"improving structural integrity"

How are you doing this?

Are the holes part of it, or is that just to lighten it?

Looks cool.

How are you doing this?

Are the holes part of it, or is that just to lighten it?

Looks cool.

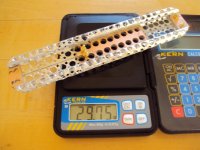

At the moment it weights 43 g, including the screws.

Approx what weight you're aiming for Joachim ?

I did not do any calculation so far.

The idea at the moment is to make it as light as possible.

I also do not know how long it will be so i may shorten it.

The idea at the moment is to make it as light as possible.

I also do not know how long it will be so i may shorten it.

Last week I got a carbon fibre rectangular rod. Will have to see how it compares with the cylindrical rod received a few weeks earlier.

I have access to a Stanford Research SR-785 which does a great job of vibration analysis.

I have access to a Stanford Research SR-785 which does a great job of vibration analysis.

Now that we are back on arms.

I realise that most of you diy'ers are into Tangental tracking arms but I would like to try & better my RB 300 & LP 12

I am still collecting parts for a Diy Uni Pivot; I may also try & make Golf ball arm as well but no hurry for that.

Some Questions:

1. What is the preferred tone arm wire (Iv'e read about using PC mouse wire !!) & where can it be sourced for a reasonable price in the UK. or can it be made by the Diy er.

2. If I use a metal biro insert (these seem to be more difficult to find than I imagined, as their now mostly made from plastic) for the Uni Pivot, What do I use for the 'ball' to rest in, inside the arm tube.

3. Is a 12" arm length the most preferred now.

4. What is the correct Angle for the cartridge to track at in a 12" arm.

5. I understand VTA, but would like any input on building it into the arm body / base so that it can be adjusted "on the fly" an elegant solution would be nice!

6. Don't understand 'Azimuth' so well, any tips on how & what to do with it.

7. Also simple / elegant, Anti Skating solution would be appreciated.

Not daft just got started late.

Jay

I realise that most of you diy'ers are into Tangental tracking arms but I would like to try & better my RB 300 & LP 12

I am still collecting parts for a Diy Uni Pivot; I may also try & make Golf ball arm as well but no hurry for that.

Some Questions:

1. What is the preferred tone arm wire (Iv'e read about using PC mouse wire !!) & where can it be sourced for a reasonable price in the UK. or can it be made by the Diy er.

2. If I use a metal biro insert (these seem to be more difficult to find than I imagined, as their now mostly made from plastic) for the Uni Pivot, What do I use for the 'ball' to rest in, inside the arm tube.

3. Is a 12" arm length the most preferred now.

4. What is the correct Angle for the cartridge to track at in a 12" arm.

5. I understand VTA, but would like any input on building it into the arm body / base so that it can be adjusted "on the fly" an elegant solution would be nice!

6. Don't understand 'Azimuth' so well, any tips on how & what to do with it.

7. Also simple / elegant, Anti Skating solution would be appreciated.

Not daft just got started late.

Jay

jackinnj,

I'll be interested to see your results of the test of the two different shapes. Intuitively the rectangle should be stiffer, but this is different than a vibration test. I would think that a triangular shape could have the best shape between these two other profiles. Can we assume that these are straight section composites? After you do your testing it would be interesting to see how different the vibration properties would change with a very low density foam material fill in the same shape. I am thinking of a 2lb density urethane foam expanded into the shape. Just some thoughts.

Steven

I'll be interested to see your results of the test of the two different shapes. Intuitively the rectangle should be stiffer, but this is different than a vibration test. I would think that a triangular shape could have the best shape between these two other profiles. Can we assume that these are straight section composites? After you do your testing it would be interesting to see how different the vibration properties would change with a very low density foam material fill in the same shape. I am thinking of a 2lb density urethane foam expanded into the shape. Just some thoughts.

Steven

Now that we are back on arms.

I realise that most of you diy'ers are into Tangental tracking arms but I would like to try & better my RB 300 & LP 12

I am still collecting parts for a Diy Uni Pivot; I may also try & make Golf ball arm as well but no hurry for that.

Some Questions:

1. What is the preferred tone arm wire (Iv'e read about using PC mouse wire !!) & where can it be sourced for a reasonable price in the UK. or can it be made by the Diy er.

2. If I use a metal biro insert (these seem to be more difficult to find than I imagined, as their now mostly made from plastic) for the Uni Pivot, What do I use for the 'ball' to rest in, inside the arm tube.

3. Is a 12" arm length the most preferred now.

4. What is the correct Angle for the cartridge to track at in a 12" arm.

5. I understand VTA, but would like any input on building it into the arm body / base so that it can be adjusted "on the fly" an elegant solution would be nice!

6. Don't understand 'Azimuth' so well, any tips on how & what to do with it.

7. Also simple / elegant, Anti Skating solution would be appreciated.

Not daft just got started late.

Jay

Don't dick about with mouse wire, just buy Cardas.

Litz.......😀

Seriously, a small gauge copper stranded wire that you could easily braid yourself would work as good as anything else.

Seriously, a small gauge copper stranded wire that you could easily braid yourself would work as good as anything else.

jackinnj,

I'll be interested to see your results of the test of the two different shapes. Intuitively the rectangle should be stiffer, but this is different than a vibration test. I would think that a triangular shape could have the best shape between these two other profiles. Can we assume that these are straight section composites? After you do your testing it would be interesting to see how different the vibration properties would change with a very low density foam material fill in the same shape. I am thinking of a 2lb density urethane foam expanded into the shape. Just some thoughts.

Steven

Well, I have to speak with one of my physics/optics guys -- he has one of those vibration proof/auto leveling tables they use in laser physics -- and i can get some help with the equations. I am thinking that any play in the horizontal hinge mechanism will undo any benefit of a stiff arm.

Instead of accelerometers, can probably just use optics.

jackinnj,

I would think a laser interferometer would show you what you want to see. As far as any loose fit in the gymbal bearing that should be at least partially taken out by gravity and the weight of the assembly keeping it sitting in the bottom of the clearance. I just don't see that assembly bouncing up off the pivot point, doesn't seem like you would have the movement to do that at that position.

I would think a laser interferometer would show you what you want to see. As far as any loose fit in the gymbal bearing that should be at least partially taken out by gravity and the weight of the assembly keeping it sitting in the bottom of the clearance. I just don't see that assembly bouncing up off the pivot point, doesn't seem like you would have the movement to do that at that position.

This is the end of the line. Slightly under 30gr.

I could drill a small hole here and there but that will not help much to reduce the weight even further.

I think i reduced it by over 40%.

Lokks like a hot rod from here 🙂

The complete assembly is very "dead" when i tab it.

I have an idea for a tangential sliding mechanism. I am waiting for parts to build it.

I have an idea for a tangential sliding mechanism. I am waiting for parts to build it.

Joachim,

When you say tangential are you saying that it will be a linear tracking arm, or is are you saying that the head shell will move as the arm tracks?

When you say tangential are you saying that it will be a linear tracking arm, or is are you saying that the head shell will move as the arm tracks?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- The Good Turntable