn't is already out of their depth. It takes some skill to know when something is beyond you .. and honesty with yourself. Ego is the biggest block to doing a good job.

I trained technicians for decades. Recommended procedures exist for extremely good reasons. Even being able to efficiently find the fault is a very good reason. So why fight it?

A truly good technician does have the proper, recommended equipment and knows how to use them. They invested money and time and guess what? It does pay off. I have yet to see even one very good technician that doesn't work this way.

What else can I say?

Triad and Stancor have exported their transformer production to *****. The fewer ****ese tools I buy, the less money they have to attack friendly nations. You are not allowed in USA to know where any product was made that you mail order, phone order, or internet order, until you open the box.

Well, if you need something, you need it. Period.

Those countries would not have manufacturing had US companies given it to them.

Those countries would not have manufacturing had US companies given it to them.

Unfortunately, I don’t think you will find a variac that ISNT made in China, unless it’s 20 or 30 years old. Or a 1500 watt room heater, or incandescent light bulb.

OnSemi and Toshiba are moving their **** to China too. Eventually you won’t even be able maintain old equipment without giving them money, unless you have a stockpile from Hell.

OnSemi and Toshiba are moving their **** to China too. Eventually you won’t even be able maintain old equipment without giving them money, unless you have a stockpile from Hell.

- Home

- Amplifiers

- Solid State

- Yet another Adcom GFA-555 cry for help