Hi thanks for reading.

Is there anyway to address the noise, buzzing, and vibrations from a mains transformer.

What do you think of varnishing, or perhaps submerging the transformer in oil. Or both. Or anything else.

If so which varnish would you use, or which type of oil would you consider.

Thanks.

Is there anyway to address the noise, buzzing, and vibrations from a mains transformer.

What do you think of varnishing, or perhaps submerging the transformer in oil. Or both. Or anything else.

If so which varnish would you use, or which type of oil would you consider.

Thanks.

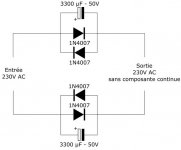

What type of transformer are you referring to? If the problem is coming from DC on the mains you may be helped with a DC trap.

Last edited:

Soak in insulating varnish, or at least brush on too much on load.

Transformer oil is available, in barrels. Smaller quantities are difficult, ask your electric utility...it is dehydrated hydro treated Naptha.

Varnish as in the stuff used in motor winding, not the furniture variety.

Transformer oil is available, in barrels. Smaller quantities are difficult, ask your electric utility...it is dehydrated hydro treated Naptha.

Varnish as in the stuff used in motor winding, not the furniture variety.

Hello,(sorry for my basic english.....)

It's a simple question, and at the same time very complex to answer it.

The noise of a transformer can be generated by a whole set of elements:

.the manufacturing quality

.the type of transformer

.the fixing on the frame

.the power in VA

.the identification of the phase in reverse primary and secondary

.problems on the arrival of the sector

.poor earthing of the amplifier and / or the system (earth and / or earth loop)

Before working on the transformer, it is good to check these various points mentioned.

regards

It's a simple question, and at the same time very complex to answer it.

The noise of a transformer can be generated by a whole set of elements:

.the manufacturing quality

.the type of transformer

.the fixing on the frame

.the power in VA

.the identification of the phase in reverse primary and secondary

.problems on the arrival of the sector

.poor earthing of the amplifier and / or the system (earth and / or earth loop)

Before working on the transformer, it is good to check these various points mentioned.

regards

It is part of my battle to find the source of some mains noise that has been troubling me for some time.

So i am taking it one step at a time, eliminate one possibility at a time.

I have an oil filled transformer taken out of a quad amplifier, and i am not getting the mains noise issue with that, so perhaps maybe worth looking into further which is the purpose of this post. If it does not work then i will try the dc blocker / trap the thing with that is the dc blockers are so expensive.

Do you have a brand name recommendation for the varnish.

For the oil i have two sources, what do you think of these:

1L Transformer Oil IEC 60296 Insulating Dielectric Oil Mineral alt to Diala B 5081941867841 | eBay

500ml Transformer Mineral Insulating Dielectric Oil High Voltage Shell Diala B | eBay

So i am taking it one step at a time, eliminate one possibility at a time.

I have an oil filled transformer taken out of a quad amplifier, and i am not getting the mains noise issue with that, so perhaps maybe worth looking into further which is the purpose of this post. If it does not work then i will try the dc blocker / trap the thing with that is the dc blockers are so expensive.

Do you have a brand name recommendation for the varnish.

For the oil i have two sources, what do you think of these:

1L Transformer Oil IEC 60296 Insulating Dielectric Oil Mineral alt to Diala B 5081941867841 | eBay

500ml Transformer Mineral Insulating Dielectric Oil High Voltage Shell Diala B | eBay

Price here is less than engine oil, and it is almost water clear.

Soaking a transformer which is intended for air cooling may do long term damage to its components.

Loosen it slightly, and use varnish for an air cooled design.

Tighten up after it is warm, on load, it works.

So do rubber feet.

Muffled housings will restrict air flow.

Soaking a transformer which is intended for air cooling may do long term damage to its components.

Loosen it slightly, and use varnish for an air cooled design.

Tighten up after it is warm, on load, it works.

So do rubber feet.

Muffled housings will restrict air flow.

Build your own DC blocker --basic circuit is shown if you scroll down to -Description.

HIGH-POWER DC Blocker Trap Filter – Assembled Device – ATL Audio Ltd.

HIGH-POWER DC Blocker Trap Filter – Assembled Device – ATL Audio Ltd.

Hi,

In my opinion forgetting the oil, it does nothing.

The insulating varnish either, because it must be injected with a vacuum pump.

About twenty years ago, I worked on the transformer of my LINN-LK2 amplifier, I used cyanolit-green(and only this one), it is extremely fluid, and is perfect for this kind of use, on the other hand it takes a lot .... guaranteed result.

See photos

Regards

In my opinion forgetting the oil, it does nothing.

The insulating varnish either, because it must be injected with a vacuum pump.

About twenty years ago, I worked on the transformer of my LINN-LK2 amplifier, I used cyanolit-green(and only this one), it is extremely fluid, and is perfect for this kind of use, on the other hand it takes a lot .... guaranteed result.

See photos

Regards

Attachments

I said soak or brush on too much varnish on load...the humming will provide a path for the varnish to enter, and fill the gaps.

Please post a clearer and larger picture of what you used, so we can read the label clearly.

Please post a clearer and larger picture of what you used, so we can read the label clearly.

Please post a clearer and larger picture of what you used, so we can read the label clearly.

If you read all my post it is clearly mentioned.....""I worked on the transformer of my LINN-LK2 amplifier, I used cyanolit-green(and only this one)

you don't need another picture.

Regards

It is a slightly slow setting super glue...cyanoacrylate, more specifically it seems to be ethyl cyanoacrylate.

Regular instant glue is methyl cyanoacrylate.

The solvent for it is acetone, which is a powerful solvents for plastics and insulation.

Use with care.

It sets too fast to penetrate the transformer...

Regular instant glue is methyl cyanoacrylate.

The solvent for it is acetone, which is a powerful solvents for plastics and insulation.

Use with care.

It sets too fast to penetrate the transformer...

Charly you said that varnish or oil will do nothing from your experience, yet you used cyanolit-green, what did you notice after administration.

Thanks

Thanks

Hello,

In 1970, this type of Cyanolit-green appeared in France, she is a very special glue, because it sticks by infiltration only and it is extremely ultra-fluid and flows a lot so its perfect for isolated and reduce transformer noise.

The Linn-LK2 have a 500VA toroidal transformer, after dismantling I emptied a +/-20 of cyanolit-green tube on the top and the bottom of the toroid.

Excellent results very reduced noise, and a little better in terms of sound.

One of the interests of this glue is its extreme fluidity which allows it to go in depth.

About, varnish or oil used in audio transformer ... it's mostly good for manufacturing, not really after, and not for reducing a transformer that makes too much noise.

Here is a list of 3 excellent transformer manufacturers:

Toroidal transformers SUPREME AUDIO GRADE V2 - Shop Toroidy.pl

Transformer_James transformer-custom toroidal transformer|R core transformer|O core transformer|C core transformer|EI transformer

J&K Audio Design: About Us

regards

In 1970, this type of Cyanolit-green appeared in France, she is a very special glue, because it sticks by infiltration only and it is extremely ultra-fluid and flows a lot so its perfect for isolated and reduce transformer noise.

The Linn-LK2 have a 500VA toroidal transformer, after dismantling I emptied a +/-20 of cyanolit-green tube on the top and the bottom of the toroid.

Excellent results very reduced noise, and a little better in terms of sound.

One of the interests of this glue is its extreme fluidity which allows it to go in depth.

About, varnish or oil used in audio transformer ... it's mostly good for manufacturing, not really after, and not for reducing a transformer that makes too much noise.

Here is a list of 3 excellent transformer manufacturers:

Toroidal transformers SUPREME AUDIO GRADE V2 - Shop Toroidy.pl

Transformer_James transformer-custom toroidal transformer|R core transformer|O core transformer|C core transformer|EI transformer

J&K Audio Design: About Us

regards

Do you mean you purchased the Cyanolit-green in the 70's

Is it the same as the stuff available today. It says in the description the setting time is 1-5 secs. That sounds fast, not much time available to rub the green into the transformer.

Is it the same as the stuff available today. It says in the description the setting time is 1-5 secs. That sounds fast, not much time available to rub the green into the transformer.

One common cause of buzzing mains transformers is that the transformer has been designed to work too near the flux density limit for the core size and is saturating. They do this for cost reasons.

High quality transformer manufacturers will use a bigger core ie a 500VA core in a 300VA transformer (not the same as just using a 500VA one) but they will be more expensive as a result.

Canterbury Windings in the UK used to make them like this but I think they may have stopped taking orders now.

High quality transformer manufacturers will use a bigger core ie a 500VA core in a 300VA transformer (not the same as just using a 500VA one) but they will be more expensive as a result.

Canterbury Windings in the UK used to make them like this but I think they may have stopped taking orders now.

There are many factors in noise, and the cause may be poor deign and manufacture onwards.

Basically something is vibrating due to magnetic flux reversal, and needs to be restrained from doing so.

Laminations, windings, bobbins, fasteners and so many other parts.

At the do it yourself level, and in a Covid affected world, my solution was from my personal experience.

By all means ask a transformer manufacturer that you want a repair, not rebuild, by vacuum impregnation or varnishing...since the openings are almost closed, mostly you will get a refusal.

Then what will you do?

Varnish allows you time, in hours if needed to work it.

Cyano Acrylate can be slowed from seconds to minutes by adding acetone or using special grades, which may be in bulk packs. Acetone dissolves some plastics, and most insulation on transformer winding wires....

Another way is to use a very fluid epoxy compound, high flow, slow setting epoxy or polyester potting compounds may be available in your area in small packs, you need 100 ml or so, mostly you will get at least a lire.

Try varnish out, done it many times, works.

Basically something is vibrating due to magnetic flux reversal, and needs to be restrained from doing so.

Laminations, windings, bobbins, fasteners and so many other parts.

At the do it yourself level, and in a Covid affected world, my solution was from my personal experience.

By all means ask a transformer manufacturer that you want a repair, not rebuild, by vacuum impregnation or varnishing...since the openings are almost closed, mostly you will get a refusal.

Then what will you do?

Varnish allows you time, in hours if needed to work it.

Cyano Acrylate can be slowed from seconds to minutes by adding acetone or using special grades, which may be in bulk packs. Acetone dissolves some plastics, and most insulation on transformer winding wires....

Another way is to use a very fluid epoxy compound, high flow, slow setting epoxy or polyester potting compounds may be available in your area in small packs, you need 100 ml or so, mostly you will get at least a lire.

Try varnish out, done it many times, works.

Last edited:

goodguys;6731173..That sounds fast said:Cyano glues set only when in very thin film.

Drop it into the open parts of the winding. When it wicks into the thinner spaces it will set.

Hello,

In the immediate "goodguys" we still do not know the type of your transformer used ........

The original "Cyanolit-green" have a green tube, as i already mentioned, this is in a 2gr tube(and expensive 3 to 5 Euros unit), it can be found in a 20 gr packaging.

It may be, for you, easier, and cheaper to change the transformer, if in addition you are not a handyman.

No sorry its incorrect, most of transformer used good insulation winding wires, like "enamelled wire".

None of my transformer windings can't be removed with acetone or other solvent, they must be scraped with a knife, including and especially the windings in a square file.

Regards

In the immediate "goodguys" we still do not know the type of your transformer used ........

The original "Cyanolit-green" have a green tube, as i already mentioned, this is in a 2gr tube(and expensive 3 to 5 Euros unit), it can be found in a 20 gr packaging.

It may be, for you, easier, and cheaper to change the transformer, if in addition you are not a handyman.

NareshBrd said:Acetone dissolves some plastics, and most insulation on transformer winding wires....

No sorry its incorrect, most of transformer used good insulation winding wires, like "enamelled wire".

None of my transformer windings can't be removed with acetone or other solvent, they must be scraped with a knife, including and especially the windings in a square file.

Regards

How about this one?

Slip-Fit Extra slow set cyanoacrylate cyano glue 5 min set adhesive

Look for ethyl cyano acrylate, or slow setting super glue.

I still think varnish is better, but the skill and tools may not be suitable for everybody.

Slip-Fit Extra slow set cyanoacrylate cyano glue 5 min set adhesive

Look for ethyl cyano acrylate, or slow setting super glue.

I still think varnish is better, but the skill and tools may not be suitable for everybody.

- Home

- Amplifiers

- Power Supplies

- Transformer noise suppression