Pass DIY Addict

Joined 2000

Paid Member

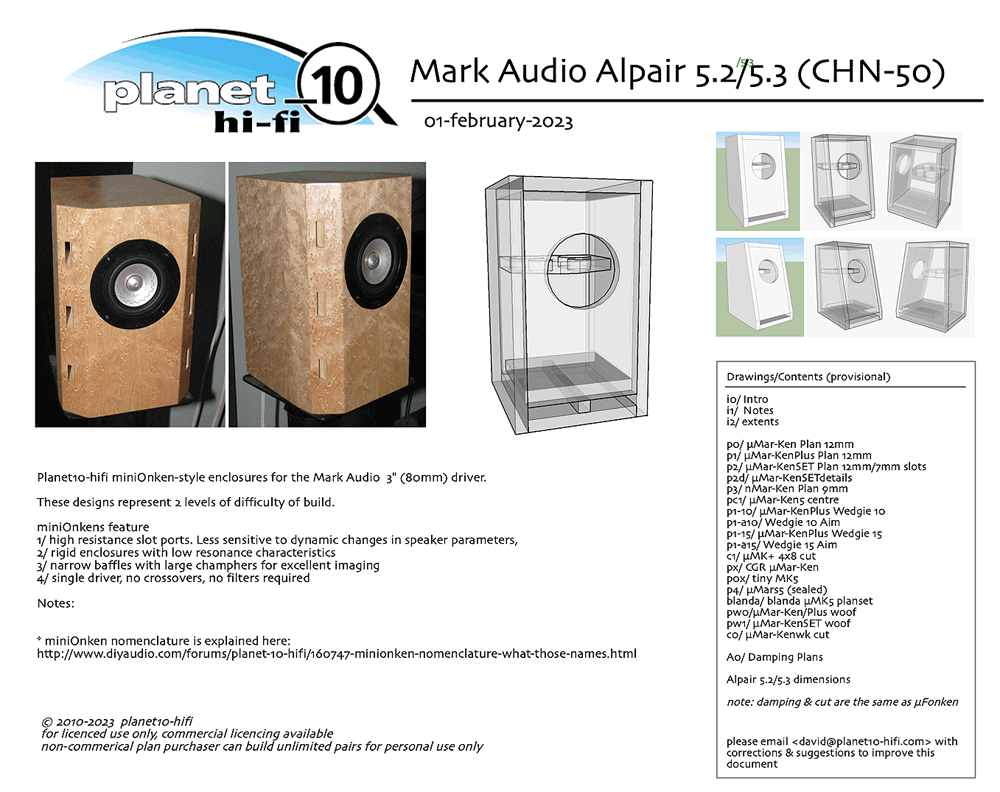

I'm curious to learn a little about the uMar-KenSET speaker design that's been shown here. I'm looking for a relatively small speaker that will be used with my computer. Playback chain will be Focusrite Scarlett 2i4 DAC ---> ACA ---> nice small speakers that will flank the monitor on my desktop and be pushed up against the wall behind the desk.

The uMar-KenSET looks like an interesting speaker that seems to fit my criteria. Will this design perform well in this context? I figure it probably won't generate much bass (maybe wall and desktop boundaries will help a little?), but I need something that is pretty accurate on the top end for click and pop editing on vinyl rips. Open to other ideas, of ocurse, but I'd like to keep driver cost under about $100 each and keep the footprint small.

The slanty-front baffle design also looks like it might be worthwhile, given the nearfield listening.

The uMar-KenSET looks like an interesting speaker that seems to fit my criteria. Will this design perform well in this context? I figure it probably won't generate much bass (maybe wall and desktop boundaries will help a little?), but I need something that is pretty accurate on the top end for click and pop editing on vinyl rips. Open to other ideas, of ocurse, but I'd like to keep driver cost under about $100 each and keep the footprint small.

The slanty-front baffle design also looks like it might be worthwhile, given the nearfield listening.

You could also look at the Woden Bloodhound in the BabyLabs series. I built a pair with Alpair 5.3. They are 8" x 11" x 8" deep. I use mine as computer speakers. They have decent bass output. They are rear ported. I have about 4" behind them to the wall. I am running them with an old Denon stereo receiver. I need to update my ACA power supply before I can use them again. Also have a Scarlett 2i2. Are you using the Scarlett as the ADC?

Pass DIY Addict

Joined 2000

Paid Member

I've come across the Woden Baby Labs designs, they look interesting for sure. The reason that I kept looking for something else is that these are all rear-ported design and I wanted to push the speakers up against the wall to so they don't eat up more desk space. I've been using the Scarlett 2i4 as the ADC for ripping, but it looks like it has a decent DAC built in as well, so I was going to use that to drive an amp & speakers.

Should work great, even with the bass performance limitations. I've been using Dave's miniOnken style speakers on my desktop for years. Mostly the larger 4" variants, but the smaller MA drivers like the now OOP A6p also work really well.Will this design perform well in this context?

jeff

Will this design perform well in this context?

It is its official target.

An early box that lead to the µ-size miniOnken trapezoids.

Add woofers and they give up little to a much bigger system.

dave

Pass DIY Addict

Joined 2000

Paid Member

Pass DIY Addict

Joined 2000

Paid Member

Got the plans, Dave. Many thanks! Aside from the differences in construction difficulty, are there any appreciable performance differences between the uMar-KenSET trapezoid box and the Wedgie box? Overall interior volume looks "close" so the primary difference that I see is the venting arrangement and how that might impact the amount of mid/bass that comes from the box. Any thoughts about listening "on-axis" with the Wedgie vs being more off-axis with the SET design?

Pass DIY Addict

Joined 2000

Paid Member

So, I'm looking at padding to affix to the inside of the cabinets and I've found two different materials. Are either of these any good?

Frost King Cotton Insulation. Says it's 1" thick, but people say it's closer to 1/2"

https://www.amazon.com/Frost-King-CF1-Multi-Purpose-Insulation/dp/B004Y6SX1Y/ref=sr_1_2

Zoro 1/2" F26 Felt Pads. Ranges from F1 (hardest) to F26 (softest):

https://www.ebay.com/itm/335018232696

If neither of these are good choices, does anyone have a good source?

I've already got enough left over wood from other projects and just might have enough veneer to make them look spiffy when I'm done.

Frost King Cotton Insulation. Says it's 1" thick, but people say it's closer to 1/2"

https://www.amazon.com/Frost-King-CF1-Multi-Purpose-Insulation/dp/B004Y6SX1Y/ref=sr_1_2

Zoro 1/2" F26 Felt Pads. Ranges from F1 (hardest) to F26 (softest):

https://www.ebay.com/itm/335018232696

If neither of these are good choices, does anyone have a good source?

I've already got enough left over wood from other projects and just might have enough veneer to make them look spiffy when I'm done.

Pass DIY Addict

Joined 2000

Paid Member

Pass DIY Addict

Joined 2000

Paid Member

Pass DIY Addict

Joined 2000

Paid Member

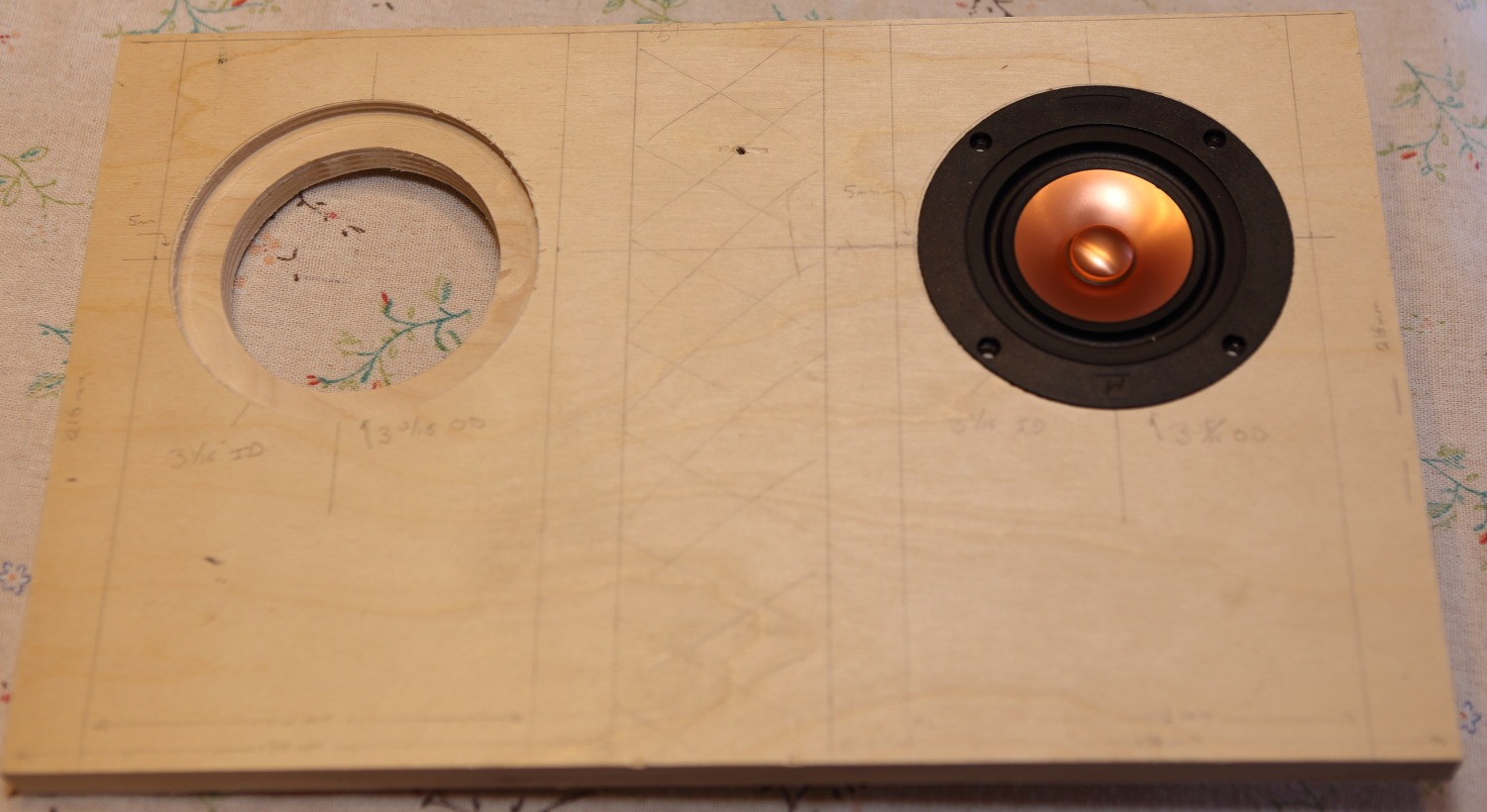

Things are progressing along and I have to say that in addition to these being my smallest ever speaker construction project, it's also been the most challenging in terms of angle cuts and precision. Whichever one of you guys came up with this design (Dave, Chris, ??) may have some masochistic tendencies

I altered the plans just a little to fit the mix of 18mm Baltic Birch and 12mm ply that I already had on hand from previous projects. It was also a good excuse to spend a few minutes building a makeshift router table. I've been contemplating buying one for a long time, and I just decided to cut some wood to make one.

So, after this little side project, I cut the outer side panels from 18mm birch and then routed the vents into them. I thought this would be easier than trying to cut down four strips of "spacer" wood to make the vents. It seems that wood glue works more like wood lube until it finally grabs, so I figured this approach would keep things from slipping around while I clamped it together.

After plowing the vents into the side panels, I cut the front edges at a 35 degree angle and then adjusted the saw to make the 10 degree side cut. I masked off and painted both sides of each vent, then glued them together. The sides are a few mm longer than indicated in the plan to account for the added thickness of the front and rear baffles that are also made from 18mm birch.

The front panel also needed some adjustment to make the vents work properly for the thicker wood. After routing and test-fitting the driver holes, I cut the 45 degree angle and then plowed out 6mm from the side edges of the back of the baffle, restoring them to the 12mm thickness shown in the plan. This allowed the vents to line up the way they are shown in the plan set. I neglected to make a close-up image of the front baffle profile, but you can see some of it in the lower image below.

So far, the four sides of the boxes are glued up. I dry clamped (no glue) the top and bottom panels along with some wax paper to make sure I maintained proper panel alignment while the straps held the rest of the panels in place while the glue dried.

I'll add some additional images as work progresses. I have just enough quartersawn Bubinga veneer left over from my FHXL build to make these look nice as well. The hard work is done (needed lots of test cuts along the way), though there is still plenty of work to do...

I altered the plans just a little to fit the mix of 18mm Baltic Birch and 12mm ply that I already had on hand from previous projects. It was also a good excuse to spend a few minutes building a makeshift router table. I've been contemplating buying one for a long time, and I just decided to cut some wood to make one.

So, after this little side project, I cut the outer side panels from 18mm birch and then routed the vents into them. I thought this would be easier than trying to cut down four strips of "spacer" wood to make the vents. It seems that wood glue works more like wood lube until it finally grabs, so I figured this approach would keep things from slipping around while I clamped it together.

After plowing the vents into the side panels, I cut the front edges at a 35 degree angle and then adjusted the saw to make the 10 degree side cut. I masked off and painted both sides of each vent, then glued them together. The sides are a few mm longer than indicated in the plan to account for the added thickness of the front and rear baffles that are also made from 18mm birch.

The front panel also needed some adjustment to make the vents work properly for the thicker wood. After routing and test-fitting the driver holes, I cut the 45 degree angle and then plowed out 6mm from the side edges of the back of the baffle, restoring them to the 12mm thickness shown in the plan. This allowed the vents to line up the way they are shown in the plan set. I neglected to make a close-up image of the front baffle profile, but you can see some of it in the lower image below.

So far, the four sides of the boxes are glued up. I dry clamped (no glue) the top and bottom panels along with some wax paper to make sure I maintained proper panel alignment while the straps held the rest of the panels in place while the glue dried.

I'll add some additional images as work progresses. I have just enough quartersawn Bubinga veneer left over from my FHXL build to make these look nice as well. The hard work is done (needed lots of test cuts along the way), though there is still plenty of work to do...

Whichever one of you guys came up with this design (Dave, Chris, ??) may have some masochistic tendencies

I designed, Chris built. I have designed more torturous stuff. Chris learned stuff as did i.

dave

Last edited:

Pass DIY Addict

Joined 2000

Paid Member

Pass DIY Addict

Joined 2000

Paid Member

Pass DIY Addict

Joined 2000

Paid Member

Thanks, Zman. My wife keeps calling them "lovely little bird houses"... They're definitely tiny guys, though using mostly 18mm birch, they're also surprisingly heavy and rather non-resonant (I suppose with was the design goal considering the lack of parallel side walls).

I think the completed speaker might just fit into the horn recess for my behemoth Calpamos speakers. I'll have to stack one on top of the other for a photo shoot when I'm done. They will have matching finishes.

I have some memory of you building a pair of FHXLs, but I don't recall seeing an image of them....

I think the completed speaker might just fit into the horn recess for my behemoth Calpamos speakers. I'll have to stack one on top of the other for a photo shoot when I'm done. They will have matching finishes.

I have some memory of you building a pair of FHXLs, but I don't recall seeing an image of them....

- Home

- Loudspeakers

- Full Range

- uMar-KenSET for Computer Desktop Speaker?