That's a sexy midbass driver! 😊

Which one is it?

Beyma PA midwoofer with neo magnets. Happened to be on sale then... https://usspeaker.com/beyma 12MwNd-1.htm

Which one is it?

Beyma PA midwoofer with neo magnets. Happened to be on sale then... https://usspeaker.com/beyma 12MwNd-1.htm

I held a nude woofer while it played loud and the vibration in my hand was not that significant, imo. When I held any metal of the frame to an MDF panel it made a harsh vibrating sound, and no matter how hard I pressed the two together by hand the vibration/rattle would not stop. When placing the woofer's foam gasket on the MDF I did not hear any significant sound being transmitted from the panel itself. It would have been hard to hear much next to the loud woofer, though.

So I guess it makes sense to me to avoid metal/metal and metal/wood contact just to avoid the rattle, but I can't detect any significant movement or distortion being transferred through the baffle when a foam gasket is used. I'll be using a heavy 1.5" thick MDF H-frame for the subs, not a flat baffle, so I'll have a good bit of mass to help too.

So I guess it makes sense to me to avoid metal/metal and metal/wood contact just to avoid the rattle, but I can't detect any significant movement or distortion being transferred through the baffle when a foam gasket is used. I'll be using a heavy 1.5" thick MDF H-frame for the subs, not a flat baffle, so I'll have a good bit of mass to help too.

According to this https://www.linkwitzlab.com/frontiers_2.htm#N magnet mount has more effect when the driver basket isn't that stiff and works as a spring. Good explanation behind the link.

So, magnet mount might be advantageous depending on the driver, how good the basket and how heavy the magnet I guess. Good stiff basket and light weight neodymium magnet less problematic than stamped steel frame with big chunk of iron hanging on it.

Driver always vibrates as per Newton's third law of motion, which the bad basket and normal mounting could make even worse, which then would vibrate the baffle. So baffle gets always vibrated if driver is firmly mounted to it.

I guess decoupling the driver from baffle is always advantageous regardless whether it's magnet mount or not, to reduce the baffle vibrating if there is fear that the vibration reduces system performance.

So, magnet mount might be advantageous depending on the driver, how good the basket and how heavy the magnet I guess. Good stiff basket and light weight neodymium magnet less problematic than stamped steel frame with big chunk of iron hanging on it.

Driver always vibrates as per Newton's third law of motion, which the bad basket and normal mounting could make even worse, which then would vibrate the baffle. So baffle gets always vibrated if driver is firmly mounted to it.

I guess decoupling the driver from baffle is always advantageous regardless whether it's magnet mount or not, to reduce the baffle vibrating if there is fear that the vibration reduces system performance.

I held a nude woofer while it played loud and the vibration in my hand was not that significant, imo. When I held any metal of the frame to an MDF panel it made a harsh vibrating sound, and no matter how hard I pressed the two together by hand the vibration/rattle would not stop. When placing the woofer's foam gasket on the MDF I did not hear any significant sound being transmitted from the panel itself. It would have been hard to hear much next to the loud woofer, though.

So I guess it makes sense to me to avoid metal/metal and metal/wood contact just to avoid the rattle, but I can't detect any significant movement or distortion being transferred through the baffle when a foam gasket is used. I'll be using a heavy 1.5" thick MDF H-frame for the subs, not a flat baffle, so I'll have a good bit of mass to help too.

There is a way to completely decouple a driver AND have it in a baffle: You cut out a hole that is a bit larger than the OD of the driver frame. Then you hang the driver (contact me for details on how to do that) so that it sits perfectly centered within this hole. There must be a small gap, so that there is no driver-baffle contact and this means there is a leakage path. But since the air at front and back of the driver is completely unconstrained and open to the room, no appreciable leakage will occur through the gap until it becomes rather large.

in this way you will be able to get a longer front-to-back pathlength of the dipole driver but since the driver is not connected to the baffle physically there is no mechanical coupling that can transfer vibration. The acoustic output of the driver is not enough to excite the baffle, either. I always wanted to try it, but I have moved away from large planar baffles in my systems. Maybe someone else wants to try this and compare to mounting the driver directly?

I guess decoupling the driver from baffle is always advantageous regardless whether it's magnet mount or not, to reduce the baffle vibrating if there is fear that the vibration reduces system performance.

No there are pros and cons. The pro for (competently implemented) decoupling is reducing the amount of mechanical energy transmitted into the cabinet structure which needs to be removed by damping (good) or radiating away as sound (bad). The con is the magnet/frame moving around resulting in the cone no longer following the input signal. There might also be issues with rattling, hitting stops and the driver continuing to bounce about after the signal has stopped. As one might expect a panel-type open baffle is going to flap about significantly more than a closed box when driven making it more of an issue.

The degree to which the magnet/frame is going to move around is determined primarily by the ratio of the moving mass (air+cone/coil assembly) to the rigidly attached mass around the magnet (the reaction force is applied to the magnet). The frame isn't necessarily going to be rigid and can have resonances in the passband when mounted to a baffle. Ditto baffles themselves. Structures rigidly attached to the magnet and a stiff frame will add to the mass whereas those attached via soft gaskets, grommets or springs won't. As a rough rule of thumb typical tweeters tend to be fine decoupled, midranges tend to be borderline and woofers tend to bounce too much. One can design to improve the situation though.

I'm left wondering if anyone uses only elastic adhesive to mount the driver frame. How about service, dismantling? Drivers have holes for screws or bolts, you know... Inadequate tightening will make noise by leakage or rattling.

Someone here told how KEF had woofer's magnet attached to a pole inside and frame used some elastic seal. That must be pretty demanding to make right too...

Most hifi woofers and mids have cast aluminium frames nowdays. If one clicks the frame the resonant sound is very high, but I haven't analyzed the spectrum actually.

Loose or poor attachment of driver, connector panel or wires is very common problem in diy and commercial speakers.

Someone here told how KEF had woofer's magnet attached to a pole inside and frame used some elastic seal. That must be pretty demanding to make right too...

Most hifi woofers and mids have cast aluminium frames nowdays. If one clicks the frame the resonant sound is very high, but I haven't analyzed the spectrum actually.

Loose or poor attachment of driver, connector panel or wires is very common problem in diy and commercial speakers.

Last edited:

Elastic adhesive is not very good at "decoupling" anything...

Typically if you want to decouple a driver you want it to move axially on very soft springs while remaining largely in place in the other 2 directions (soft->stiff springs are likely to place the resonant frequency in the driver passband and amplify rather than decouple and very stiff springs will do nothing). Attaching pegs to the driver bolt holes and placing the pegs in holes in the baffle sealed with elastic adhesive is a simple and cheap way to achieve this. Not the best but a fairly cheap and easy way to assess the pros and cons.

What is rarely done if you have your own house and you want open baffle sound just implement your woofer(s) into the wall using the room behind as its "box".

With corner placement you get the sound of open box or infinite baffle plus horn like sound reinforcement.

When building a house you can spare space in two corners in your living room for putting later a fitting piece of wood for mounting your woofers.

This kind of room installation should give the best sound achievable.

And in the second room you can use the woofers as bass drivers, too(!)

With corner placement you get the sound of open box or infinite baffle plus horn like sound reinforcement.

When building a house you can spare space in two corners in your living room for putting later a fitting piece of wood for mounting your woofers.

This kind of room installation should give the best sound achievable.

And in the second room you can use the woofers as bass drivers, too(!)

You could even add like this a fullrange driver for mid and highs and dsp it from both sides the be linear and switching between the linearized responses for each room depending where you want to hear music. Would be fun.

It’s all cumulative…..everything adds up. OB goes through many sacrifices to remove resonant behaviors from the performance by eliminating the box…….but yet the baffle remains. I believe at some point, practicality must be a factor in the equation. Linkwitz uses the baffle to what I agree is the best potential…..support the driver and shape the response……those benefits outweigh the resonant potential IMO. He then goes on to make best use by decoupling everything from the most resonant part of the system…..practical.I've seen a number of open baffle builds that hang drivers, or attach them to flexible mounts to decouple them from the vibrations of other drivers. The LX521 uses a stand to decouple the subwoofer frame from the rest.

I have not found any measurements to show how useful this is. Does anyone have some measurements to show the difference this decoupling creates?

While I don’t have any measurements to share to support my thoughts , given the delicate and light weight design of AMT and true ribbon tweeters I believe these devices should be decoupled as much as possible because of their design. I did a take on the Curt Campbell Statement monitors a while ago and went thorough the effort of decoupling the Ribbon my mounting the ribbon to Owens XPS foamcore and then securing the XPS to the baffle with expanding spray foam. Subjectively speaking, and only since I did the baffle mods one at a time, the improvement was profound in the clarity of the ribbon with complex music. On the other hand, I don’t think a cone or some device would benefit……..the surround and spider takes care resonant behavior from the outside.

I tried having the 18" midbass and 8" midrange on swings. The midrange barely vibrated while the 18" was noticeable. An option was to attach a heavy weight to the 18" magnet, as user Mattes has done.

But I opted for the 18" sitting on a tripod, detached from midrange and tweeter, which are now mounted on their own panel. I couldn't hear any detriment to sound and looks quite less weird than the swings.

Next I will try xrk971 approach in his XSD speaker with force canceling woofers and see if those vibrations are small enough to place the midrange/tweeter baffle sitting on top, making a much more aesthetically friendly speaker.

I haven't measured the impact of vibrations from the 18" midbasses, but to my ears it sounded better with this driver decoupled from midrange and tweeter.

But I opted for the 18" sitting on a tripod, detached from midrange and tweeter, which are now mounted on their own panel. I couldn't hear any detriment to sound and looks quite less weird than the swings.

Next I will try xrk971 approach in his XSD speaker with force canceling woofers and see if those vibrations are small enough to place the midrange/tweeter baffle sitting on top, making a much more aesthetically friendly speaker.

I haven't measured the impact of vibrations from the 18" midbasses, but to my ears it sounded better with this driver decoupled from midrange and tweeter.

My experience is the opposite. The most effective OB's I have heard were small motor, high Q, light coned, short excursion PA type drivers.OB woofers must be large and have heavy moving mass and high excursion.

I have had no luck with strong motor, low Q, long throw units. They sound lifeless and dry to me.

The warmth of the 'lesser' driver is what adds the appeal IME. Especially when coupled to a low damped tube amp.

This has its merits for sure but again methinks this is best with a high Q driver as the infinite baffle ie: Volume = 4x Vas or greater, means that unless you like to EQ the heck out of a low Q driver or multi-amp the system, the bass will be disappointing. The reason I am against the EQ'ing is you are still fighting transient response with a heavy motor/cone set up and since many of us prefer what is oft referred to as 'tight' bass, I like to use the easy route and not have to correct all the compromises made when designing an OB system.With corner placement you get the sound of open box or infinite baffle plus horn like sound reinforcement.

I watched a couple videos on youtube about speaker isolation, with measurements and explanations, and now I'm convinced. These videos talk about isolating the speaker cabinet from the surface it is resting on, but I think the same concept applies to a tweeter resting on a mid resting on a subwoofer. Cleaning up the sound by reducing interactions with nearby structures is my primary goal with OB so now I'll pay more attention to decoupling each driver.

D

Deleted member 375592

my 2c: afaik, it has nothing to do with OB. The idea is to lower the acceleration of the cabinet itself, and the floor it stands on. The diaphragm weights say, 30g, the driver weights ~2Kg, and the cabinet ~30, You have to ensure that the F resonance of each suspension is lower than f3 of the driver, preferably much lower — a typical vibration isolation solution, tried and tested. There was a patent on it.

btw, spk decoupling is easy with "4pcs HiFi Aluminium Alloy Shock Spikes Spring Damping Pad For Audio CD HiFi Amplifier/Speaker/Turntable/Player" currently ~25 CAD on temu. There are 7 springs inside each "spike". You can lower the F resonance (back'n'forth, not up-n-down) by removing some springs (increasing compliance).

btw, spk decoupling is easy with "4pcs HiFi Aluminium Alloy Shock Spikes Spring Damping Pad For Audio CD HiFi Amplifier/Speaker/Turntable/Player" currently ~25 CAD on temu. There are 7 springs inside each "spike". You can lower the F resonance (back'n'forth, not up-n-down) by removing some springs (increasing compliance).

Hi.

Decoupling is paramount in OB. Bass/mid-bass became the most important areas to decouple if you use separated subs. Bass/mid-bass decoupling will impact mid/tw performance, big deal.

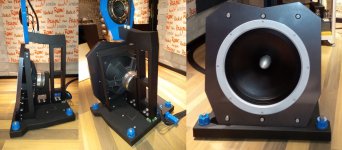

I always liked mounting the woofer from the motor. There are papers from Linkwitz, A. Jones, M. Gerstgrasser and others explaining this is beneficial. However I do not like the front section of the driver sort of hanging from a plate which is glued to a piece of ferrite, besides, I do not consider this an elegant construction.

I envisioned a "woofer support" that acts as a cradle. Then you secure the back plate of the woofer to the cradle. AE woofers have a M10 female thread to do this. I'm using the Dipole-18 (70-250Hz).

I do not like nude drivers so I designed a thick panel inside which I hide the rim of the basket.

The rim can either float inside the panel or smoothly touch a soft gasket. The difference between rim floating VS gasket touching is clear, rim touching sounds far better. I used waterjet cut, very soft natural latex as gasket. The rubber ring of the Dipole-18 must be removed as it is useless.

Finally, the aluminum cover ring is only for cosmetic but must not touch the driver.

Decoupling is paramount in OB. Bass/mid-bass became the most important areas to decouple if you use separated subs. Bass/mid-bass decoupling will impact mid/tw performance, big deal.

I always liked mounting the woofer from the motor. There are papers from Linkwitz, A. Jones, M. Gerstgrasser and others explaining this is beneficial. However I do not like the front section of the driver sort of hanging from a plate which is glued to a piece of ferrite, besides, I do not consider this an elegant construction.

I envisioned a "woofer support" that acts as a cradle. Then you secure the back plate of the woofer to the cradle. AE woofers have a M10 female thread to do this. I'm using the Dipole-18 (70-250Hz).

I do not like nude drivers so I designed a thick panel inside which I hide the rim of the basket.

The rim can either float inside the panel or smoothly touch a soft gasket. The difference between rim floating VS gasket touching is clear, rim touching sounds far better. I used waterjet cut, very soft natural latex as gasket. The rubber ring of the Dipole-18 must be removed as it is useless.

Finally, the aluminum cover ring is only for cosmetic but must not touch the driver.

Attachments

yes, with an appropriate resistor Q can be adjusted to an ideal Qts of 0.5 with best impulse response.This has its merits for sure but again methinks this is best with a high Q driver as the infinite baffle ie: Volume = 4x Vas or greater, means that unless you like to EQ the heck out of a low Q driver or multi-amp the system, the bass will be disappointing. The reason I am against the EQ'ing is you are still fighting transient response with a heavy motor/cone set up and since many of us prefer what is oft referred to as 'tight' bass, I like to use the easy route and not have to correct all the compromises made when designing an OB system.

As corner placement reinforces the sound pressure an OB system using two rooms with a wall in between won't suffer from a weak bass. But it would profit from Q adjustment, certainly.

D

Deleted member 375592

The B&W patent on driver decoupling https://patents.google.com/patent/US20140348369A1/en I forgot to link

- Home

- Loudspeakers

- Multi-Way

- Why OB driver decoupling?