Purifi - find it on they're web page or in voice coil mag.Do you have any internal diagram, that would help?

That is a claim with modifications that's not entirely true , depends how you view it, Not counting the top plate (5), above the copper sleeve then yes.They claim that there is no iron next to the coil but only magnet, but it does not look like that from the outside.

What can you see from the 2 copper sleeves?

There is a inverted, extended T-pole, encircled in a large copper sleeve (6), all the way down to (3).

Immediately below that, there is (3) a NdFeB magnet slug, as you saw in my previous post, it's magnetic permeability is close to air at 1,05.

And on the opposing side of where the NDfeb ends, you again see a full length copper sleeve (7).

Also do notice that the copper sleeves overlap from one side to the other.

So they have gone very far with 'inductance control', and "mimicing air core behavior" in the motor design.

On the very bottom of the gap below (3) there is again magnetic permeable material, but that is by design to let the field reduction and suspension parts, stop the coil from destroying itself on the backplate.

You should also note the voice coil wind is not of a "standard flat topology" with a even layup over the whole length.

I do not believe you can make a "air core" motor design with Ferrite magnets, but im not updated on magnet tech.

Børresen and Focal (mids) does it with Neo. As close to a air core as is possible to get with todays tech.

here is some high end hifi commerical showing one:

You will find the Aurasound whiepaper, and the Super Flux Magnet document added explaining in more detail.Also Aurasound neo radial technology, NRT, needs discussion too, it has neodymium magnets next to the coil on both sides, many problems being discussed about FE and Alnico would simply not be there with NRT.

And you are far from done.

AE:

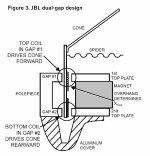

JBL DD has barely been touched upon.

There are version with shorted turns.

patents for copper cap/sleeves and demodulation rings.

There is also a few -ND versions (2216ND-1 fx.) using the Low TCR voice coil alloy to reduce power compression.

Also take notice that all they're "top of the line" HF drivers used to use internal Neio magnets, as opposed to the traditional topology, (except for the 476 who had to compromise on that to fit in the copper sleeve).

The HO "midrange" drivers (2012 and 2020H) had some interesting motors.

The 2242 (only reamining) SVG JBLs incorporated a copper cap back when.

1400/1401 ND used a interesting motor structure too.

W15GTI has a interesting motor for being such a old "car"sub .

And last but not least the 1500AL/1501AL top of the line, underhung Alnico drivers.

Do notice the alternating copper/steel gap rings.

Also take notice of the magnet, it is internal where the pole piece would normally sit.

Those 2 features again makes the driver close to a "air core" Alnico 5 has a permeability around 2, just with a internal magnet on the inside of the coil, utilizing the basket as demodulation and heat conduction. And they largely designed away the Alnico heat related demag issues in the same time.

Also look at the magnetic circuit and see how much copper the path has to go through.. There is a reason it is expensive and have such a insane magnet strength, with a fairly normal gap density.

And there are still loads of design variations to look into.

AE Lamba motors overhung and underhung.

18S has the AIC (added) Tetracoil in different configurations and sizes with demodulation rings etc., there are also so copper sleeved drivers with demod rings (15MB1000, 12MB1000, 12NMB420, etc).

Børresen as mentioned.

Focal mid range in the top line.

Kef has a 'air core' driver concept, name escapes me.

B&W both the FST that's added, and they're dual coil 800 series bass driver that has a interesting motor topology.

Beymas LEX is interesting in terms of quiet excursion and cooling.

Kartesian has some interesting designs out too, with "assembly drawings"

For pure subwoofer Duty Stereo Integrity has showed some impressive BL(x), Kms(x) linearity, and good Le curves on the top of the line drivers.

Pioneer and Rockford also made some interesting motor topologies over the years in theyre top of the line drivers.

Including Pioneer/TADs unified frame 1102 and 1601C.

BMS 18N862 is still excellent today for what it is, nothing radical just good design.

US designed, China made Redcatt, has made a few 18/21 with they're XR motor, that has an impressive amount of xmax, for the sensitivity, and well controlled inductance, judgung by datasheets.

Chinese A&D uses copper and alu demod rings, but it's not found in the marketing, Klippel tested in R&D. Can be read in the Impedance curves. and spec sheets.

The list is "endless"

You barely touched the surface. And i am by no means a expert in the subject.

There are far more knowledgeable people about this, then me on this forum.

Attachments

-

AuraSound_White_Paper.pdf150 KB · Views: 22

-

Super Flux Magnets - Radiale.docx46.6 KB · Views: 26

-

Prof_Klippel_Interview.pdf270.4 KB · Views: 34

-

AIC.pdf1.1 MB · Views: 26

-

700SeriesWhitepaper - inductance.pdf529.1 KB · Views: 22

-

whitepaperdistortion.pdf4.3 MB · Views: 30

-

shorting rings.pdf9.2 MB · Views: 31

-

jbl_differential_drive_motor (1).jpg61.7 KB · Views: 31

jbl_differential_drive_motor (1).jpg61.7 KB · Views: 31

Last edited:

The highest efficiency driver listed there, the 15" JBL 2220H/J has an 8.7% efficiency (half space) due to it's high Bl driving a light weight cone and underhung voice coil (7.2mm height in a 9mm gap), incapable of much excursion or deep bass, Mms is only 70 grams.By the way, in JBLs pdf "JBL Technical Note - Vol.1, No.3A LF transducers.pdf" attached in post 5 there are driver efficiencies mentioned in Table 1 as high as 4% to 10%. How does one get that high efficiency from the motor, is it just high BL?

Higher excursion requires longer, heavier voice coils, and heavier cones to withstand the stress induced when pushing and pulling more air mass further, lowering efficiency.

The differential drive 15" JBL 2265 Mms is 125g, with Bl less than half of the 2220, dropping efficiency to 1.99%.

I forgot but from what i have seen of Wavecore, mostly measurements that is. Just the WF midwoofers, and the new carbon/kevlar woven cones really.This Wavecor has a regular drive and is $120

View attachment 1461740

For $51 more you can get a symmetrical drive.

View attachment 1461741

Clearly this isn't a one to one. But I am wondering how much more you get. Is it a huge difference? Or is it just a "nice to have"

Well behaved in the TIme domain performance, fairly easy to filter.

BD is better controlled inductance then a normal version generally.

Kilippel result have not been super impressive.

Look at the distortion measurements at mfg. website for a indicator.

and be aware that most TS specs and data sheets is based on mathematical Xmax = 70% of BL point.

It does not touch on any form of linearity over excursion like a Klippel test.

And it usually does not account for the suspension limitations or other factors.

There really isn't a lot of information on the Wavecor drivers. They don't seem popular and I can see why. They are expensive for what they look like.and be aware that most TS specs and data sheets is based on mathematical Xmax = 70% of BL point.

It does not touch on any form of linearity over excursion like a Klippel test.

And it usually does not account for the suspension limitations or other factors.

However, I am interested in the for their bonkers QMS specs. I have found a trend. Every driver I have heard that plays the 30-500hz hynamics I praise above all else seem to all have a high QMS. I know this isn't end all be all. But it is definitely related.

Some of the Wavecor drivers have a QMS as high 19! That's nearly 10 times the QMS of a 6" Dayton RS. A driver I found to be quite dull sounding.

I know the alternative is a huge cone like a Nero. Something I do not have space for.

Getting high QMS like that is mainly from using a nonconductive former. I have seen QMS that high on some of my motor designs from simply winding the coil on .1mm grade 2 titanium former.

If all else was equal.However, I am interested in the for their bonkers QMS specs. I have found a trend. Every driver I have heard that plays the 30-500hz hynamics I praise above all else seem to all have a high QMS. I know this isn't end all be all. But it is definitely related.

Some of the Wavecor drivers have a QMS as high 19! That's nearly 10 times the QMS of a 6" Dayton RS. A driver I found to be quite dull sounding.

I know the alternative is a huge cone like a Nero. Something I do not have space for.

And a "normal motor with a core.

If you are chasing the highest possible QMS, then you are looking for a fiberglass former in a very simple motor structure without any form of 'inductance control'.

Meaning LE(x) and BL(x) nonlinearity, will be detrimentally worse.

And you need a 'soft bottoming' design by either suspension or BL(x) losses to hinder the coil from crushing itself on the backplate, in such a setup.

The highest values of QMS, used to be found in RCF's protifolio of PA drivers with some consistency.

Some close to 30.

Also do understand there are 2 different major mechanisms affecting QMS, one is the supension.

And one is the motor related eddy currents from using conductive normally Aluminium Vocie coil formers.

Might it be that the last option mentioned is what you do not like?

There is also the very rare, ALU/Kapton coil former from Skaaning/Audiotechnology.

From they're FAQ:

Kapton is a non-conductive material and is therefore not influenced by the eddy-current effect like aluminum, when situated in a magnetic gap.

In practice this means no mechanical brake and therefore a very high mechanical Q-factor and low Mechanical resistance.

Drivers with Kapton voice coil former often perform a more detailed midrange with higher dynamic and less coloration and distortion.

Due to the lack of mechanical brake, we do not recommend the use of Kapton drivers as bass driver, because if the x-max is exceeded there is nothing to prevent the driver from bottoming out. For sub woofer applications, please use drivers with aluminum voice coil formers.

For use in the drivers with 77 mm and 102 mm voice coils, we have made a hybrid between the two - the Kapton Alu system (KA system). It utilizes the advantages from both systems. When the driver is within it´s x-max, the voice coil works as a Kapton voice coil but if the driver exceeds x-max, it works like an aluminum voice coil, braking the cone.

Drivers with Kapton voice coil former, can have a tendency to a more pronounced break-up before roll off, because of the lack of mechanical brake.

Last edited:

There is a lot I do not know about drivers and specs. I am just starting to understand Q factors and how they relate to tone and dynamics.Also do understand there are 2 different major mechanisms affecting QMS, one is the supension.

And one is the motor related eddy currents from using conductive normally Aluminium Vocie coil formers.

I am trying to find a driver with high QMS that didn't achieve it with just a crappy motor design I supposeMight it be that the last option mentioned is what you do not like?

I wonder how Wavecor is doing it then considering most of their lineup subsists of Subwoofers.Due to the lack of mechanical brake, we do not recommend the use of Kapton drivers as bass driver, because if the x-max is exceeded there is nothing to prevent the driver from bottoming out. For sub woofer applications, please use drivers with aluminum voice coil formers.

This is why I find them so interesting. The few reviews I could find praise their dynamics. They measure decent, but we all know that isn't the whole story.

All this is driven by a 65 mm diameter (2.5”) voice coil wound with round wire on a black fiber glass non-conducting former.I wonder how Wavecor is doing it then considering most of their lineup subsists of Subwoofers.

The motor shouldn’t figure into QmsI am trying to find a driver with high QMS that didn't achieve it with just a crappy motor design I suppose.

Something with a good motor design and a non conductive former is a good place to start, but it will not have the highest possible theoretical QMS.I am trying to find a driver with high QMS that didn't achieve it with just a crappy motor design I suppose

If that is what you're looking for.

Fiberglass, Nomex, Kapton. Kapton is the least temp. resistant.

There are also some specialty materials.

If you want a high performance PI film similar to Nomex fx :

https://www.ube.com/ube/en/contents/chemical/polyimide/upilex/

I am just starting to understand Q factors and how they relate to tone and dynamics.

Qms = Res / (BL2 * Cms * 6.283 * Fs)

Last edited:

Grade 2 titanium works as well, and is the most heat resistant out of any former material.

Here is one of my subwoofers with a titanium former and over 30 qms. 20mm one way linear xmax.

Here is one of my subwoofers with a titanium former and over 30 qms. 20mm one way linear xmax.

Last edited:

yes high strength, heat restistance and high thermal transfer as with a alu former. Meaning glue joints etc gets heated more, must be taken into account.Grade 2 titanium works as well, and is the most heat resistant out of any former material.

Good for phaseplugs for thermal transfer.

Distributes the heat more evenly along the whole VC assembly though so depends on your thermal design.

And buy quality, bad heat treatment can make some grades brittle.

The opposite would be fiberglass which is a outstanding heat insulator, keeping most of the temperature in the coil, putting more strain on the coil insulation etc.

But it is conductive, "pure" Titanium Grades X has a IACS of ca 3-4%, which makes it a high resistance material.

It is however non ferrous/magnetic just like Aluminium, and has a lower conductivity.

Grade 2 ca 3,6%.

A higher Qms is reached with a nonconductive former.

Last edited:

Titanium has some of the lowest thermal conductivity out of any metal, so it does not transfer much heat at all.

Aluminum has a thernal conductivity of 210 W/m-K, titanium is only 17 W/m-K. They use titanium as heat shields in aerospace.

Even though it has a ~3% IACS electrical conductivity (compared to Aluminum's 61%), it is low enough that it does not even yield a qms difference vs. kapton/fiberglass.

The klippel parameters I showed is my subwoofer with a titanium former, I would like someone to find a subwoofer that uses a kapton/fiberglass former that has a qms over 30.

Aluminum has a thernal conductivity of 210 W/m-K, titanium is only 17 W/m-K. They use titanium as heat shields in aerospace.

Even though it has a ~3% IACS electrical conductivity (compared to Aluminum's 61%), it is low enough that it does not even yield a qms difference vs. kapton/fiberglass.

The klippel parameters I showed is my subwoofer with a titanium former, I would like someone to find a subwoofer that uses a kapton/fiberglass former that has a qms over 30.

Yes and fiberglass is about 0,3. so about 68 times less conductive then Ti.Aluminum has a thernal conductivity of 210 W/m-K, titanium is only 17 W/m-K. They use titanium as heat shields in aerospace.

Ti is about 12 times less conductive then Alu, and very low for a metal.

As i said Alu. is good for thermal transfer to phaseplugs etc.

Ti, will give you a more evenly distributed heat over the length of the former.

While FG insulates more heat in the windings and is harsher on the insulation of the coil (which is often the weakest link in terms of temp.).

Heat shields use comes from the combination of several qualities,also the high melting point, no corrosion, and strength/weight ratio etc.

Also for other mil. applications. Stainless steel is often used in industry as a cheaper alternative.

Aluminium in general is never the best material for anything, but it is cheap, lightweight for the strength, plentiful and a decent conductor as long as it is treated correctly.

With a good motor design, probably not. But it is not completely inert. Yet the difference might be close to neglible.Even though it has a ~3% IACS electrical conductivity (compared to Aluminum's 61%), it is low enough that it does not even yield a qms difference vs. kapton/fiberglass.

As i said a high resistance material, have been used for resistors even

FG and plastic are obviously.

Tungsten is the only metal who is not at normal temp i believe? Not that it is suited.

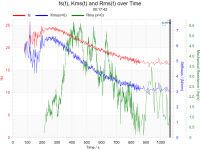

20mm Xmax for a ~12" subwoofer is impressive!Here is one of my subwoofers with a titanium former and over 30 qms. 20mm one way linear xmax.

Interesting to see the small/large signal changes, thanks for sharing them.

I'm curious why the large signal Kms is ~half of the small signal value, Cms and Vas ~double.

The Fs drops almost 1/3 octave, from 24.5Hz (small) to 16.73Hz (large).

What is the voltage for the small signal compared to the large?

Are those small/large signal parameter changes typical and unreported for high excursion subwoofers, or more specific to your driver, and if specific to your driver, what causes the changes?

Thanks,

Art

I'm not an expert in motors, but I will say I tend to be a big fan of composite cones and in that sense the Revelators have not disappointed me. Glad to know the Dayton subs are so well thought of as I have a stack of them in my living room which I hope to use next. 🙂

Last edited:

That is actually a 15" subwoofer. Yes, it is common to see that kind of variation on subwoofers with large rubber surrounds. Foam, not as drastic, but it will still change noticeably. The properties of rubber change more with temperature/movement. I have never actually tested any driver from 2" mids up to 18" subwoofers that did not show a deviation between large/cold and small signal suspension parameters. Large/cold is usually the best match to real world conditions for box design.

Attachments

Very large rubber surround, interesting to see the changes over ~15minutes, especially the mechanical resistance up/down fluctuations.That is actually a 15" subwoofer. Yes, it is common to see that kind of variation on subwoofers with large rubber surrounds.

What voltage on the "over time" test?

And what were the voltages used for the small signal compared to the large signal T.S. measurements?Large/cold is usually the best match to real world conditions for box design.

I wouldn't call it very large, this particular one is just a 1" roll, slightly smaller than what you'd see on an Ultimax.

Looks like LPM small signal voltage was .05, I always start my LSI runs for subwoofers at 1v, and peak voltage for the run was 20.5.

Looks like LPM small signal voltage was .05, I always start my LSI runs for subwoofers at 1v, and peak voltage for the run was 20.5.

- Home

- Loudspeakers

- Multi-Way

- What are "Symmetrical Drive" woofers?