I could not resist and used a few minutes to glue the side panels together. I made a small mistake - I wanted to hide the gap on the tongue/groove connection inside, but did not glue the panels mirrorred. I kind of like the looks of OSB, so if I ever build a second one, it will be OSB again. Still not decided on the finish, it will be most probably some darker paint on the inside and lighter on the outside, maybe two tones of blue would look good. And the horns in reverse - light on inside and darker outside.

Attachments

Theoretically it is very simple, practically I consider this a learning project. I already learned a lesson or two on how to make things better next time🙂 It was a good decision to use the wooden beams (is that a proper name?), even like this they make the construction very solid. Next time I need to pay more attention to cutting as well🙂

Attachments

I experimented a bit with Hornresp, as GM advised, I tried to add a (more or less random) vent / loading to the back and it indeed does what one would expect. The tuning slats definitely improve the low end. The 7331 baffle is really amazing taking into account when it was designed. My highest respect to the smart guys of the past!

Attachments

I built it not to the original specs, but based on Hornresp simulations with the Eminence Deltalite II 2515 I have. I do not own any suitable 12" woofer to be used with the original.

... I was too early at your home ;-)Almost finished🙂 I just need to add a few more braces and clean up the edges a bit.

What was always on my roadmap to investigate different front "chambers" volumes. So why is the front higher than the back? Is there any verification from the sims? If so I would like to have the woofer in the upper part to be closer to the horn but this would mean a totally different construction especially if higher crossovers points are targeted.

I posted the HR records a few posts back, so you can try to experiment with them. The height and width of the front chamber is close to the original. The height of the back chamber was dictated by available wood and I also wanted to keep the external look similar - including the step. When it is finished, I want to experiment with damping and some sort of mass loading of the rear chamber.

The box is huge, a 2/3 sized version would have been much more practical, since I will use it with the bass horns anyways.

The box is huge, a 2/3 sized version would have been much more practical, since I will use it with the bass horns anyways.

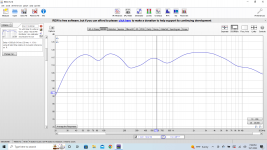

This is comparison of the front chamber depth. Black is 44 cm, grey is 22 cm. The rear chamber stays the same.

And this is a comparison of the model with original dimensions (grey) and my modification (black):

The low end will be different in room and with stuffing/louvers/mass loading on the back. Ed's measurements show extension down to 40's. And so do my Yamato YS-500 clones - they look like a box, but have open back - which simulate (U baffle simulation, of course, simplifies the reality) like this:

And this is a comparison of the model with original dimensions (grey) and my modification (black):

The low end will be different in room and with stuffing/louvers/mass loading on the back. Ed's measurements show extension down to 40's. And so do my Yamato YS-500 clones - they look like a box, but have open back - which simulate (U baffle simulation, of course, simplifies the reality) like this:

Yes, I'd say framing. Here is one of a pair of large woofer boxes I built for the Altec 604 coax. OSB and 2x4 framing studs. It was an easy build and fairly sturdy. Your build looks more refined than mine. 🙂Framing, beams, etc..

Attachments

I think it is more lack of light and resolution of my pictures, than a more refined build🙂 My studs are 19x44 mm, the cheapest I could get🙂

It is a pity that the box is still unloaded and serves as a work table. It is too large - I can fit either this one or the bass horns into the room, not both. It would make a good stand/bass unit for my smaller 2 way MEH, so its time will definitely come.

Ok, I again lost the measurements...but the good news is that Hornresp predicted the low end of this modification really nicely. It is not bad at all but unfortunately unusable for me due to the size and need for a subwoofer anyway. I could imagine this box below a large horn, so I will still keep it for a while - to compare it to a K15 in the same role.

- Home

- Loudspeakers

- Multi-Way

- Western Electric TA-7331-A Baffle