Zen Mod said:

me wanna porn , ya kwayzee MetalBoy .....

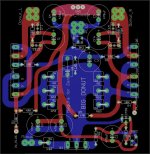

Ok, some test-porn.

Just made it to see if it works, to not waste my PTFE board, and test how the compensation worked.

The real thing is soon to come.

Magura 🙂

Attachments

Magura said:

Ok, some test-porn.

Just made it to see if it works, to not waste my PTFE board, and test how the compensation worked.

The real thing is soon to come.

Magura 🙂

wazzat ?

plexy ?

ya know that I'm blind as Bat ........

or ya are lousy with cam .....

hehe

Zen Mod said:

wazzat ?

plexy ?

ya know that I'm blind as Bat ........

or ya are lousy with cam .....

hehe

Yes, I used a piece of polycarbonate sheet for the test, to spare the end mills.

1) yes, I know you're blind as a bat

2) Bad lighting, cell phone camera, me operating it, and that's what you get.

Magura 🙂

Zen Mod said:

thicker ......... but not too thick .....

dumb ........ but I'm always dumber ........

good ole L profile , also known as Winkel 😉 ,

40x40x4 mm always seems good enough

just look on pics of Papa's old Alephs , and some other hot amps ;

what you wanna see as "enough meat" , is certainly good for your amp too .

I was thinking for a 6" high heat sink, 4"x4"x0.5" .. too thick? 🙂 combination heat spreader and L bracket.

I've never seen copper L profile either my Danske friend... I'm not sure if one can stick copper plate in a sheetmetal brake either...

Originally posted by Zen Mod wazzat ?

looks like he used the shower door to me...

luvdunhill said:

I've never seen copper L profile either my Danske friend... I'm not sure if one can stick copper plate in a sheetmetal brake either...

I have 😀

with a little skill, you can bend it in a sheetmetal brake, that's how I did it.

These are 10mm thick, machined on mounting surfaces.

Magura 🙂

Attachments

luvdunhill said:

looks like he used the shower door to me...

And?

What do you find most important, a shower door, or a fancy PCB? 😎

Magura 🙂

when it comes to doing new and strange things to metal, you can bet Magura has done it

As always, thicker is better for heat through metal. Surface area rules for metal to air transfer -- but if your fins are too long and the ends are cold, that surface area isn't helping you any.

JJ

As always, thicker is better for heat through metal. Surface area rules for metal to air transfer -- but if your fins are too long and the ends are cold, that surface area isn't helping you any.

JJ

luvdunhill said:if I can cover the entire heat sink, that's good too

Are you sure ?

Suppose you go one step further and wrap the bracket around the entire heatsink surface, what happens to the heatsink's Rth ?

A bracket requires a reasonable flange thickness to prevent it from warping.

It's the cross-sectional area at the 90 degree angle crossing between both flanges that is of importance.

The prettier bracket will look like this =>

Attachments

jacco vermeulen said:

whazzat ?

even dutchie whales have bear's winter snoring habit ?

winter over ?

Zen Mod said:

whazzat ?

Still lacking a trim cut on the edges, and mounting holes.....but that's it.

Magura 🙂

Attachments

Magura said:

Still lacking a trim cut on the edges, and mounting holes.....but that's it.

Magura 🙂

fugly !

CNC-ed

whazzat ?

will it drive F4 ?

Zen Mod said:

fugly !

CNC-ed

whazzat ?

will it drive F4 ?

Yeah, as CNC'ed as they come 😎

Sure it will drive an F4, ok, maybe rather blow it, than drive it

Magura 🙂

Magura said:

Yeah, as CNC'ed as they come 😎

Sure it will drive an F4, ok, maybe rather blow it, than drive it

Magura 🙂

another serbian/danske collaboration ......

some can say - they're

Zen Mod said:

another serbian/danske collaboration ......

Yeah, that seems to be a re-occuring issue

Magura 🙂

Zen Mod said:

another serbian/danske collaboration ......

some can say - they're

Hmm, and we should not forget Slobo, after all he is the one whom got this on the track 😎

Magura 🙂

Magura said:

Hmm, and we should not forget Slobo, after all he is the one whom got this on the track 😎

Magura 🙂

hehe

he's big enough ....... so I shouldn't try to even forget him for a moment ....

I'm just (back of ) napkin (drawing) man .......... and there is real result of Sloba's brainstorming (hehe) and MetalDanske polishing ......

Attachments

whazzat ?

I'm back in time , on top of my back problems ?

I think that I saw two LL's posts - one worshiping MGs and "soon to be here " Tannoys ..... and another one with pic of usual DC blocking gadget .....

Steen - I also adore MGs ...... but I have opportunity to live only with pair of SMG's for a while , driving them with skunky EL84 SE amp 😉

hehe ...... besides some other ...... multi-hundred watt ones 😉

believe it or not , Apogee Minors were pretty same in character .... you can sleep with them singing .....

regarding Tannoys ....... you can't beat olde horn coffins ......

😉

I'm back in time , on top of my back problems ?

I think that I saw two LL's posts - one worshiping MGs and "soon to be here " Tannoys ..... and another one with pic of usual DC blocking gadget .....

Steen - I also adore MGs ...... but I have opportunity to live only with pair of SMG's for a while , driving them with skunky EL84 SE amp 😉

hehe ...... besides some other ...... multi-hundred watt ones 😉

believe it or not , Apogee Minors were pretty same in character .... you can sleep with them singing .....

regarding Tannoys ....... you can't beat olde horn coffins ......

😉

Tannoy 15 inch 385/HPD's are one of our primary in-house

references. We have three pair using Joe Sammut's extra-

special crossover in Jensen Imperial and Ultraflex enclosures.

😎

references. We have three pair using Joe Sammut's extra-

special crossover in Jensen Imperial and Ultraflex enclosures.

😎

Nelson Pass said:Tannoy 15 inch 385/HPD's are one of our primary in-house

references. We have three pair using Joe Sammut's extra-

special crossover in Jensen Imperial and Ultraflex enclosures.

😎

I have just these ones - Poor Serbian Man Tannoys .......

edit:

seems that Steen deleted these two posts ..... but dunno why .... 😱

Attachments

- Home

- Amplifiers

- Pass Labs

- The Pass Pub: The High-End Off Topic Thread