I finished a sub that i started with a hornresp question in this thread...

https://www.diyaudio.com/community/...-slot-loaded-build.409197/page-2#post-7625371

Got lot's of good discussion and advice there...but thought it would be better to post finished product in new thread...

So here it is: 2 x bms18n862. 36"w x 44"h x 29" deep. Height doesn't include permanent 6" wheels. Made to match up with the blue unity/synergy horn on top of it.

470L net. f-3 @ 25Hz

The reason for the 90 degree "V" between the drivers, is an attempt to go halfway to a push-push slot loaded (PPSL) design (where the drivers would face parallel,

and be halfway towards conventional forward facing drivers mounted on the same baffle.

I've had a pair of PPSLs I've been using for several years as left and right main subs, and love em. I've also had two conventional single 18" reflex subs that I've used for a center channel sub. All with the same bms drivers.

The conventional 18"s just hit a little harder on bass transients I think.....something seems a little more directional with all the cone surface area point straight ahead.

But I totally love the force reduction, vibration reduction, the PPSL give with opposed drivers.

Soooo...the 90 degree V angle is my idea on how to compromise...i figure i get 70.7% of both maximum possible force cancellation, and 70.7% of maximum possible forward radiating vector.........we'll see....

Driveway tuning has been easy. Every box i've tried with the 18n862...sealed, ported, PPSL, and now this has been so easy to get very smooth response.

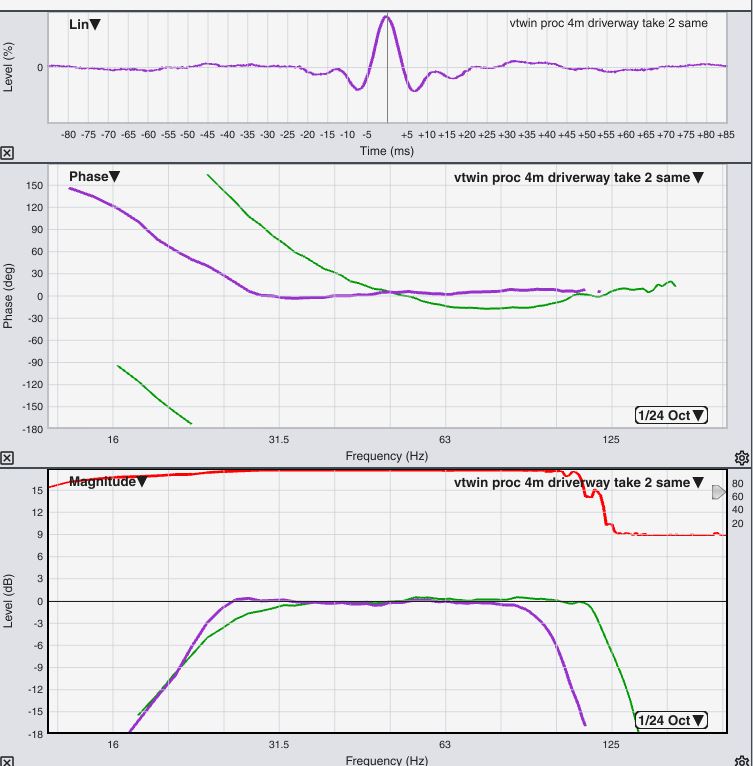

Green trace below has a 120Hz linear phase low pass and only two small PEQ cuts of -2dB or less...no boost. So a natural f-3 of 25Hz.

Purple is a FIR file with 100Hz lin phase low pass, includes the PEQ cuts from green, as well as about +2.5 dB of boost at 25Hz, to take f-3 to 23Hz.

https://www.diyaudio.com/community/...-slot-loaded-build.409197/page-2#post-7625371

Got lot's of good discussion and advice there...but thought it would be better to post finished product in new thread...

So here it is: 2 x bms18n862. 36"w x 44"h x 29" deep. Height doesn't include permanent 6" wheels. Made to match up with the blue unity/synergy horn on top of it.

470L net. f-3 @ 25Hz

The reason for the 90 degree "V" between the drivers, is an attempt to go halfway to a push-push slot loaded (PPSL) design (where the drivers would face parallel,

and be halfway towards conventional forward facing drivers mounted on the same baffle.

I've had a pair of PPSLs I've been using for several years as left and right main subs, and love em. I've also had two conventional single 18" reflex subs that I've used for a center channel sub. All with the same bms drivers.

The conventional 18"s just hit a little harder on bass transients I think.....something seems a little more directional with all the cone surface area point straight ahead.

But I totally love the force reduction, vibration reduction, the PPSL give with opposed drivers.

Soooo...the 90 degree V angle is my idea on how to compromise...i figure i get 70.7% of both maximum possible force cancellation, and 70.7% of maximum possible forward radiating vector.........we'll see....

Driveway tuning has been easy. Every box i've tried with the 18n862...sealed, ported, PPSL, and now this has been so easy to get very smooth response.

Green trace below has a 120Hz linear phase low pass and only two small PEQ cuts of -2dB or less...no boost. So a natural f-3 of 25Hz.

Purple is a FIR file with 100Hz lin phase low pass, includes the PEQ cuts from green, as well as about +2.5 dB of boost at 25Hz, to take f-3 to 23Hz.

Thx Art,

The syn horn is a 90 degree horiz pattern too. So yes, its walls are parallel to the 18" baffles. Albeit the syn horn has a wider mouth.

Easier seen from the side view below.

2.83V sensitivity came in at 100.6dB. Just as hoped for.

I knew it would be a little lower than the 101.5 dB i'm used to, with previous double 18"s tuned to 30Hz.

(This was using pink with processing in place, using my LEQ vs average voltage taken oven same 1 minute interval.)

The syn horn is a 90 degree horiz pattern too. So yes, its walls are parallel to the 18" baffles. Albeit the syn horn has a wider mouth.

Easier seen from the side view below.

2.83V sensitivity came in at 100.6dB. Just as hoped for.

I knew it would be a little lower than the 101.5 dB i'm used to, with previous double 18"s tuned to 30Hz.

(This was using pink with processing in place, using my LEQ vs average voltage taken oven same 1 minute interval.)

2.83V is 2.4 watts into the impedance minima of 3.35 ohms, but ~97+dB at 1w/1m is still a great average for a cabinet flat to 25Hz!2.83V sensitivity came in at 100.6dB. Just as hoped for.

Yep. That's what I make of it, make of the numbers, too.

There's simply a max SPL price to pay for taking a sub low ...flat..

If want max clean SPL.....which I do ...I'll high pass such that 25Hz becomes f-3.

That's what my FIR filter with small 2.5 dB boost is intended for...to be able to put in a high-pass which is still needed, and hit f-3 at 25 Hz.

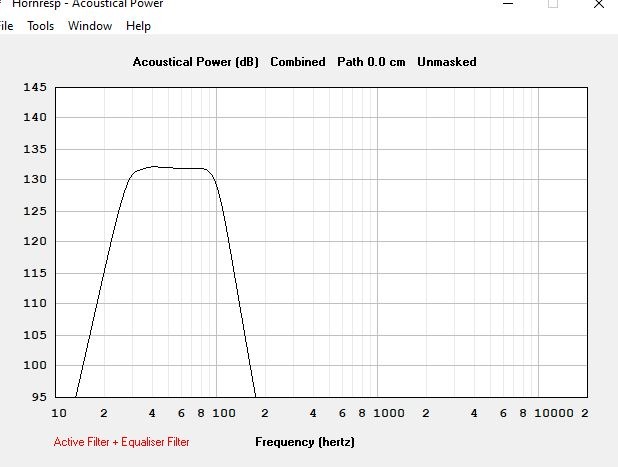

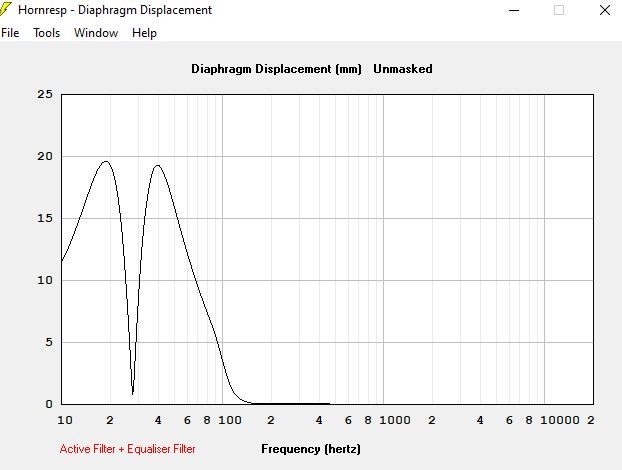

Hopefully max will end up looking like hornresp predicts....

There's simply a max SPL price to pay for taking a sub low ...flat..

If want max clean SPL.....which I do ...I'll high pass such that 25Hz becomes f-3.

That's what my FIR filter with small 2.5 dB boost is intended for...to be able to put in a high-pass which is still needed, and hit f-3 at 25 Hz.

Hopefully max will end up looking like hornresp predicts....

Mark, doesn’t the height of the bass cab make the Syn a bit high for seated listening ?

Hi Studley,

When I was dabbling with providing speakers for live-sound about 10 years ago, I observed two things that have led me away from normal seated listening.

First was speakers sound better when overhead. Now admittedly this holds more true for outdoor venues, but i found the same influence to a lesser degree indoors.

Second thing...and much more important......I found that lovely ladies are more likely to want to listen longer, and request their choice of tunes, when standing than when seated.

So I ditched the idea of cushy chair, sweet-spot listening, and moved to the idea of a nice dance floor. And it works !!!

I get dancing ladies all the time, dudes too. Heck...it's hard for me to just sit and listen, even when alone.

Sound is so gloriously intense and live-sounding, when uncompressed unclipped SPL is on tap across the spectrum.

When i do sit for critical stereo or LCR listening , it's on a bar chair with its extra height. Puts ears about 6" below horn center.

Good for you Dancing Dad !!! Me tooI’ve been re-defining the meaning of Dad dancing for decades now.🕺

Got a reguest for any drawings, details, in the "need Hornresp help PPSL" thread..which started this sub...

Sorry for the two threads folks...won't let happen again....

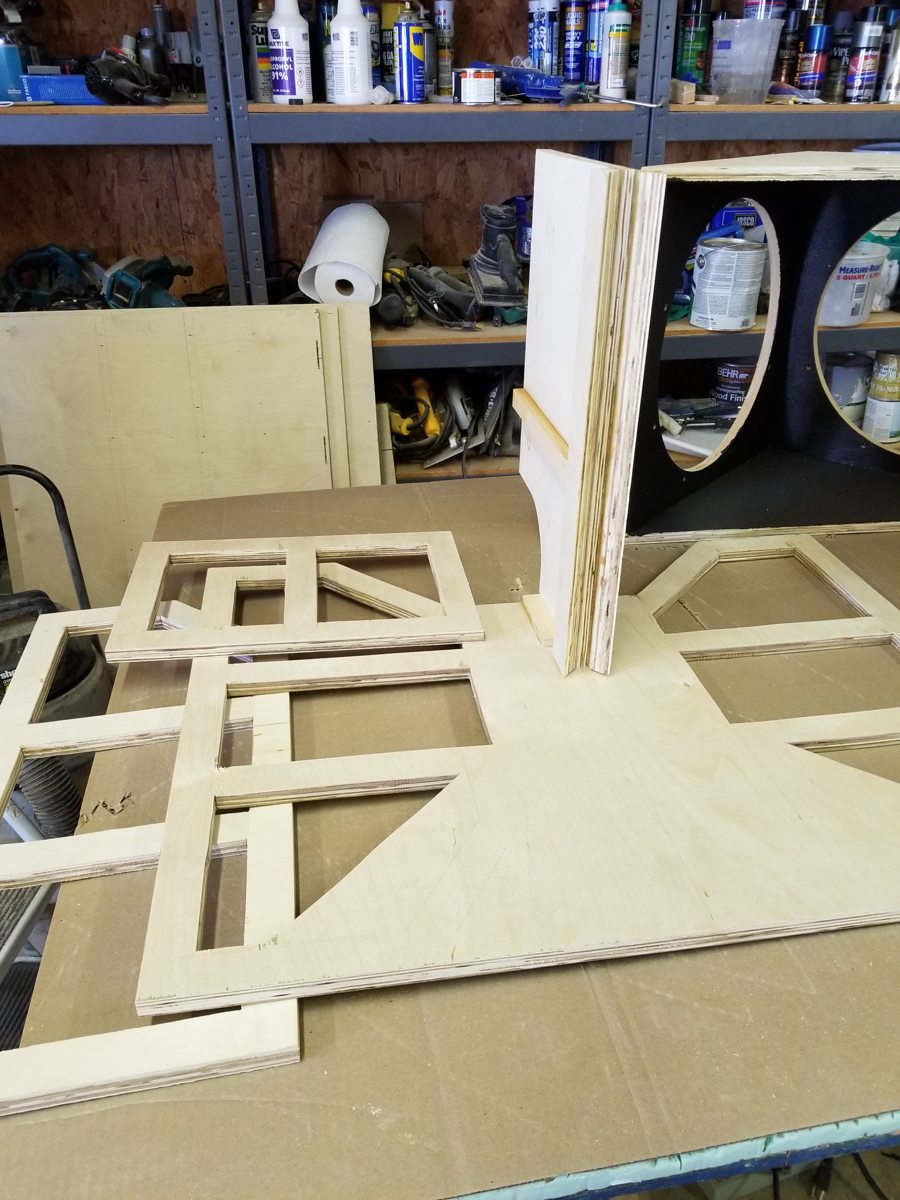

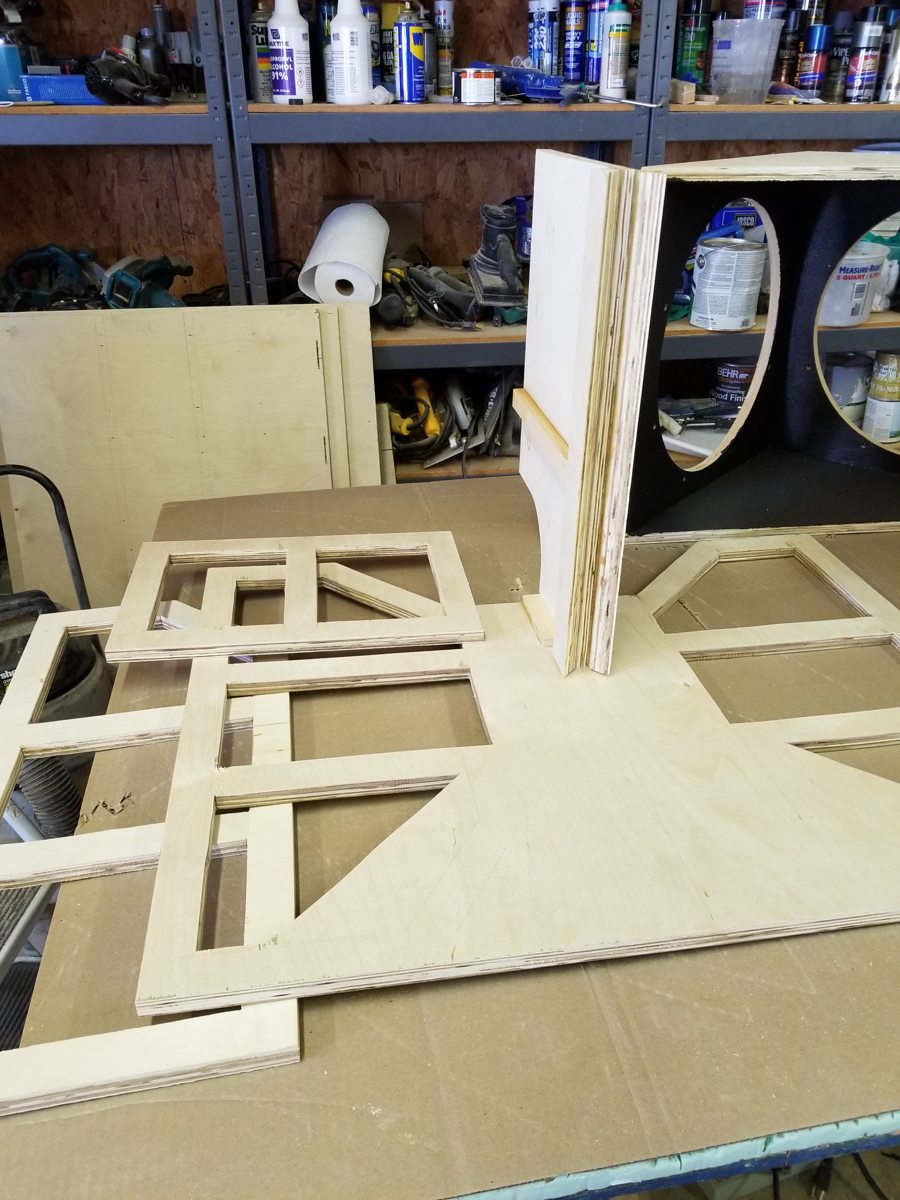

Anyway, don't have any drawings, but have a few build picts and overall explanations that should help.

Overall size goal, was as much volume as possible..., as always for ported, right?

Width needed to match syn10 horns 36".

Depth needed to fit through sliding patio door opening of 30".....so sub depth was set at 29".

Height needed to fit under same doors, with syn10 on top and 6" castor wheels below. 1"clearance meant height set at 44".

Engineering almost over ......Lol

Knowing I wanted the V-twin design, it just came down to the port that fit, go low, and not chuff.

Which is this box here...made a standalone port assy.

And aade standalone Vee baffle assy.

Braces. Big one goes into middle of box, between port on bottom and vee baffle on top.

All to look like this without front.

So that's the picture...I think it would be pretty easy to scale up down in size and drivers.

I like the method of building the braces in a "floor level" fashion. Never done that before.

And making the one big central brace that fits between port and baffle, really helped keep the box square thru assembly.

As did using biscuits joint...man I will never build another box without them.

Other than the one clamp shown above and the fact the port and baffle are premade modules, there is not a single nail. screw, or tad of glue holding the box together as pictured.

It's just stacked up like a kid's play building...damn biscuits work!

Sorry for the two threads folks...won't let happen again....

Anyway, don't have any drawings, but have a few build picts and overall explanations that should help.

Overall size goal, was as much volume as possible..., as always for ported, right?

Width needed to match syn10 horns 36".

Depth needed to fit through sliding patio door opening of 30".....so sub depth was set at 29".

Height needed to fit under same doors, with syn10 on top and 6" castor wheels below. 1"clearance meant height set at 44".

Engineering almost over ......Lol

Knowing I wanted the V-twin design, it just came down to the port that fit, go low, and not chuff.

Which is this box here...made a standalone port assy.

And aade standalone Vee baffle assy.

Braces. Big one goes into middle of box, between port on bottom and vee baffle on top.

All to look like this without front.

So that's the picture...I think it would be pretty easy to scale up down in size and drivers.

I like the method of building the braces in a "floor level" fashion. Never done that before.

And making the one big central brace that fits between port and baffle, really helped keep the box square thru assembly.

As did using biscuits joint...man I will never build another box without them.

Other than the one clamp shown above and the fact the port and baffle are premade modules, there is not a single nail. screw, or tad of glue holding the box together as pictured.

It's just stacked up like a kid's play building...damn biscuits work!

Niceee! so basically you made the volume box then added inside the baffle box,

and you did not make any drawings of it ?, maybe some paper an pencil sketches ?

did you made a pair of those ?

hey i read you did FIR, what processor and how did you came up with the FIR table

wish you can post some measurements

and you did not make any drawings of it ?, maybe some paper an pencil sketches ?

did you made a pair of those ?

hey i read you did FIR, what processor and how did you came up with the FIR table

wish you can post some measurements

Mark,Other than the one clamp shown above and the fact the port and baffle are premade modules, there is not a single nail. screw, or tad of glue holding the box together as pictured.

It's just stacked up like a kid's play building...damn biscuits work!

Your bracing reminded me I once used biscuits to make "continental" stage platform risers.

They were used as drum risers a few times, then were stored.

The platform decks were used more frequently above scaffold risers, which were then sold with a PA.

After years of storage, it was time to sell the parallel risers before a cross country move.

Found most of the damn biscuit joints had failed while stored, which made the risers junk.

Did you use any other fasteners other than glue and biscuits in the V twin?

Art

Niceee! so basically you made the volume box then added inside the baffle box,

and you did not make any drawings of it ?, maybe some paper an pencil sketches ?

did you made a pair of those ?

hey i read you did FIR, what processor and how did you came up with the FIR table

wish you can post some measurements

Yep, just added pieces to the inside of the box.

I didn't really need to make drawings, because everything was referenced to the internal box dimensions. All I had to do was fit stuff inside snugly.

I am making three of them for a LCR rig. Two are done.

Last will be done by this time next week..57 pieces of wood cut, per box.

I use a q-sys Core as the processor, and FirDesigner as the FIR filter generating software.

The purple traces in #1 show the FIR processing.

But really, FIR processing isn't really needed on this sub at all, other than a plain old linear-phase xover to main speaker.

Here's is the raw response with just a LR 24 dB/oct low pass at 120Hz.

You have sure made your share of innovative stuff over the years !!! Incredible really...Your bracing reminded me I once used biscuits to make "continental" stage platform risers.

Yep. I glued all joints as if there were no biscuits, and also did my usual brad nailing all around.Did you use any other fasteners other than glue and biscuits in the V twin?

Even got 6 new 50" Bessey's to try to do these subs really right.

I like the biscuits more for their alignment property, than for counting on their strength.

I sanded sooooo much less than ever before....and the damn subs are fully square and plumb !!!

The alignment property of the biscuits is a nice feature on huge cabinets, sanding sucks..

I'm impressed by your builds and measurement posts!

Still curious to see the "V twin" raw response including the upper "horn" response and the port pipe resonance frequency range, which are implied in the LR 24 dB/oct low pass at 120Hz picture, but require too much math for me to see clearly.

I'm impressed by your builds and measurement posts!

Still curious to see the "V twin" raw response including the upper "horn" response and the port pipe resonance frequency range, which are implied in the LR 24 dB/oct low pass at 120Hz picture, but require too much math for me to see clearly.

Still curious to see the "V twin" raw response including the upper "horn" response and the port pipe resonance frequency range, which are implied in the LR 24 dB/oct low pass at 120Hz picture, but require too much math for me to see clearly.

Thx Art, kind words.

Not sure what you are looking for, but maybe it's just the raw response... here it is... same 4m outdoor that's been the basis for all posts..

Since I never use a sub past about 120Hz, I don't bother thinking about response higher up in freq, .....other than making sure of no resonances, rattles, etc when cranking lol.

- Home

- Loudspeakers

- Subwoofers

- "V-Twin" double 18" bass reflex build