I building a 25W Class A amp using TIP2955 & TIP3055, using KiCad.

powersupply is +/-25.4V

The schematic is done and i now started with the actual PCB.

I now try to fix "netClasses" and atuck with the PWR & OUTPUT net.

When i asked both CoPilot & chatGPT about the trace their answer was:

"

For a current of 10A, a trace width of approximately 200 mils (5.08 mm) with 1 oz/ft² copper is typically recommended3

.For a current of 15A, you might need a trace width of around 300 mils (7.62 mm) with 1 oz/ft² copper3

."

Well, sound great, but the space between the pins are less thatn that. How to solve tthat ?

powersupply is +/-25.4V

The schematic is done and i now started with the actual PCB.

I now try to fix "netClasses" and atuck with the PWR & OUTPUT net.

When i asked both CoPilot & chatGPT about the trace their answer was:

"

For a current of 10A, a trace width of approximately 200 mils (5.08 mm) with 1 oz/ft² copper is typically recommended3

.For a current of 15A, you might need a trace width of around 300 mils (7.62 mm) with 1 oz/ft² copper3

."

Well, sound great, but the space between the pins are less thatn that. How to solve tthat ?

You could use heavier copper. And/or parallel traces on top and bottom, although that would complicate trace routing. Plating the traces with solder would decrease resistance as well.

Place the components to reduce trace lengths so the total resistances and voltage drops are minimized.

You could also use a four layer board so there are separate power and ground layers.

Place the components to reduce trace lengths so the total resistances and voltage drops are minimized.

You could also use a four layer board so there are separate power and ground layers.

The traces have to be 1 mil (width of pin) near the chip and then be larger for the longer connections.

Thanks all.

I got it now.

I've also viewed a couple of KiCad tutorial and figured out netclass as well.

So far i'm working with 2 layers, but 4 layers sound nice, maybe i go there.

One more, maybe stupid but anyway, question.

How long is a "long" trace ? is it more than 5mm or more than 50mm

The board is 120mm x 100mm.

Maybe it's better to make the board 150mm x 120mm and get a bit space between some component for the wider traces?

ex: is it better to have 50mm long and 3mm wide trace than 20mm long and only 1.5mm wide ?

I got it now.

I've also viewed a couple of KiCad tutorial and figured out netclass as well.

So far i'm working with 2 layers, but 4 layers sound nice, maybe i go there.

One more, maybe stupid but anyway, question.

How long is a "long" trace ? is it more than 5mm or more than 50mm

The board is 120mm x 100mm.

Maybe it's better to make the board 150mm x 120mm and get a bit space between some component for the wider traces?

ex: is it better to have 50mm long and 3mm wide trace than 20mm long and only 1.5mm wide ?

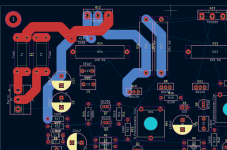

Have a look at the diyAudio Store's product called M2x . It is a 25 watt Class A amplifier, just like the one you propose to build. Most of top layer copper PCB traces are visible in the photos on the Store website; maybe you can get some ideas about trace width and trace routing to power transistors. The Store also sells PCBs for other 25W Class A amplifiers, including F4 and F6. Study their PCB photos too.

A long trace is longer than it is wide by some factor chosen to taste, perhaps 3 or more? A short trace will be cooled by heat conduction to the ends so it can tolerate somewhat larger currents.

A 10mm long trace would be "long" for a 0.2mm trace width, but not for a 5mm trace width, for instance. Your examples of 50mm and 20mm traces are both "long", so the narrower one will self-heat much more.

For high current 2oz copper is the standard option, but that limits the minimum pitch components you can use as the thicker copper doesn't etch as precisely. 1/2oz copper can be used for very fine pitch work with no large currents involved. However options often cost extra, 1oz is typically the default, 35µm in SI units.

And if you only have occasional high current transients you can de-rate the traces as the temperature-rise takes some time to occur. However its wise to be sure the traces won't blow before any fuses you have - it might run cool enough normally but you don't want it vaporizing on a short-circuit event!!

4+ layers is used for digital commonly so that you can have unbroken ground and power planes buried in the board, and controlled-impedance traces can be relied on (and be narrow). For analog work you might not want a ground-plane 0.1 mm from every trace, that's a lot of stray capacitance - planes are usually very shallow under the surface in standard stack-ups.

A 10mm long trace would be "long" for a 0.2mm trace width, but not for a 5mm trace width, for instance. Your examples of 50mm and 20mm traces are both "long", so the narrower one will self-heat much more.

For high current 2oz copper is the standard option, but that limits the minimum pitch components you can use as the thicker copper doesn't etch as precisely. 1/2oz copper can be used for very fine pitch work with no large currents involved. However options often cost extra, 1oz is typically the default, 35µm in SI units.

And if you only have occasional high current transients you can de-rate the traces as the temperature-rise takes some time to occur. However its wise to be sure the traces won't blow before any fuses you have - it might run cool enough normally but you don't want it vaporizing on a short-circuit event!!

4+ layers is used for digital commonly so that you can have unbroken ground and power planes buried in the board, and controlled-impedance traces can be relied on (and be narrow). For analog work you might not want a ground-plane 0.1 mm from every trace, that's a lot of stray capacitance - planes are usually very shallow under the surface in standard stack-ups.

Trace Width Calculator hope that helps. Also, there may be a plugin. If I find more details I'll post it here.I building a 25W Class A amp using TIP2955 & TIP3055, using KiCad.

powersupply is +/-25.4V

The schematic is done and i now started with the actual PCB.

I now try to fix "netClasses" and atuck with the PWR & OUTPUT net.

When i asked both CoPilot & chatGPT about the trace their answer was:

"

For a current of 10A, a trace width of approximately 200 mils (5.08 mm) with 1 oz/ft² copper is typically recommended3

.For a current of 15A, you might need a trace width of around 300 mils (7.62 mm) with 1 oz/ft² copper3

."

Well, sound great, but the space between the pins are less thatn that. How to solve tthat ?

Regards,

Dan

- Home

- Design & Build

- Electronic Design

- what is recomended PCB tracewidth...