It seems to me that the resistors were under sized from the start being 2 maybe 3

Watts and since the total resistance is 3.3 ohms they will dissipate a good fraction

of the power into the midrange. The midrange is rated for a lot of power as can be

seen in the spec sheet that I linked.

I would replace each 10 ohm with 1o to 12 Watt types for a total of 30 or more and

they should be raised well above the circuit board so that there is good air flow

around them.

Ok, I will do that. I have played a lot more music and although it has helped by changing to a high power amp. the sibilance can still be a bit much on some recordings.

I have checked the spec of the Mid Range unit and it says: 41/2" die-cast basket with linear surround and curvilinear polycone. Ferrofluid voice coil cooling. Range of operation:600Hz - 5KHz.

Vandersteen 2Ce

I replaced all the resistors with wire wound types and notice you state not to use these so I will order some other types and change them over. Why would I not use these?

I replaced all the resistors with wire wound types and notice you state not to use these so I will order some other types and change them over. Why would I not use these?

I have checked the spec of the Mid Range unit and it says: 41/2" die-cast basket with linear surround and curvilinear polycone. Ferrofluid voice coil cooling. Range of operation:600Hz - 5KHz.

replace the derro fluid of a cone driver is a mess because the speeder and you have t know the FF grade : easier to purchase two new mid units hoping they are avaliable and not made with specifications for Vandersteen. Ask perhaps at Madison or Solen about a replacment part, some have also adress for spider and suround remplacment after such operations but will you cost more than brand new drivers.

I don't understand wht a reliable brand is using FF in the mids because of the span life of it and the difficulty to rerfurbish FF with a cone unit 🙁

Vandersteen 2Ce

This part is no longer available. 🙁

replace the derro fluid of a cone driver is a mess because the speeder and you have t know the FF grade : easier to purchase two new mid units hoping they are avaliable and not made with specifications for Vandersteen. Ask perhaps at Madison or Solen about a replacment part, some have also adress for spider and suround remplacment after such operations but will you cost more than brand new drivers.

I don't understand wht a reliable brand is using FF in the mids because of the span life of it and the difficulty to rerfurbish FF with a cone unit 🙁

This part is no longer available. 🙁

If you keep this driver, it just means you can not push it towards Xmax for a long time or play lower spl in order to avoid stress on it and too much harmonic distorion and further failure.

You could measure such behavior with a free soft like Arta (sticky), a mic (dayton for instance) if you already don't have one. and a soundcard 'external or internal.

It will give you many things : T&S of the driver in order to know its working state or to try to find one with the genuine spec if not known (really ask Madison or solen shops), distorsion behaviors, matching beteen the two drivers, spl curves of the speaker at different places : nearfield, listening position. I don't know if the cheap Dayton mic for smartphone with a lighted soft on Smartphone do that as well.😕

You can ask if the suround and spider is avaliable as spares not to change the T&S parameters if you go that road. maybe expensive but mess than a coll 2ce speaker 😀

There is certainly some other solutions I'm not aware about...😉

You could measure such behavior with a free soft like Arta (sticky), a mic (dayton for instance) if you already don't have one. and a soundcard 'external or internal.

It will give you many things : T&S of the driver in order to know its working state or to try to find one with the genuine spec if not known (really ask Madison or solen shops), distorsion behaviors, matching beteen the two drivers, spl curves of the speaker at different places : nearfield, listening position. I don't know if the cheap Dayton mic for smartphone with a lighted soft on Smartphone do that as well.😕

You can ask if the suround and spider is avaliable as spares not to change the T&S parameters if you go that road. maybe expensive but mess than a coll 2ce speaker 😀

There is certainly some other solutions I'm not aware about...😉

If you keep this driver, it just means you can not push it towards Xmax for a long time or play lower spl in order to avoid stress on it and too much harmonic distorion and further failure.

You could measure such behavior with a free soft like Arta (sticky), a mic (dayton for instance) if you already don't have one. and a soundcard 'external or internal.

It will give you many things : T&S of the driver in order to know its working state or to try to find one with the genuine spec if not known (really ask Madison or solen shops), distorsion behaviors, matching beteen the two drivers, spl curves of the speaker at different places : nearfield, listening position. I don't know if the cheap Dayton mic for smartphone with a lighted soft on Smartphone do that as well.😕

You can ask if the suround and spider is avaliable as spares not to change the T&S parameters if you go that road. maybe expensive but mess than a coll 2ce speaker 😀

There is certainly some other solutions I'm not aware about...😉

I have tried just about everything to solve this and am now thinking that what you suggest could be the problem. I will try to find a replacement but I am not going to hold my breath. I have no measuring equipment available and I wouldn't know how to use it in any case!! 🙁

If you had a close neighboor here at diya (but well, sars-cov-2 doesn't help) or in you relationship to putt a cabinet speaker to try the level of sibilance, could you re assure you by a sort of proof of concept about the said bad drivers.

Anyway, it has not to be expensive to beginn with measurment, a smartphone and a smartphone daytin mic may be enough to beginn with... just an idea, ask to the clever & experienced people here with measurment...

Anyway, it has not to be expensive to beginn with measurment, a smartphone and a smartphone daytin mic may be enough to beginn with... just an idea, ask to the clever & experienced people here with measurment...

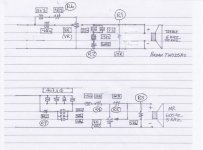

Vandersteen 2Ce

I know that this is difficult as RV says that all the speakers are are sounded and components chosen on these listening tests but I wondered if any of the experts could maybe point me in a direction of travel regarding my choice of resistors for the XO problem. I have experimented for a long time but just cannot seem to land on the right combination to rid me of the sibilance. I have attached a diagram of them as they are now and any suggestions will be greatly appreciated, I have numbered the resistors for easy identification for my benefit as I don't know which resistors do what!!!! 🙁 The resistors that burnt out originally were R1, R3 & R4. Thanks.

I know that this is difficult as RV says that all the speakers are are sounded and components chosen on these listening tests but I wondered if any of the experts could maybe point me in a direction of travel regarding my choice of resistors for the XO problem. I have experimented for a long time but just cannot seem to land on the right combination to rid me of the sibilance. I have attached a diagram of them as they are now and any suggestions will be greatly appreciated, I have numbered the resistors for easy identification for my benefit as I don't know which resistors do what!!!! 🙁 The resistors that burnt out originally were R1, R3 & R4. Thanks.

Attachments

Sandcast resistor then is what you want, but it will be strange the resistors are involved.

Try to listen to each driver alone speaker per speaker to check from what register mid or treble comes the sibilance...but could be as said harmonics of the mid as well towards the treble... sibilance are more hearable around 6 k hz as already pointed out.

Try to listen to each driver alone speaker per speaker to check from what register mid or treble comes the sibilance...but could be as said harmonics of the mid as well towards the treble... sibilance are more hearable around 6 k hz as already pointed out.

I'm afraid it sounds like a classic case of over-driving to me.

I'm probably not going to win many friends here, but a point worth keeping in mind is that we're looking at 1st order electrical crossovers, which if we set aside all other considerations, are rarely great on power-handling. The sibilance you are hearing may (may) be a result of the fact that with a 1st order electrical high pass, the tweeter excursion still continues to increase below the crossover frequency. And the harder you push the speaker, the greater the excursion will be, and distortion will start to rise. If that is the case, I'm afraid that you either need to completely change the crossover to something with at least a 2nd order electrical slope, or a different set of speakers because the design priorities of these does not align with your requirements. Changing the component values significantly will likely foul up the transfer functions, so there is very little you're likely to be able to do from that engineering POV. I'll have a gander in a minute to see if anything suggests itself electrically which won't completely screw things up, but if I were you, I'd at least consider changing the speakers to something more in line with your taste.

I'm probably not going to win many friends here, but a point worth keeping in mind is that we're looking at 1st order electrical crossovers, which if we set aside all other considerations, are rarely great on power-handling. The sibilance you are hearing may (may) be a result of the fact that with a 1st order electrical high pass, the tweeter excursion still continues to increase below the crossover frequency. And the harder you push the speaker, the greater the excursion will be, and distortion will start to rise. If that is the case, I'm afraid that you either need to completely change the crossover to something with at least a 2nd order electrical slope, or a different set of speakers because the design priorities of these does not align with your requirements. Changing the component values significantly will likely foul up the transfer functions, so there is very little you're likely to be able to do from that engineering POV. I'll have a gander in a minute to see if anything suggests itself electrically which won't completely screw things up, but if I were you, I'd at least consider changing the speakers to something more in line with your taste.

Problem is there are testimonials the speaker sounds good, maybe an accident, years with ferrofluids, production problems but here i doubt it s not controlled...

Vandersteen 2Ce

The problem appears to be the mid range.

Sandcast resistor then is what you want, but it will be strange the resistors are involved.

Try to listen to each driver alone speaker per speaker to check from what register mid or treble comes the sibilance...but could be as said harmonics of the mid as well towards the treble... sibilance are more hearable around 6 k hz as already pointed out.

The problem appears to be the mid range.

Vandersteen 2Ce

Once I get this kind of sorted, even just to an acceptable level I will consider the option of changing to something else. But would like to be in a position to sell them with confidence, but if I can get them back to the sound previously before the resistors burnt out I would be very happy with them as I consider them to have a very listenable sound.I'm afraid it sounds like a classic case of over-driving to me.

I'm probably not going to win many friends here, but a point worth keeping in mind is that we're looking at 1st order electrical crossovers, which if we set aside all other considerations, are rarely great on power-handling. The sibilance you are hearing may (may) be a result of the fact that with a 1st order electrical high pass, the tweeter excursion still continues to increase below the crossover frequency. And the harder you push the speaker, the greater the excursion will be, and distortion will start to rise. If that is the case, I'm afraid that you either need to completely change the crossover to something with at least a 2nd order electrical slope, or a different set of speakers because the design priorities of these does not align with your requirements. Changing the component values significantly will likely foul up the transfer functions, so there is very little you're likely to be able to do from that engineering POV. I'll have a gander in a minute to see if anything suggests itself electrically which won't completely screw things up, but if I were you, I'd at least consider changing the speakers to something more in line with your taste.

The problem appears to be the mid range.

It certainly is, but due to the further question of the poster, I believe he will be more confident to check it by himself... The resistors question is odd after all what have been said.😉

Once I get this kind of sorted, even just to an acceptable level I will consider the option of changing to something else. But would like to be in a position to sell them with confidence, but if I can get them back to the sound previously before the resistors burnt out I would be very happy with them as I consider them to have a very listenable sound.

Well, short version: if from your POV it was OK before, isn't now, and you've replaced the resistors you burned out with the nearest equivelents, then it isn't the resistors and something else has also been damaged. QED. No amount of changing resistors will fix that; it would be like injecting pencillin into a skeleton. So you'll have to check other components and the drivers for faults.

Vandersteen 2Ce

I have had a few suggestions as to what the problem could be with my XO but I decided to carry on with the notion that it is just finding the correct resistance that will solve my problem.

For information it was R1, R3 & R4 that burnt out originally.

The problem does seem to be in the midrange.

I have been doing some more experimenting and changed another value as can be seen on the latest provided drawing, I now find with this is configuration if I wind back the treble control about three quarters of its movement that the sound is OK . Unfortunately I have no idea how many db’s is available using the tone controls as I do not have the pre-amp spec. sheet.

So at least now I can listen and enjoy my music once again.

I have had a few suggestions as to what the problem could be with my XO but I decided to carry on with the notion that it is just finding the correct resistance that will solve my problem.

For information it was R1, R3 & R4 that burnt out originally.

The problem does seem to be in the midrange.

I have been doing some more experimenting and changed another value as can be seen on the latest provided drawing, I now find with this is configuration if I wind back the treble control about three quarters of its movement that the sound is OK . Unfortunately I have no idea how many db’s is available using the tone controls as I do not have the pre-amp spec. sheet.

So at least now I can listen and enjoy my music once again.

Attachments

I'll say it once again and then drop it. If the ferrofluid in the midrange is gone then it isn't damping the high end of the midrange. If it overheated, likely considering the burnt resistors, it may well have dissipated. Replacing the resistors won't change the now malfunctioning midrange.

Is R4 really marked 20 ohms (looks huge here!), is it not 2.0 ?

R1 & R3 are a part of impedance correction, I will not play with that values but advices of very experienced members. If they didn't fire already, it's your idea is maybe not a good one imho ? You eventually may cause more damages. And at least some very valuable fellows have had inputs (I'm not but being there) you don't listen to.

Some pre have a loudness button that bump an area of treble and bass. The treble pot on an integrated amp I know is centred aroud 10K hz, don't know about how much db nore the slope though. So midrange is not near 10 k hz.

R5 is a variable resistor from your schematic ? If it's a pot, consider it may be faulty !

R1 & R3 are a part of impedance correction, I will not play with that values but advices of very experienced members. If they didn't fire already, it's your idea is maybe not a good one imho ? You eventually may cause more damages. And at least some very valuable fellows have had inputs (I'm not but being there) you don't listen to.

Some pre have a loudness button that bump an area of treble and bass. The treble pot on an integrated amp I know is centred aroud 10K hz, don't know about how much db nore the slope though. So midrange is not near 10 k hz.

R5 is a variable resistor from your schematic ? If it's a pot, consider it may be faulty !

Last edited:

Vandersteen 2Ce

I realise what you are saying and appreciate it, but I have to try all eventualities with the resistors first as it will be expensive to start playing with midrange drivers as the original is no longer in pruction.

I'll say it once again and then drop it. If the ferrofluid in the midrange is gone then it isn't damping the high end of the midrange. If it overheated, likely considering the burnt resistors, it may well have dissipated. Replacing the resistors won't change the now malfunctioning midrange.

I realise what you are saying and appreciate it, but I have to try all eventualities with the resistors first as it will be expensive to start playing with midrange drivers as the original is no longer in pruction.

- Home

- Loudspeakers

- Multi-Way

- Vandersteen 2Ce sibilance problem