OK chaps, I have managed to cut away a little of the sphere's lip to allow a baffle of up to 18mm thickness.....

So what would people pick if they had free choice of a cld sandwich 18mm thickness?

I was thinking 3mm aluminum top layer, 3mm 80 shore nitrile rubber sheet then 12mm MDF, might make a nice cld baffle???

So what would people pick if they had free choice of a cld sandwich 18mm thickness?

I was thinking 3mm aluminum top layer, 3mm 80 shore nitrile rubber sheet then 12mm MDF, might make a nice cld baffle???

I'm not a physics expert, but as I remember, Earl Geddes (who is) said that CLD is most effective when both outer layesrs are the same and the inside layer is a thin-as-practical lossy medium. He used to use a layer of "Melamine Glue" as the inside, but now uses some proprietary goop. When I made a CLC cabinet some years back it was half inch mdf on the outsides and the Melamine glue between. Worked well as far as I could tell, very dead cabinet. Got the Melamine glue from Grainger. The MDF is nasty stuff to work with (guessing you already found that).

3mm aluminium, 3mm sorbothane, 10mm perspex??

The options seem fairly limitless... But I want aluminum top layer for a nice finish.

I seem to remember some info on cld turntable plinths.......

The options seem fairly limitless... But I want aluminum top layer for a nice finish.

I seem to remember some info on cld turntable plinths.......

I'm not a physics expert, but as I remember, Earl Geddes (who is) said that CLD is most effective when both outer layesrs are the same and the inside layer is a thin-as-practical lossy medium. He used to use a layer of "Melamine Glue" as the inside, but now uses some proprietary goop. When I made a CLC cabinet some years back it was half inch mdf on the outsides and the Melamine glue between. Worked well as far as I could tell, very dead cabinet. Got the Melamine glue from Grainger. The MDF is nasty stuff to work with (guessing you already found that).

Thanks bwaslo, I think I better do some research, as I am going to great lengths with these spheres to maximize engineered properties.

Just ordered some 4mm silent coat buytl mastic sheets for the inside. Then 18mm 100% wool underlay.....so I want to get the baffles right.

Hmmm, aluminium/MDF/aluminum does well....as does acrylic over MDF....

damping factor values : damping factors

damping factor values : damping factors

OK.

Lots of reading up and looking up various sheet composite damping values, transmission factors etc.

I have decided to combine a CLD composite baffle, with a 'floating isolation' or 'decoupling' technique.

So I am going to make a 3mm aluminium/6mm MDF/3mm aluminium CLD baffle ring - looking at the various charts - they agree with bswalo and Geddes that same thickness constraining layers (3mm aluminium) with double thickness 6mm MDF in the middle appears to produce excellent damping and low transmission factors. This will give a combined thickness of 12mm and should be very stiff and well damped.

Then this will be isolated with a 3mm sorbothane gasket - looking at the literature on sorbothane - they advise against glueing it on both sides- i.e. they don't advise using it as CLD - more as a damping decoupling layer.

So I am hoping a well damped, stiff, 12mm al/MDF/al baffle, floating on 3mm sorbothane will have the best of both worlds.

I will use over-sized holes with rubber washers to ensure no 'shorting' of the isolation via the bolts to the enclosure.

Lots of reading up and looking up various sheet composite damping values, transmission factors etc.

I have decided to combine a CLD composite baffle, with a 'floating isolation' or 'decoupling' technique.

So I am going to make a 3mm aluminium/6mm MDF/3mm aluminium CLD baffle ring - looking at the various charts - they agree with bswalo and Geddes that same thickness constraining layers (3mm aluminium) with double thickness 6mm MDF in the middle appears to produce excellent damping and low transmission factors. This will give a combined thickness of 12mm and should be very stiff and well damped.

Then this will be isolated with a 3mm sorbothane gasket - looking at the literature on sorbothane - they advise against glueing it on both sides- i.e. they don't advise using it as CLD - more as a damping decoupling layer.

So I am hoping a well damped, stiff, 12mm al/MDF/al baffle, floating on 3mm sorbothane will have the best of both worlds.

I will use over-sized holes with rubber washers to ensure no 'shorting' of the isolation via the bolts to the enclosure.

OK.

Lots of reading up and looking up various sheet composite damping values, transmission factors etc.

I have decided to combine a CLD composite baffle, with a 'floating isolation' or 'decoupling' technique.

So I am going to make a 3mm aluminium/6mm MDF/3mm aluminium CLD baffle ring - looking at the various charts - they agree with bswalo and Geddes that same thickness constraining layers (3mm aluminium) with double thickness 6mm MDF in the middle appears to produce excellent damping and low transmission factors. This will give a combined thickness of 12mm and should be very stiff and well damped.

Then this will be isolated with a 3mm sorbothane gasket - looking at the literature on sorbothane - they advise against glueing it on both sides- i.e. they don't advise using it as CLD - more as a damping decoupling layer.

So I am hoping a well damped, stiff, 12mm al/MDF/al baffle, floating on 3mm sorbothane will have the best of both worlds.

I will use over-sized holes with rubber washers to ensure no 'shorting' of the isolation via the bolts to the enclosure.

I can attest to the effectiveness of sorbothane.

I used a 1/8" sorbothane layer sandwiched between an 18 mm baltic birch baffle and an 18 mm BB driver mounting plate. The baffle was rigidly braced by the horn flares that formed the slot that loaded the woofer. The driver mounting plate was free floating as the mounting bolts are isolated with rubber washers. The driver has a thick rubber gasket which partially isolates the driver from its mounting plate. The woofer is an AE TD15H, 14mm Xmax. When pounding bass you feel nothing on the front panel but if you open the box and touch the driver mounting plate, it "thrumms" against your fingers.

A structural two part epoxy I have used before with good effect on my previous builds.

Baffle dead to knuckle tap.

Baffle dead to knuckle tap.

So what happens if you take one heavy gauge peony plant support, turn it upsidedown, angle grind off the legs, and spray it black......? 😁

Attachments

Nice work with the plant support. How does your wife feel about you taking her plant support frame? Is it rigid enough to support the weight of the speaker fully loaded with woofers?

A structural two part epoxy I have used before with good effect on my previous builds.

Baffle dead to knuckle tap.

Are you making brand new waveguides or are these the old ones? I don't see the drivers attached or the glued on bondo woofer adapter plate.

Nice work with the plant support. How does your wife feel about you taking her plant support frame? Is it rigid enough to support the weight of the speaker fully loaded with woofers?

She was initially very pleased I had thought of her......😱

They are made from 8mm steel rod, and because of the three circles and five supporting legs are actually very strong - I can happily sit on them!

They will need isolating from the globe though - so some sorbothane rings are being cut.

Are you making brand new wave-guides or are these the old ones? I don't see the drivers attached or the glued on bondo woofer adapter plate.

These are the old ones stripped down. Once I have mounted them on the alumium baffles I will be sanding back the overhang on the corners and making a nice smooth transition.

I think I will paint the baffles matt black - a shame to loose the aluminum, but I think it will help the horn blend into the circular baffle.

Bolting waveguide onto aluminium baffle. 6mm bolts. Will have a mastic rope gasket between waveguide and baffle. Then sorbothane gasket between baffle and sphere....

Attachments

Last edited:

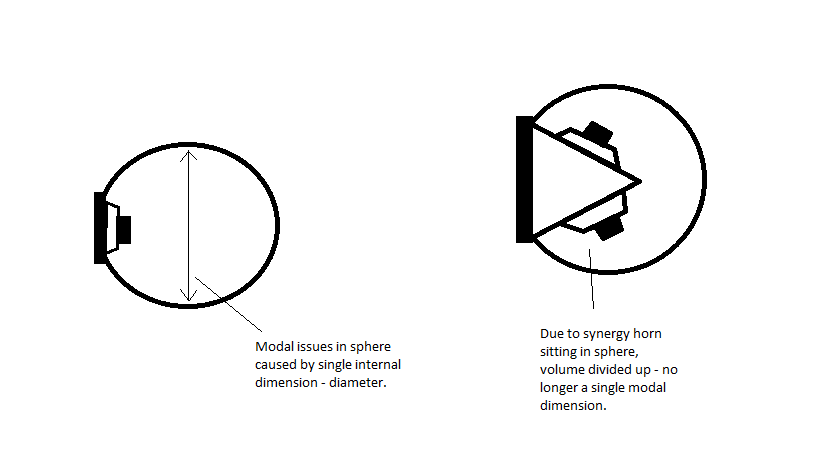

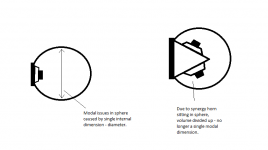

Nice work! There may be spherical resonance mode that will cause a small peak. But if you have enough damping and things to break up that mode it should be ok. I noticed a small peak on a small hypercube enclosure which resembled a sphere. If you can have a brace inside to break that spherical symmetry it will help.

Thanks X.

There should be no mode, due to the horn which essentially cleaves the volume in half like a giant central wedge. Combined with the angled woofers the internal volume is actually not a sphere at all!

If I had mounted the driver flat on the front baffle as is usual, there would have been modal issues!

There should be no mode, due to the horn which essentially cleaves the volume in half like a giant central wedge. Combined with the angled woofers the internal volume is actually not a sphere at all!

If I had mounted the driver flat on the front baffle as is usual, there would have been modal issues!

Nice work - that is a tight fit on the skinny little baffle, if you can even call it that - more like a mounting ring adapter. 🙂

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- The XBush Mark 2. A synergy/Unity horn of spherical proportions