Let's be honest in a domestic setting you are very unlikely to notice any difference. The hardest part of doing that comparison would be finding somewhere with high EMI/RFI.Impossible to torn out connector on Neutrik's XLR thanks to the knurled chuck strain? Too bad we can't bet on this! 🙂

Let me see if i have pictures of some in old hardrive, i had documented this in our locker room as students did not understood why we checked cable ( and mics and all gear in fact... you wouldn't believe how people do not care when they did not spend money to buy things...) after each sessions and applyed fees if they were 'destroyed'. We had to have visual example not to discuss for hours. 🙂

I can garantee you there is nothing impossible and why we did our cable the way i explained. The Neutrik's system is clever and give a increased level of protection but in no way it's bulletproof as it rely on the wire jacket material and all are not very good quality or at least supposed to be exposed to such constraints.in particular when it's repeated.

Anyway, i'm not telling you how to do things.

I gave you a way to do, free to you to try it or not if you face the issue we had ( i told about it in my first post in this thread but did not revealed the method because it's not mandatory for the kind of use regular people in here have, i said the same about Starquad cables too as i think if you ask about it then you don't really have a use for it...).

It's like for Starquad. Some members told why and how we use it with example of where they bring things.

Other defeat the principle.

If you are curious, you buy 10 meters of Mogami 2534 ( or other Brand like Canare), a pair of Neutrik's connector and you compare it to a regular cable in harsh EMI/RFI environnement. Basreflex gave a real life example of such thing as i did too.

If it's placebo then it can be sold on second hand market, people will buy it if reasonably priced and soldering job is good, no worry about it. We are talking what... maybe 40 euros for the whole 10m cable you can sell for same price? Not bad for a test imho.

My thoughts:

a] the only good thing that Silver plating does for an analog audio cable is make it easier to solder to the connectors.

b] some of the pics in this thread are of very poor XLR interconnects. XLR interconnects should use a Shielded Twisted Pair made by a major bulk cable manufacture with a braided shield.

c] StarQuad is great for harsh noise/interference venues. Like auditoriums with theater lights and smoke machines (not needed in home hi-fi).

a] the only good thing that Silver plating does for an analog audio cable is make it easier to solder to the connectors.

b] some of the pics in this thread are of very poor XLR interconnects. XLR interconnects should use a Shielded Twisted Pair made by a major bulk cable manufacture with a braided shield.

c] StarQuad is great for harsh noise/interference venues. Like auditoriums with theater lights and smoke machines (not needed in home hi-fi).

Incorrect.the only good thing that Silver plating does for an analog audio cable is make it easier to solder to the connectors.

SPC can facilitate and recover headroom in the audible higher frequency range of a signal path as it has a lower capacitance than copper. This can be especially useful for TT owners. It's also measurable.

It's also the reason why vanDamme offer the Silver Series LoCap range of cable with 3 different capacitance specifications:

https://www.van-damme.com/vandamme_product/van-damme-silver-series-session-grade-instrument-cable/

I'm also confused about how much 'easier' SPC is to solder than copper. Care to elaborate?

Quite a bold and restrictive statement. According to what doctrine?XLR interconnects should use a Shielded Twisted Pair made by a major bulk cable manufacture

It's like saying 'Burgers should only be eaten at McDonalds or Burger King'. Weird.

Some of the single-strand, unshielded cable I use comes from very small, limited volume manufacturers and applies, measures and sounds perfect as used in some of my own braided cables.

You must not have done much soldering in your life.I'm also confused about how much 'easier' SPC is to solder than copper. Care to elaborate?

Why do you think that Silver solder is sometimes used?

Tinned copper is easier to solder than bare copper and SPC is easier yet.

Insulation thickness is much more important than SPC in cable capacitance.SPC can facilitate and recover headroom in the audible higher frequency range of a signal path as it has a lower capacitance than copper.

Yes total cable capacitance is of interest in phono cartridge to pre-amp cables.

But in modern line level interconnects, cable capacitance is not a factor.

* * * * * * * * * * * * * *

Speedskater said:

XLR interconnects should use a Shielded Twisted Pair made by a major bulk cable manufacture

1) many Audio Engineering Society papers on the subject.Quite a bold and restrictive statement. According to what doctrine?

Jim Brown retired AES noise & interference expert has some of the papers on his page:

http://www.audiosystemsgroup.com/publish.htm

2) Stephen (Steve) Lampen, retired Belden Wire, covers the subject in his books:

"Wire, Cable, and Fiber Optics for Video & Audio Engineers"

"Audio / Video Cable Installer's Pocket Guide"

3) Bill Whitlock retired Jensen Transformers, touches on the subject in his seminars :

https://www.jensen-transformers.com/application-notes/

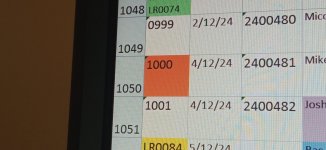

After recently reaching 1000 units sold in the last 2 years of operating my cable-making enterprise (analogue and digital interconnects, speaker-cables, headphone cables), mostly involving soldering, I would counter-propose that I have 'some' experience of soldering. Also, previous to this approximately 35 years of hobbyist soldering.You must not have done much soldering in your life.

Why do you think that Silver solder is sometimes used?

Tinned copper is easier to solder than bare copper and SPC is easier yet.

You state that 'SPC is easier to solder to the connectors' and then again you make an assertion of 'easier yet' than copper without offering much of a technical rationale or credible explanation.

Suggesting that silver solder has some relevance to that claim is somewhat irrelevant, bordering on ludicrous.

I therefore have to conclude that in fact you do'nt have much experience of soldering, otherwise you would find it easy to solder any given wire type to any given connector without making irrelevant and ill thought-out inferences about SPC or silver solder having any relevance.

What exactly is a 'modern line level interconnect'?? And why wouldn't capacitance be a factor?Yes total cable capacitance is of interest in phono cartridge to pre-amp cables.

But in modern line level interconnects, cable capacitance is not a factor.

You just contradicted yourself in the space of a single line of text.

No, you missed my confusion at 'XLR interconnects should ...[be] ...made by a major bulk cable manufacture'many Audio Engineering Society papers on the subject.

What exactly is a 'major bulk cable manufacturer' and what relevance does the size of a cable manufacturer have to being an authority on the production XLR interconnects?

I'm literally all sorts of confused by your hyperbole.

There are certainly arguments to that effect. Doesn't make them all correct though. I used to think all mic cable was the same; didn't understand why studios were being wired up with fancy Mogami cable when it couldn't make any difference. I was wrong, just like a lot of other people who think they know more than enough about cable. Finding out I was wrong was quite an eye opener as it turned out.XLR interconnects should use a Shielded Twisted Pair made by a major bulk cable manufacture...

Do you have any data regarding this effect? I had always assumed that it was cable construction which affected capacitance, not the wire type/plating.SPC can facilitate and recover headroom in the audible higher frequency range of a signal path as it has a lower capacitance than copper.

I agree I cannot so how silver plated copper would be easier to solder. Maybe tin plated copper would be?Incorrect.

SPC can facilitate and recover headroom in the audible higher frequency range of a signal path as it has a lower capacitance than copper. This can be especially useful for TT owners. It's also measurable.

It's also the reason why vanDamme offer the Silver Series LoCap range of cable with 3 different capacitance specifications:

https://www.van-damme.com/vandamme_product/van-damme-silver-series-session-grade-instrument-cable/

I'm also confused about how much 'easier' SPC is to solder than copper. Care to elaborate?

An issue with silver plating imo is it perhaps encourages skin effect which would reduce higher frequency signal slightly? But that would not be audible imo. I fail to see how it would audibly increase headroom.

Best cable for me is just ordinary oxygen free copper. Anything else is a waste of time. And stranded better than solid core as that reduces skin effect too (not audibly but still).

You just have to look at any cable manufacturers' website to compare capacitance specs in pF/m between diffrent types of cable.Do you have any data regarding this effect? I had always assumed that it was cable construction which affected capacitance, not the wire type/plating.

Cable construction does have have an influence and capacitance specs are usually given for conductor-conductor and conductor-shield but it isn't the only factor.

vanDamme's Silver Series cable has 3 different capacitance specs as I mentioned earlier, but they all have exactly the same construction. It's principally the copper:silver ratio and strand-count that has an influence. I think they also use a small deviation of +/- 0.3mm as overall diameter, perhaps to result in different capacitance specs, although this is not stated as such.

You can verify this via their own data:

https://www.van-damme.com/wp-conten...me_Silver_Series_Session_Grade_Instrument.pdf

I also use their Silver Series LoCap55 for one of my cable models and have verified their claim of 55pF/m, within a small margin of error.

I also developed two extremely low-capacitance braided cables especially for the TT market. One is full SPC and the other is a hybrid SPC/copper mix.

They both have exactly the same braided construction but measure slightly differently due to the conductor type.

SPC (36.2pF/m)

SPC/copper hybrid (41.2 pF/m)

TT owners love them and I supply different connection methods - RCA, DIN and pre-tinned ends for direct soldering to a TT's internal connection points.

Last edited:

Let's be honest in a domestic setting you are very unlikely to notice any difference. The hardest part of doing that comparison would be finding somewhere with high EMI/RFI.

I never said anything different than your first sentence and as i wrote in this thread in chronological order it can be easily checked.

Somewhere with high EMI/RFI perturbation: It depends where you live, some place are relatively immune but with mobile phones and other wireless protocol there is more chance than ever to be in a place where there is some perturbations.

If they don't bother you or your system then fine. No need to bother with all this until you need to.

The FR graphs, vanDamme and the musicians who use their cables, as well as my customers may wish disagree with you.As long as capacitance isnt too high it will have no audible effect.

Last edited:

I have, and for 40+ years I have seen the differences, however you stated that "SPC can facilitate and recover headroom in the audible higher frequency range of a signal path as it has a lower capacitance than copper.". According to Van Damme, all three capacitance variations use 100% silver plated conductors and screen. This suggests that specific construction is the method used to control capacitance, not wire type, and this is evidenced in the differing conductor sizes and count stated for the three variations; what other changes are made - if any - seem not to be revealed, however the resistance/km of the three variations vary quite widely...You just have to look at any cable manufacturers' website to compare capacitance specs in pF/m between diffrent (sic) types of cable.

I would still like to understand how (or if!) a few microns of silver plating would alter the capacitance of solid copper conductors in cables of otherwise identical construction, and by what mechanism it can actually increase dynamic range and by how much. (I trust that I am interpreting your claim 'recover headroom' correctly).

Thanks, Carl.

I once purchased some HP cables for Audeze LCD-X. The cables were from nobody here, but they were braided and had some silver strands mixed in to add what I think may be more like "artificial brightness." The cables cost me a few hundred dollars and were custom made to order. When I tried them they sounded awful. Absolutely unusable. So, yes, they did affect the sound alright, just in a very bad way. It was sometime later that I tried making my own cables for LCD-X using 22-ga star quad cable. Better than the original cable that came with the headphones. A friend suggested removing the rubber jacket from the star quad cable, which I took a chance on. Wow! Best sound we ever heard from LCD-X, also my from my friend's LCD-4. Well defined bass, more space between instruments, deeper depth of field, etc. Still can't buy those cables commercially, but I would highly recommend them to anyone looking for better cable for headphones.

I they can show the db level difference between constructions that would be interesting. As others have said no evidence of silver plating altering capacitance has been provided.The FR graphs, vanDamme and the musicians who use their cables, as well as my customers may wish disagree with you.

vanDamme doesn't stipulate the copper:SPC ratio in their data sheet and I would suggest this is the main distinguisher within the capacitance values.This suggests that specific construction is the method used to control capacitance, not wire type

All 3 capacitance specs are verifiable however. It would be nice to know what the specific construction dimensions and material ratios are. Maybe an email to vanDamme could shed some more light and give clarity.

Recovering headroom in the signal path from a turntable to amp/pre-amp has many sections of wire and connections along its' overall length; from the headshell to the amp input stage and everything in between. The cable connecting TT to amp is just one section where overall signal path capacitance can be reduced relatively easily by a cable with a lower pF/m spec.I trust that I am interpreting your claim 'recover headroom' correctly

Why?vanDamme doesn't stipulate the copper:SPC ratio in their data sheet and I would suggest this is the main distinguisher within the capacitance values.

I refer you to the vanDamme datasheet. Link provided earlier.no evidence of silver plating altering capacitance has been provided

- Home

- General Interest

- Everything Else

- thinking of making my own balanced XLR cables