🙂 The 8" Alu Peerless are in a 34L sealed enclosure, the EQ limits SPL to give max ~85dB with a 9Watt amp. At 20Hz you can really see the cone move, good job they have 1 3/4" Xmax 🙂 For a first build they do OK. but could be better... looking forward to hearing twin 8" in action 🙂

Yes, hadn't put enough stuffing into the Nautaloss... just pushed more into the rear chamber, bulking up the density and filling 2/3 behind the driver did the job 🙂

Have all the MDF needed now and will make a start on the template this week, with a long weekend ahead 🙂

Yes, hadn't put enough stuffing into the Nautaloss... just pushed more into the rear chamber, bulking up the density and filling 2/3 behind the driver did the job 🙂

Have all the MDF needed now and will make a start on the template this week, with a long weekend ahead 🙂

BMS,

1 and 3/4 inch xmax is crazy huge. 🙂. Going to dual drivers should cut your xmax and HD (I typically see about 5dB improvement). Have you tried Nautaloss tops with your 15 inch OB as woofer? That may sound very good.

1 and 3/4 inch xmax is crazy huge. 🙂. Going to dual drivers should cut your xmax and HD (I typically see about 5dB improvement). Have you tried Nautaloss tops with your 15 inch OB as woofer? That may sound very good.

Hadn't even thought about trying the Alpha 15A's, certainly worth a listen 🙂

Hmm... Alpha 15A in a H-frame with the Nautaloss sat atop... MJ King outlines a U and H frame build for the Alpha's. Worth a go at a latter stage perhaps!

Hmm... Alpha 15A in a H-frame with the Nautaloss sat atop... MJ King outlines a U and H frame build for the Alpha's. Worth a go at a latter stage perhaps!

X, have you downloaded the new Beta version of REW? v5.20 was made available a couple of days ago... For use with RTA, they've added 'twin tone' to the Generator covering SMPTE, DIN, CCF, plus custom settings... Plus other updates and bug fixes 🙂

Got that Xmax wrong, it's 6.4mm with an 1 3/4 inch voice coil. Their wording makes it sound like it has an 1 3/4 inch Xmax 🙁

Anyhow ... made a start on the MDF Nautaloss. Whole thing isn't going to happen quickly, really need a drill press to do the line-up holes but don't have a drill press or the room if I buy one. So, just need to be really careful when I clamp and router the curves.

Constant expansion spiral from SketchUp to MDF ... 5° kick-back and a flat area for the speaker terminals included on the template. Path length is ~36 inches, Vb is ~5.6L [not taking into account stuffing].

Anyhow ... made a start on the MDF Nautaloss. Whole thing isn't going to happen quickly, really need a drill press to do the line-up holes but don't have a drill press or the room if I buy one. So, just need to be really careful when I clamp and router the curves.

Constant expansion spiral from SketchUp to MDF ... 5° kick-back and a flat area for the speaker terminals included on the template. Path length is ~36 inches, Vb is ~5.6L [not taking into account stuffing].

Attachments

BMS,

That looks beautiful! Will you have some sort of support near the front? Those drivers may be heavy and want to tip it forward, although that was a problem with FC, maybe with MDF you have enough weight behind the first foot to counterbalance? Very nice work though and I can't wait to see the final product. Is this for the 4FE35? How are you handling the ugly bezel on those?

That looks beautiful! Will you have some sort of support near the front? Those drivers may be heavy and want to tip it forward, although that was a problem with FC, maybe with MDF you have enough weight behind the first foot to counterbalance? Very nice work though and I can't wait to see the final product. Is this for the 4FE35? How are you handling the ugly bezel on those?

I'm hoping there'll be enough mass behind the centre line of that front foot to stop it tipping forward. Going to use the Vifa TC9FD, it's SPL should match the Alpha 15A in a H-frame [86dB SPL with f3 of 28Hz].

Attachments

Last edited:

I'm hoping there'll be enough mass behind the centre line of that front foot to stop it tipping forward. Going to use the Vifa TC9FD, it's SPL should match the Alpha 15A in a H-frame [86dB SPL with f3 of 28Hz].

BMS,

Were you thinking of a Nautaloss sub at some point? The sealed Peerless you have would probably work pretty well and maybe you can make an integrated top and bottom as a floor stander?

Interesting idea about an integrated top & bottom based on the Nautaloss. It's something I have thought about trying and could be made with the outward appearance of a normal tower unit. Was thinking that the pathways could be stretched out a little [like a Tuba's shape].

One design direction I like is a sealed variant on the lower part of the twin 8" B&W 802 Diamond enclosure... hefty internal brace and curved side walls... difficult build though.

Vb for the twin 8" Peerless is ~51L for a sealed system Q of 0.65... what length does the pathway need to be? Still ~36 inches? Sd of the twin 8" is about that of a single 12" unit [464.8cm^2 Vs 483.1cm^2].

One design direction I like is a sealed variant on the lower part of the twin 8" B&W 802 Diamond enclosure... hefty internal brace and curved side walls... difficult build though.

Vb for the twin 8" Peerless is ~51L for a sealed system Q of 0.65... what length does the pathway need to be? Still ~36 inches? Sd of the twin 8" is about that of a single 12" unit [464.8cm^2 Vs 483.1cm^2].

templetes #525

Hi there BME: Love those spiral templates and your method of generating. Glad your project sounds so good. Hope you keep us informed of progress with more posts. What is 5-degree kickback? ...regards, Michael

Got that Xmax wrong, it's 6.4mm with an 1 3/4 inch voice coil. Their wording makes it sound like it has an 1 3/4 inch Xmax.

Anyhow ... made a start on the MDF Nautaloss. Whole thing isn't going to happen quickly, really need a drill press to do the line-up holes but don't have a drill press or the room if I buy one. So, just need to be really careful when I clamp and router the curves.

Constant expansion spiral from SketchUp to MDF ... 5° kick-back

and a flat area for the speaker terminals included on the template. Path length is ~36 inches, Vb is ~5.6L [not taking into account stuffing].

Hi there BME: Love those spiral templates and your method of generating. Glad your project sounds so good. Hope you keep us informed of progress with more posts. What is 5-degree kickback? ...regards, Michael

Interesting idea about an integrated top & bottom based on the Nautaloss. It's something I have thought about trying and could be made with the outward appearance of a normal tower unit. Was thinking that the pathways could be stretched out a little [like a Tuba's shape].

One design direction I like is a sealed variant on the lower part of the twin 8" B&W 802 Diamond enclosure... hefty internal brace and curved side walls... difficult build though.

Vb for the twin 8" Peerless is ~51L for a sealed system Q of 0.65... what length does the pathway need to be? Still ~36 inches? Sd of the twin 8" is about that of a single 12" unit [464.8cm^2 Vs 483.1cm^2].

The length is not critical but from 4 to 6 ft should work. You want it long enough to serve as sound black hole and not to long to have resonance mode where you don't want it to be. Since it is sealed it tunes with half wave and not quarter wave.

Thanks X, I'll aim for about 5ft and see what I can come up with in SketchUp... just playing with box sizes in Basta!. If I trade off F3 for a Q of 0.707 I can get Vb down to 37L [before stuffing]... I loose about 3dB at 20Hz, but cone excursion becomes less with the Q 0.707 ...

Hi Michael, 5° kick-back = baffle tilted 5° reward from vertical...

Will certainly keep posting updates as I go... I've stencilled 10 outlines on the 1" MDF and 4 on the 3/4" MDF. Will hopefully start on the cutting out tomorrow 🙂 A CNC router would be real handy for this kind of work.

Hi Michael, 5° kick-back = baffle tilted 5° reward from vertical...

Will certainly keep posting updates as I go... I've stencilled 10 outlines on the 1" MDF and 4 on the 3/4" MDF. Will hopefully start on the cutting out tomorrow 🙂 A CNC router would be real handy for this kind of work.

Last edited:

I think if you can get 30 Hz at -3dB it will sound great for most music. Trying to limit excursion is good - helps to keep the HD down.I lose about 3dB at 20Hz

Sorry to report but the MDF build has temporarily stopped 🙁 The idea of using the template is sound and it's a widely used technique... However, I just don't have the equipment to do this properly at the moment. A good starting point will be a router table.

I've tried doing a few of the outer sections and wasn't able to clamp the template securely enough to stop any flex/movement, plus keep a reasonable working area for the plunge router. Each routed piece is slightly misshaped and not really of acceptable quality for using 🙁

I could screw the template onto the piece to be trimmed, but the hand held router is still not ideal for this type of work. Going to see what is needed to make a basic router table. Plus I'm going to need a longer bit for cutting the 1" MDF...

|-O-|

Stay tuned...

I've tried doing a few of the outer sections and wasn't able to clamp the template securely enough to stop any flex/movement, plus keep a reasonable working area for the plunge router. Each routed piece is slightly misshaped and not really of acceptable quality for using 🙁

I could screw the template onto the piece to be trimmed, but the hand held router is still not ideal for this type of work. Going to see what is needed to make a basic router table. Plus I'm going to need a longer bit for cutting the 1" MDF...

|-O-|

Stay tuned...

A router table isn't hard to figure out:

I used a folding workbench (workmate) so I could clamp the router and a piece of multiply with a centre hole and some clamps underneath

using the routers guiding system.

The template is another matter. I have used a few wooden templates but they were easy to get out of shape (burned by the spinning bearing).

If I had to do more than one cut with a wooden template I covered the edge the bearing follows with a thin strip of sheet aluminium.

I used a folding workbench (workmate) so I could clamp the router and a piece of multiply with a centre hole and some clamps underneath

using the routers guiding system.

The template is another matter. I have used a few wooden templates but they were easy to get out of shape (burned by the spinning bearing).

If I had to do more than one cut with a wooden template I covered the edge the bearing follows with a thin strip of sheet aluminium.

Many years ago, I made a table saw from a portable circular saw using a similar method. I used an old table that was one of those extendable adjustable length ones. Slide it out enough for the blade to fit through and screw it to bottom of table. Then use C-clamps to hold a wooden rail in place.

Thanks wesayso and X, could do with a table saw and workbench also...

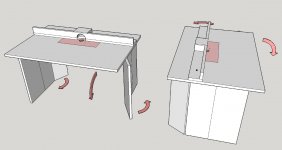

Done a quick design for a fold-away router table, BOM: one 4'x8' 18mm MDF sheet, one 2'x4' 6mm MDF sheet and 10 hinges. I'll go get the materials in the morning, and hopefully have a workable unit by evening 🙂

Done a quick design for a fold-away router table, BOM: one 4'x8' 18mm MDF sheet, one 2'x4' 6mm MDF sheet and 10 hinges. I'll go get the materials in the morning, and hopefully have a workable unit by evening 🙂

Attachments

Not very far of completing the router table today. Just the insert and fence to finish. Stopped for the evening, and about to relax and do some reading.

Followed the design as per the SketchUp drawing, total cost of materials £37 plus a few bits I already had.

Photo 1: all the bits for the job at hand

Photo 2: top, legs and braces cut

Photo 3 & 4: work position and folded up... work top is 60cm x 90cm

Followed the design as per the SketchUp drawing, total cost of materials £37 plus a few bits I already had.

Photo 1: all the bits for the job at hand

Photo 2: top, legs and braces cut

Photo 3 & 4: work position and folded up... work top is 60cm x 90cm

Attachments

Very nice! Nothing like building something to build something, but then your name is Buildmesomething! 🙂

Looks like you really cut wood right inside your living room! How did you get such nice cuts? Did the store do that for you or you did it with a circular saw and your own BMS table-saw?

Looks like you really cut wood right inside your living room! How did you get such nice cuts? Did the store do that for you or you did it with a circular saw and your own BMS table-saw?

- Home

- Loudspeakers

- Full Range

- The Nautaloss Ref Monitor