It is all very cool and interesting, but where we -- average mortals can get those mats 🙂 Thanks for sharing though!No problem, Bon and I did a lot of R&D on SP10 platters to improve the TT. What we found was POMC (Acetal) in thicknesses of at least 20mm ontop of the platter improved the micro detail in the music significantly. The impulse response confirms what we both heard.

The issue with damping a platter is what frequencies are you damping with different platter mats. Most mats damp a narrow frequency band at higher frequencies than most of the noise. If said mat is very narrow in its damping (high Q) then at what F is this Q, without measurements it's a hit and miss affair.

Caveat - Some colouration depending on the spectrum can be pleasing to the ear.

Damping is relative to a resonance. Platters typically lack any resonances at very low frequencies, so you can't damp them. These low frequencies are typically the domain of arm/cartridge and deck suspension resonances. The platter simply isn't involved.

A very thick mat will alter the mass of the whole suspended deck and change its resonant frequency, but it won't damp it per se.

A very thick mat will alter the mass of the whole suspended deck and change its resonant frequency, but it won't damp it per se.

I was not talking about frequencies that low. A stock SP10mk2 platter resonates at about 25Hz, look at the spectrum plot on page 1, no platter mat will damp this effectively.Damping is relative to a resonance. Platters typically lack any resonances at very low frequencies, so you can't damp them. These low frequencies are typically the domain of arm/cartridge and deck suspension resonances. The platter simply isn't involved.

A very thick mat will alter the mass of the whole suspended deck and change its resonant frequency, but it won't damp it per se.

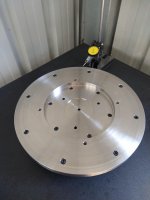

What I did is NOT a mat. I bolted 20mm POMC to the top of a stock platter. I have found if the POM is not fixed to the platter it eventually warps because I made them from 20mm sheet. Round 300mm OD POM $1000AUD a meter, where as 300x300x20mm sheet is about $200AUDIt is all very cool and interesting, but where we -- average mortals can get those mats 🙂 Thanks for sharing though!

If you had a local machine shop that could do the job at a reasonable price it would be worth the effort.

That's a bit too much platter-mod for me. I have some nostalgic-aspect in this too, SL-1210Mk2 still needs to be "Dj" so original platter with slipmat is something I'm not giving up at least yet. So no 20mm "on top disc's" for me.

It can be a concern thinking about taking part in producing the modifications that can be discovered being carried out on a DD TT's Platter.

After a period of time pondering the work undertaken by Warrjon, from considering having a SS Platter produced, also having an owned Gunmetal Platter offered as a donor platter which is to be modified to work with the SP10 MkII.

The method of the Mechanically Fastened Acetal Plates to the original platter is initially the most appealing and I have opted to go for the Acetal Plates as the first experience of a modified platter to be encountered.

Fortunately an individual referred to below has access to a vast quantity of Thermoplastic sheets and State of the Art CNC Cutting Methods.

I was not content with the idea of working with the originally owned SP10 MkII Platter due to the need to bore additional holes into it, and after a period of time I have managed to acquire 3 X Spare SP10 MkII Platters.

This has been quite beneficial as a I have farmed 2 Platters out to Two Individuals, who are both capable at machining materials, and both work with the SP10 MkII with the intention for betterment, hopefully my donor platters will enable them to see if there are other materials/methods along with Acetal that can make a good impression.

I would like to think that methods developed can be extended in there use and be attached to the donor Gun Metal Platter.

At present all outlays for the Donor Platters are mine, and from this point I am dependant on a support from others to take these investigations forward to produce a Modified Platter.

Working with Thermoplastics should not increase the costs by a noticeable margin to the availability of Off Cut Materials suitable for the production of a Platter Mat , other materials/methods beyond the use of Thermoplastics, may incur further costs, but as there has already been monies spent by others on these investigations, I am happy to feel obliged to reciprocate this.

These upcoming trials, I do not see undergoing any measurements to confirm their dampening capabilities.

There will be as the minimum, an offer to broadening the experiences for a Local HiFi Enthusiast Group and when the meet takes place, it should prove to show audible differences are able to be achieved using different assemblies of mechanically fastened materials on a Platter.

For the OP, there are other methods that can be considered to create a perception that the SQ is being improved as a result of working with the Platter.

Within the Local HiFi Group, it has been shown before on a variety of occasions, by having a selection of Platter Mats demonstrated on owned TT's within the Group, ranging from Metal, Ceramic, Foam, Rubber.

Platter Mats will show quite noticeable differences when compared to each other and it is also a outcome that a Single Type Mat does not show as the most attractive on different TT's set up in different environments and mounting methods.

Working with TT Mounting Methods and Platter Mats Materials can create a very positive impression on the perceived SQ.

During the Local Groups meetings the Original Platter > Modified Platters on a SP10 MkII, will be assessed at the time of the comparison demonstrations, it would be of interest to see the outcome of a groups thoughts and the impressions made.

After a period of time pondering the work undertaken by Warrjon, from considering having a SS Platter produced, also having an owned Gunmetal Platter offered as a donor platter which is to be modified to work with the SP10 MkII.

The method of the Mechanically Fastened Acetal Plates to the original platter is initially the most appealing and I have opted to go for the Acetal Plates as the first experience of a modified platter to be encountered.

Fortunately an individual referred to below has access to a vast quantity of Thermoplastic sheets and State of the Art CNC Cutting Methods.

I was not content with the idea of working with the originally owned SP10 MkII Platter due to the need to bore additional holes into it, and after a period of time I have managed to acquire 3 X Spare SP10 MkII Platters.

This has been quite beneficial as a I have farmed 2 Platters out to Two Individuals, who are both capable at machining materials, and both work with the SP10 MkII with the intention for betterment, hopefully my donor platters will enable them to see if there are other materials/methods along with Acetal that can make a good impression.

I would like to think that methods developed can be extended in there use and be attached to the donor Gun Metal Platter.

At present all outlays for the Donor Platters are mine, and from this point I am dependant on a support from others to take these investigations forward to produce a Modified Platter.

Working with Thermoplastics should not increase the costs by a noticeable margin to the availability of Off Cut Materials suitable for the production of a Platter Mat , other materials/methods beyond the use of Thermoplastics, may incur further costs, but as there has already been monies spent by others on these investigations, I am happy to feel obliged to reciprocate this.

These upcoming trials, I do not see undergoing any measurements to confirm their dampening capabilities.

There will be as the minimum, an offer to broadening the experiences for a Local HiFi Enthusiast Group and when the meet takes place, it should prove to show audible differences are able to be achieved using different assemblies of mechanically fastened materials on a Platter.

For the OP, there are other methods that can be considered to create a perception that the SQ is being improved as a result of working with the Platter.

Within the Local HiFi Group, it has been shown before on a variety of occasions, by having a selection of Platter Mats demonstrated on owned TT's within the Group, ranging from Metal, Ceramic, Foam, Rubber.

Platter Mats will show quite noticeable differences when compared to each other and it is also a outcome that a Single Type Mat does not show as the most attractive on different TT's set up in different environments and mounting methods.

Working with TT Mounting Methods and Platter Mats Materials can create a very positive impression on the perceived SQ.

During the Local Groups meetings the Original Platter > Modified Platters on a SP10 MkII, will be assessed at the time of the comparison demonstrations, it would be of interest to see the outcome of a groups thoughts and the impressions made.

Whyever not? Most loss mechanisms work all the way down to "DC", be it visco-elastic or solid friction, since there is an underlying hysteresis phenomenon leading to lost energy per deformation cycle.I was not talking about frequencies that low. A stock SP10mk2 platter resonates at about 25Hz, look at the spectrum plot on page 1, no platter mat will damp this effectively.

Consider equal energy vibrations at different frequencies/modes - they will have similar velocities as kinetic energy must be the same, thus displacement amplitude will be greater for the lower frequency, and per-cycle hysteresis losses increase with displacement amplitude in most situations. So the fact there are fewer cycles per second can be compensated for by the larger displacements increasing the loss per cycle.

@ warrjon, how did you accommodate the extra 20mm of required arm height and how might that change in arm mounting affect the measurements?

Also consider that 10 drops of oil of wintergreen is about equivalent to an Aspirin tablet - If you feel better while you use it, you'll know why 😀

FWIW: I "tested" (not scientifically, just listening to the sound the platter makes when you hit the edge with a screwdriver)...

The naked platter rings like a bell as expected.

The stock rubber mat eliminates the ringing.

A 3mm silicon mat damped the sound but was not as good as the stock rubber mat.

A 3mm acrylic mat eliminated the ringing and almost the resonance, too.

So I settled on the acrylic one - and it has a scope and protractor on it.

https://www.amazon.ca/Turntable-Pro...75d960&pd_rd_wg=uAanN&pd_rd_i=B01MU6AD2E&th=1

The turntable is a Toshiba SR255.

FWIW: I "tested" (not scientifically, just listening to the sound the platter makes when you hit the edge with a screwdriver)...

The naked platter rings like a bell as expected.

The stock rubber mat eliminates the ringing.

A 3mm silicon mat damped the sound but was not as good as the stock rubber mat.

A 3mm acrylic mat eliminated the ringing and almost the resonance, too.

So I settled on the acrylic one - and it has a scope and protractor on it.

https://www.amazon.ca/Turntable-Pro...75d960&pd_rd_wg=uAanN&pd_rd_i=B01MU6AD2E&th=1

The turntable is a Toshiba SR255.

Last edited:

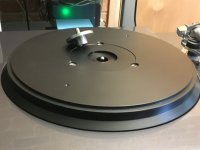

20mm height adjustment is well within the range of most tonearms. This is how the platter warrjon built for me looks.@ warrjon, how did you accommodate the extra 20mm of required arm height and how might that change in arm mounting affect the measurements?

It has since been superseded by a 40mm POM/Gunmetal version that is superior but requires more intricate machining. Fitting a plain POM disc on top of a stock aluminium platter is much easier to achieve and very effective.

Attachments

I used the old original Sorbothane mat on my Thorens. It was only slightly thicker than the OEM rubber mat.

A layer or two of Dynamat on the underside if cut to fit well so as to be very even would probably work and keep the OEM mat. It will lower the resonant frequency and widen the Q. It does NOT absorb sound.

The biggest improvement is a cabinet to stop acoustic feedback in the first place. Most extreme one I ever saw was an old chest freezer and the table was suspended on bungi cords inside. I try to remember not to drop marbles on my record while paying. 😛

Back in olden times they used to sell "platen restorer" for typewriters. Worked pretty well.

A layer or two of Dynamat on the underside if cut to fit well so as to be very even would probably work and keep the OEM mat. It will lower the resonant frequency and widen the Q. It does NOT absorb sound.

The biggest improvement is a cabinet to stop acoustic feedback in the first place. Most extreme one I ever saw was an old chest freezer and the table was suspended on bungi cords inside. I try to remember not to drop marbles on my record while paying. 😛

Back in olden times they used to sell "platen restorer" for typewriters. Worked pretty well.

I believe I qualify as a turntable mat obsessive. The small selection shown are:

Technics SP10 mk2 OEM, 6mm rubber

Thorens 125 mk2, 6mm rubber

Platter Matter, 6mm Sorbothane

Boston Audio, 5mm Carbon Graphite

TTWeights Ultimat, 6mm SS/Carbon Fibre

TTWeights Ultimat, 6mm Copper/Carbon Fibre

DIY cork/rubber

Technics OEM 3mm rubber (similar to SL1200)

Technics SP10 mk2 rubber platter damping pads

I have used an SP10 mk2 in modified guise, almost daily for over 2 decades. Quite early on, I found that it sounded different depending on what the LP was sitting on. I never liked the grooved OEM mat. The large channels are purely there to facilitate removal/placement of 10" and 7" discs. Also, in many of the samples I have encountered. the rubber OEM mat and under platter damping has stiffened greatly and even cracked. The Thorens 125 mk2 mat was an improvement and fit the platter recess almost perfectly after a small outer lip was trimmed. I realise the OP is concerned with the SL1200 but my experience is that underneath platter damping does not effectively eliminate platter ringing, which is primarily due to material selection and manufacturing compromises.

Technics SP10 mk2 OEM, 6mm rubber

Thorens 125 mk2, 6mm rubber

Platter Matter, 6mm Sorbothane

Boston Audio, 5mm Carbon Graphite

TTWeights Ultimat, 6mm SS/Carbon Fibre

TTWeights Ultimat, 6mm Copper/Carbon Fibre

DIY cork/rubber

Technics OEM 3mm rubber (similar to SL1200)

Technics SP10 mk2 rubber platter damping pads

I have used an SP10 mk2 in modified guise, almost daily for over 2 decades. Quite early on, I found that it sounded different depending on what the LP was sitting on. I never liked the grooved OEM mat. The large channels are purely there to facilitate removal/placement of 10" and 7" discs. Also, in many of the samples I have encountered. the rubber OEM mat and under platter damping has stiffened greatly and even cracked. The Thorens 125 mk2 mat was an improvement and fit the platter recess almost perfectly after a small outer lip was trimmed. I realise the OP is concerned with the SL1200 but my experience is that underneath platter damping does not effectively eliminate platter ringing, which is primarily due to material selection and manufacturing compromises.

Attachments

I share a similar experience as Bon has in relation to Platter Mats and the use of Spindle Puck Weights.

The Platter Mats used to assess changes made to the TT are a Gun Metal Tenuto, Technihard AT 677, Ceramic 600, Foams of varying thickness, Rubber and Sony's Liquid Filled Rubber Mat.

Rubber has not been an attractor, but all others can produce a attractive presentation, foam needs to be a correct thickness or smearing can be detected.

Weights are the same use differing Weights on the Spindle with the Mat Materials and slight perceptions of resolving of the details can be detected, this is not a deal breaker when the chosen mat is noticeable for the performance it can offer.

I am tempted to add a periphery ring as this is a experience I have not had in the home system.

Out of all the above trials undertaken, not one has had the impact that the mounting of the TT had when believed to have been prepared for correctly, this was an improvement beyond my imagination for the outcome.

Finding the correct method for mounting in the listening environment is a challenge, but very much worth the time taken and exchanges of materials used as support during the discovery process.

The Platter Mats used to assess changes made to the TT are a Gun Metal Tenuto, Technihard AT 677, Ceramic 600, Foams of varying thickness, Rubber and Sony's Liquid Filled Rubber Mat.

Rubber has not been an attractor, but all others can produce a attractive presentation, foam needs to be a correct thickness or smearing can be detected.

Weights are the same use differing Weights on the Spindle with the Mat Materials and slight perceptions of resolving of the details can be detected, this is not a deal breaker when the chosen mat is noticeable for the performance it can offer.

I am tempted to add a periphery ring as this is a experience I have not had in the home system.

Out of all the above trials undertaken, not one has had the impact that the mounting of the TT had when believed to have been prepared for correctly, this was an improvement beyond my imagination for the outcome.

Finding the correct method for mounting in the listening environment is a challenge, but very much worth the time taken and exchanges of materials used as support during the discovery process.

- Home

- Source & Line

- Analogue Source

- Turntable platter dampening?