While I'm eagerly waiting for the customized SL-1210MK2 to arrive and external power supply is nearly ready I apparently have too much time to think other stuff. So, platter.

We know that the platter it self in SL-1200's are "light" to put it mildly, and they do "ring" quite a lot. I would not like to have a thick (and ugly) rubber or APM or anything like that on the platter so I was thinking, why not put the dampening on the underside? There's for example bitum- or polyuretan-mats designed to reduce high-frequencies in panels and olaso reduce vibrations.

Any thoughts?

We know that the platter it self in SL-1200's are "light" to put it mildly, and they do "ring" quite a lot. I would not like to have a thick (and ugly) rubber or APM or anything like that on the platter so I was thinking, why not put the dampening on the underside? There's for example bitum- or polyuretan-mats designed to reduce high-frequencies in panels and olaso reduce vibrations.

Any thoughts?

You'll have to be careful to not unbalance the platter. The extra weight should be very uniform.

A heavier or more absorbent record mat on top could also help at the same time.

A heavier or more absorbent record mat on top could also help at the same time.

While I'm eagerly waiting for the customized SL-1210MK2 to arrive and external power supply is nearly ready I apparently have too much time to think other stuff. So, platter.

We know that the platter it self in SL-1200's are "light" to put it mildly, and they do "ring" quite a lot. I would not like to have a thick (and ugly) rubber or APM or anything like that on the platter so I was thinking, why not put the dampening on the underside? There's for example bitum- or polyuretan-mats designed to reduce high-frequencies in panels and olaso reduce vibrations.

Any thoughts?

You truly believe that japanese designes would never thought of that?

I believe you are about to destroy your turntable.

Last edited by a moderator:

I think you'll find the SL1210 platter already has damping material under the platter. If it's anything like the SP10km2 the damping material will be ineffective due to age and not being bonded over its whole surface. Others have reported good results removing the OEM damping and adding Dynamat to the underside of the platter.

This is one of my SP10mk2 platters the other platter has had the damping rubber removed and POM bolted to the top of the platter. There is a significant improvement in SQ with the POM platter.

This is one of my SP10mk2 platters the other platter has had the damping rubber removed and POM bolted to the top of the platter. There is a significant improvement in SQ with the POM platter.

A large sheet (to the inside rim) of Sorbothane perhaps 1/8" thick, and cut carefully, also allowing the centeral area clear for the DD motor might aid in stopping the ringing effect.You'll have to be careful to not unbalance the platter. The extra weight should be very uniform.

A heavier or more absorbent record mat on top could also help at the same time.

It could be carefully bonded to the platter with spray adhesive like 3M "200".

Even a thin rubber slipmat will damp strongly compared to bare metal, and even better with a disc on top.

If you don't need slip, of the best mats I have come across for damping and decoupling the record from platter noise is Herbie's Audio Labs Way Excellent II turntable mat, available in a multitude of diameters and thicknesses for virtually any turntable platter and tonearm VTA offset.

Way Excellent II Turntable Mat

Way Excellent II Turntable Mat

Thanks for the comments, both for and against 🙂

There's always people who will say "you ruined the original deck", but my deck is far from original anyway so let's toss that out of window. Now, what comes to platters original rubber, as said here too it's rarely glued on the whole surface and I honestly wonder what it's true dampening effect is after 20 years in various conditions? I'm quite sure new material will do a better job at it. Those I found who have done are talking about good success. Balancing is not an issue with good planning, measuring and cutting. And. of course, some balancing 🙂

We'll see how it goes, also some comparison will be nice to do 🙂

There's always people who will say "you ruined the original deck", but my deck is far from original anyway so let's toss that out of window. Now, what comes to platters original rubber, as said here too it's rarely glued on the whole surface and I honestly wonder what it's true dampening effect is after 20 years in various conditions? I'm quite sure new material will do a better job at it. Those I found who have done are talking about good success. Balancing is not an issue with good planning, measuring and cutting. And. of course, some balancing 🙂

We'll see how it goes, also some comparison will be nice to do 🙂

If you balance it, I think you should be able to do whatever you like, assuming you don‘t add an inordinate amount of mass to the point that the motor is struggling against it.

For what it’s worth, I’ve done most of the various mods to the SL-1200 including platter damping… the biggest positive changes are PSU, changing the feet, changing the platter mat to Acromat/Herbie’s/cork, and rewiring the internal tonearm wire if it’s a Mk2 due to the corrosion issues. Everything else does little to nothing.

For what it’s worth, I’ve done most of the various mods to the SL-1200 including platter damping… the biggest positive changes are PSU, changing the feet, changing the platter mat to Acromat/Herbie’s/cork, and rewiring the internal tonearm wire if it’s a Mk2 due to the corrosion issues. Everything else does little to nothing.

Damping is a delicate art. Very easy to overdo it. Seen this happen, so rather use materials that make it easy to reverse if you end up hating the sound.

There is an simple method to auralise the actual effect of platter ringing on the sound reproduced by a pickup cartridge. With the platter in place remove the mat and use your knuckle or a soft mallet to hit the platter and make it ring. Try to remember or 'learn' the character of this sound. Replace the platter mat and play recordings of instruments that have quasi-impulsive waveforms (anything percussive, including piano - hammers that hit strings). This will reveal platter ringing because the unique character of the platter's sound in the decay of the stimulus notes is unmasked. Adding damping to the platter reduces the amount of the platters innate acoustic character that crosstalks into the reproduced audio.

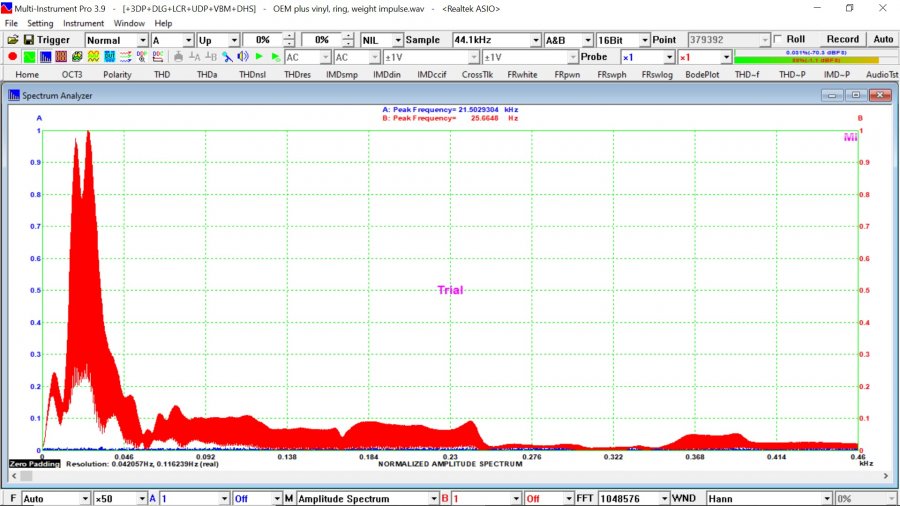

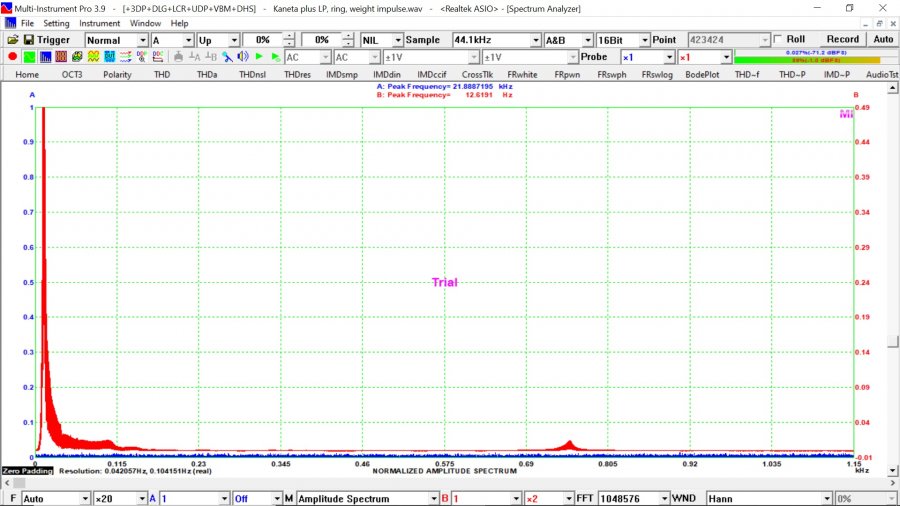

These are impulse tests of an SP10mk2. Test was done with an old LP on the platter with the stylus resting on the stationary LP and marble dropped from 300mm above the LP.

IMO you can't over damp a TT when we are talking about vibration damping. Any unwanted excitation will smear the signal. What these tests and my experimentation with various platters for the SP10 show is as platter thickness increases, specifically the POMC SQ improves. POMC has similar acoustic Z to rigid vinyl so coupling the LP the POMC platter increases the platters ability to sink stylus/LP interface vibrations away from the stylus. The thicker POMC provides greater vibration attenuation before the wave hits the bottom of the platter and is reflected back to the LP.

All changing the mat will do is to change the spectrum of the reflected vibration energy, changing spectrum where the colouration is.

The first is the OEM platter / mat and the second is a stainless steel platter with 16mm POMC bolted to the top.

IMO you can't over damp a TT when we are talking about vibration damping. Any unwanted excitation will smear the signal. What these tests and my experimentation with various platters for the SP10 show is as platter thickness increases, specifically the POMC SQ improves. POMC has similar acoustic Z to rigid vinyl so coupling the LP the POMC platter increases the platters ability to sink stylus/LP interface vibrations away from the stylus. The thicker POMC provides greater vibration attenuation before the wave hits the bottom of the platter and is reflected back to the LP.

All changing the mat will do is to change the spectrum of the reflected vibration energy, changing spectrum where the colouration is.

The first is the OEM platter / mat and the second is a stainless steel platter with 16mm POMC bolted to the top.

Interesting measurements, thanks for sharing. Some people seem to like the sound of their records with condiments on top - go figure.These are impulse tests of an SP10mk2. Test was done with an old LP on the platter with the stylus resting on the stationary LP and marble dropped from 300mm above the LP.

IMO you can't over damp a TT when we are talking about vibration damping. Any unwanted excitation will smear the signal.

No problem, Bon and I did a lot of R&D on SP10 platters to improve the TT. What we found was POMC (Acetal) in thicknesses of at least 20mm ontop of the platter improved the micro detail in the music significantly. The impulse response confirms what we both heard.

The issue with damping a platter is what frequencies are you damping with different platter mats. Most mats damp a narrow frequency band at higher frequencies than most of the noise. If said mat is very narrow in its damping (high Q) then at what F is this Q, without measurements it's a hit and miss affair.

Caveat - Some colouration depending on the spectrum can be pleasing to the ear.

The issue with damping a platter is what frequencies are you damping with different platter mats. Most mats damp a narrow frequency band at higher frequencies than most of the noise. If said mat is very narrow in its damping (high Q) then at what F is this Q, without measurements it's a hit and miss affair.

Caveat - Some colouration depending on the spectrum can be pleasing to the ear.

Warrjon, thanks for visualizing what I suspected 🙂 I had measurements exactly like that in mind too, should be fun to do!

No need to glue it on at all for damping, and unless its gone rigid it will have damping properties. You can revitalize old rubber in a simple process with boiling water and glycerine: https://sciencing.com/restore-natural-rubber-products-7593605.htmlas said here too it's rarely glued on the whole surface and I honestly wonder what it's true dampening effect is after 20 years in various conditions?

I honestly have no desire to start cooking glycerine (or use ammonia) in my apartment, thanks for the tip tho, will save that for later. Sometimes I miss a fully separate work-room :/

I've only used it on a small scale for tired old motor-mount bushings, can be done in a coffee mug (remember to rinse thoroughly afterwards!).

You don't heat the glycerine, only need a kettle for the water. I'd definitely avoid the ammonia technique 🙂

You don't heat the glycerine, only need a kettle for the water. I'd definitely avoid the ammonia technique 🙂

Oil of Wintergreen .. Works Well.. period.I've only used it on a small scale for tired old motor-mount bushings, can be done in a coffee mug (remember to rinse thoroughly afterwards!).

You don't heat the glycerine, only need a kettle for the water. I'd definitely avoid the ammonia technique 🙂

Been using it for years to soften age and even heat hardened rubber bits.

Only downside being it has a lingering smell of erm .. 'Wintergreen' for a few days a week.

Paint it on.. let dry.. overnite at least .. as the process takes time/continues for a couple of days,

even a week in some cases. It's a gradual but steady process.

Then evaluate as to whether another or More applications are needed.

G'luck

- Home

- Source & Line

- Analogue Source

- Turntable platter dampening?