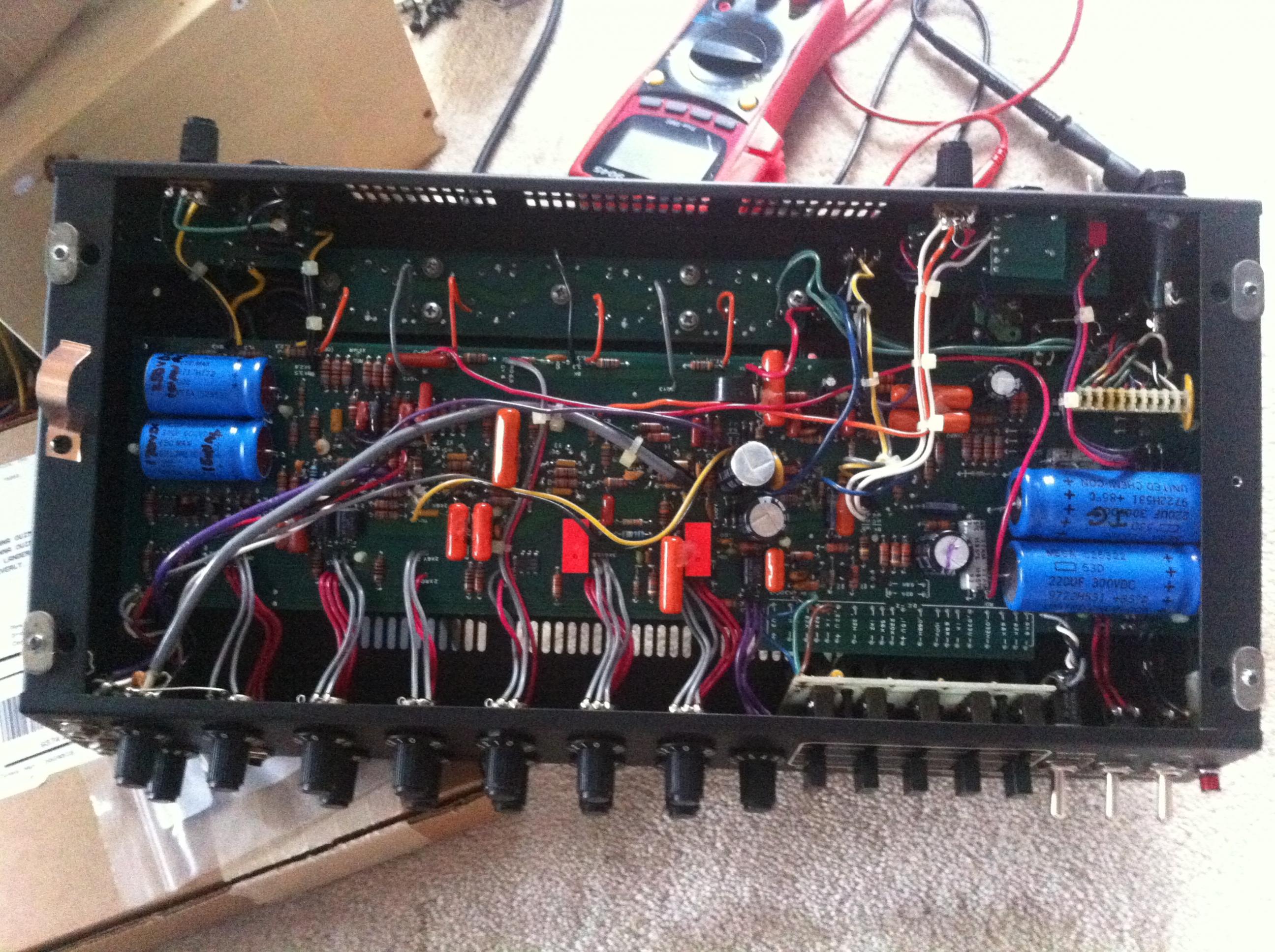

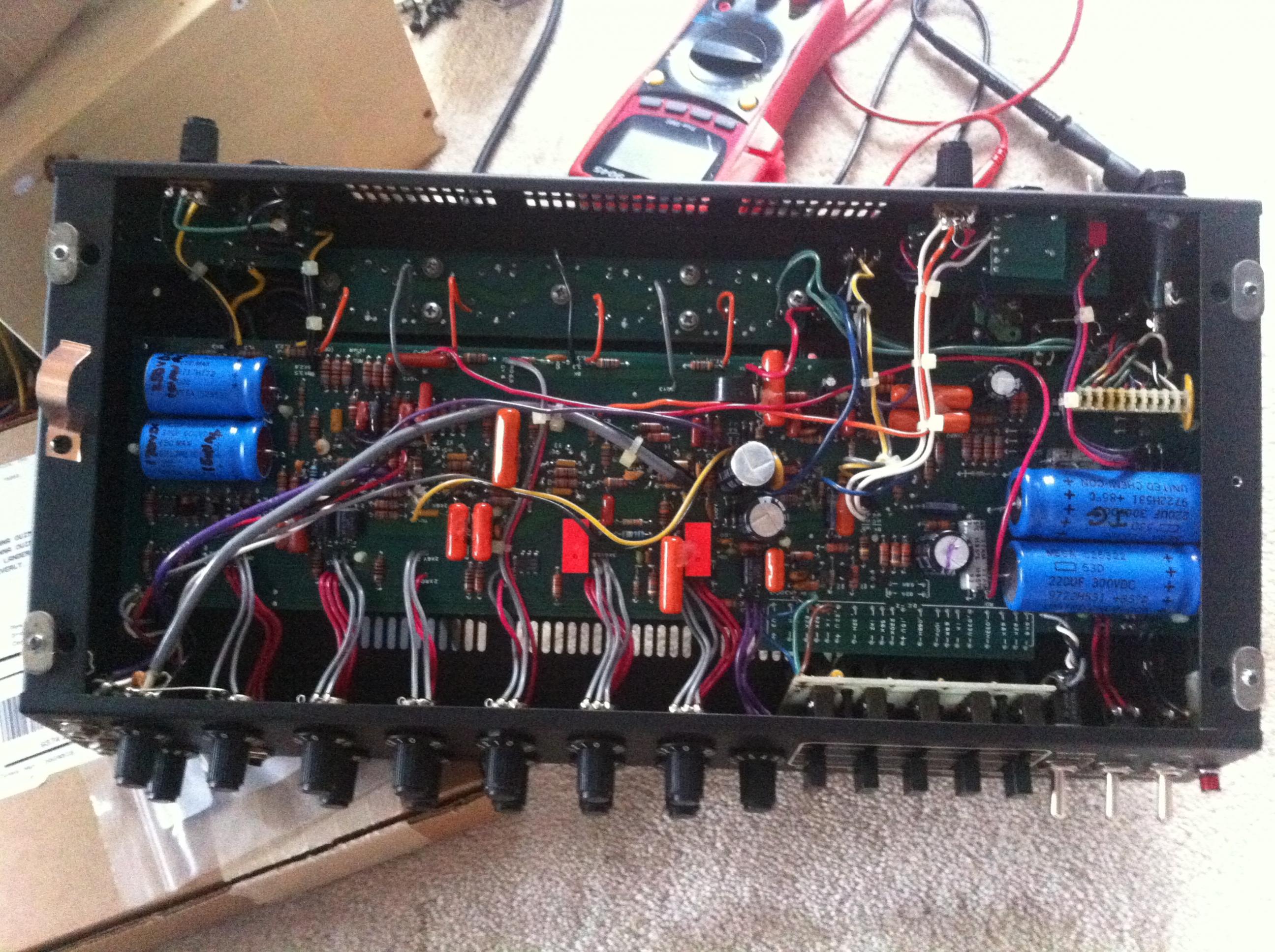

So I have a Mesa Boogie that a friend wants me to look at. I can say the internal layout is a mess. You have to unsolder a bunch of wires to actually get the main board out.

Anyways his message to me was

With that, it also makes a chattering noise (similar to a failing hard drive)

So something is screwed up. No fuses blowing, and no hard shorts (DBT dims down)

I'm more fimilar with SS, NOT tube gear. So I would like to learn. I do know about the dangers of tube gear and the high voltage, etc. So.. where do I start checking?

Video: Mesa Boogie DC 3 - YouTube

I changed the photo to my own instead of the one I found on Google. How do I resize it? It screws up the thread.

Anyways his message to me was

The volume was dropping intermittently or when our bassist dropped a real loud low note. I figured it was a tube issue. I finally completely re-tubed it an gave it a fairly good(I think) cleaning. It seemed to be fine then developed a loud buzz that went away when I turned down the gain on channel 2. Strange thing is, it wasn't on channel 2. Luckily I rarely use the 2nd channel. Then it started doing the volume drop thing again. I think it must be a loose connection somewhere but I can't seem to locate anything as its hard to duplicate.

With that, it also makes a chattering noise (similar to a failing hard drive)

So something is screwed up. No fuses blowing, and no hard shorts (DBT dims down)

I'm more fimilar with SS, NOT tube gear. So I would like to learn. I do know about the dangers of tube gear and the high voltage, etc. So.. where do I start checking?

Video: Mesa Boogie DC 3 - YouTube

I changed the photo to my own instead of the one I found on Google. How do I resize it? It screws up the thread.

Last edited:

Yes, MB's are complex beasts.

First of all, try to google the schematic or politely ask for it at MB themselves.

Supply full name, model, serial number, whatever is written on the ID tag.

Being an intermittent get a chopstick or a plastic BIC pen or something similar and lightly start tapping everywhere, carefully wiggle wires back and forth, tap on pots, jacks and switches, at PCB connectors, even tube sockets, filter caps, etc.

Use an even lighter touch to tap on tubes themselves.

Also flex PCBs slightly or apply pressure in different points.

ALWAYS WITH A WELL INSULATED TOOL MADE OF DRY WOOD OR PLASTIC.

Before all this you may apply the patented "Enzo whack", a good solid thump on the roof of the cabinet with a closed fist.

Any effect? (it crackles/mutes/unmutes/whatever).

Try to succeed in recreating the noise at will, it's 50% of the journey.

Check which controls affect the noise. (also an Enzo tip).

First of all, try to google the schematic or politely ask for it at MB themselves.

Supply full name, model, serial number, whatever is written on the ID tag.

Being an intermittent get a chopstick or a plastic BIC pen or something similar and lightly start tapping everywhere, carefully wiggle wires back and forth, tap on pots, jacks and switches, at PCB connectors, even tube sockets, filter caps, etc.

Use an even lighter touch to tap on tubes themselves.

Also flex PCBs slightly or apply pressure in different points.

ALWAYS WITH A WELL INSULATED TOOL MADE OF DRY WOOD OR PLASTIC.

Before all this you may apply the patented "Enzo whack", a good solid thump on the roof of the cabinet with a closed fist.

Any effect? (it crackles/mutes/unmutes/whatever).

Try to succeed in recreating the noise at will, it's 50% of the journey.

Check which controls affect the noise. (also an Enzo tip).

Clean the sockets first, get a can of Deoxit or some electrical cleaner safe for PCB, work the tubes in out real well, could be some crappy solder joints they might need re-flowed. volume drop sounds kinda like that scenario but usually you hear some wild *** popping/hissing/cracking too associated with it.

Loss of power is usually a jack socket switching issue, if the amp has an effect in/out socket. If you use switch cleaner on the output valve sockets, you will write the amp off in a short while as the lubricant in the cleaner fluid attracts dust and will carbonize and track at high voltages!

If the output valves are arcing, it will be obvious.

If the output valves are arcing, it will be obvious.

Last edited:

That's why I said specifically an electrical cleaner and fast drying with no lubricant so dust does build up and further the arcing.

those preamp tube sockets are looking a bit rough, that junk/gunk that builds up etc or it was possible arcing, tear it all apart clean re-flow them xD

All the controls were cleaned with deoxit, and the board was flooded with the contact cleaner before I got it.😡 So I spend a LONG time degreasing the boards. All components look fine, and I reflowed all the solder joints for all the tube sockets before I made the video. This seems like a major PITA to disassemble. I have the manual and schematic for it, so thats a thing.

What could that rattling noise be?

Also the picture shown in the OP isn't mine, but one from Google but the one I'm working with looks the same.

What could that rattling noise be?

Also the picture shown in the OP isn't mine, but one from Google but the one I'm working with looks the same.

Last edited:

Okay. Powered it with the DBT. Here is what happens. Channel A (top row of controls) seems dead. Playing with the switches doesn't help. Channel B has a very annoying hiss and growl. Then when I put it in standby before powering it off, It growls louder and dies out. I tapped the power tubes with a pen and no change, so the tubes are fine. Unless it could be the preamp tubes. I'll tap those later.

I'll make a video on it.

EDIT: Video

Growl Boogie - YouTube

I'll make a video on it.

EDIT: Video

Growl Boogie - YouTube

Last edited:

Just a thought, this has happened to me enough times I now look for it whenever a Mesa come into the shop.

You have the two rows of controls. The rear covers can come loose, and when they do, there is nothing to maintain co0cntact within the pot. The backs get sprung usually when something hits the knob out front. That shoves the shaft in, whwich pushes out the rear of the control. The rear is just held on by little bent tabs. They give, and the back is now loose.

I just go down the rows, grasp the body of each pot and wiggle to se if any are loose. Pots like this become open circuits, which can kill the signal.

You have the two rows of controls. The rear covers can come loose, and when they do, there is nothing to maintain co0cntact within the pot. The backs get sprung usually when something hits the knob out front. That shoves the shaft in, whwich pushes out the rear of the control. The rear is just held on by little bent tabs. They give, and the back is now loose.

I just go down the rows, grasp the body of each pot and wiggle to se if any are loose. Pots like this become open circuits, which can kill the signal.

The pots are fine. I checked them with a DMM. All are secure and happy. Except one has a broken shaft, but still functions.

It sounds a lot like the clean signal not getting through, have you checked voltages? do you have access to an oscilloscope?

No scope. What voltages would I be checking. Not familiar with tube gear, only solid state, so I will be learning.

Didn't check the preamp tubes, however the owner took a shotgun approach and replaced ALL the tubes (preamp and power) So I doubt they are the issue considering shotgunning it didn't fix the problem.

That does kinda sound like Power supply hum too, but still that clean signal sounds like its dieing somewhere in the preamp, bad coupling maybe?

I also asked on AudioKarma, and the folks there strongly suggest replacing the filter caps. I guess they have a hard life, and don't last that long?

Would I check for AC ripple, or is that not what the issue would be with the filters?

Would I check for AC ripple, or is that not what the issue would be with the filters?

not sure what preamp tubes he went with, but you can try pulling them out and swapping them around to see if he it goes away or changes, maybe one of them is really bad/went horribly microphonic.

- Status

- Not open for further replies.

- Home

- Live Sound

- Instruments and Amps

- Tube Arcing?