My sincere apologies in advance to those who will find the appallingly sloppy and incorrect usage of the term "phase plug" to be irritating. I am with you in spirit, but the flesh compels me.

I have often wondered about phase plugs and what is the optimal shape, how do you design one? Manufacturers seem to see no need to go beyond the generic bullet shape. I suspect it is the base of the phase plug that matters more than the tip. I mention my thoughts on phase plugs in another thread:

An alternate take on phase plugs was done by Decware which experimented with a resonant cavity in the phase plug

https://www.decware.com/paper46.htm

If I am allowed a personal opinion I don't really want a resonator built into my speaker, It's all we can do just to stop the cone from flapping around. But, I would eagerly listen to this speaker and see for myself if I had the opportunity.

A very different take on phase plugs is given by Mark McKenzie in one of his patents. This is very interesting to me as it demonstrates application of acoustic theory to the design of a phase plug for woofers. I'm not sure of the boundary layer acoustics he speaks of, although it resembles the discussion on the Decware plug.

https://patents.google.com/patent/US20070297638A1/en?inventor=Mark+McKenzie&page=1

Mark makes some interesting comments on phase plugs when he first mentions his patent US20070297638A1:

How do we find the optimal geometry of a woofer phase plug? Is the optimal shape round or pointed, or neither? Are straight sides ideal? Facets? Flat ended? Should it be bulbous or should be it conical in shape? Or are we all fools for not having McKenzie's top hat shaped phase plugs?

I have often wondered about phase plugs and what is the optimal shape, how do you design one? Manufacturers seem to see no need to go beyond the generic bullet shape. I suspect it is the base of the phase plug that matters more than the tip. I mention my thoughts on phase plugs in another thread:

I suspect there is something to the opening angle of the crevice between the phase plug and cone, but a bulbous phase plug becomes obstructive and the "horn" this creates points away from the listener.

The point on the tip of the phase plug helps the wavefront separate from the tip rather than form a standing wave node like on dustcaps with a large radius. Sort of like Fostex drivers with pointed dustcaps although according to them it seems to be more about vibrations of the dustcap itself than it's affect on the wavefront. A dustcap below it's breakup modes behaves more like a plane radiator with beaming whereas a phase plug or pointed dustcap produces less of a planar wave.

For similar reasons a phase plug should probably be longer than it is wide, to minimize circumferential standing waves.

That said, phase plug geometry seems to be fairly forgiving and the effect of these details might be tiny compared to the ragged response you can expect in affordable fullrange drivers. Perhaps that is why I have never seen a detailed discussion on phase plugs.

I suppose a conical dustcap could be configured like a Walsh driver with the taper matching the speed of sound in the cap to the speed of sound radially outward, but I don't know if the radiation pattern would be an advantage.

An alternate take on phase plugs was done by Decware which experimented with a resonant cavity in the phase plug

https://www.decware.com/paper46.htm

If I am allowed a personal opinion I don't really want a resonator built into my speaker, It's all we can do just to stop the cone from flapping around. But, I would eagerly listen to this speaker and see for myself if I had the opportunity.

A very different take on phase plugs is given by Mark McKenzie in one of his patents. This is very interesting to me as it demonstrates application of acoustic theory to the design of a phase plug for woofers. I'm not sure of the boundary layer acoustics he speaks of, although it resembles the discussion on the Decware plug.

https://patents.google.com/patent/US20070297638A1/en?inventor=Mark+McKenzie&page=1

Mark makes some interesting comments on phase plugs when he first mentions his patent US20070297638A1:

Simple answer is no. Also, I feel that explanations of the why and how of phase plugs is inadequate. I touch on this problem briefly in my AudioXpress article on modifying the TB W3-881S (not to be confused with its replacement, the 881SD) transducer. I go into more detail in my second patent application I filed last year. This patent application is not scheduled for publication until December of this year.

The plugs I am now designing based upon this new theory are looking completely different from anything that exists now.

Now, for me, here is the most important point of my reply. The major sound problems with the Fostex 126/127 are not caused by the dome dust cap. Nor can these problems be corrected by any plug replacement of the dust cap. Replacing the dust cap with some type of plug will make the 126/127 sound slightly different, it will not be better.

Best wishes on your quest for better sound,

Mark

How do we find the optimal geometry of a woofer phase plug? Is the optimal shape round or pointed, or neither? Are straight sides ideal? Facets? Flat ended? Should it be bulbous or should be it conical in shape? Or are we all fools for not having McKenzie's top hat shaped phase plugs?

Last edited:

I should add that it makes perfect sense McKenzie would be the one to start optimizing woofer phase plug geometry, as he had already for several years elevated cone mode treatment to an art (and he talks about art on his archived pages). Not many people get the opportunity to have such a vantage point, where the speaker cone is so well controlled that the shape of the phase plug starts to look like good territory for improving performance.

Planet10 clearly knows some things about phase plugs, maybe he can chime in:

Today someone asked if my FE103/40-1197 phase plugs would fit into the FE127.

So i was oblidged to do a dustcapectomy... after a bit of a struggle getting some errant bits of dust cap out of the gap....

The FE127 has quite long voice coil that extends quite a bit beyond the apex of the cone. The 103/1197 phase plug is the right diameter but i think needs about 9-10mm more "shoulder".

It was interesting to see some ripples in the out-of-the-box impedance curve disappeared with the dust cap removal (some came back with the too short phase plug)...

dave

I'm not Dave, but it rather depends on the objective behind using a central pole-piece extension (aka 'phase plug' in common, questionably-accurate parlance). There isn't a single goal shared by all designers and drive units, so seeking 'the one true shape' is a bit like trying to find the one true physic, solid form of least resistance, or aesthetically perfect human being.

Setting aside aesthetics etc., in wideband drivers, the main functional purpose is typically to enhance HF dispersion in relatively deep cone profiles and / or to reduce cancellation effects from time-delayed interactions of output from different parts of the cone or cones -especially if sub-emitters like whizzer cones are present. Since these cones vary in profile, and you have inherently different responses etc., then the extension / plug ideally needs to vary in profile -length, exact geometry etc. for optimum results. I'm not saying they always are, but they usually do vary a bit more than a quick glance might suggest -rather as literal bullets do. Additional uses are to fill hollow pole-piece cavities, eliminating in some cases an 'oil can' type resonance, and also occasionally to reduce VC heating by acting as a radiator (material depending for obvious reasons). The last is not usually too relevant to wideband drive units though, since power demands are usually modest.

Setting aside aesthetics etc., in wideband drivers, the main functional purpose is typically to enhance HF dispersion in relatively deep cone profiles and / or to reduce cancellation effects from time-delayed interactions of output from different parts of the cone or cones -especially if sub-emitters like whizzer cones are present. Since these cones vary in profile, and you have inherently different responses etc., then the extension / plug ideally needs to vary in profile -length, exact geometry etc. for optimum results. I'm not saying they always are, but they usually do vary a bit more than a quick glance might suggest -rather as literal bullets do. Additional uses are to fill hollow pole-piece cavities, eliminating in some cases an 'oil can' type resonance, and also occasionally to reduce VC heating by acting as a radiator (material depending for obvious reasons). The last is not usually too relevant to wideband drive units though, since power demands are usually modest.

On a closer read of the patent and some of Mark's comments, the patent seems more targeted toward midrange speakers IE 3 inches, where the plug is more critical, although it is still applicable to woofers.

As to other questions. . . The larger the diameter the cone, the less important is the phase plug. It really just fills the void in the center of the voice coil. If it is not filled, the air mass in it resonates and interferes with the desired output. The plug can be just slightly recessed or slightly long. Neither is a problem to the ear or to the test equipment. Again with diameter. A little off is no problem. A lot off is. 95% of the improvement is getting rid of the dust cap and then displacing the air filling the voice coil tube.

Graeme,

Thanks for your reply and question. I have addressed this phase plug shape before and one respondent just about took my head off.

As I speak about in the AudioXpress article, the plug isn't about phase. It is about loading the diaphragm. The larger the cone the less impact the plug has. With a two-inch cone, the shape above the front edge of the voice coil is very important. For five-inch and large cones, within certain constraints, it just doesn't matter anymore. Do you remember any of your high school biology? Why is there a limit on the size of a single celled organism? Both area and volume to increasing diameter are non linear relationships.

If, however, you flare out the plug so that it looks like a mushroom, it can still load the cone. This also sets up a reflecting surface within the cone that is never a good thing. It actually becomes a phase plug and does some really bad things.

Somewhere, whether it is on my Web site or elsewhere, I state that copper is used merely for the appearance. I also put a little bevel on the plug so that the tip ends with a simple cone shape. Again, purely for appearance.

Sorry for taking so long to get to your question, but I tend to think about things in complex ways. Anyway, as long as the shape tapers in to a diameter less than the ID of the voice coil, feel free to make it bullet shaped. You will do no harm. Okay, again thinking complexly, almost no harm. Extreme off-axis response will be impacted by having the plug extend beyond the top edge of the voice coil. But it is not very much and unless you orient your speakers in an extremely odd way you will never do any serious listening this far off-axis. So, again, feel free to make the plug bullet shaped and extend it above the top of the voice coil.

...

Good designing and good building,

Mark

This is a confirmation of what @Scottmoose is saying.I'm not Dave, but it rather depends on the objective behind using a central pole-piece extension (aka 'phase plug' in common, questionably-accurate parlance). There isn't a single goal shared by all designers and drive units, so seeking 'the one true shape' is a bit like trying to find the one true physic, solid form of least resistance, or aesthetically perfect human being.

Setting aside aesthetics etc., in wideband drivers, the main functional purpose is typically to enhance HF dispersion in relatively deep cone profiles and / or to reduce cancellation effects from time-delayed interactions of output from different parts of the cone or cones -especially if sub-emitters like whizzer cones are present. Since these cones vary in profile, and you have inherently different responses etc., then the extension / plug ideally needs to vary in profile -length, exact geometry etc. for optimum results.

I'm a cone tweaker who is not afraid to experiment, and I have had very agreeable experiences with various treatments for cone breakup. I have been in the process of taming Lowther 8" "full range" drivers, which I use with crossover for midrange. (Second order upper rolloff @ 4600Hz) The Lowther DX series come with two styles of phase plug. The standard one is very similar to those that Dave at Planet10 makes. The "exotic" one on the DX4 is a wave guide dubbed the 'holy doorknob'. I read that the doorknob is less desireable when the driver is not back loaded, so I tried removing it. The result was an obvious increase in apparent detail and thus began an experimental trial of different plug shapes. My son was kind enough to share his 3D printing skills, and made just about everything you might imagine sticking out beyond a voice coil, including a series of resonators based on the Decware article noted above. Our microphone was 12" from the driver, and we were in my very challenging listening room with lots of midrange modes.

The stock 'holy doorknob' causes a gigantic cancellation trough at 3 kHz, which is missing when it is removed. That trough was nasty - a sharp 30 dB or so... The exposed pole piece is recessed 1/2" from the cone/coil former joint, and with the stock plug removed that recess causes a ~5 dB bump in the frequency response centered at 2.5kHz.

Here is a summary of what we observed with various shapes of 'phase plugs':

1. Cylindrical resonators (a la Decware) were a bust at any length and extension. The shortest one extended only about 1/8" beyond the V.C. former and it allowed all of the 2.5kHz bump of an empty cavity. The longest one was about even with the edge of the whizzer cone and it caused the 3kHz cancellation trough like the stock phase plug. In fact, on these drivers ANY cylindrical extension out from the cone base produced this obvious 3k problem. So ANY kind of exotic junk - bound to fail with respect to the 3k downward trough.

2. Bullet shapes were better as long as they were short, with the beginning of the taper at or near the base of the cone. They gave an attenuated combination of both the 2.5k bump and the 3k dip. We decided to go back to the printer and make some spikes...

3. As long as there was precious little cylinder emerging from the pole piece, spikes were the best. The 2.5k bump and 3k trough were further attenuated, though not absent. OK, so we cranked up some very high res music comparing the short bullet to the spike. The spike was better and its effects on audio clarity were a little startling! On very familiar recordings suddenly there was an improvement in source locations, and maaannn... you could hear every singer's every breath and all the sounds of handling acoustic instruments, etc. Oh, and audience applause sounded quite real. We may make nice metal versions of the spikes, but I wouldn't expect them to sound any better.

Regards,

Frank

Attachments

I should add that the mods that I have made to the cones of these drivers make their frequency response scans somewhat different from published scans. So in general, I suggest using REW scans to also help guide the choice of center plug mods.

More information on these specific cone mods are found in this thread: https://www.diyaudio.com/community/...ssions-techniques.119676/page-60#post-6062404

More information on these specific cone mods are found in this thread: https://www.diyaudio.com/community/...ssions-techniques.119676/page-60#post-6062404

From a collage professor 25+ years ago, he claimed the material is more important than the shape. He suggested wool felt in the shape of a cylinder. Then he ended with a comment that a dust cap may be the better option after all, since the phase plug removes prime cone area hurting efficiency. I think all commercial phase plugs are mostly cosmetic (pure opinion) and made of durable materials that may not be optimized for the acoustic task. A lot of audio folks listen with their eye after all.

Curiously, the patent referenced earlier was abandoned, "fee related", so apparently it didn't make financial sense to maintain. Also, the patent could have been circumvented from day one if using a VC former 31mm diameter or larger.

Curiously, the patent referenced earlier was abandoned, "fee related", so apparently it didn't make financial sense to maintain. Also, the patent could have been circumvented from day one if using a VC former 31mm diameter or larger.

@Scottmoose nailed it that the plugs can have different purposes. Certainly, dust caps are not just an inert, pistonic space filler. They can be very resonant. Wool felt would simply be subtractive rather than reflective. I use wool liberally behind the cones, as detailed in the link posted above. IMHO, Lowthers have excellent motors but poorly designed cones whose sound can really improve by subtractive modifications. But then they are (even) less suitable as wide band sources. So it is really no surprise that the stock phase plug is detrimental once the cone properties are changed. Big picture: For me, iterating the ‘make-measure-listen’ cycle is the foundation of this hobby. Enjoy!

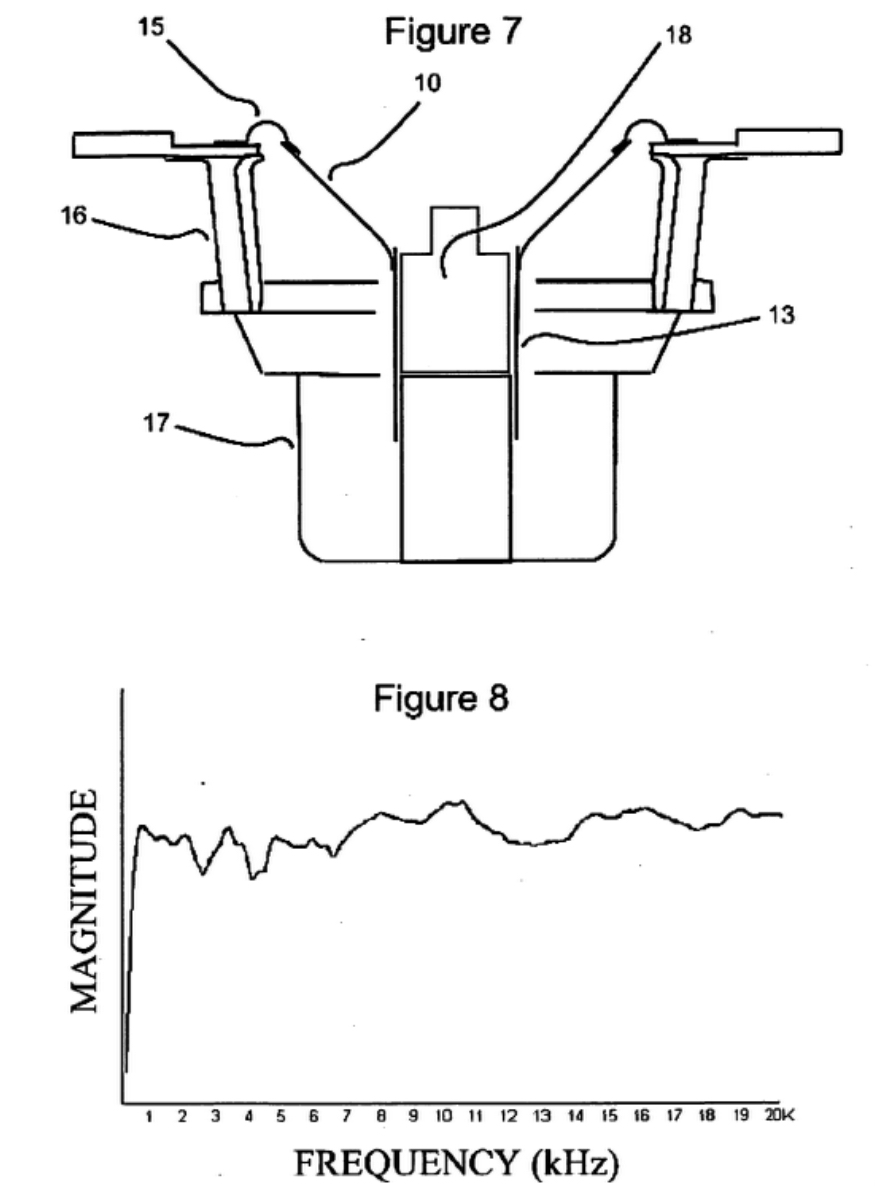

To save folks time of having to click on the link to the patent, here is what the investor is proposing:

I think TB W4-1879 was perhaps following the similar line of thought with boundary layer and molecular adhesion modifications near the middle and the cone. Note the cutouts and slots in the phase plug. Probably tuned for some frequencies to interact.

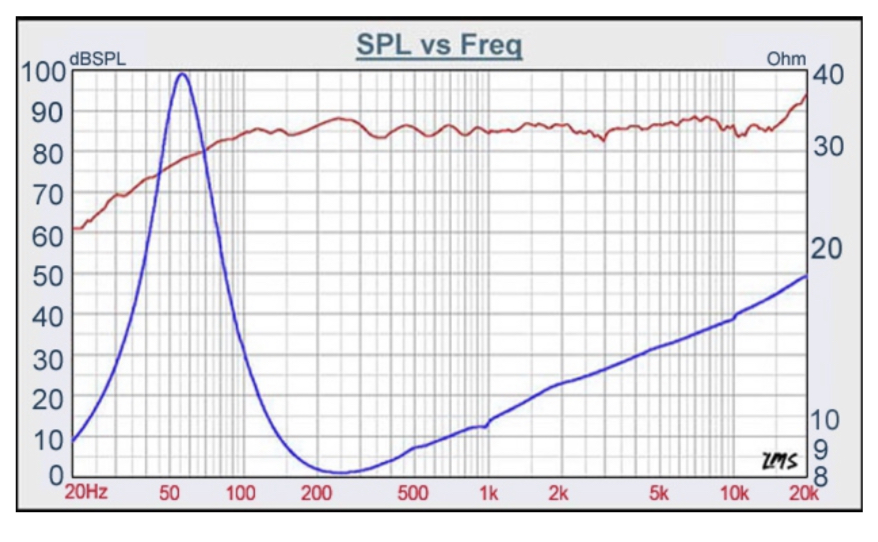

impressively flat response too:

I think TB W4-1879 was perhaps following the similar line of thought with boundary layer and molecular adhesion modifications near the middle and the cone. Note the cutouts and slots in the phase plug. Probably tuned for some frequencies to interact.

impressively flat response too:

Last edited:

I'd like someone to explain what mechanism causes molecular adhesion in a gas, and how that relates to acoustics in general and FR drivers in particular. I'm no expert, but I'm pretty sure nothing on the molecular level is even remotely at play when it comes to phase plugs. Boundary conditions and geometry on the other hand certainly does. It sounds like a patent intended for marketing purposes only. Adding "Patent Applied For" in your product literature may impress another target and open his wallet.

Molecular adhesion is the fancy term for the fundamental boundary condition of incompressible flow fluid dynamics: at the boundary of a solid surface, the gas molecules near the boundary can be assumed to have “zero velocity” because they “stick” or “adhere” to the wall. In reality, at the microscopic level, kinetic theory of gas model (a good assumption) says they impact the wall like billiard balls and transfer their momentum to the wall and vice versa. The velocity of the gas boundary layer varies from zero at the wall to the free stream velocity some distance away, this is the boundary layer thickness. It depends on gas properties, the local bulk velocity and if laminar or turbulent flow. We are neglecting forces like static electricity, chemical reactions, van der Wall forces etc.

From what I understand when the wavelength is lower than the size of the object, surface friction losses become very small. I suppose the Tangband phase plug increases surface area so maybe that has an effect. It resembles the cap on condenser mics so maybe similar principles apply.

One analogue is a Tesla turbine, where the efficiency is maximal when the fluid velocity matches the velocity of the discs. Velocity across the surface reduces the boundary layer width so the friction decreases. However to have any significant effect you need a high surface area to fluid volume ratio. I think for an air tesla turbine the ideal plate spacing was something like 0.2-0.4mm or less.

I was very interested in the "surface acoustic wave" physics when Decware brought it up years ago, but I think to a large degree it is a red herring. Most solid object reflect almost all of the sound that hits them, as I understand this is almost all accounted for by the mechanical impedance of the object and not it's surface air resistance. To get significant loss we always end up increasing the surface area disproportionately, by using wool or foam.

EDIT: Maybe the Tangband phase plug could also be seen like a tweeter lens with the plate edges affecting the direction of sound like a prism? In this case higher frequency sound would be directed more toward the sides of the woofer.

One analogue is a Tesla turbine, where the efficiency is maximal when the fluid velocity matches the velocity of the discs. Velocity across the surface reduces the boundary layer width so the friction decreases. However to have any significant effect you need a high surface area to fluid volume ratio. I think for an air tesla turbine the ideal plate spacing was something like 0.2-0.4mm or less.

I was very interested in the "surface acoustic wave" physics when Decware brought it up years ago, but I think to a large degree it is a red herring. Most solid object reflect almost all of the sound that hits them, as I understand this is almost all accounted for by the mechanical impedance of the object and not it's surface air resistance. To get significant loss we always end up increasing the surface area disproportionately, by using wool or foam.

EDIT: Maybe the Tangband phase plug could also be seen like a tweeter lens with the plate edges affecting the direction of sound like a prism? In this case higher frequency sound would be directed more toward the sides of the woofer.

The patent appears to be techno mumbo jumbo IMHO. As far as I'm aware, wave theory and fluid dynamics are two different things and different physics apply. Sure, both use similar boundary conditions, but energy transfer vs mass transfer are not the same thing.

I think the TB plug makes the node diffuse so it's effect cover a (slightly) wider range. I admit that is pure speculation. I also think someone at TB thought it looked cool.

I think the TB plug makes the node diffuse so it's effect cover a (slightly) wider range. I admit that is pure speculation. I also think someone at TB thought it looked cool.

The less expensive TB drivers use solid plug surfaces of a similar size but slightly dimpled on the end.

Back to the original post, isn’t dispersion generally not a problem down at woofer frequencies? On the 8” drivers I measured, the lowest slight difference I found was about 1500 hz. The lowest significant difference was 2500Hz, whose quarter wavelength is within a few percent of the phase plug diameter. On woofers, large dust caps can resonate and beam significantly but there are diy methods to make them behave. I would certainly try those before excising them and wondering how and with what to fill that space.

The photo is from a very difficult old JBL dust cap. First step is the center dot of elmer's glue. Second is the perimeter row of cancellation dots. If still needed, additional rows of cancellation dots can help. On woofers, I've never needed more than the first two. Also works to smooth out dome tweeters, btw. [Disclaimer - the exact mechanism of action is not well understood nor consistent among the wide range of transducer materials. I'm comfortable with that...]

Back to the original post, isn’t dispersion generally not a problem down at woofer frequencies? On the 8” drivers I measured, the lowest slight difference I found was about 1500 hz. The lowest significant difference was 2500Hz, whose quarter wavelength is within a few percent of the phase plug diameter. On woofers, large dust caps can resonate and beam significantly but there are diy methods to make them behave. I would certainly try those before excising them and wondering how and with what to fill that space.

The photo is from a very difficult old JBL dust cap. First step is the center dot of elmer's glue. Second is the perimeter row of cancellation dots. If still needed, additional rows of cancellation dots can help. On woofers, I've never needed more than the first two. Also works to smooth out dome tweeters, btw. [Disclaimer - the exact mechanism of action is not well understood nor consistent among the wide range of transducer materials. I'm comfortable with that...]

Attachments

Last edited:

I believe the answer to your question lies in the final line of the post:

[Disclaimer - the exact mechanism of action is not well understood nor consistent among the wide range of transducer materials. I'm comfortable with that...]

- Home

- Loudspeakers

- Full Range

- Woofer phase plug acoustics, geometry and McKenzie patent