Does anyone have any experience with a tube shaped subwoofer enclosure? Would it even work?

Little bit of background. I am trying to upgrade my office system, which is a pair of Polk Monitor 30 Series II powered by a Dayton APA150. I do not have a ton of space, and do not want to spend a ton of money.

On either side of my desk I have one of these lamps, where the Polks sit.

Adesso 3138-01 Wright 150-Watt 62.5-Inch Tall Floor Lamp with White Poly/Cotton Shade, Black Pine Wood - Paper Lantern Lamps - Amazon.com

My idea would be to modify the shelving, and stuff a down firing 10 inch woofer up the middle, inside of one of these cardboard cement form tubes

SAKRETE 10 in. x 48 in. Concrete Form Tube-65470006 - The Home Depot

With the current dimensions of the lamp, I can fit up to 1.5 cu ft of 10 in tube in there, and would leave around a 3.5 in gap between the driver and the floor.

The drivers I plan to use are these

GRS 10SW-4 10" Poly Cone Subwoofer 4 Ohm

They list a 1.5 cu ft ported enclosure as ideal, but I find that hard to believe. A 1.0 cu ft sealed is listed, but would it hurt to go bigger?

Is using a tube enclosure a dumb idea in general?

Little bit of background. I am trying to upgrade my office system, which is a pair of Polk Monitor 30 Series II powered by a Dayton APA150. I do not have a ton of space, and do not want to spend a ton of money.

On either side of my desk I have one of these lamps, where the Polks sit.

Adesso 3138-01 Wright 150-Watt 62.5-Inch Tall Floor Lamp with White Poly/Cotton Shade, Black Pine Wood - Paper Lantern Lamps - Amazon.com

My idea would be to modify the shelving, and stuff a down firing 10 inch woofer up the middle, inside of one of these cardboard cement form tubes

SAKRETE 10 in. x 48 in. Concrete Form Tube-65470006 - The Home Depot

With the current dimensions of the lamp, I can fit up to 1.5 cu ft of 10 in tube in there, and would leave around a 3.5 in gap between the driver and the floor.

The drivers I plan to use are these

GRS 10SW-4 10" Poly Cone Subwoofer 4 Ohm

They list a 1.5 cu ft ported enclosure as ideal, but I find that hard to believe. A 1.0 cu ft sealed is listed, but would it hurt to go bigger?

Is using a tube enclosure a dumb idea in general?

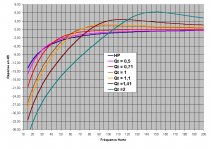

Better enclosure is a sealed about 1.5cf that you can get as much bass as the reflex. With the sealed you have low extension with F3@39Hz and Qtc of 1, 1.1 (~) as good as the reflex with big ports. Bigger volume makes a lower Qtc what might be OK. You can also work good for a LT with the sealed, if you know what I mean. Have fun😀

Linkwitz Transform Subwoofer Equaliser

Linkwitz Transform Subwoofer Equaliser

Attachments

Does anyone have any experience with a tube shaped subwoofer enclosure? Would it even work?

GRS 10SW-4 10" Poly Cone Subwoofer 4 Ohm

but would it hurt to go bigger?

Is using a tube enclosure a dumb idea in general?

Sonotube/concrete tube woofers was all the rage in the '90s until fairly recently and still the staple of SVSound that built a successful business 'riding the wave' of DIYers: https://www.google.com/webhp?source...675US675&ion=1&espv=2&ie=UTF-8#q=sonotube+sub

https://www.google.com/webhp?source...n=1&espv=2&ie=UTF-8#q=sonotube+sub+calculator

They weren't unknown to DIYers, I was using them in the '60s along with concrete pipes, but these folks actively promoted them, starting the fad: HSU FAQ - Frequently Asked Questions

Ron Stimpson further promoted them, ultimately starting SVSound that still sells them: Welcome Secrets of Home Theater and High Fidelity

Cylinder Subwoofers | Best Powered Home Theater Subs – SVS

The short answer is the idea is 'dumb like a Fox'. ;)

WRT your driver choice, its Qts spec is a bit high for a basic reflex, but doable.

Unfortunately, a 10" dia. x 48" tube is too small for a proper vented alignment when its Vas spec is factored in, but its larger size than recommended makes for a bit better stuffed sealed alignment as inductor suggests even if you choose to use a LRT to re-tune it to be a better 'fit' with the room's acoustics.

GM

So it sounds like I am generally on the right track, and that the quoted 1.5 cu ft ported enclosure is optimistic at best. So for now I think the plan will just be to build it sealed, and put a ~100Hz passive crossover on the driver. Then just hope for decent response from ~40Hz to the cutoff.

I plan to use a cheap TPA3116 mono board to amplify, one for each channel. The Monitor 30s will be switched over from the APA150s to a mono TPA3118 on each channel as well, just to keep everything contained in the lamp and to make wiring easier.

I may go in later and add a Linkwitz to get some more low end extension. Am I correct in assuming the LRT goes in to the signal path right before the power amp? My signals are coming from a PC, generated by a Dr.DAC3 DAC/HPA which is probably the most expensive part of my setup.

The driver choice is not set in stone. Any other recommendations for ~$30 or less per driver? I actually have some car audio subwoofers from Polk laying around too, DB 1040s. But I have been told that generally car audio drivers in home use is not recommended.

db1040 - Polk Audio

I plan to use a cheap TPA3116 mono board to amplify, one for each channel. The Monitor 30s will be switched over from the APA150s to a mono TPA3118 on each channel as well, just to keep everything contained in the lamp and to make wiring easier.

I may go in later and add a Linkwitz to get some more low end extension. Am I correct in assuming the LRT goes in to the signal path right before the power amp? My signals are coming from a PC, generated by a Dr.DAC3 DAC/HPA which is probably the most expensive part of my setup.

The driver choice is not set in stone. Any other recommendations for ~$30 or less per driver? I actually have some car audio subwoofers from Polk laying around too, DB 1040s. But I have been told that generally car audio drivers in home use is not recommended.

db1040 - Polk Audio

I was mistaken, the car subwoofers I have on hand are 8 inch polk DB840s. Doing some quick calculations these might actually be ideal for the space I have, I can put them in a 1.5 cu ft ported enclosure and get a -3dB point around 30Hz if my math is right. Here is the spec page of the woofer.

db840 - Polk Audio

Would I still be able to do a Linkwitz on a ported box later on, or would driving the woofer that hard cause too much port "chuff"? If not I can live with 30Hz for now.

db840 - Polk Audio

Would I still be able to do a Linkwitz on a ported box later on, or would driving the woofer that hard cause too much port "chuff"? If not I can live with 30Hz for now.

I haven't messed with LRTs in ages, but at the time it was decided that they shouldn't be used on vented alignments, but there's been huge advances in DSP since then, so kind of curious myself, though a quick search didn't return any results beyond its use for sealed alignments only.

FYI, it's generally not a good plan to tune a vented alignment < ~0.707x Fs unless corner loaded and/or a hi-pass is used to protect it.

GM

FYI, it's generally not a good plan to tune a vented alignment < ~0.707x Fs unless corner loaded and/or a hi-pass is used to protect it.

GM

Not 100% sure what I am looking at there, but the total system response looks pretty flat from 30 - 100 Hz in the SPL graph, which is where I will operate. So maybe the 8 inch car sub is OK? If not it would be very little effort to change the mounting plate to accept a 10 inch driver and run sealed since enclosure volume is the same. I have a 150W CO2 laser cutter so making up new plates is a breeze, and MDF is cheap. The DB840s are just collecting dust, so may as well try them out.

For the port, does it matter where on the enclosure it is located? I can put it on either end of the tube, is the driver side, or the opposite of driver side better? I will probably run 4x ~1.5in ports at a bit over 11 inches each (I plan to use paper towel tubes with a 3D printed horn flare on either end). If I can put the port on the back I can use a single 3in port also.

For the port, does it matter where on the enclosure it is located? I can put it on either end of the tube, is the driver side, or the opposite of driver side better? I will probably run 4x ~1.5in ports at a bit over 11 inches each (I plan to use paper towel tubes with a 3D printed horn flare on either end). If I can put the port on the back I can use a single 3in port also.

The Theory in using a tube concrete form is sound, and is especially applicable when considering mass and cost. The major problem in practice is that they are never cylindrical. Half of the ones you see in the home stores are totally bummed up, but even the ones that miraculously remain as-manufactured have minor dimensional asymmetries which become a huge problem when you are expecting pure tensile load and get flexure instead. The only way around it is to add a whole bunch of braces, internal or external, preferably ones that go all the way around the inner or outer surface in a plane, and are perfectly round. I've made enclosures out of 8" tube that were only 15 inches long and it was still a problem. It leads to very high distortion at sub frequencies and serious response problems if you dare go over 100 Hz.

Of course the product is fine for the intended purpose, as the distortion of the finished cast exterior dimensions makes hardly any difference.

Of course the product is fine for the intended purpose, as the distortion of the finished cast exterior dimensions makes hardly any difference.

The two I got from home depot are fairly round, but certainly not perfect. The more important thing i tried to match in the store was the actual diameter, my two are almost identical to eachother.

I do plan to have some external bracing in the form of MDF plates that the tube runs up the middle of in a few spots. Contact area is only the thickness of the plate though, so 1/2 in. I would expect the non-uniformity will be less of an issue with a ported box since the pressures should be less?

Will try it and see what happens, worst case I scrap this idea and spend a bit more on MDF and a bit more time to just box in the entire lamp frame. The tube idea just makes things cheap and easy.

I do plan to have some external bracing in the form of MDF plates that the tube runs up the middle of in a few spots. Contact area is only the thickness of the plate though, so 1/2 in. I would expect the non-uniformity will be less of an issue with a ported box since the pressures should be less?

Will try it and see what happens, worst case I scrap this idea and spend a bit more on MDF and a bit more time to just box in the entire lamp frame. The tube idea just makes things cheap and easy.

Yeah somehow they can't make them all the same diameter either. Compression / enclosure stress actually increases at port frequency. After you build and drive the thing, you'll most likely be able to hear and feel (if you run your hands over the cardboard surface) the instabilities. Once you try to bearhug the thing and the funny noises still don't cease you begin to understand the near futulity of the adventure.

It's strange and sad because very accurately constructed paper tube of radically varying application exists and is used in many things, just not the locally available concrete forms.

It's strange and sad because very accurately constructed paper tube of radically varying application exists and is used in many things, just not the locally available concrete forms.

Last edited:

Well shoot. Maybe if I shove a piece of metal ducting up the inside and foam it in place so it doesn't rattle?

Also, any rules for port placement I should be aware of? A lot of design websites show the port on the same face as the driver, is that required or can I put the port opposite the driver?

Also, any rules for port placement I should be aware of? A lot of design websites show the port on the same face as the driver, is that required or can I put the port opposite the driver?

Double walling with foam (as complete as possible) would help a lot, steel is a great idea too. Port opposite the driver is fine, just make sure you have ample clearance at the end of the duct internally, same as any other box.

Injecting the foam so that it sets uniformly would most likely be a complicated and messy process. Funny, using thin set concrete would work really well.

Injecting the foam so that it sets uniformly would most likely be a complicated and messy process. Funny, using thin set concrete would work really well.

Last edited:

I spent a lot of time building some sonosubs back inna day- as mentioned, they're really not the ideal enclosures they're made out to be. I fitted circular braces and coated them in epoxy, but in retrospect, I'd have been better to just build a pair with a nice gap and fill with sand.... or just stick with ply.

At this point I think I will try to insert some steel ducting inside the tube and use some of the expanding spray foam or RTV to glue it to the cardboard, and hopefully both together will be stiff enough. Otherwise I will just have to build a square tube out of MDF. I think the tube would look a lot better if it works though.

Pass DIY Addict

Joined 2000

Paid Member

Another consideration for building your sub (whether tube or cube) is the orientation of the driver and if it can stand up to pull of gravity of you orient the driver horizontally. Dan Wiggins wrote up a white paper on this topic some time ago and I have a copy of it on my web page: http://www.facstaff.bucknell.edu/esantane/movies/DriverOrientation.pdf

Just noticed that is the DVC, mine are SVC DB840s. Either way should be similar. At this point I think the plan is to make a cube-tube, roughly 1ft x 1ft x 3ft outside dimensions, 2x 3in ports. Sub will be down firing with a 3.5in gap below it, ports will fire down as well.

That should get me fairly flat down to almost 30Hz which I can live with. If I want deeper I will have to get some of those GRS 10 in drivers, with an SC4 ported alignment they hit an f3 of 19Hz. Would be $20 well spent.

That should get me fairly flat down to almost 30Hz which I can live with. If I want deeper I will have to get some of those GRS 10 in drivers, with an SC4 ported alignment they hit an f3 of 19Hz. Would be $20 well spent.

An engineer I worked with in Florida built these several years ago. His neighbors didn't like them! There are several pictures detailing the build.

Lordofthebass Image Gallery: Details

Lordofthebass Image Gallery: Details

Pass DIY Addict

Joined 2000

Paid Member

Yikes! The looks like a boat-load of bass. I have sonotube envy now 😱 I'm guessing he wasn't married 😀

Here's mine from 15 years ago and still going strong:

Here's mine from 15 years ago and still going strong:

An externally hosted image should be here but it was not working when we last tested it.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Tube Subwoofer Enclosure