The internal coating is usually green but it may also be white. It distribute the charge inside the tube over a greater surface area. Corona could form on the high voltage TV set tubes such as dampers, line output and HT rectifiers due to humidity and accumulation of grime on the external glass surface. Those tube often had recessed socket: the chassis was almost touching the side of the tube. By spreading the charge on a bigger area, the likehood of pinhole formation trough the glass is reduced.

The cynic in me thinks that green band is just a marketing ploy. Old RCAs sometimes tipped their tubes in green paint denoting special low-noise tubes for phono use.

The internal coating is usually green but it may also be white. It distribute the charge inside the tube over a greater surface area. Corona could form on the high voltage TV set tubes such as dampers, line output and HT rectifiers due to humidity and accumulation of grime on the external glass surface. Those tube often had recessed socket: the chassis was almost touching the side of the tube. By spreading the charge on a bigger area, the likehood of pinhole formation trough the glass is reduced.

I've read quite some enigmatic posts here over the years, but this beats 'em all. Love it!

Simon

I have a fair number of 18GB5 tubes with the green ring. Some others have a ring that looks like deposited carbon or graphite.

The green ring is usually found on Japanese and Korean TV horizontal sweep (line output) tubes. It's much like the metallic ring found on some European sweep tubes. Since these rings seem to only be found on horizontal output tubes, they probably have a specific function for that application which involves high voltages and fast pulses.

Consensus seems to be that they were used to prevent arcing and / or damp out spurious oscillation. I haven't measured a broken tube with a green ring, but I would suspect that is slightly conductive or lossy at RF frequencies, maybe both.

Consensus seems to be that they were used to prevent arcing and / or damp out spurious oscillation. I haven't measured a broken tube with a green ring, but I would suspect that is slightly conductive or lossy at RF frequencies, maybe both.

Seems to me a gobbledygook.I've read quite some enigmatic posts here over the years, but this beats 'em all. Love it!

Simon

I've read quite some enigmatic posts here over the years, but this beats 'em all. Love it!

Simon

Maybe not a joke,

Wolfgang Scharschmidt, who had worked as an engineer for Philips/Valvo in Hamburg wrote this on radiomuseum.org: Zeilenendrohren metallischer Ring

Translation:

Now that I have been asked from different sides what the purpose of the metallic ring attached to the outside of the glass bulb of PL500 to PL519 tubes is, I would like to make the answer available to the general public here in the forum.

As is well known, line sweep tubes were designed for higher operating voltages and became extremely hot, which can lead to electrolysis, i.e. chemical decomposition, in the glass over time due to various charges.

In order to avoid this, a ring made of conductive silver, a so-called equipotential bonding ring, was rolled up from outside at the level of the lower mica washer. It should compensate for static fields, ie charges on the glass surface, and thus prevent high voltage breakdowns.

From a hermetic poetic point of view I find it a rare find. Then again, maybe I'm just frequenting the wrong forum...

I don't contest anything that might be signified.

All best,

Simon

I don't contest anything that might be signified.

All best,

Simon

Last edited:

: )From a hermetic poetic point of view I find it a rare find. Then again, maybe I'm just frequenting the wrong forum...

I don't contest anything that might be signified.

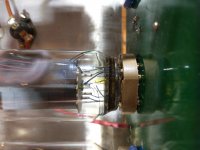

Thanks for the info everyone. Here's another item that may mean something.

I have amps that use 36KD6 with very high voltages (+/- 3.3KV). I have had these for a few years so I have experienced numerous tube failures.

Almost 100% of the tubes that failed cracked around the base as I tried to remove them from the socket. Most recent example shown in photos. When there's a failure like this I pull & test all the tubes in the unit. None of the others (the good ones) have ever cracked. Just the ones that failed, and those are cracked nearly 100% of the time.

Also, I have a FLIR camera and it shows me the base of these tubes is by far the hottest part, over 400 degrees F.

None of my tube inventory has had any rings aound their bases. So there seems to clearly be a process that weakens the glass when these failures happen. I wonder if these rings are meant to somehow prevent this? I have no idea... anyway thanks for the comments.

I have amps that use 36KD6 with very high voltages (+/- 3.3KV). I have had these for a few years so I have experienced numerous tube failures.

Almost 100% of the tubes that failed cracked around the base as I tried to remove them from the socket. Most recent example shown in photos. When there's a failure like this I pull & test all the tubes in the unit. None of the others (the good ones) have ever cracked. Just the ones that failed, and those are cracked nearly 100% of the time.

Also, I have a FLIR camera and it shows me the base of these tubes is by far the hottest part, over 400 degrees F.

None of my tube inventory has had any rings aound their bases. So there seems to clearly be a process that weakens the glass when these failures happen. I wonder if these rings are meant to somehow prevent this? I have no idea... anyway thanks for the comments.

Attachments

The datasheet for the 36KD6 states 990 V as the maximum DC plate supply voltage. I would think that the supply voltage has to be higher than 990 V in order to swing to 3.3KV on a regular basis.

Maybe these tubes need their sockets connected straight to a metal surface in order to loose more heat?

Maybe these tubes need their sockets connected straight to a metal surface in order to loose more heat?

Usually, sweep tubes are only rated for the high voltage pulse that occurs during horizontal retrace, not continuous application of HV.

I wonder if you could accomplish the same purpose by painting a ring of Aquadag around the outside of the tube in a similar position?

Yup, direct drive electrostatics. Beveridge model 2SW-1.

And I share the same concerns about running the tubes above spec but hey it's not my design. This is how the thing was built.

It actually workls fine until... it doesn't ":^)

Again thanks for the conversation and happy Thanksgiving.

And I share the same concerns about running the tubes above spec but hey it's not my design. This is how the thing was built.

It actually workls fine until... it doesn't ":^)

Again thanks for the conversation and happy Thanksgiving.

Seems like adding some small fans would be the best solution. Noctua fans are incredibly quiet and long lived.

those amps do run a fan. Since the tubes are mounted horizontally and the fan air flows straight into the tubes is there a possibility there is enough uneven cooling to cause a problem? No controlled airflow.

Also I read somewhere? about running the speakers upside down with the top plate of the amps off for better cooling.

Also I read somewhere? about running the speakers upside down with the top plate of the amps off for better cooling.

- Home

- Amplifiers

- Tubes / Valves

- Why do some tubes have a green ring on them?