Now clearly as you say there are still pathways for sound to travel between the braces and the parallel sides. No question there. However the only places that allow a direct path for reflections to form between the side panels should be the tiny spaces between the driver cutouts and the drivers

One thing to watch out for with this type of complicated brace structure is something that B&W found with their matrix bracing, it presents an uneven load to the woofer with aluminium cones not liking it at all.

I think that tmuikku was trying to say that standing waves aren't really a big problem in most enclosures if there is the appropriate damping put in place, and that bracing should be designed primarily for increasing stiffness.

I think there are not so much diagonal vibration that needs dampening so 100% diagonal brasings wont stiffen much if Im right. Angling a bit, (maybe there is an optimal angle?) seems sound.

Cheers!

Edit: dont count me as an expert on the matter�� Or anything for THAT matter. Wow In really jugling the English language.

Cheers!

Edit: dont count me as an expert on the matter�� Or anything for THAT matter. Wow In really jugling the English language.

Last edited:

tmuikku, thanks for the reply but sorry, I'm still not getting it.

First let's make sure we agree on the definition of standing waves. Standing waves form when a soundwave is reflected back and forth between 2 parallel surfaces such that each reflected wave is a mirror image of the other and the wavelength of the standing wave will be equal to twice the wavelength of the reflected wave.

Now in case we are each thinking of a different bracing situation, attached is a very simple rendering of the cabinet in question with 2 vertical braces as I suggested in my original post. The 2nd pic shows only the braces from the side with the intent to highlight that the breathing holes in each brace are offset, or in other words that they do not line up in the vertical dimension and therefore will not allow a straight path from 1 side of the cabinet to the other.

Now clearly as you say there are still pathways for sound to travel between the braces and the parallel sides. No question there. However the only places that allow a direct path for reflections to form between the side panels should be the tiny spaces between the driver cutouts and the drivers (in the tweeter's case, the waveguide also) pic 1, top arrow. Otherwise, the side to side reflections and therefore the horizontal standing waves now should only exist between each side wall and the surfaces of each brace including through each hole in 1 brace to the surface of the next brace (middle arrows), as well as between the parallel surfaces between each brace (bottom arrow). Pic 1 doesn't include any horizontal braces but I would add some of those in as well. One could also take it a step further and install the braces at angles so there would be virtually no parallel surfaces at all.

I'm also having a hard time understanding your difficulty accepting the idea that something can perform more than 1 function. Yes, the primary function of bracing should be to solve panel resonance problems but as a secondary function they can also break up the formation of standing waves. Damping material will also most certainly help to prevent the formation of standing waves, but it will also help prevent reflected sound from leaking back through the driver cones, help to diminish the sound transmission through panel walls and thereby also help to attenuate the amplitude of panel vibrations, as well as function to alter the internal volume that a driver will see. Multiple functions in other words.

The same can be said for xo components. A single series inductor can function to compensate for baffle step loss, help to determine the driver roll-off at the xo frequency and with the addition of a parallel capacitor, it can also function to create a deep notch. Designing with something that performs multiple functions just seems like good engineering to me.

If any of the above is incorrect, please let me know.

Hi,

well those braces might actually work to some degree at least because the brace has got some surface area and the wave lengths are relatively short! Have you made comparison with and without? Impedance measurement should show a difference, not sure if it is audible though since acoustically significant obstacle would be about one wavelength in proportion, so twice as big as the distance between the box walls thus not fitting inside the box for the lowest mode (*). If you rotated the braces (or single brace) to be directly behind the driver instead (parallel to the front and back) could make more difference in the impedance plot. Not sure if it would be for better or for worse audibly. I made a test year or two ago and got smoother FR plot with wide and shallow mid enclosure where back wall was as close as possible behind the driver (making the half wave length distance above the crossover frequency) than with a box that was narrower and deeper. I didn't have time to listen the difference which is a bummer, was in a hurry. There might be a 3D pattern that one could use inside the box to mitigate the back wave entirely. There might be some kind of labyrinth as well (many individual resonators, search for KEF meta material tweeter info). I have no idea how to design or simulate one though.

The trade off with all this is in the complexity of course and I'm not sure if it is worth the investment. I haven't done testing with audibility of the internal standing waves but they have been my interest and I'd like to see and hear the difference.

The longest standing waves happen between the longest dimension (top and bottom) though and I'm in the belief that this is the worst offender, at least it is the one that is most in the pass band of all the standing waves if any. On the other hand the side-to-side standing waves are somewhat less problematic than anything else since the driver is in the middle of that dimension preventing the lowest mode (* your brace might work because of this, the brace size is enough for the higher modes between side panels). Hence my thinking: the significant brace should be to help with the longest dimension standing wave, between top and bottom. The first mode is so long though, that you cannot stop it with holes in the brace unless it is a tuned resonator which might work but not sure if it is worth the hustle since the longest mode can be cancelled putting the driver in the middle which is a lot easier to do, set and forget no tuning or calculation. A three way speaker would be another "easy solution". This is out of the scope though, just trying to say it gets very complex quick and stuff have their trade offs. Best to optimize the bracing for the panel stiffness first and foremost. If they help with the standing waves it is a good thing and I don't have any problem with that, I just haven't been able to figure out a meaningful way yet. By meaningful I mean there is a problem, but that is partially solved with stuffing and what is left unsolved cannot be solved by the bracing 😉

Last edited:

And another property of the SW is when the stimulus ceases, the phenomenon still continues: now tell me if this happens inide a closed box like speaker enclosures!?tmuikku, thanks for the reply but sorry, I'm still not getting it.

First let's make sure we agree on the definition of standing waves. Standing waves form when a soundwave is reflected back and forth between 2 parallel surfaces such that each reflected wave is a mirror image of the other and the wavelength of the standing wave will be equal to twice the wavelength of the reflected wave.......................

Well, er, we should define sound...I don't call sound what exists inside an enclosureNow clearly as you say there are still pathways for sound to travel between the braces and the parallel sides. No question there..................

Just see my remarks...as usual the terms SW and sound are used incorrectly..................If any of the above is incorrect, please let me know.

Last edited by a moderator:

One thing to watch out for with this type of complicated brace structure is something that B&W found with their matrix bracing, it presents an uneven load to the woofer with aluminium cones not liking it at all.

That's quite interesting, I hadn't read that before. I went back and re-read what B&W called their Development paper on the 800D and I couldn't find the reference.

Tmuikku, thanks again for the detailed response.

…well those braces might actually work to some degree at least because the brace has got some surface area and the wave lengths are relatively short! Have you made comparison with and without?

No unfortunately. I'm just talking from a theoretical perspective.

The longest standing waves happen between the longest dimension (top and bottom) though and I'm in the belief that this is the worst offender, at least it is the one that is most in the pass band of all the standing waves if any. On the other hand the side-to-side standing waves are somewhat less problematic than anything else since the driver is in the middle of that dimension preventing the lowest mode.

Yes agreed. I probably could have done a better job explaining that my diagram with the vertical braces was just an example and that you'd need to add more horizontal bracing to break up the vertical standing waves too which are probably the bigger problem with this speaker. (More on that in the next post too.)

First I should probably apologize for not taking a closer look at the speaker in question before giving some advice for it. My bad. I dislike when other people do that and I’ve got to admit that I’m guilty of it this time. Having looked at it in a little more detail now, I’ve got some different suggestions:

1. You want to be very careful about keeping the internal volume exactly the same as the original (unless you want to start playing with the port tuning as well). If the original cab’s internal dimensions are about 864mm x 450mm x 550mm, then the gross internal volume will be about 214L. If your revision uses 990mm x 450mm x 470mm instead, then you’re looking at about 204L gross and that is without losing even more volume to curved sides and perhaps more internal bracing to make the curved sides work. So you are looking at a significant volume difference with your proposed cabinet right now which is not a good thing.

2. These are big speakers. They weigh about 75kg each. So adding in a matrix of bracing whose primary purpose is to mitigate panel resonances when this isn’t even necessary despite the fact that it might help with standing waves is just not a good idea. That’s added weight and even more internal mass that will subtract from the internal volume and need to be compensated for with an even bigger cabinet. Just not a good idea. *

3. Same as I mentioned before, the best way to change the front baffle is to increase the length at the bottom under the vents and keep everything else the same. If you want to keep the curved sides and keep the same internal volume, you are going to have to either increase the height some more and/or increase the depth some more. One thing to note about changing the height is that you want to keep the tweeter at about ear height at the listening position which is probably about where it is right now with your proposed change to 990mm. So going another 90mm above that or more probably is another poor idea. So I think to achieve what you want, you are going to have to go with a larger depth than you seem to want to. Welcome to speaker design where conflicting objectives are the norm. 😱

4. So if I was doing this, I could live with about an internal height of somewhere around 1m and then I’d go for more depth than 470mm in order to curve the sides and create enough internal volume as the original at the same time. In terms of making any other changes to the cabinet, I would keep them very minimal. This actually looks like quite a good design.

If I did make any changes, they would be something like the following (do note however that at least 2 people who have built them have no complaints about the original at all, whatever that is worth):

1. This speaker has a very low xo point, like about 650Hz which means you don’t have to work too hard to raise the panel resonance frequencies up very high in order for them to never be excited in the 1st place. That means the panel subdivisions created with bracing don’t have to be as small as with many other speakers. Still, a few of them could be braced just a bit more with the 40mm x 40mm lumber (or 2 by 2’s as we still call them over here) to ensure all the resonance frequencies get up high enough. I would probably add in just a couple of the 2 x 2’s as cross braces on the biggest panels to increase the effectiveness of the bracing as well. For your cab, exactly where and how many would depend on your design.

2. In terms of standing waves, usually the front to back dimensions are the most problematic but as I said before, in the Calpamos with most of the front baffle taken up with the non-parallel surfaces of the woofer and the tweeter and waveguide, I don’t think those are going to be a problem. So if the width and depth dimensions are pretty close to each other it’s kind of moot.

3. Instead, the top to bottom standing waves look to be the most problematic as others have also suggested. In the front of the speaker though, the driver and the waveguide are again going to help prevent some of them from forming so I think the problem will mostly exist in the back 2/3 or so of the speaker. Thus note the positioning of the 1 and only plywood brace in the speaker. You could try adding some stuffing in there but that may alter the port tuning negatively. So I think the simplest solution is to just add a piece of wood internally to the back 2/3 of the bottom and top panels at a small vertical angle so there will no longer actually be parallel top and bottom panels back there for the standing waves to form in the 1st place. If you can visualize what I am talking about, I think it might also help to reverse the horizontal placement of the 2 x 2 bracing on the side panels (and therefore the top and bottom panels as well) to help make this work. Keeping the 1 internal 450mm x 160mm x 18mm horizontal brace perhaps wouldn’t seem to be necessary any more either.

4. In terms of the side to side standing waves, the woofer and waveguide are again breaking some of them up towards the front and if you curve the sides at the back 2/3 of the cabinet both externally and internally this time, that should take care off the problem as well too.

5. I would try those things and then if I still thought that I heard any resonances, then I would start playing around with adding internal stuffing. Note that generally most people are happy with vented enclosures that only have the walls lined and that seems to be the case here.

Hope that helps. Post up any further cabinet diagrams so we can have a look, double check and make any further recommendations.

*Although angling the bracing structures might help with standing waves, you would need a combination of both vertical and horizontal front to back braces, a matrix in other words, to make this kind of thing work. It’s hard enough and time consuming enough to build this kind of structure when all the braces are all at right angles – just for the sheer challenge of cutting and building them properly I wouldn’t even entertain the notion of doing them at some kind of angle.

1. You want to be very careful about keeping the internal volume exactly the same as the original (unless you want to start playing with the port tuning as well). If the original cab’s internal dimensions are about 864mm x 450mm x 550mm, then the gross internal volume will be about 214L. If your revision uses 990mm x 450mm x 470mm instead, then you’re looking at about 204L gross and that is without losing even more volume to curved sides and perhaps more internal bracing to make the curved sides work. So you are looking at a significant volume difference with your proposed cabinet right now which is not a good thing.

2. These are big speakers. They weigh about 75kg each. So adding in a matrix of bracing whose primary purpose is to mitigate panel resonances when this isn’t even necessary despite the fact that it might help with standing waves is just not a good idea. That’s added weight and even more internal mass that will subtract from the internal volume and need to be compensated for with an even bigger cabinet. Just not a good idea. *

3. Same as I mentioned before, the best way to change the front baffle is to increase the length at the bottom under the vents and keep everything else the same. If you want to keep the curved sides and keep the same internal volume, you are going to have to either increase the height some more and/or increase the depth some more. One thing to note about changing the height is that you want to keep the tweeter at about ear height at the listening position which is probably about where it is right now with your proposed change to 990mm. So going another 90mm above that or more probably is another poor idea. So I think to achieve what you want, you are going to have to go with a larger depth than you seem to want to. Welcome to speaker design where conflicting objectives are the norm. 😱

4. So if I was doing this, I could live with about an internal height of somewhere around 1m and then I’d go for more depth than 470mm in order to curve the sides and create enough internal volume as the original at the same time. In terms of making any other changes to the cabinet, I would keep them very minimal. This actually looks like quite a good design.

If I did make any changes, they would be something like the following (do note however that at least 2 people who have built them have no complaints about the original at all, whatever that is worth):

1. This speaker has a very low xo point, like about 650Hz which means you don’t have to work too hard to raise the panel resonance frequencies up very high in order for them to never be excited in the 1st place. That means the panel subdivisions created with bracing don’t have to be as small as with many other speakers. Still, a few of them could be braced just a bit more with the 40mm x 40mm lumber (or 2 by 2’s as we still call them over here) to ensure all the resonance frequencies get up high enough. I would probably add in just a couple of the 2 x 2’s as cross braces on the biggest panels to increase the effectiveness of the bracing as well. For your cab, exactly where and how many would depend on your design.

2. In terms of standing waves, usually the front to back dimensions are the most problematic but as I said before, in the Calpamos with most of the front baffle taken up with the non-parallel surfaces of the woofer and the tweeter and waveguide, I don’t think those are going to be a problem. So if the width and depth dimensions are pretty close to each other it’s kind of moot.

3. Instead, the top to bottom standing waves look to be the most problematic as others have also suggested. In the front of the speaker though, the driver and the waveguide are again going to help prevent some of them from forming so I think the problem will mostly exist in the back 2/3 or so of the speaker. Thus note the positioning of the 1 and only plywood brace in the speaker. You could try adding some stuffing in there but that may alter the port tuning negatively. So I think the simplest solution is to just add a piece of wood internally to the back 2/3 of the bottom and top panels at a small vertical angle so there will no longer actually be parallel top and bottom panels back there for the standing waves to form in the 1st place. If you can visualize what I am talking about, I think it might also help to reverse the horizontal placement of the 2 x 2 bracing on the side panels (and therefore the top and bottom panels as well) to help make this work. Keeping the 1 internal 450mm x 160mm x 18mm horizontal brace perhaps wouldn’t seem to be necessary any more either.

4. In terms of the side to side standing waves, the woofer and waveguide are again breaking some of them up towards the front and if you curve the sides at the back 2/3 of the cabinet both externally and internally this time, that should take care off the problem as well too.

5. I would try those things and then if I still thought that I heard any resonances, then I would start playing around with adding internal stuffing. Note that generally most people are happy with vented enclosures that only have the walls lined and that seems to be the case here.

Hope that helps. Post up any further cabinet diagrams so we can have a look, double check and make any further recommendations.

*Although angling the bracing structures might help with standing waves, you would need a combination of both vertical and horizontal front to back braces, a matrix in other words, to make this kind of thing work. It’s hard enough and time consuming enough to build this kind of structure when all the braces are all at right angles – just for the sheer challenge of cutting and building them properly I wouldn’t even entertain the notion of doing them at some kind of angle.

I have seen it mentioned in a few places and some of them in B&W information (which of course I can no longer remember where I found it from 😉) There is mention of it in this audioxpress articleThat's quite interesting, I hadn't read that before. I went back and re-read what B&W called their Development paper on the 800D and I couldn't find the reference.

Speaker Design: Driver-Induced Vibrations | audioXpress

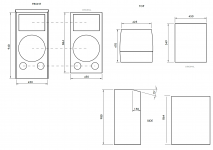

After all your comments, I'm thinking of something like this.

Original gross volume is 213 liter, mine is 206. Original design has 18L worth of bracing. I'll probably have less, or I'll add another centimeter (or two) to the bottom (height).

Baffle is exactly the same, except the extra 7.5cm added to the bottom.

Only thing that might not be ideal is the square-ish profile. width:depth ratio is around 1:1.06 but front to back standing waves shouldn't be too big a problem due to the front baffle being almost all driver and horn.

Any comments?

Now I have to make up my mind, build something like this or wait for the Mezzo Calpamos, a smaller 12 inch version of this design that could be released any time soon, or could take another year, who knows 🙄

Original gross volume is 213 liter, mine is 206. Original design has 18L worth of bracing. I'll probably have less, or I'll add another centimeter (or two) to the bottom (height).

Baffle is exactly the same, except the extra 7.5cm added to the bottom.

Only thing that might not be ideal is the square-ish profile. width:depth ratio is around 1:1.06 but front to back standing waves shouldn't be too big a problem due to the front baffle being almost all driver and horn.

Any comments?

Now I have to make up my mind, build something like this or wait for the Mezzo Calpamos, a smaller 12 inch version of this design that could be released any time soon, or could take another year, who knows 🙄

Attachments

Looks workable.

I think you'll need to keep all the 40 x 40mm lumber in the corners for structural integrity though. I'd keep the 1 on the front baffle too. If you remove the rest of the bracing though it'll be panel resonance behavior that you need to worry about more than standing waves now I think. In effect the cabinet will be functioning more like what the BBC does for their panel resonances which is to not use bracing but lots of damping on thinner walled panels in order to keep the panel resonances quite low in frequency instead of trying to push them up high.

For structural purposes with a cab this large I wouldn't go with thinner panels though and you don't need to anyways because the panels are so large that the resonances are low enough to start off with. The problem is that your side and back panels are all almost the exact same size now so all of them will have about the same resonant frequencies without bracing. Although the resonances will be perceived as less audible because they are so low in frequency and because the damping will reduce their amplitude, 3 of the panels doing the same thing might add up to something undesirable.

What to do? If you ditch all the panel bracing I would still keep what the Calpamos did on the back panel which is glue the driver cutout to the back panel. That will raise the resonance frequency a bit so it's different than the side panels but still not too high. Then apply the damping material like the original. Or alternatively maybe keep the single brace on the back panel.

If your net volume does end up a little lower than the original, in that case adding in some stuffing to the back half of the speaker may be a good idea as it will increase the effective volume of your cabinet just a little and it will also help with the standing waves back there too, both vertical and side to side. Make sure to leave the back of the driver and the back of the ports clear.

I think you'll need to keep all the 40 x 40mm lumber in the corners for structural integrity though. I'd keep the 1 on the front baffle too. If you remove the rest of the bracing though it'll be panel resonance behavior that you need to worry about more than standing waves now I think. In effect the cabinet will be functioning more like what the BBC does for their panel resonances which is to not use bracing but lots of damping on thinner walled panels in order to keep the panel resonances quite low in frequency instead of trying to push them up high.

For structural purposes with a cab this large I wouldn't go with thinner panels though and you don't need to anyways because the panels are so large that the resonances are low enough to start off with. The problem is that your side and back panels are all almost the exact same size now so all of them will have about the same resonant frequencies without bracing. Although the resonances will be perceived as less audible because they are so low in frequency and because the damping will reduce their amplitude, 3 of the panels doing the same thing might add up to something undesirable.

What to do? If you ditch all the panel bracing I would still keep what the Calpamos did on the back panel which is glue the driver cutout to the back panel. That will raise the resonance frequency a bit so it's different than the side panels but still not too high. Then apply the damping material like the original. Or alternatively maybe keep the single brace on the back panel.

If your net volume does end up a little lower than the original, in that case adding in some stuffing to the back half of the speaker may be a good idea as it will increase the effective volume of your cabinet just a little and it will also help with the standing waves back there too, both vertical and side to side. Make sure to leave the back of the driver and the back of the ports clear.

- Home

- Loudspeakers

- Multi-Way

- Tweaking cabinet shape - form over function or acceptable?