If the mass of any o-ring or whatever added widget is significant relative to the mass of the valve, then the total mass increase can be a reason for reduced acceleration of the valve mass by an outside influence, given the compliance of the mounting has a low natural resonance with the valve mass.

External vibrations can cause both the glass envelope and the internal electrodes to resonate at their own specific natural frequencies, the analysis of which requires the application of the physics of simple harmonic motion (SHM).

Depending on the exact mechanism of the SHM, the mass may, or may not, affect the frequency of resonance.

If damping of the glass envelope is light then it will respond sharply, with large amplitude, to external vibrations which coincide with its resonant frequency, but will reject vibrations outside of a narrow band around this frequency.

If damping is large then the amplitude of the oscillations at resonance will decrease, but the resonant effect will happen over a wider range of external frequencies.

It may be a case of swings and roundabouts as far as the use of tube dampers is concerned.

Some points:

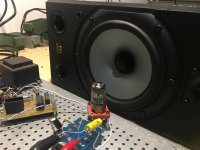

- The test set up was found after some check. The main goal is to isolate the valve from vibration comes from table, mechanical stuff as rigid cables form test board to socket, etc. This was done because I put a two way speaker (Monitor Audio) directly pointed to the tube and installed on my table:

Foto_10

In this situation with a sweep from 20 Hz to 10 kHz nothing happen on a low range frequency while at high frequency the results are comparable with the one obtained with Fostex .

The vibration to the tubes comes in two way, first trough the mechanical stuff as rack, foot of the equip and metal box; second by the air with the sound pressure.

So the first thing to do is to eliminate ( as much as possible) the mechanical way.

The reviews from Mullard are the only one that I take as reference for one simple reason because some test results are shown and this must be the only way to speak about the facts.

Of course I haven't the beautiful equipments they used but with some time to spent and the AP Sys1 and 2 is possible to have a reasonable test set.

The article on Audioreview contain a good number of photo and diagram and I can't now pot it because the magazine is now on newsstand; I will ask to th Mega-director (my friend Mauro Neri) to have the possibility to put in a future a link here. It is in Italian language but some translation can be done.

Regarding the O-ring the effect is very good: the E88CC Siemens is very good tube well made ( as normally for thr Nos) but a little bit microphonic so the test tell us that an improvement is obtained.

It is an improvement and not a solution because, in my opinion, the limits of the quality of the mechanical costruction are always present and, in every case, a metal structure has a proper vibrational charatheristic.

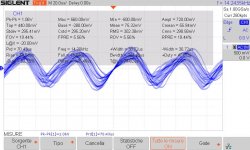

In Figura_15 there is a capture from a scope of a spurious signal at the output of the test circuit with a 6H23 russian with a single point getter; I sent a 1 w / 14.600 Hz signal to Fostex, this frequency is resonance seen on Test_B9 (Trobbins was fine, was my typing error!!!)

Is possible to see a signal with an amplitude and seem to be instable.

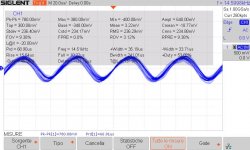

On Figura_16 the same with the O-ring installed, the signal is more clear but the amplitude is lower. peak to peak from 1,06 volt to 780mV

I teste the same type with two different getter, one fix point and two fix point; the results are better for the two fix point.

On the Mullard tests there was a results with a tube with two different getter fixed in different mode

The better result is with the getter fixed stronger.

to Trobbins

I test at 1 watt with Fostex just because this loudspeaker can't handle more power; in my opinion this is fine because the main goal is to understand what happen. In future will be possible to check.

I have also test with a can installed on McMurdo socket, I haven't found great changes; the impression is that was worst but I haven't spent lot of time.

Interesting is the use of the teflon strip ( same used by plumber) but the O-ring are better

Last thing is about the O-ring; the vibrational mode of the glass is different for each type of glass used, of course; in my test I used three types ( + 1 a PCC88 Tesla) and the results is the same so the issue is common ( other test on different types will come). The ring allow the glass to stop ( or almost stop) these vibrations so, consequently, the mics are attenuate.

Walter

- The test set up was found after some check. The main goal is to isolate the valve from vibration comes from table, mechanical stuff as rigid cables form test board to socket, etc. This was done because I put a two way speaker (Monitor Audio) directly pointed to the tube and installed on my table:

Foto_10

In this situation with a sweep from 20 Hz to 10 kHz nothing happen on a low range frequency while at high frequency the results are comparable with the one obtained with Fostex .

The vibration to the tubes comes in two way, first trough the mechanical stuff as rack, foot of the equip and metal box; second by the air with the sound pressure.

So the first thing to do is to eliminate ( as much as possible) the mechanical way.

The reviews from Mullard are the only one that I take as reference for one simple reason because some test results are shown and this must be the only way to speak about the facts.

Of course I haven't the beautiful equipments they used but with some time to spent and the AP Sys1 and 2 is possible to have a reasonable test set.

The article on Audioreview contain a good number of photo and diagram and I can't now pot it because the magazine is now on newsstand; I will ask to th Mega-director (my friend Mauro Neri) to have the possibility to put in a future a link here. It is in Italian language but some translation can be done.

Regarding the O-ring the effect is very good: the E88CC Siemens is very good tube well made ( as normally for thr Nos) but a little bit microphonic so the test tell us that an improvement is obtained.

It is an improvement and not a solution because, in my opinion, the limits of the quality of the mechanical costruction are always present and, in every case, a metal structure has a proper vibrational charatheristic.

In Figura_15 there is a capture from a scope of a spurious signal at the output of the test circuit with a 6H23 russian with a single point getter; I sent a 1 w / 14.600 Hz signal to Fostex, this frequency is resonance seen on Test_B9 (Trobbins was fine, was my typing error!!!)

Is possible to see a signal with an amplitude and seem to be instable.

On Figura_16 the same with the O-ring installed, the signal is more clear but the amplitude is lower. peak to peak from 1,06 volt to 780mV

I teste the same type with two different getter, one fix point and two fix point; the results are better for the two fix point.

On the Mullard tests there was a results with a tube with two different getter fixed in different mode

The better result is with the getter fixed stronger.

to Trobbins

I test at 1 watt with Fostex just because this loudspeaker can't handle more power; in my opinion this is fine because the main goal is to understand what happen. In future will be possible to check.

I have also test with a can installed on McMurdo socket, I haven't found great changes; the impression is that was worst but I haven't spent lot of time.

Interesting is the use of the teflon strip ( same used by plumber) but the O-ring are better

Last thing is about the O-ring; the vibrational mode of the glass is different for each type of glass used, of course; in my test I used three types ( + 1 a PCC88 Tesla) and the results is the same so the issue is common ( other test on different types will come). The ring allow the glass to stop ( or almost stop) these vibrations so, consequently, the mics are attenuate.

Walter

Attachments

Walter,

You may want to consider also using a software tool such as REW with a suitable soundcard and perform sweep measurements with waterfall processing - that may provide more insight on the resonances.

Tim

You may want to consider also using a software tool such as REW with a suitable soundcard and perform sweep measurements with waterfall processing - that may provide more insight on the resonances.

Tim

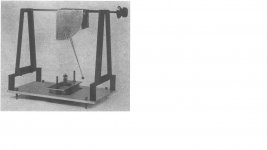

The test with REW I think will be better with the tool that Mullard use in the past, it is a pendulum gradued that shot the glass with different forces. See Figura_2; it is no complicate to buid but it takes time. Mullard call it "direct shock stimulation"

Walter

Walter

Attachments

to Galu

I am prearing for next future a O-ring with Teflon in different size, just for test

Walter

I am prearing for next future a O-ring with Teflon in different size, just for test

Walter

Thanks Walter. As you can tell, I'm sceptical about the efficacy of tube dampers.

However, I am following your investigations on microphony with interest. 🙂

However, I am following your investigations on microphony with interest. 🙂

In the past I considered the the tube damper (some of them) as a "esoteric" stuff.

But after these test where the benefit are visible I will investigate in deep.

I have lot of friend with the gold ear ( 🙂 ) so I can also check the benefit under the sonic aspect.

Walter

But after these test where the benefit are visible I will investigate in deep.

I have lot of friend with the gold ear ( 🙂 ) so I can also check the benefit under the sonic aspect.

Walter

The test with REW I think will be better with the tool that Mullard use in the past, it is a pendulum gradued that shot the glass with different forces. See Figura_2; it is no complicate to buid but it takes time. Mullard call it "direct shock stimulation"

Walter

Today you could use a piezo element which would could deliver a repeatable force upon the valve each time it was actuated (mass and acceleration are known, and there is only one vector to consider).

Mullard papers from 1962: Valve microphony

http://www.thevalvepage.com/valvetek/microph/ValveMicrophony_pt1.pdf

http://www.thevalvepage.com/valvetek/microph/ValveMicrophony_pt2.pdf

http://www.thevalvepage.com/valvetek/microph/ValveMicrophony_pt1.pdf

http://www.thevalvepage.com/valvetek/microph/ValveMicrophony_pt2.pdf

Note that Jon Evans is updating the first part of that Mullard article soon, as it was missing the last page.

And Robert Gribnau just posted a link (Mullard Technical Communications - Nov 1962 - UK Vintage Radio Repair and Restoration Discussion Forum) to the associated article in Philips Tech Review http://www.extra.research.philips.com/hera/people/aarts/_Philips%20Bound%20Archive/PTechReview/PTechReview-22-1960_61-071.pdf

Walter, as I see it, REW uses its sweep measurement process to get the required data to perform a waterfall analysis - John Mulcahy has certainly continued to advance the capability of that process over the years. The spectrum sweep can be abridged to the frequency span of interest, and can be made reasonably 'long' such that mechanical actions have time to build up, and then decay away. Although the use of a speaker to provide the acceleration force on the valve is not as 'direct' as a professional shaker table, or is it a linear relationship, I'd suggest it would provide a good qualitative assessment, and may be relatively easy for you to set up (although nothing is 'easy' when doing experiments).

And Robert Gribnau just posted a link (Mullard Technical Communications - Nov 1962 - UK Vintage Radio Repair and Restoration Discussion Forum) to the associated article in Philips Tech Review http://www.extra.research.philips.com/hera/people/aarts/_Philips%20Bound%20Archive/PTechReview/PTechReview-22-1960_61-071.pdf

Walter, as I see it, REW uses its sweep measurement process to get the required data to perform a waterfall analysis - John Mulcahy has certainly continued to advance the capability of that process over the years. The spectrum sweep can be abridged to the frequency span of interest, and can be made reasonably 'long' such that mechanical actions have time to build up, and then decay away. Although the use of a speaker to provide the acceleration force on the valve is not as 'direct' as a professional shaker table, or is it a linear relationship, I'd suggest it would provide a good qualitative assessment, and may be relatively easy for you to set up (although nothing is 'easy' when doing experiments).

Last edited:

Yout test proceedure is most interesting. However, it is the vibrations of the elements inside the glass that cause the issue.Hi-Fi News did a technical report on tube dampers, but found very little difference with or without the rings.

The following site explains the cause of microphony in valves and suggests what to do if it occurs: Microphony in Valves - What Causes it? - ampvalves.co.uk

The article says all valves are microphonic. I haven't found that.

I usually just tap them with my finger nail to see how microphonic they are.

I have had some success with rubber rings but not always.

Many amps are nicely isolated from vibrations. Valve amps in radiograms, or on benches that also support a speaker (or even where the floor is wooden), and especially in 'combo' instrument amps, are exposed to vibrations. It's only when microphonic levels reach a noticeable level, or even howl from a feedback state, that people get annoyed.

Amps may have <<1% distortion, but few ever measure the amount of background 'noise' in their typical listening environment to see what spurious signals are in the background along with their music. Such background noise is easily masked by enjoyment of the music. And it probably invades many subjective tube-rolling tests with guitar amps, and biases personal opinion. It's not an easy issue to measure realtime, so isn't.

Amps may have <<1% distortion, but few ever measure the amount of background 'noise' in their typical listening environment to see what spurious signals are in the background along with their music. Such background noise is easily masked by enjoyment of the music. And it probably invades many subjective tube-rolling tests with guitar amps, and biases personal opinion. It's not an easy issue to measure realtime, so isn't.

Last edited:

....the tool that Mullard use......

It was a standard Izod Impact test, scaled-down from when Izod proposed it to test brittle steel.

Izod impact strength test - Wikipedia

Attachments

The main goal is done because, in my opinion, the test results I found are, less or more, compatible with the ones made by Mullard and Philips ( they were same family so the test are quite similar) . Regarding the mic of the valve, yes each tube is microphonic in different levels just because their construction, no way. The level of the microphonic "noise" is related to the use; if I have a chain with 60dB of gain this "noise" can be heavy. The solution to isolate the equipment from base where is located is one way, the vibration (indirect stimulation) comes from loudspeaker are more invasive and the band of this vibration is much larger than the ones come from mechanical coupling (pavment+rack+box). If we tap on tube and no noise we hear this don't means that it isn't microphonic; there are "noise" over 10 kHz that is not so easy to ear and, in some case, aren't so low. As the test says.

Walter

Walter

Thx, do you have some link of products?

Walter

Mide Technology | Engineering Solutions & Products

Piezo Systems: Piezoceramic, PZT, Piezoelectric Transducers, Piezoelectric Actuators and Sensors, Piezoelectric Fans, Piezoelectric Amplifiers, Piezoelectric Engineering, Ultrasonic Transducers, and Energy Harvesters

STEMINC

to name a few.

i have a piezo actuator from Mide, but it is now discontinued.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- tubes & microphonic