Cyc,

Would your experiences say that the knuckle test on material works pretty good? Bamboo has always seemed very ringy and zingy when rapped, where Baltic is certainly deader...

Any broad observations?

Would your experiences say that the knuckle test on material works pretty good? Bamboo has always seemed very ringy and zingy when rapped, where Baltic is certainly deader...

Any broad observations?

Ringy/zingy, yeah I think that pretty much covers it.

All of the plyboo bases ended up alters to "Plumbum" as we added mass in attempt to change the "Q" of the resonance.

Very similar to the plinth jpg you posted, the "best of breed" had a number of cavities, with screw down covers. To which we added "bead blasting shot", to taste.

The "Down and Dirty" proto's we simply piled dive weight upon.

The consensus: Plyboo makes attractive furniture.

Cyclotronguy

All of the plyboo bases ended up alters to "Plumbum" as we added mass in attempt to change the "Q" of the resonance.

Very similar to the plinth jpg you posted, the "best of breed" had a number of cavities, with screw down covers. To which we added "bead blasting shot", to taste.

The "Down and Dirty" proto's we simply piled dive weight upon.

The consensus: Plyboo makes attractive furniture.

Cyclotronguy

If someone wanted to play around with an Sp10MKII plinth in "Caramelized Bamboo" a heavy-weight, meaning about 5" thick, Interchangeable arm-board: you may be able to pick one off at a good price. PM me and I'll give you contact as to where it resides.

Usual disclaimer: no affiliation

Cyclotronguy

Usual disclaimer: no affiliation

Cyclotronguy

Well, ring/zingy it is not very correct term for it. If you think of MDF it is more "dead" that Baltic. You need to look and think about the spectrum density, and how vibrations will be propagating in the media. If you fill some holes with just "Plumbum", it will not guarantee "deadening" the plinth. There is not only one resonance with one "Q". That's actually why I started this discussion 🙂.

The fibre density (or 'packing') is very varied in bamboo. The outer fibres are densely packed but become far looser as the central core is approached. There is a lot of pith between the looser fibres. Further, a lot of the very densest fibres are planed away during the making of board; alternatively board which has not been fully flattened will have a greater air content than that which has. Bamboo also has a very high water content unless baked and formed and sealed in a very dry atmosphere. In a typical home with normal heating it will undoubtedly shrink, to some degree, over time.

My own belief is that good close-formed/dense slate with layers of Duralumin is about as good as you will get without spending $1000 on tank wood.

I still believe that to mount just the motor (with all electronics 'off board' is the way to go. That big metal top-plate is a real bug!! Get rid of it; Cotter did and produced a top TT for that time. Also, a vibration drain under the main bearing is a big advantage.

My own belief is that good close-formed/dense slate with layers of Duralumin is about as good as you will get without spending $1000 on tank wood.

I still believe that to mount just the motor (with all electronics 'off board' is the way to go. That big metal top-plate is a real bug!! Get rid of it; Cotter did and produced a top TT for that time. Also, a vibration drain under the main bearing is a big advantage.

SH-10E PSU Pilot Light

Quick questions guys - Pilot Light on all 3 of the SH-10E PSU's i've got, don't work for some reason. Fuses are ok. Might be unlucky and have 3 duff lights of course...

1. Any ideas on what voltages i should be expecting for the pilot light as the schematics don't seem to indicate that?

2. Can it be replaced with an LED (and appropriate current limiting resistor)?

Cheers!

Chris.

Quick questions guys - Pilot Light on all 3 of the SH-10E PSU's i've got, don't work for some reason. Fuses are ok. Might be unlucky and have 3 duff lights of course...

1. Any ideas on what voltages i should be expecting for the pilot light as the schematics don't seem to indicate that?

2. Can it be replaced with an LED (and appropriate current limiting resistor)?

Cheers!

Chris.

2 More SP10 MkIIs

Last weekend I bought two SP10 MkIIs from an old radio station stash when I went there to pick up a Gates TT that I had bought on Ebay. The SP10s don't have power supplies, and I spent slightly more than I was comfortable with to roll the dice. If I get one good one I'll be very happy. Two would be major good luck.

They will hereby be known as Thing 1 and Thing 2. Pix below.

I have some questions of course.

1) Any thoughts regarding how to find a known working PS to see if I have a spinning turntable. I have looked at making supplies and am comfortable putting one or two together, but I'd sure like to know sooner rather than later if that's a fool's errand. I own the Fool label already. I live about 80 miles south of San Francisco CA.

2) Does anyone know what the PS connector is so I can order the PS box end that will mate with the cables from the TTs? I have the PS schematic that shows the pinout, but I am not sure about the convention that would tell me which side of which connector (male or female) that diagram indicates.

3) Does the black chassis tag versus the bright tag mean anything?

4) One table has platter to hub screws, the other does not. The ones that are present do not have shoulders as I have seen on posts. Can these be sourced, or should I make something up?

5) Not a question, but they didn't have the transportation motor fixing plates, so I will be making those from the template.

Thanks for your help -- Here's hoping.

Skip

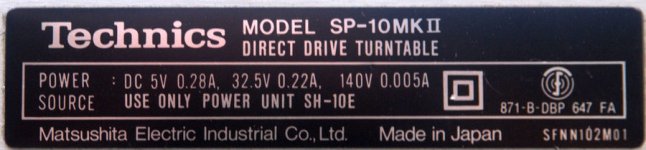

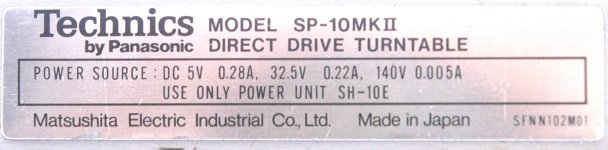

Thing 1 tag and top photo on left; Thing 2 on right:

Last weekend I bought two SP10 MkIIs from an old radio station stash when I went there to pick up a Gates TT that I had bought on Ebay. The SP10s don't have power supplies, and I spent slightly more than I was comfortable with to roll the dice. If I get one good one I'll be very happy. Two would be major good luck.

They will hereby be known as Thing 1 and Thing 2. Pix below.

I have some questions of course.

1) Any thoughts regarding how to find a known working PS to see if I have a spinning turntable. I have looked at making supplies and am comfortable putting one or two together, but I'd sure like to know sooner rather than later if that's a fool's errand. I own the Fool label already. I live about 80 miles south of San Francisco CA.

2) Does anyone know what the PS connector is so I can order the PS box end that will mate with the cables from the TTs? I have the PS schematic that shows the pinout, but I am not sure about the convention that would tell me which side of which connector (male or female) that diagram indicates.

3) Does the black chassis tag versus the bright tag mean anything?

4) One table has platter to hub screws, the other does not. The ones that are present do not have shoulders as I have seen on posts. Can these be sourced, or should I make something up?

5) Not a question, but they didn't have the transportation motor fixing plates, so I will be making those from the template.

Thanks for your help -- Here's hoping.

Skip

Thing 1 tag and top photo on left; Thing 2 on right:

Attachments

1) I bought a Rolls Royce ps and am very satisfied, but I am a long term SP10 mk11 user. It might be pricey for just curiosity.

Technics SP 10 Power Supply NEW 5 Year Warranty SH10 E SH 10ea Replacement PSU | eBay

4) The platter screw "shoulders" are actually a clear hard plastic sleeve. You should find some suitable plastic tube to fit.

Technics SP 10 Power Supply NEW 5 Year Warranty SH10 E SH 10ea Replacement PSU | eBay

4) The platter screw "shoulders" are actually a clear hard plastic sleeve. You should find some suitable plastic tube to fit.

Hi Chris, only just seen this. I use a 12v filament bulb, easy to get and works well.

Hi Skip, the connector is a 4 pin XLR, it should be marked with pin numbers. I would try to borrow a PSU to see if they are working at all.

Hi Bon, thanks for your compliment !

Dave

Hi Skip, the connector is a 4 pin XLR, it should be marked with pin numbers. I would try to borrow a PSU to see if they are working at all.

Hi Bon, thanks for your compliment !

Dave

Thanks Bon and Dave!

I thought it looked like XLR but wanted to be sure. Don't want 140 VDC on the 5 VDC pin into the TT. I sure would like to borrow a PS for the first trial, and I'm more than willing to drive several hours with the 'Things' to test them at the PS owner's location. Hope that opportunity arises.

Skip

I thought it looked like XLR but wanted to be sure. Don't want 140 VDC on the 5 VDC pin into the TT. I sure would like to borrow a PS for the first trial, and I'm more than willing to drive several hours with the 'Things' to test them at the PS owner's location. Hope that opportunity arises.

Skip

Last edited:

Can someone put me out my misery and buy the SP-10 motor that's currently on ebay uk for £169 or best offer. The seller had a plinth as well which has gone. But with each passing day I get more tempted...

Because its a 3-phase BLDC motor at the end of day. Last 15 years has been a lot of development in motor drive tech such that a £60 board from Farnell will drive it. Even washing machines are direct drive now!

Whether it will drive it as well or better than the 70s tech is of course the open question, and the one I would like to answer...

Whether it will drive it as well or better than the 70s tech is of course the open question, and the one I would like to answer...

Well Dave....they could start by buying a PS as did Bon (Post 828 above) from you and then try to find a platter etc - I have one but NOT for sale as I have a motor + PS which has been with Richard Peachy of the now defunct Vantage Audio for more years than I can remember!

As I live a good few hundred miles away from that man it is hardly likely that I will camp out on his doorstep with a baseball bat until I have it returned. As he has ignored every email, posts on UK websites etc. it is now probable that I will have to take full legal action to have it returned, or, alternatively pigs may fly!!!

As I live a good few hundred miles away from that man it is hardly likely that I will camp out on his doorstep with a baseball bat until I have it returned. As he has ignored every email, posts on UK websites etc. it is now probable that I will have to take full legal action to have it returned, or, alternatively pigs may fly!!!

Sorry no. There isn't any BLDC driver that will work with it. And MY PSU needs the driver boards too.

Dave

Dave

Last edited:

Am I right in now thinking that your PS provides no more than the raw voltages needed to supply the driver boards?

Sorry no. There isn't any BLDC driver that will work with it. And MY PSU needs the driver boards too.

Dave

Well having gone through the service manual I cannot see anything magic about that motor that would prevent it. Could you please explain why?

Oh my ! No, my PSU provides three regulated voltages. As for controllers, it's the position sensors that are totally incompatible.

Dave

Dave

I don't see an issue with position sensors. I'm looking at a number of ways around that. Some controllers use flux measurements to commutate. I don't hold out much hope for its absolute accuracy, but want to test it on some cheapy motors of which I have a good collection now.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread