WHat the paper shows is if the recording digital chain of some studio is bad from the beginning, so their recordings are ?.... No hope on our side whatever the sota masterclocks we use : too late, the recording is corrupted so will be the playback ?

One downside to having digital audio driven by such a good (local) clock is that it exposes the quality of the recording and the mastering without mercy. It is hard to appreciate the bad ones when the good ones sound so much better.

The article clearly shows that an external clock is worse (results in a higher noise floor) than the local clock, whatever the external clock performance (and cost) is. Explanation is the always imperfect transmission line between the external clock and the driven digital equipment, which affects the jitter at the receiving point (see the eye diagrams).

How are you guys connecting your super clocks to your DACs? Based on what photos I’ve seen, that’s exactly what you are doing, cable between the “super clock” and the DAC... That cable will create more jitter than the local $5 clock generator already has. How much, obviously depends on the cable length, quality, terminations, etc... all of which can be calculated and measured. But I see no interest for such details here, so enough to know that even the “cabling” at the chip level clock distribution can affect the jitter at those fs levels, making the super clock moot.

How are you guys connecting your super clocks to your DACs? Based on what photos I’ve seen, that’s exactly what you are doing, cable between the “super clock” and the DAC... That cable will create more jitter than the local $5 clock generator already has. How much, obviously depends on the cable length, quality, terminations, etc... all of which can be calculated and measured. But I see no interest for such details here, so enough to know that even the “cabling” at the chip level clock distribution can affect the jitter at those fs levels, making the super clock moot.

External clocks used in studios are Word Clock, which runs at 44.1kHz (or whatever the sample rate is). In that case any devices requiring a master clock would need a PLL to produce one that is phase locked to Word Clock. Always that results in more jitter and phase noise than using a good crystal clock. Modern ASRCs are so good they often preferred to using a Word Clock system when synchronization is necessary.

Last edited:

Ovidiu (syn08) still keeps confused, now about clock transmission.

1 meter coaxial cable with SMA connectors from the oscillator to the measurement gear creates a lot of jitter, even 43 femto seconds!

What a bad jitter performance!

1 meter coaxial cable with SMA connectors from the oscillator to the measurement gear creates a lot of jitter, even 43 femto seconds!

What a bad jitter performance!

Attachments

A good 50ohm cable with RF connectors, matched properly, would not be a problem. After all, such cables are used at GHz frequencies, even at 100GHz with 1mm specialized connectors (you don't want to know how much they cost).

Now, please describe how such a SMA cable is fitted and matched in your next audio DAC equipment.

Now, please describe how such a SMA cable is fitted and matched in your next audio DAC equipment.

Hi Ovidiu,

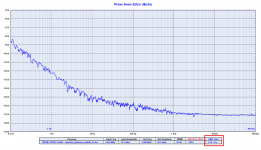

just like in the first picture.

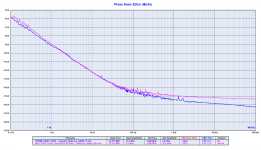

Then the second picture is a reclocker board connected to the FIFO board with u.fl cable, while the oscillators are connected with SMA cable to the FIFO.

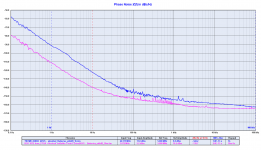

Third picture is the phase noise comparison between the external oscillator and the MCK output of the FIFO board (after sine to square conversion).

Finally the last picture is the phase noise comparison between the external oscillator and the BCK coming from the reclocker board (after sine to square converter and u.fl cable).

Practically there is no added jitter, only a little noise floor, still below -150dB.

I hope this helps to understand.

just like in the first picture.

Then the second picture is a reclocker board connected to the FIFO board with u.fl cable, while the oscillators are connected with SMA cable to the FIFO.

Third picture is the phase noise comparison between the external oscillator and the MCK output of the FIFO board (after sine to square conversion).

Finally the last picture is the phase noise comparison between the external oscillator and the BCK coming from the reclocker board (after sine to square converter and u.fl cable).

Practically there is no added jitter, only a little noise floor, still below -150dB.

I hope this helps to understand.

Attachments

Not asking about yourself, although I see you are using series resistors to (as much as possible) avoid reflections, that's far from "matching". Asking about your average customer who purchased your supa-dupa clock boards. They have a DAC board of unknown source, they are routing your clock into, replacing the on board oscillator/clock. Assuming a decent (say) Crystek on board clock, this surgery can only worsen the outcome, this is what the article describes.

Which is precisely the article point (noise floor is the direct result of additive jitter). It may be low enough, the point is, have you compared the noise floor of a decent (again, say Crystek) DAC on board clock noise floor with the resulting noise floor of your supa-dupa clock routed to the same DAC board? Can you guarantee that by using your clock boards, any DAC it is feeding won't have a post surgery worse noise floor?

Now, please, don't tell me the noise floor doesn't matter for audio...

Practically there is no added jitter, only a little noise floor, still below -150dB.

Which is precisely the article point (noise floor is the direct result of additive jitter). It may be low enough, the point is, have you compared the noise floor of a decent (again, say Crystek) DAC on board clock noise floor with the resulting noise floor of your supa-dupa clock routed to the same DAC board? Can you guarantee that by using your clock boards, any DAC it is feeding won't have a post surgery worse noise floor?

Now, please, don't tell me the noise floor doesn't matter for audio...

Last edited:

Indeed I was not talking about myself, these boards was developed for the audio community, not for ourselves.

Our digital front end will be a 3-4 chassis device, much more complex and expensive, with optic fiber cables to carry dirty signals (the brickwall).

So everyone could get these board since we share all of our designs.

About other boards please ask the designers if you think they are not well designed to accept external clocks.

I cannot help on this.

Our digital front end will be a 3-4 chassis device, much more complex and expensive, with optic fiber cables to carry dirty signals (the brickwall).

So everyone could get these board since we share all of our designs.

About other boards please ask the designers if you think they are not well designed to accept external clocks.

I cannot help on this.

Even so, those boards (FIFO and others) do have to be somehow integrated with the customer equipment (say, a DAC board). You are selling a product, you may want to guarantee to your customers some end-to-end performance metric.

I agree that a full "product", build and sold by yourself and your DIY associates for the audio community, integrating the whole digital chain from (say) USB to the DAC chip could be a top notch product, but this is not what you are selling today. It is questionable if such an integrated full product will show any objective improvements over the existing products on the market, but then it is your right to compete, no doubts about. Let me though make an educated guess: in such an "integrated full product" you will observe that the mega care for digital signal integrity will be obscured by the DAC performances themselves. Using a standard decent clock generator (again, like the Crystek) won't provide a iota of performance degradation over your supa-dupa solution(s). Time will tell.

I agree that a full "product", build and sold by yourself and your DIY associates for the audio community, integrating the whole digital chain from (say) USB to the DAC chip could be a top notch product, but this is not what you are selling today. It is questionable if such an integrated full product will show any objective improvements over the existing products on the market, but then it is your right to compete, no doubts about. Let me though make an educated guess: in such an "integrated full product" you will observe that the mega care for digital signal integrity will be obscured by the DAC performances themselves. Using a standard decent clock generator (again, like the Crystek) won't provide a iota of performance degradation over your supa-dupa solution(s). Time will tell.

Last edited:

@ syn08

as I clearly demonstrated, there is no issue at all, even at poor cabling (for comparison sake), to recognize the improved sound stage and details using Andrea's clock versus 5$ clocks. It was definitively worth buying, regardless of your condescending words on his products.

I suggest you stop interfering with your bold statements and let us do our thing. If you believe we are on the wrong path, well let us go there, why would you care anyway? Unless you are a woke / green person. They typically want to tell others what to think/feel/say/experience. If that is your goal, fine also, I also do not care, but may be you want to spend your time somewhere else with people in your own bubble with similar opinions so you can continue petting each other on the back (we do that as well by the way because we help each other getting a nicer hobby experience - goal of this forum)

and... I do not care how much your 100GHz connectors cost.

and... I mean it, your inputs are soooooooo irrelevant on this topic, so please stay out polluting it with your over the top technical moral insights - I/we do not care the least.

thanks, much appreciated

as I clearly demonstrated, there is no issue at all, even at poor cabling (for comparison sake), to recognize the improved sound stage and details using Andrea's clock versus 5$ clocks. It was definitively worth buying, regardless of your condescending words on his products.

I suggest you stop interfering with your bold statements and let us do our thing. If you believe we are on the wrong path, well let us go there, why would you care anyway? Unless you are a woke / green person. They typically want to tell others what to think/feel/say/experience. If that is your goal, fine also, I also do not care, but may be you want to spend your time somewhere else with people in your own bubble with similar opinions so you can continue petting each other on the back (we do that as well by the way because we help each other getting a nicer hobby experience - goal of this forum)

and... I do not care how much your 100GHz connectors cost.

and... I mean it, your inputs are soooooooo irrelevant on this topic, so please stay out polluting it with your over the top technical moral insights - I/we do not care the least.

thanks, much appreciated

as I clearly demonstrated, there is no issue at all, even at poor cabling (for comparison sake), to recognize the improved sound stage and details using Andrea's clock versus 5$ clocks.

I am not willing to comment on uncontrolled subjective opinions, these are to me at best good worded proses, not facts.

But I admit this is what most of the participants in this thread are happy to discuss, probably because lacking any serious technical insights and understanding. Please go ahead, you have the right to create a dream land as much as anybody else. I also admit that wake up calls from the dream land could be annoying.

Last edited:

Even so, those boards (FIFO and others) do have to be somehow integrated with the customer equipment (say, a DAC board). You are selling a product, you may want to guarantee to your customers some end-to-end performance metric.

I agree that a full "product", build and sold by yourself and your DIY associates for the audio community, integrating the whole digital chain from (say) USB to the DAC chip could be a top notch product, but this is not what you are selling today. It is questionable if such an integrated full product will show any objective improvements over the existing products on the market, but then it is your right to compete, no doubts about. Let me though make an educated guess: in such an "integrated full product" you will observe that the mega care for digital signal integrity will be obscured by the DAC performances themselves. Using a standard decent clock generator (again, like the Crystek) won't provide a iota of performance degradation over your supa-dupa solution(s). Time will tell.

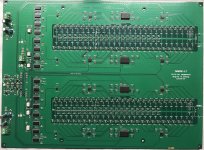

Our FIFO Lite has been designed to be used with our discrete DAC which uses a custom protocol, so it could be a fully integrated product.

So we have made the board compliant with other DACs as we have received requests from many members.

Attachments

Within the limits of our DIY hobby skills, we do actually give some thought to these things. The Iancanada FIFO design provides impedance matching to 50ohm cables. I use Ryanj's GB PCB for a TDA1541a DAC where he went to considerable lengths to design a 4 PCB that also provides the required match. Yes, we end users of these subcomponents are merely assembling a digital LEGO set, but the choices on subcompnents, PS(s), I/V, buffer, layout, chassis build are also all part of the hobby. Pretty rewarding actually.Even so, those boards (FIFO and others) do have to be somehow integrated with the customer equipment (say, a DAC board). You are selling a product, you may want to guarantee to your customers some end-to-end performance metric.

Andrea did in fact provide a performance claim. He showed extensive measurement of phase noise as he developed each of his PCBs and even offers to run a test of the individual board/crystal for a nominal fee. Not much different from ordering any component or subassembly. At some point it is Caveat emptor. This is DIY and not every bit will be a winner. This one is.

Since it's audio, it would involve audible traits. So, how did the listening evaluation go?This demonstrates that we build state of the art audio devices.

And not oscillators only.

Does anyone know where are the BOM and manual of the first TTWMC generation- old discroll and power supplies with AT Cut and first SC-Cut, please ?

Does anyone know where are the BOM and manual of the first TTWMC generation- old discroll and power supplies with AT Cut and first SC-Cut, please ?

The Well Tempered Master Clock - Building a low phase noise/jitter crystal oscillator

.... got it : 2017 : The Well Tempered Master Clock - Building a low phase noise/jitter crystal oscillator

We shot at the same time 🙂

We shot at the same time 🙂

Last edited:

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Line Level

- The Well Tempered Master Clock - Building a low phase noise/jitter crystal oscillator