Hi guys,

I see a lot of DIY designs and measurements on the internet that shows a very flat frequency response. How is that possible when diffraction should ruin the treble response? I built a speaker out of BB plywood, and the frequency response looks like a typical speaker suffering from diffraction issues with predictable peaks and dips in the response.

My question is, assuming you have a perfectly flat FR tweeter, can you have a flat treble response, say +- 2dB from 3KHz and up from just flush mounting the tweeter on a MDF or BB plywood cabinet?

I've seen some commercials speakers where the front baffle is not the same as the rest of the sides, and the front baffle is extremely smooth. The Paradigm Mini Monitor is an example. What is it they're doing? How effective it is at combating diffraction?

I see a lot of DIY designs and measurements on the internet that shows a very flat frequency response. How is that possible when diffraction should ruin the treble response? I built a speaker out of BB plywood, and the frequency response looks like a typical speaker suffering from diffraction issues with predictable peaks and dips in the response.

My question is, assuming you have a perfectly flat FR tweeter, can you have a flat treble response, say +- 2dB from 3KHz and up from just flush mounting the tweeter on a MDF or BB plywood cabinet?

I've seen some commercials speakers where the front baffle is not the same as the rest of the sides, and the front baffle is extremely smooth. The Paradigm Mini Monitor is an example. What is it they're doing? How effective it is at combating diffraction?

One way is smoothing the response curve in the graph.

Another way is to use a waveguide, which helps the wavefront avoid the cabinet edge at least at higher frequencies.

Another way is to use a waveguide, which helps the wavefront avoid the cabinet edge at least at higher frequencies.

Lower,

You can also try my trick, PSA backed felt around the tweeter. 🙂 It won't fix everything, but in combination with rounded sides and an offset tweeter can be very helpful. This trick is also used by Wilson and Vandersteen to one degree or another.

Best,

Erik

You can also try my trick, PSA backed felt around the tweeter. 🙂 It won't fix everything, but in combination with rounded sides and an offset tweeter can be very helpful. This trick is also used by Wilson and Vandersteen to one degree or another.

Best,

Erik

The dimensions of the baffle and the distance from the tweeter to the edges is important, rounding the edges is useful. On a typical baffle you will have a bump and then some smaller ripples above that.

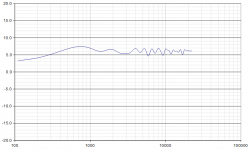

Here is a simple excel sim of a sharp edged baffle 18"x8" with (point source) tweeter centered and 10" high. This sim doesn't have tremendous frequency resolution, but it is a good rough guide.

Here is a simple excel sim of a sharp edged baffle 18"x8" with (point source) tweeter centered and 10" high. This sim doesn't have tremendous frequency resolution, but it is a good rough guide.

Attachments

In 1950 Harry Olson's paper "Direct Radiator Loudspeaker Enclosures" used high quality diffraction measurements on several geometric cabinet shapes. A few speaker manufacturers use the lowest diffraction shapes. Many manufactures taper or round edges at modest cost for measureable diffraction reductions.

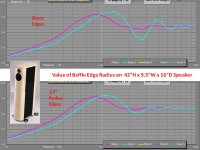

Both the size of the baffle and the speaker placement on the baffle produce noticable changes/improvements in edge diffraction and crossover shape. A larger baffle can lower the potential tweeter crossover frequency, but will also change the room's sound stage. Mounting a tweeter slightly off-center can spread edge resonances over a wider frequency range, which reduces the peak SPL bumps. There are a few good quality baffle simulators which allow grading many placement and edge-shape options before a build.

There are 1.5" quarter-round router bits for 0.5" chuck hand routers. There are 3" quarter-round cutters for 1" chuck 3-5HP shop shapers.

http://www.aes.org/aeshc/pdf/how.the.aes.began/olson_direct-radiator-loudspeaker-enclosures.pdf

Both the size of the baffle and the speaker placement on the baffle produce noticable changes/improvements in edge diffraction and crossover shape. A larger baffle can lower the potential tweeter crossover frequency, but will also change the room's sound stage. Mounting a tweeter slightly off-center can spread edge resonances over a wider frequency range, which reduces the peak SPL bumps. There are a few good quality baffle simulators which allow grading many placement and edge-shape options before a build.

There are 1.5" quarter-round router bits for 0.5" chuck hand routers. There are 3" quarter-round cutters for 1" chuck 3-5HP shop shapers.

http://www.aes.org/aeshc/pdf/how.the.aes.began/olson_direct-radiator-loudspeaker-enclosures.pdf

Attachments

My sim above has 1/12 octave resolution. Since the sim is for a point source it predicts higher deviation than reality above the point where the driver becomes directive. Effectively at high frequencies the driver no longer paints the edge with sound.

There are several free diffraction simulators out there.

The oft mentioned harry olson figures are all sort of worst-case since he placed the ~2" driver at the geometric center of the baffle in all cases. You can fairly easily find out with software that even a sharp edged circular baffle can work if you are careful with driver position. For example, placing the driver just ~1/4 way from the center of the circle to the edge smooths things out a fair amount.

There are several free diffraction simulators out there.

The oft mentioned harry olson figures are all sort of worst-case since he placed the ~2" driver at the geometric center of the baffle in all cases. You can fairly easily find out with software that even a sharp edged circular baffle can work if you are careful with driver position. For example, placing the driver just ~1/4 way from the center of the circle to the edge smooths things out a fair amount.

Many commercial speakers are pretty narrow. This effectively reduces the sound wave intensity which illuminates the baffle edges as the tweeter would be more directional. Cabinets are also often rectangular with the tweeter having only two symmetric dimensions - usually to the sides. Many tweeters are often loaded by a small waveguide which drops the frequency of 2pi transition, even if they`re very small at 90 degrees they can have substantial effect. Then when you address the remaining ripples in the crossover and use smoothing - you can get a pretty flat response. If the tweeter is offset properly, the loudspeaker can be made ruler flat from 1Khz up even with 1/12 smoothing.

Many commercial speakers are pretty narrow. This effectively reduces the sound wave intensity which illuminates the baffle edges as the tweeter would be more directional. Cabinets are also often rectangular with the tweeter having only two symmetric dimensions - usually to the sides. Many tweeters are often loaded by a small waveguide which drops the frequency of 2pi transition, even if they`re very small at 90 degrees they can have substantial effect. Then when you address the remaining ripples in the crossover and use smoothing - you can get a pretty flat response. If the tweeter is offset properly, the loudspeaker can be made ruler flat from 1Khz up even with 1/12 smoothing.

This is very interesting. Could you explain the small waveguide dropping frequency to 2pi transition a bit more? How does a waveguide help?

The waveguide would load the driver down to a lower frequency than the natural ( faceplate mounted ) +/-90 degree directional frequency. The diffracted energy from the speaker corners is the 90+ degrees one, this is why tweeters are pretty flat in the upper range as diffraction plays little role there. Seas have a few tweeters with a small waveguide attached to them. The waveguide is a horn and not exactly a horn, there will be some energy reaching the cabinet corners but it would normally be lower in amplitude than the waveguide beam area. When you go over 180 degrees you`re not in 2pi anymore, this is what I meant ( although it is not entirely correct ).

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Tweeter diffraction on a cabinet