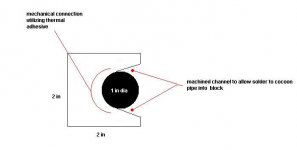

I think this will solve the issue for a nice solid metal to metal connection. Per the pic, a channel is machined to encapsulate the pipe into the block creating a solid metal to metal connection. Yes it will take a lot of solder with the length of the piece at 12", but I think this will be optimal.

With this setup, the cooling block will be housed in a chassis, with all water connections external, the cooling system will be remote. The only thing that will get damaged if there is a water fault are the downstairs ceiling; again another impossibility, because this system will only be used when yours truly is present. As long as the connections are sound, there really is no issue. It is an open cooling system, so no dangerous pressures to deal with. Also the car radiator i'm using with fans is coming out of a 190HP jeep, thats roughly 142kW. This system at most will be asked to dissipate 1200-1500watts of heat, so theres no dangerous temps involved. Of course if the pump fails, the output fets will die a most horrific death. Adding a manual resetting thermal cut-off onto the cooling block solves that. I can see the benefits of using distilled water in this system, but non-conductive coolant is really only beneficial if failure results in components getting sprayed i.e. over-clocking. Unless this type of coolant is used to prevent EMF build-up due to flowing water(?) through an assembly; which I don't think is possible as long as everything is properly grounded. For the DIYer on a budget wanting to experiment, this is the most elegant solution. IMO

With this setup, the cooling block will be housed in a chassis, with all water connections external, the cooling system will be remote. The only thing that will get damaged if there is a water fault are the downstairs ceiling; again another impossibility, because this system will only be used when yours truly is present. As long as the connections are sound, there really is no issue. It is an open cooling system, so no dangerous pressures to deal with. Also the car radiator i'm using with fans is coming out of a 190HP jeep, thats roughly 142kW. This system at most will be asked to dissipate 1200-1500watts of heat, so theres no dangerous temps involved. Of course if the pump fails, the output fets will die a most horrific death. Adding a manual resetting thermal cut-off onto the cooling block solves that. I can see the benefits of using distilled water in this system, but non-conductive coolant is really only beneficial if failure results in components getting sprayed i.e. over-clocking. Unless this type of coolant is used to prevent EMF build-up due to flowing water(?) through an assembly; which I don't think is possible as long as everything is properly grounded. For the DIYer on a budget wanting to experiment, this is the most elegant solution. IMO

Attachments

Variac said:

I meant to have the switches turn off the AC supply to the amp channels if the temp goes high.

Sorry, missed your intention on that one. Obviously, you'd need a bigger switch for the amp's main power.

ostripper said:Grollins, maybe some of us don't want 5-12 gallons of water

swirling around under natural convection,just trying to

pass some more practical ideas around.

When I worked at GE plastics I had to remove 12 kilowatts of

heat (totally silent instrument shack ,fans external)

from industrial control semiconductors so I've seen all the

options, (except for yours).

Water cooling was never a option (safety concerns) with the

control systems involved ,as we were using non-conductive

coolant ,phase change or forced air thermal solutions

way back in the 20th century.

I would just get a real cold feeling if our fellow DIY,ers had

a horrible accident so I just wanted to "modernize" the

discussion.Even the PC mod group has moved to non-

conductive coolant..

Radio tower transmitters used to use only purified de-ionized

water (for safety)but now even they to have moved on to

liquid gases or non-conductive coolants.

What we have here is a failure to communicate...

Okay, let me see if I can distill your post into salient points:

1) Convection.

--My system as it stands now is not based on convection. There's this little thing called a pump. I've mentioned it repeatedly. It's even in one of the pictures--it's the black and bluish-gray cylinder off to the right of the heat exchanger.

That's not to say that I'm not interested in a convective system. I'll give it a shot when I get time. I fail to see how your ideas are 'more practical' than a pump or convection.

In other words, your reading comprehension scores are falling, not rising.

2) GE's cooling system.

--I'm sure someone at GE is smart enough to come up with water as a coolant. After all, cars (air cooled engines excepted) have been doing it since forever. It's not all that difficult a concept.

You might wish to argue that my cooling system is physically larger than it has to be. True. Sort of. But its size will remain constant while dissipating more and more heat, whereas you'd have to buy more and more and more and more passive heat sinks (or CPU coolers), each adding to the bulk in your listening room. At some point relatively early in the process my cooling system will be dwarfed by the aggregate of all the passive heat sinks...and will keep my output devices (and listening room) cooler in the bargain. Better still, my cost remains fixed while yours keeps climbing. I don't know about you, but this appeals to my Scottish ancestry.

3) Your final three paragraphs seem to revolve mainly around water being conductive.

--That's why they invented insulators. The heat sinks aren't electrically "live." (Whew! That was a toughie! I almost hurt myself figuring that one out...)

4) '...more practical ideas...' '...wanted to "modernize" the discussion.'

--Let's see here...I get the impression that you're feeling that water is old-fashioned or something.

Cons: Water is conductive. If you can't solder well you might end up with a leak.

Pros: Water is cheap to free (I have a well, so mine's as close to free as you could ask for--in a pinch, wait for it to rain or snow). You don't have to have a license to work with it the way you do with Freon. It's non-toxic and environmentally benign. It's easy to work with. It's not under pressure, so there's nothing to explode. My way of doing things only has one moving part. A convective system would have no moving parts (loooooong MTBF). I'm a big fan of K.I.S.S. and the fewer moving parts, the better.

Gimmie that good ol' fashioned dihydrogen monoxide.

By the way, even if you should discover that you have a leak, water dries. Granted, I prefer to make good pipe joints the first time, but hey, if leaks are your thing then have at it.

5) '...way back in the 20th century.'

--Goodness me, how the time flies when you're having fun. Again, note the date on the first post in this thread. This is a thoroughly 21st century solution to a vexing problem all DIY folks face, sooner or later.

lineup said:another issue with circulating water system

may be:

what if there is some stop in water supply, circulation

then circuit would be overheated

I admit, that most times when I have no water pressure

in my flat (one apartment among many)

is when the electrical pump in our house have stopped

by mains electrical drop out

... and so the amplifier would be off on these occations

but suppose we get a leakage

somewhere in those pipes

At times like this, I begin wondering whether people actually read things or if it's a matter of reading comprehension. Or perhaps they just teleport in from another dimension immediately before posting. All these points have been covered--some many times...try reading Variac's posts above, amongst others.

I would think that if your mains power dropped, your amplifier would turn off also. This may not apply if your amplifier is solar powered. But then I'd think you'd have a solar powered cooling system, too. (More on this at a later date...)

Grey

Ditch the motherboard and drop in a (pre)amp. -25C at 250W

Vapochill

See inside

Vapochill

See inside

An externally hosted image should be here but it was not working when we last tested it.

Hi Mega,

Another, simpler way, would be to simply take a block of copper or Al of thickness 10mm and drill a 6.3mm (1/4") hole right through, end to end. Tap each end, screw in a brass fitting for attaching plastic tube. Then tap each side of the block for the semiconductor clamp.

That's a little bit simpler than soldering, and has the advantage that it's all low temp tapping and boring.

Grey, take heart. Teleporting in from another dimension works well until the Klystron fails....... see The Fly, Jeff Goldblum....

Hugh

Another, simpler way, would be to simply take a block of copper or Al of thickness 10mm and drill a 6.3mm (1/4") hole right through, end to end. Tap each end, screw in a brass fitting for attaching plastic tube. Then tap each side of the block for the semiconductor clamp.

That's a little bit simpler than soldering, and has the advantage that it's all low temp tapping and boring.

Grey, take heart. Teleporting in from another dimension works well until the Klystron fails....... see The Fly, Jeff Goldblum....

Hugh

AKSA said:

Grey, take heart. Teleporting in from another dimension works well until the Klystron fails....... see The Fly, Jeff Goldblum....

Shoulda water-cooled that Klystron before it overheated!

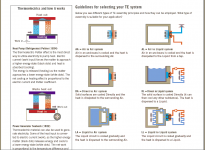

lineup said:there are many possibilities

using Air, Water and Peltier in various ways

It's easy to draw solutions. Practical implementation is another matter and you still haven't really gained anything in the end.

Grey

Originally posted by AKSA

Another, simpler way, would be to simply take a block of copper or Al of thickness 10mm and drill a 6.3mm (1/4") hole right through, end to end. Tap each end, screw in a brass fitting for attaching plastic tube. Then tap each side of the block for the semiconductor clamp.

Why didn't I think of that, its so simple!?!? (its late, is my only excuse) So much better! A piece of Al at current spec is about 80USD. Of course I made it a bit bigger, just because. Thanks for the idea Hugh!

Final Block:

Attachments

By Grollins:

I definitely agree, for I also didn't have the cash to properly

heatsink my projects. fortunately, I went with a class AB

amp so I could use my 16$ socket A

forced air "windtunnel" heatsinks.

Not wanting to be counterproductive let's discuss how to

actually bring this to reality since I,ve noticed over 50%

class A downloads from my websites "projects" page.

(a lot of diy'ers won't sweat pipes)

I was looking at this cooler:

http://www.xbitlabs.com/articles/coolers/display/16watercooling_14.html#sect0 it can keep 400 watts down to 60C..

good enough for a krell clone ksa 50 or similar with an appropriate

coolant block.. It is very expensive at 260 US dollars.

This site sells separate components...

http://www.frozencpu.com/cat/l1/g30/Liquid_Cooling.html?id=t9pXkUrS

, all stainless steel industrial grade stuff , better than the

name brand kits ,and would allow you to use your own DIY

"salvage" to get it going..

I've also seen convective "towers" that could warm the room

with no fans.

BTW .. My dimension here IS warped, the klystron already

melted down at Oak Ridge (right next door!!)

This is a thoroughly 21st century solution to a vexing problem all DIY folks face, sooner or later.

I definitely agree, for I also didn't have the cash to properly

heatsink my projects. fortunately, I went with a class AB

amp so I could use my 16$ socket A

forced air "windtunnel" heatsinks.

Not wanting to be counterproductive let's discuss how to

actually bring this to reality since I,ve noticed over 50%

class A downloads from my websites "projects" page.

(a lot of diy'ers won't sweat pipes)

I was looking at this cooler:

http://www.xbitlabs.com/articles/coolers/display/16watercooling_14.html#sect0 it can keep 400 watts down to 60C..

good enough for a krell clone ksa 50 or similar with an appropriate

coolant block.. It is very expensive at 260 US dollars.

This site sells separate components...

http://www.frozencpu.com/cat/l1/g30/Liquid_Cooling.html?id=t9pXkUrS

, all stainless steel industrial grade stuff , better than the

name brand kits ,and would allow you to use your own DIY

"salvage" to get it going..

I've also seen convective "towers" that could warm the room

with no fans.

BTW .. My dimension here IS warped, the klystron already

melted down at Oak Ridge (right next door!!)

Hello

Here is a site with some others stuff about water cooling, maby there is few other ideas, but it is more about cpu cooling;

http://procooling.com/index.php?func=articles&type=1&cat=all

Bye

Gaetan

Here is a site with some others stuff about water cooling, maby there is few other ideas, but it is more about cpu cooling;

http://procooling.com/index.php?func=articles&type=1&cat=all

Bye

Gaetan

I think this will solve the issue for a nice solid metal to metal connection.

Of course Grey said that the soldered on 1/8" piece of copper worked perfectly, so using an expensive block of copper would be a lot more money, and drilling a hole through the middle of the block seems a lot more work than soldering a plate onto a copper pipe.etely sealed as the plate is soldered to the outside of the pipe. The barbs in the end of the block could leak, and the hole would need to be threaded to screw them in..

I have some huge aluminum heatsinks that use an 1/8" tab to mount the devices even though the base of the fins is about 3/8"

and they work very well...

The plate on a copper pipe scheme is completely sealed as the plate is soldered to the outside of the pipe. . Soldered seems less likely to fail

I think that this is the most clever part of Grey's design. I too was hung up on how to machine something but he came up with a better idea IMHO.

But Grey, I think that you should accept that this idea stimulates people , and they just HAVE to share their ideas, even though they are mentioning issues and solutions brought up many times before.

Chill Dude 😉

ostripper said:

I've also seen convective "towers" that could warm the room

with no fans.

BTW .. My dimension here IS warped, the klystron already

melted down at Oak Ridge (right next door!!)

Now, you're talking...the cooling tower approach is one that I'm interested in, also. Somewhere around the house I've got some scribbled notes about that, but I have no idea where they've gotten to. I may have to reconstruct my line of thought from scratch if I go that route.

Funny thing about Oak Ridge. They had one of those little lightning-in-a-globe things on display. I had my hand on it, watching the patterns form around my fingers, and reached out to tap my wife on the shoulder. Nearly blasted her across the room with the shock. Didn't do me a lot of good, either. I've never gotten shocked by one of those gadgets before, so I have a suspicion that the thing was defective. Whenever I think of ORNL, that's the first thing that pops into my mind.

Grey

AKSA said:

and MEGA-amp responded:

I agree that this is conceptually more elegant; but in my (admittedly limited) experience, aluminum tends to grab cutting tools. I'd think you'd be lucky to get through 12" of the stuff with a 1/4" drill bit. Any experienced machinists want to chime in here?

[edit] MEGA-amp, I should have looked at your drawing before responding - it might be easier to drill the larger borehole you've drawn, since a drill bit or mill that size will be considerably stronger. And if you have access to tooling that will accomodate such things you probably also have a lot more machining experience than I do. [/edit]

If you do try it, you might consider drilling in from each end, so you only have to go through 6" (probably easier to find a drill bit that long as well). Do let us know the result if you give it a try.

Regards.

Aengus

Another, simpler way, would be to simply take a block of copper or Al of thickness 10mm and drill a 6.3mm (1/4") hole right through, end to end.

and MEGA-amp responded:

Why didn't I think of that, its so simple!?!?

I agree that this is conceptually more elegant; but in my (admittedly limited) experience, aluminum tends to grab cutting tools. I'd think you'd be lucky to get through 12" of the stuff with a 1/4" drill bit. Any experienced machinists want to chime in here?

[edit] MEGA-amp, I should have looked at your drawing before responding - it might be easier to drill the larger borehole you've drawn, since a drill bit or mill that size will be considerably stronger. And if you have access to tooling that will accomodate such things you probably also have a lot more machining experience than I do. [/edit]

If you do try it, you might consider drilling in from each end, so you only have to go through 6" (probably easier to find a drill bit that long as well). Do let us know the result if you give it a try.

Regards.

Aengus

other threads on the topic:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=41086&perpage=25&pagenumber=1

http://www.diyaudio.com/forums/showthread.php?postid=999420#post999420

http://www.diyaudio.com/forums/showthread.php?s=&threadid=740&perpage=10&pagenumber=1

http://www.diyaudio.com/forums/showthread.php?postid=587268#post587268

Nothing particularly useful

http://www.diyaudio.com/forums/showthread.php?s=&threadid=41086&perpage=25&pagenumber=1

http://www.diyaudio.com/forums/showthread.php?postid=999420#post999420

http://www.diyaudio.com/forums/showthread.php?s=&threadid=740&perpage=10&pagenumber=1

http://www.diyaudio.com/forums/showthread.php?postid=587268#post587268

Nothing particularly useful

Sorry about the Oak ridge experience, Grollins (klystron side effect),

here is that cooling tower..

I think 3 of these in parallel would do 1.5 KW since one

of them kept 400W at 60C .

This company...

http://www.pc-water-cooling.com/

sells individual convective cores all tapped and bored:

parallel an insane number of them together,

dissipate your KW's,

have a heated listening room. 🙂

here is that cooling tower..

An externally hosted image should be here but it was not working when we last tested it.

Made by zalmanI think 3 of these in parallel would do 1.5 KW since one

of them kept 400W at 60C .

This company...

http://www.pc-water-cooling.com/

sells individual convective cores all tapped and bored:

parallel an insane number of them together,

dissipate your KW's,

have a heated listening room. 🙂

Might as well turn it into something decorative and gain some efficiency.

=> www.fountainsoutlet.com/WallFountains.htm

Long time ago i did the watercooled amp thing with an old large diameter water fountain bowl annex air humidifier, my mom used to buy everything from trespassing salesmen in the 60/70s, worked like a charm.

My brotherinlaw just had a wall fountain installed in his garden, including fancy LED lighting that transforms the garden into a 70s disco.

The innovatek coolers resemble the works of Ypsilon amps.

=> www.fountainsoutlet.com/WallFountains.htm

Long time ago i did the watercooled amp thing with an old large diameter water fountain bowl annex air humidifier, my mom used to buy everything from trespassing salesmen in the 60/70s, worked like a charm.

My brotherinlaw just had a wall fountain installed in his garden, including fancy LED lighting that transforms the garden into a 70s disco.

The innovatek coolers resemble the works of Ypsilon amps.

Attachments

The sink mount resistors in that Zen setup are Vishay (Sfernice) RCH50's.

Vishay's "new" LTO line (25/50W-TO220, 100W-TO247) is more affordable.

Vishay's "new" LTO line (25/50W-TO220, 100W-TO247) is more affordable.

If you're looking for a cooling tower of the sort mentioned above, take a look at:

http://www.aavidthermalloy.com/cgi-...gth=3&airflow=57.2&CType=Natural&AirUnits=LFM

They have others that would work as well or better.

Incidentally, they recommend water as best for cooling, adding things only if necessary:

http://www.aavidthermalloy.com/products/liquid/index.shtml

When I think of cooling towers, I think of the sort that you see at power plants. There are a number of ways to approach this and if I get some time I may try a few out and report back. It's the time thing that hobbles me. Oh, well.

Grey

http://www.aavidthermalloy.com/cgi-...gth=3&airflow=57.2&CType=Natural&AirUnits=LFM

They have others that would work as well or better.

Incidentally, they recommend water as best for cooling, adding things only if necessary:

http://www.aavidthermalloy.com/products/liquid/index.shtml

When I think of cooling towers, I think of the sort that you see at power plants. There are a number of ways to approach this and if I get some time I may try a few out and report back. It's the time thing that hobbles me. Oh, well.

Grey

These don't have water but it seems that the chimney effect does help.

http://www.diyaudio.com/forums/showthread.php?postid=1544443#post1544443

The square tubes are open on the bottom. Possibly something similar could be done above a radiator to draw air through it. Commercial buildings cool areas by circulating chilled water. At the cooled area they have a fancoil unit which is basically a radiator with a fan blowing through it made to be placed in a duct. The chilled water is pumped throught it and it cools the air in the duct.

A sheet metal tower of the size of a finned fan coil without the fan would be very easy to impliment. I saw some used fancoil units at a metal salvage place, but they had been "repaired" with epoxy so I was scared off... just another source for radiators actually

http://www.directindustry.com/prod/ltg/fan-coil-unit-25088-60884.html

http://www.diyaudio.com/forums/showthread.php?postid=1544443#post1544443

The square tubes are open on the bottom. Possibly something similar could be done above a radiator to draw air through it. Commercial buildings cool areas by circulating chilled water. At the cooled area they have a fancoil unit which is basically a radiator with a fan blowing through it made to be placed in a duct. The chilled water is pumped throught it and it cools the air in the duct.

A sheet metal tower of the size of a finned fan coil without the fan would be very easy to impliment. I saw some used fancoil units at a metal salvage place, but they had been "repaired" with epoxy so I was scared off... just another source for radiators actually

http://www.directindustry.com/prod/ltg/fan-coil-unit-25088-60884.html

Your thinking is closer to what I had in mind. The fins-on-the-outside thing is more interesting to look at, but less efficient. I'm more interested in moving heat, although 'accidental' sex appeal wouldn't hurt my feelings.

Since I started this thread, I've acquired two more heat exchangers. Both are singles, meaning not of the A-frame construction that you see in the pictures--just one bank of tubing/fins. I was considering putting one across the bottom of a cooling tower sort of thing to help draw air through. I don't imagine that I'll really need it. Even with roughly half the heat radiating area of my current rig, it should do just fine. I was afraid when I first built the rig that it wouldn't be enough without forced air cooling through the heat exchanger. Then I was afraid that I'd be overdoing it by putting a second pair of Alephs on it. Now I'm pretty convinced that it can handle anything I care to throw at it. A system half that size should not pose any insurmountable problems.

Grey

Since I started this thread, I've acquired two more heat exchangers. Both are singles, meaning not of the A-frame construction that you see in the pictures--just one bank of tubing/fins. I was considering putting one across the bottom of a cooling tower sort of thing to help draw air through. I don't imagine that I'll really need it. Even with roughly half the heat radiating area of my current rig, it should do just fine. I was afraid when I first built the rig that it wouldn't be enough without forced air cooling through the heat exchanger. Then I was afraid that I'd be overdoing it by putting a second pair of Alephs on it. Now I'm pretty convinced that it can handle anything I care to throw at it. A system half that size should not pose any insurmountable problems.

Grey

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Water cooled audio circuitry