Hi,

Just acquired a Wadia WT-2000s transport that skips forth and back.

It reads okay lists the TOC and plays orderly when it's not skipping.

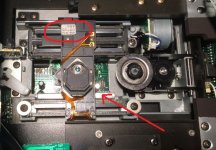

I think it's a lubrication problem but I'm not quite sure where to apply the lubrication apart from the shiny shaft at the left of the picture.

Any advice?

http://www.diyaudio.com/forums/attachment.php?attachmentid=654191&stc=1&d=1514882345

Just acquired a Wadia WT-2000s transport that skips forth and back.

It reads okay lists the TOC and plays orderly when it's not skipping.

I think it's a lubrication problem but I'm not quite sure where to apply the lubrication apart from the shiny shaft at the left of the picture.

Any advice?

http://www.diyaudio.com/forums/attachment.php?attachmentid=654191&stc=1&d=1514882345

Attachments

You will have to look where the friction points are on the opposite side of the pickup to the rail. Use a suitable grease that is metal/plastics compatible.

Is there a screw missing (upper left) ?

Is there a screw missing (upper left) ?

I will try to find them.You will have to look where the friction points are on the opposite side of the pickup to the rail. Use a suitable grease that is metal/plastics compatible.

So it's not on top of the sliders?

Is there a screw missing (upper left) ?[/QUOTE]

That was a internet picture from a Teac P2 Transport.

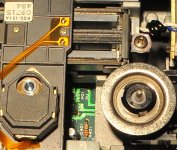

Mine looks like this and but has another clamp.

http://www.diyaudio.com/forums/attachment.php?attachmentid=654273&stc=1&d=1514919101

Attachments

it seems that the abnormality is caused by weak laser. I have several KSS151a machines and it is the symptom of weak laser.

Leo

Leo

I will try to find them.

So it's not on top of the sliders?

Perhaps under here. It should be fairly easy to see what the pickup runs on.

it seems that the abnormality is caused by weak laser. I have several KSS151a machines and it is the symptom of weak laser.

Leo

That is a distinct possibility, as is internal contamination and fogging of the optics.

The last digits of the pickup serial number give the factory set current for the laser diode which should be easy to check by calculation after measuring the volt drop across a resistor in the laser drive circuit. 484 is it on yours ? That would be 48.4 milliamps if so.

Attachments

it seems that the abnormality is caused by weak laser. I have several KSS151a machines and it is the symptom of weak laser.

Leo

Hi,

Older VRDS machines have 2 weakness showing up before laser's death. I had several KSS151 VRDS, sold cheap as fried diodes, with manual adjustements servo PCBs, skipping. But re-adjusted with no repair and never skipped anymore. Show us the servo PCB, if many pots you should re-tune first, which includes the diode's health check as per Mooly's advice.

Also the spindle lift mechanism's belt get loose and it does not grip tight enough to rotate the disc without it slipping from times to times. Check the belt under the spindle.

Roberts, if both pictures are yours then you can both re-adjust and belt check. Looks like a modded Tascam CD-701.

AFAIR magnetic rails does not call for grease but a tiny wheel to be clean, under the lasser assy.

Come back with your findings, many went to trash still alive...

Last edited:

It's the rod you see above in the last picture I send which is my machine with the 484 number on the KSS151a laserassembly.Perhaps under here. It should be fairly easy to see what the pickup runs on.

From the old Lampizator website I know how to "deep clean" the laser optics.That is a distinct possibility, as is internal contamination and fogging of the optics.

Yes mine is 484 but I'm not a technician so I've no glue which resistor I should use to measure the voltage drop but a skilled one with not your knowledge about the meaning of those numbers could benefit from that information thanks!The last digits of the pickup serial number give the factory set current for the laser diode which should be easy to check by calculation after measuring the volt drop across a resistor in the laser drive circuit. 484 is it on yours ? That would be 48.4 milliamps if so.

I hope it's just a dry rod but after your and Malefoda's remarks it could be somewhat more complex (for me).

Hi,

Older VRDS machines have 2 weakness showing up before laser's death. I had several KSS151 VRDS, sold cheap as fried diodes, with manual adjustements servo PCBs, skipping. But re-adjusted with no repair and never skipped anymore. Show us the servo PCB, if many pots you should re-tune first, which includes the diode's health check as per Mooly's advice.

Also the spindle lift mechanism's belt get loose and it does not grip tight enough to rotate the disc without it slipping from times to times. Check the belt under the spindle.

Roberts, if both pictures are yours then you can both re-adjust and belt check. Looks like a modded Tascam CD-701.

AFAIR magnetic rails does not call for grease but a tiny wheel to be clean, under the lasser assy.

Come back with your findings, many went to trash still alive...

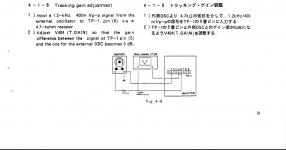

There lot's of Variable Resistors inside to govern the behavior of the transport.

It's indeed a modded Teac P2S or Tascam CD-701 for that matter.

I already ordered the belts for this unit and some lubrication as well.

There is indeed a tiny wheel also as you mentioned that I could clean but I thought the rod where the KSS151a Laserunit is gliding around needs to be cleaned and lubricated lightly also.

I can find the pots (V401 ~ V406), but I do not have the equipment nor the necessary skills to perform the adjustment.

I first try the mechanical stuff and if that fails I bring it to a workshop.

Thanks for your remarks!

http://www.diyaudio.com/forums/attachment.php?attachmentid=654300&stc=1&d=1514930330

http://www.diyaudio.com/forums/attachment.php?attachmentid=654302&stc=1&d=1514930330

http://www.diyaudio.com/forums/attachment.php?attachmentid=654301&stc=1&d=1514930330

http://www.diyaudio.com/forums/attachment.php?attachmentid=654303&stc=1&d=1514930330

Attachments

Made some detailed photo's with a SLR camera.

I presume this is the belt you were referring to.

It's rather loose when I pulled and pushed it.

http://www.diyaudio.com/forums/attachment.php?attachmentid=654436&stc=1&d=1514998100

http://www.diyaudio.com/forums/attachment.php?attachmentid=654437&stc=1&d=1514998100

I presume this is the belt you were referring to.

It's rather loose when I pulled and pushed it.

http://www.diyaudio.com/forums/attachment.php?attachmentid=654436&stc=1&d=1514998100

http://www.diyaudio.com/forums/attachment.php?attachmentid=654437&stc=1&d=1514998100

Attachments

The original general recommendation (by Sony for their early players) for lubricating the polished rod was to use a hypoid oil, and just a couple of drops. I assume the rod runs through sintered phosphor bronze bearings in the pickup.

This is the one.

Looks good but hard to say, if you feel it's loose enough to be doubtful it's cheap enough to replace. Beware of cheapest belts kit on eBay, William Thakker (spelling?) is a trusty supplier.

BTW, maybe you can look through the tiny holes on top platter that the CD is firmly pressed and show no gap at all. And some speed changes (from first tracks to last ones) will tell you through the holes if the CD slipped a bit or not.

Worth doing the whole belt changes, maybe after the laser health is known... like Mooly said, if you have a DMM you should check that first, quite easy and free. Got one? A warning here, a short of the resistor to test and you do fry your laser diode (I paid the price once...).

Looks good but hard to say, if you feel it's loose enough to be doubtful it's cheap enough to replace. Beware of cheapest belts kit on eBay, William Thakker (spelling?) is a trusty supplier.

BTW, maybe you can look through the tiny holes on top platter that the CD is firmly pressed and show no gap at all. And some speed changes (from first tracks to last ones) will tell you through the holes if the CD slipped a bit or not.

Worth doing the whole belt changes, maybe after the laser health is known... like Mooly said, if you have a DMM you should check that first, quite easy and free. Got one? A warning here, a short of the resistor to test and you do fry your laser diode (I paid the price once...).

Last edited:

This is the one.

Looks good but hard to say, if you feel it's loose enough to be doubtful it's cheap enough to replace. Beware of cheapest belts kit on eBay, William Thakker (spelling?) is a trusty supplier.

BTW, maybe you can look through the tiny holes on top platter that the CD is firmly pressed and show no gap at all. And some speed changes (from first tracks to last ones) will tell you through the holes if the CD slipped a bit or not.

Worth doing the whole belt changes, maybe after the laser health is known... like Mooly said, if you have a DMM you should check that first, quite easy and free. Got one? A warning here, a short of the resistor to test and you do fry your laser diode (I paid the price once...).

Yes I have a MM but have no glue which resistor I should measure and what the value would be.

Thanks for the advice for the platter. I will replace the belt anyway.

On the Tascam CD-701 service manual you find it page 6 section 1.2. It's R401, 22R, seems the one under the laser. Better use such: 1 Pair Small Test Hook Clip to Banana Plug for Multimeter Test Lead Cable GM | eBay but installed and removed with DMM on mV when power is off.

Elektrotanya.com website has the service manual. Hope it's OK to link it Mooly?!

Elektrotanya.com website has the service manual. Hope it's OK to link it Mooly?!

Should be OK 🙂 Its on Hifi Engine as well:

Tascam CD-701 - Manual - Compact Disc Player - HiFi Engine

Tascam CD-701 - Manual - Compact Disc Player - HiFi Engine

Great help!

Had downloaded the service-manual from the Teac P2S because that's the transport that resembles my Wadia 2000s the most but there's nothing in that manual about how to check the health of the laserdiode.

I will perform that measurement myself tomorrow (it's now 00:18 over here) and let you know.

Thanks again!

This is the resistor I think:

http://www.diyaudio.com/forums/attachment.php?attachmentid=654484&stc=1&d=1515022664

Had downloaded the service-manual from the Teac P2S because that's the transport that resembles my Wadia 2000s the most but there's nothing in that manual about how to check the health of the laserdiode.

I will perform that measurement myself tomorrow (it's now 00:18 over here) and let you know.

Thanks again!

This is the resistor I think:

http://www.diyaudio.com/forums/attachment.php?attachmentid=654484&stc=1&d=1515022664

Attachments

Last edited:

Can I measure the voltagedrop over R401 with the VDRS platter removed?

Otherwise it's almost impossible to maintain the testhook clips onto the leads of that resistor.

Otherwise it's almost impossible to maintain the testhook clips onto the leads of that resistor.

Nop, should be playing as normal. With the grip clip I linked you may be able to let the wires out of the way under the platter, nicely fitted with the player off. Or do it ghetto, solder tiny wires on the resistor for remote access... well isolated from each other, I know I'm annoying with that but a short and zap, heaven of the laser diodes.

Wires and tagging to the resistor is probably the best option. Also connect them to the meter first, before testing.

Just ordered a good set of MM measurement rods and pins with the flexible leads with miniature clips

I won't take any risk after you stipulated to me chance of frying the laserdiode when shorting the resistor.

I won't take any risk after you stipulated to me chance of frying the laserdiode when shorting the resistor.

Better safe than sorry 🙂

You can also get an accurate reading (its the same current value) during the couple of seconds the lens performs the focus search operation. So that can be done with no disc inserted (unless the Wadia detects presence of a disc by other means and inhibits focus search with no disc in the tray)

You can also get an accurate reading (its the same current value) during the couple of seconds the lens performs the focus search operation. So that can be done with no disc inserted (unless the Wadia detects presence of a disc by other means and inhibits focus search with no disc in the tray)

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Source

- Wadia WT-2000 Transport