Tube Heaters Ac Or Dc

a simple question

AC or DC heater supplies. i have heard good and bad things about both. could anyone help me understand the advantages and disadvantages of the 2 methods.

cheers

ed

a simple question

AC or DC heater supplies. i have heard good and bad things about both. could anyone help me understand the advantages and disadvantages of the 2 methods.

cheers

ed

I also read a lot...

In Valve Amplifiers Morgan Jones states that with good practice even a RIAA stage can be made quiet using AC heaters. And the RIAA stage is the most senstivive to pickup hum...

So, why DC? Although Morgan Jones speaks about an AC fed RIAA stage, he presents a schematic for the regulation of the heater supplies for the RIAA stages. I think that it is meant to avoid disappointed people that could not get it 'humfree' with AC. Following that line of though, I remember a diyaudio member once stating that DC is for people not skilled enough to use AC... (Possibly right, but I don't expect everyone to be willing to learn perfect AC dressing for a small number of projects they will be doing throughout life)

DC heaters require quite some additional efforts in the PS. Basically one needs:

- more components: bypassed diodes, elco's,

- without a regulator, higher order harmonics are added, so a regulator is a good thing,

- with a regulator comes the need for heat dissipation: is the chassis enough, or should one add a heatsink?

The common 6.3V AC from the power tranny can only be used for 6.3VDC if one uses a low drop out regulator...to obtain the 6.3VDC from a normal regulator (317, 350) one needs about 9VAC, which in most cases means a separate or custom wound transformer.

In my recent projects I am trying to use AC. In my opinions it is better to tear some hair out now (I am young and have lots of hair) figuring out, in the 'learning by doing' way, how to work with AC, than to always have to recur to the hardest and more expensive DC way in future projects.

DHT tubes are a different matter, which I leave for people as Kevin, who is using CCS to feed 300B's!

Hope this helps a little bit.

In Valve Amplifiers Morgan Jones states that with good practice even a RIAA stage can be made quiet using AC heaters. And the RIAA stage is the most senstivive to pickup hum...

So, why DC? Although Morgan Jones speaks about an AC fed RIAA stage, he presents a schematic for the regulation of the heater supplies for the RIAA stages. I think that it is meant to avoid disappointed people that could not get it 'humfree' with AC. Following that line of though, I remember a diyaudio member once stating that DC is for people not skilled enough to use AC... (Possibly right, but I don't expect everyone to be willing to learn perfect AC dressing for a small number of projects they will be doing throughout life)

DC heaters require quite some additional efforts in the PS. Basically one needs:

- more components: bypassed diodes, elco's,

- without a regulator, higher order harmonics are added, so a regulator is a good thing,

- with a regulator comes the need for heat dissipation: is the chassis enough, or should one add a heatsink?

The common 6.3V AC from the power tranny can only be used for 6.3VDC if one uses a low drop out regulator...to obtain the 6.3VDC from a normal regulator (317, 350) one needs about 9VAC, which in most cases means a separate or custom wound transformer.

In my recent projects I am trying to use AC. In my opinions it is better to tear some hair out now (I am young and have lots of hair) figuring out, in the 'learning by doing' way, how to work with AC, than to always have to recur to the hardest and more expensive DC way in future projects.

DHT tubes are a different matter, which I leave for people as Kevin, who is using CCS to feed 300B's!

Hope this helps a little bit.

AC works hum-free without any special precautions at line level stages. It has very low, frequency-independent source impedance, which is a good thing.

ErikdeBest said:

I think that it is meant to avoid disappointed people that could not get it 'humfree' with AC. Following that line of though, I remember a diyaudio member once stating that DC is for people not skilled enough to use AC...

yup.....the good old analogue skill is a fast disappearing asset.

page 265 M.J. 3rd edit regarding EF86 and spiral heaters.

NOS small signal tubes are gradually diminishing and many were designed to work on AC heater supplies with the hum and noise in the 1960's spec i.e equipment noise floor capable of -60dB down..

Today, with D/A conversion, the anticipated hum noise floor has got a min -90dB down. To get a tube preamp down to these levels and be better than the main amp, the cue for DC front end heater supplies may seem obvious.

I had a hum problem using recent made EF86 Svets, where an "up and over" heater construction is used and by using an AC heater supply, the anticipated low hum performance can't be met when changing tubes. By designing front ends to run on a DC heater supply, generally one will get a more consistent performance regardless of the same type tube.

richj

I have never had to use DC for heaters in any of my amplifier projects. Proper lead dress, and twisting of heater pairs is quite sufficient in my experience.

Glenn

Glenn

Does that include amplifiers that use DHT?I have never had to use DC for heaters in any of my amplifier projects.

not to mention filament damage on indirectly heated tubes (and possible directly heated tubes, the only ones I can afford are rectifiers) with dc...I find even with somewhat imperfect lead dress hum will not be a problem so long as the heaters are referenced and input cables etc are not too long. Bad tubes hum more too. I had a modern 12ax7 that sounded like crap and hummed more, compared to some special quality preamp tubes I've seen that you can't even tell the amp is on.

300b with AC

I breadboarded a 6sn7, 300b amp using only AC for heaters and managed to get the hum down to 4mv at the speaker. Had to twist wires tightly, move them around a bit, use a humpot and limit the voltage on the 300b to slightly less than 5v (4.6 to 4.8 vac).

I did try to use dc on the 300b but did not like the sound at all.

I also have a 6sn7, 45 power amp that is virtually hym free using ac on the heaters.

FWIW

I breadboarded a 6sn7, 300b amp using only AC for heaters and managed to get the hum down to 4mv at the speaker. Had to twist wires tightly, move them around a bit, use a humpot and limit the voltage on the 300b to slightly less than 5v (4.6 to 4.8 vac).

I did try to use dc on the 300b but did not like the sound at all.

I also have a 6sn7, 45 power amp that is virtually hym free using ac on the heaters.

FWIW

Bas Horneman said:

Does that include amplifiers that use DHT?

No, I guess I should have clarified that

O no..but I was curious. Last time I tried AC on my 300B it made a hell of a noise. It seemed as if the hum pot's did nothing...no matter how I turned them.No, I guess I should have clarified that

Another vote for just straight AC... many people simply rectify the AC and use that DC with some caps to power their heaters. Running the tubes like this, slightly under voltage causes power loss and tone issues... it's one of the worst mistakes IMO that one can make.

It doesn't mean you cannot use DC, but the additional cost, hassle and complexity can be avoided completely by using standard practices as mentioned above to keep AC hum low.

To put it in perspective, I have an AC heater driven headphone tube amp that hum is inaudible on my AKG 701s unless the gain is on max, even then, it's very, very low. That's a speaker an inch from your ear and it's inaudible...

It doesn't mean you cannot use DC, but the additional cost, hassle and complexity can be avoided completely by using standard practices as mentioned above to keep AC hum low.

To put it in perspective, I have an AC heater driven headphone tube amp that hum is inaudible on my AKG 701s unless the gain is on max, even then, it's very, very low. That's a speaker an inch from your ear and it's inaudible...

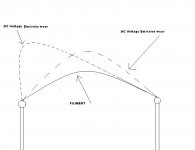

AC vs DC

It seems that excellent construction will keep AC levels down to acceptable levels, HOWEVER there are too many variables whereby hum seems to raise its ugly head.

Assembling a Dc regulation system is very easy and maintaining absolutely precise voltages regardless of line variations is only possible with DC.

Yes there is some long term damage to filiments by running current thru one way as opposed to AC, but the gains outweigh the losses. Another Pro is DC regulators can put your heaters in a standby mode......something your AC can't do.

___________________________________Rick...........

It seems that excellent construction will keep AC levels down to acceptable levels, HOWEVER there are too many variables whereby hum seems to raise its ugly head.

Assembling a Dc regulation system is very easy and maintaining absolutely precise voltages regardless of line variations is only possible with DC.

Yes there is some long term damage to filiments by running current thru one way as opposed to AC, but the gains outweigh the losses. Another Pro is DC regulators can put your heaters in a standby mode......something your AC can't do.

___________________________________Rick...........

I don't understand. How does DC damage filaments? Can anyone point to any real data that proves this or an explanation of how this occurs?

I use DC all the time, but I'm a perfectionist. It is better. However, whether or not it is measurably better is another matter. Whether a possibly immeasurable improvement is worth the additional cost and complexity is a decision you'll have to make.

I use DC all the time, but I'm a perfectionist. It is better. However, whether or not it is measurably better is another matter. Whether a possibly immeasurable improvement is worth the additional cost and complexity is a decision you'll have to make.

I heard from a tube amp MFG that DC can cause hot spots on the filaments to form shortening there life.

DC ???

My understanding is that the 'wear' on a filiment is polarity dependent...I recall someones 813 SE amp whereby each time it is powered up the polarity is switched....a solution to a perceived or real problem for sure but this guy had to use a microproccesor to accomplish it!

___________________________________Rick..........

My understanding is that the 'wear' on a filiment is polarity dependent...I recall someones 813 SE amp whereby each time it is powered up the polarity is switched....a solution to a perceived or real problem for sure but this guy had to use a microproccesor to accomplish it!

___________________________________Rick..........

Attachments

Zero Cool,

My concern with trusting a tube amp manufacturer is that I suspect that they may have been trying to sell an amp that uses an AC heater supply. One that costs less and is easier to manufacture and brings in a greater profit if they can market it well...

I'm not saying that you can't make a great amp with AC heaters, but it is in a tube amp manufacturer's best interests to create a little fear, uncertainty, and doubt regarding DC.

Let's think about it a second. The filament(in an indirectly heated tube) is a wire. It's sole purpose is to get hot and radiate that heat to the cathode, so that the cathode can emit electrons. If the resistance along this wire is not completely uniform(it isn't), then some parts will be slightly hotter than others. But I don't see how polarity or AC vs DC would make a difference with these hot spots.

Rick,

Are you talking about DHTs only? I could see maybe some emissive coating might get worn with DC due to the fact that one part of the cathode always being at a different potential than the other half. The electrons would prefer one end more than the other. However, this would not be an issue with indirectly heated tubes. What are your thoughts?

My concern with trusting a tube amp manufacturer is that I suspect that they may have been trying to sell an amp that uses an AC heater supply. One that costs less and is easier to manufacture and brings in a greater profit if they can market it well...

I'm not saying that you can't make a great amp with AC heaters, but it is in a tube amp manufacturer's best interests to create a little fear, uncertainty, and doubt regarding DC.

Let's think about it a second. The filament(in an indirectly heated tube) is a wire. It's sole purpose is to get hot and radiate that heat to the cathode, so that the cathode can emit electrons. If the resistance along this wire is not completely uniform(it isn't), then some parts will be slightly hotter than others. But I don't see how polarity or AC vs DC would make a difference with these hot spots.

Rick,

Are you talking about DHTs only? I could see maybe some emissive coating might get worn with DC due to the fact that one part of the cathode always being at a different potential than the other half. The electrons would prefer one end more than the other. However, this would not be an issue with indirectly heated tubes. What are your thoughts?

ZC, it is a faint, vague possibility for a directly heated cathode, but for a "normal" tube, that's rubbish. What amp manufacturer made that claim?

edit: Woops, I see that Spread said it already. But let's out the company who's putting stuff like that in their advertising.

edit: Woops, I see that Spread said it already. But let's out the company who's putting stuff like that in their advertising.

SpreadSpectrum said:I use DC all the time, but I'm a perfectionist. It is better. However, whether or not it is measurably better is another matter. Whether a possibly immeasurable improvement is worth the additional cost and complexity is a decision you'll have to make.

OK. Fact time. transformers are ready to go for AC heater supply. No extra work or design needed. It's ready to go.

DC is NOT ready to go. As for being measurably better, it is DEFINITELY measurable WORSE if the voltage drops as a result of converting to DC, which as I said prior happens all the time when people think they need DC because of some internet forum post and they rectify the 6.3 VAC out of their power tranny. Starve your heaters and you will destroy the sound and output of your amp.

I also think that pretty much everyone above said, "you can make a good low noise AC heater powered amp but..." That's when I go, what but? For the same reason that a manufacturer won't do it, you shouldn't do it... added cost, complexity and possibly worse results.

OK... so where's the catch? I've built headphone amps, pre amps, power amps, guitar amps and all of them AC heater powered, and the guitar amps on 10 still dont have excessive or loud hum... so what is there to debate at this point? I mean how do you say, you cannot measure it's better, but it's better? All that knowing that DC causes the heater filaments to fail earlier too... ?

I am completely against doing something that doesn't address a problem or an issue. Most people here seem to be looking to build a hifi amp for music, and in that case for line level in, speaker out, DC is just not required at all for top notch performance.

Unless there is some special low noise/ signal level issue, like say a phono or mic input, the simplicity and already ready already of using the AC out of your power transformer is the way to go.

All that knowing that DC causes the heater filaments to fail earlier too... ?

Evidence for that remarkable claim?

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Tube heaters AC or DC?