I have two speaker cabinets with Wharfedale super 8/RS/DD, I recently I have been given these speakers by a friend and was very surprised at how good they sounded. What I would like to ask is, what do the original Wharfedale cabinets look like, there is no badge on them. I have looked on the internet and can not find any that look like these, any help would be much appreciated. I have photos but do not know how to load them onto this page.

They don't seem to review very highly. Have you seen Troels's impressions of them.

Wharfedale Super 8

I concur, BTW, seems to be little indication or piccies of original cabinets.

Wharfedale Super 8

I concur, BTW, seems to be little indication or piccies of original cabinets.

I have photos but do not know how to load them onto this page.

There's a "paper clip" icon at the top of the message box. You have the option of uploading images from your computer or from an internet hosting site etc.

jeff

The Super 8/RS/DD - like other speakers in Wharfedale's model lineup of the time - was sold as a "bare" driver, for custom installation. While they did offer some packaged speaker systems in factory cabinets, the Super 8/RS/DD does not appear to have been included in any of those. Wharfedale did have a cabinet without speaker, Model PST/8 - that was recommended for use with the Super 8/RS/DD or any other of their 8" speakers. It was 24" x 12" x 12", available in a variety of veneers/finishes or unfinished. (The above info. is from a ~1962 Wharfedale catalogue that you should be able to find on the Internet.)

Thus, it is quite possible/likely that your cabinets are in fact custom built.

Thus, it is quite possible/likely that your cabinets are in fact custom built.

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6795.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6797.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6798.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6799.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6802.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfed ale /wharf1.jpg

Thanks for the info these are the speakers with the cabinets.

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6797.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6798.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6799.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfedale /IMG_6802.jpg

/Users/davemillard/Desktop/Super 8 :RD😀D wharfed ale /wharf1.jpg

Thanks for the info these are the speakers with the cabinets.

Sorry I have been having problems downloading images via Safari

Thanks to all replies

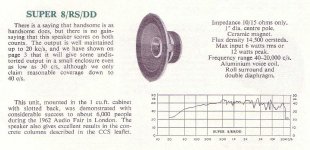

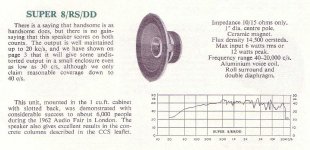

Ahh! That looks like it might be the "1 cu.ft. cabinet with slotted back" mentioned in the referenced catalogue. (here's a snip🙂

CCS = Cabinet Construction Sheet (available from Wharfedale). Unfortunately, I don't have a copy of that. So, it appears that your cabinets may have been DIY constructed following a Wharfedale published design. That's not to say you couldn't come up with a better-performing cabinet design, but if they sound good, why not just enjoy them as they are for a while? There may be some merit in replacing the foam strip behind the whizzer cone - that's said to help tame some of the higher-frequency response peaks. (It appears from your picture that said foam has disintegrated, as it is prone to do.)

Wilf

CCS = Cabinet Construction Sheet (available from Wharfedale). Unfortunately, I don't have a copy of that. So, it appears that your cabinets may have been DIY constructed following a Wharfedale published design. That's not to say you couldn't come up with a better-performing cabinet design, but if they sound good, why not just enjoy them as they are for a while? There may be some merit in replacing the foam strip behind the whizzer cone - that's said to help tame some of the higher-frequency response peaks. (It appears from your picture that said foam has disintegrated, as it is prone to do.)

Wilf

Here is the Cabinet Construction Sheet with various enclosures for the Super 8...

Attachments

My pleasure Wilf, you mention in your previous post about replacing the foam behind the whizzer cones.

I have a couple of Super 10's which need that - can you perhaps suggest how to go about it?

Regards,

Gordon

I have a couple of Super 10's which need that - can you perhaps suggest how to go about it?

Regards,

Gordon

Wharfedale Whizzer Cone Re-Foam

Gordon:

Hi - sorry for the delayed reply. Well, you have called my bluff; I was only passing on hearsay information from memory, and haven't actually done such a repair myself. Upon researching my source for said info, I could only come up with a mention of the subject by a former Wharfedale staffer, as related in correspondence with Troels Gravesen on the latter's website here: The Wharfedale Super 8/

Now, the quoted staffer does seem confused (failing memory?) about some of the construction details of the speakers under discussion. Be that as it may, upon reading Briggs' writings, it's apparent to me that the R&D at his company was as scientifically rigorous as was possible in those days, with enthusiastic experimentation and listening tests supported by careful measurements. So, if they put foam behind the whizzer cone (a configuration unique to Wharfedale AFAIK), then I would trust that they had good reason to do so, and I would attempt the repair in good faith. I do not have instrumentation to test the results, and would rely on my ears to judge the outcome.

Ok, so - that tiny strip of foam would likely not do much by way of absorption; rather - I think it's function is (primarily) that of damping the free edge of the whizzer cone against breakup vibrations. Hence, I would avoid low-density open-cell foam; instead choosing a medium-density foam that rebounds slowly when compressed and then released. I would try something like "memory foam" or weatherstripping tape. The latter with a pressure-sensitive adhesive backing film might work well, although it might prove difficult to remove without damage to the paper cone in the event you are unhappy with the results. I seem to recall from grade-school art class that rubber cement - if applied to only one surface and left to tack up for a moment - would allow fairly clean removal from paper; perhaps you could experiment with something like that before committing to a more permanent adhesive. (But please DON'T blindly rely on my own failing memory, though! )

)

On the subject of meticulous repairs to Wharfedale speakers, I have to also refer "Grumpy's Place" - this fellow documents his obvious patience & love of the craft! GRUMPY'S PLACE

GRUMPY'S PLACE

Anyway, you asked how I would approach this, so there it is... You - or others - may have different ideas, and that's ok with me. Good luck, and please let us know how it goes if and when you decide to tackle this.

Wilf

Gordon:

Hi - sorry for the delayed reply. Well, you have called my bluff; I was only passing on hearsay information from memory, and haven't actually done such a repair myself. Upon researching my source for said info, I could only come up with a mention of the subject by a former Wharfedale staffer, as related in correspondence with Troels Gravesen on the latter's website here: The Wharfedale Super 8/

Now, the quoted staffer does seem confused (failing memory?) about some of the construction details of the speakers under discussion. Be that as it may, upon reading Briggs' writings, it's apparent to me that the R&D at his company was as scientifically rigorous as was possible in those days, with enthusiastic experimentation and listening tests supported by careful measurements. So, if they put foam behind the whizzer cone (a configuration unique to Wharfedale AFAIK), then I would trust that they had good reason to do so, and I would attempt the repair in good faith. I do not have instrumentation to test the results, and would rely on my ears to judge the outcome.

Ok, so - that tiny strip of foam would likely not do much by way of absorption; rather - I think it's function is (primarily) that of damping the free edge of the whizzer cone against breakup vibrations. Hence, I would avoid low-density open-cell foam; instead choosing a medium-density foam that rebounds slowly when compressed and then released. I would try something like "memory foam" or weatherstripping tape. The latter with a pressure-sensitive adhesive backing film might work well, although it might prove difficult to remove without damage to the paper cone in the event you are unhappy with the results. I seem to recall from grade-school art class that rubber cement - if applied to only one surface and left to tack up for a moment - would allow fairly clean removal from paper; perhaps you could experiment with something like that before committing to a more permanent adhesive. (But please DON'T blindly rely on my own failing memory, though!

)

)On the subject of meticulous repairs to Wharfedale speakers, I have to also refer "Grumpy's Place" - this fellow documents his obvious patience & love of the craft!

GRUMPY'S PLACE

GRUMPY'S PLACEAnyway, you asked how I would approach this, so there it is... You - or others - may have different ideas, and that's ok with me. Good luck, and please let us know how it goes if and when you decide to tackle this.

Wilf

For the Wharfedale 8 RS DD and the 10 RS DD model; the foam used for the damping ring on the HF cone is made from a soft 1/4'' thick plastic foam with small pores. It was cut out from a sheet of foam as an annulus ,I.D. = 2.75'';O.D.= 3.5''. A section ,approx. a quarter of the circumference was removed to allow it to be fitted to the edge of the tweeter cone. A latex adhesive should be used to attach it and it must be tensioned in such a way as to to provide a small amount of compression to the cone edge.

VaNarn:

Excellent - thanks for providing those measurements & details! Now we'll have no excuse to not get it right on the first try. BTW: in your experience, does that foam ring make a big improvement to the performance? Makes me wonder if HF cones in other brands of speakers might benefit equally from such treatment, despite it not being done by their manufacturers... I've heard some people advocate for cutting them out to improve the sound; I'd obviously be inclined to try the foam damping treatment instead.

Wilf

Excellent - thanks for providing those measurements & details! Now we'll have no excuse to not get it right on the first try. BTW: in your experience, does that foam ring make a big improvement to the performance? Makes me wonder if HF cones in other brands of speakers might benefit equally from such treatment, despite it not being done by their manufacturers... I've heard some people advocate for cutting them out to improve the sound; I'd obviously be inclined to try the foam damping treatment instead.

Wilf

Will, many thanks for your reply and for the link to Grumpy's fascinating website.

Looks like VaNarn has given us the info needed but I am not sure when I will get around to the Wharfedales as I have some other projects to complete first including a pair of Lowther TP1 corner horns.

VaNarn, many thanks to you too.

Gordon

Looks like VaNarn has given us the info needed but I am not sure when I will get around to the Wharfedales as I have some other projects to complete first including a pair of Lowther TP1 corner horns.

VaNarn, many thanks to you too.

Gordon

If you consider the shape of the tweeter cone as a being bell like in form, then any ringing mode should be suppressed by the foam ring fitted to the free end. In reality paper has a high internal friction (providing it has not been impregnated with a hardening solution) and the method that Goodmans used, three slits padded with foam is possibly a neater method that could be tried. The first Wharfedale Super 12 RSDD and the RS12DD speakers used a larger tweeter cone than later units. A foam ring under slight compression was placed between the main cone and the tweeter flare. Unfortunately this arrangement was changed to a smaller tweeter cone without the foam as it was thought that this gave a better sonic balance.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Wharfedale super 8/RS/DD