I once read all Radio Electronica magazines from the 1950's, back then a Dutch magazine meant for electronics hobbyists. I was amazed to read the things some DIYers built then.

There were quite some DIY amplifier designs and valve radios in it, but also DIY televisions using radar cathode ray tubes from dump stores. The CRT's screen was about the size of a postcard, so you see advertisements for special magnifying lenses for it in later issues.

There was one design for a tape recorder (the Herx recorder, named after its designer). The designer had made his own tape heads using mu metal from a military microphone transformer from the dump store. He had made the complete mechanical part of the recorder himself, including the capstan. The motor was a bicycle dynamo. He made the electronics from valves that were available at dump stores.

I've seen measurements of it and it worked remarkably well for a 1950's recorder. At start-up, one had to give the dynamo a little push to make it rotate in the correct direction.

There were quite some DIY amplifier designs and valve radios in it, but also DIY televisions using radar cathode ray tubes from dump stores. The CRT's screen was about the size of a postcard, so you see advertisements for special magnifying lenses for it in later issues.

There was one design for a tape recorder (the Herx recorder, named after its designer). The designer had made his own tape heads using mu metal from a military microphone transformer from the dump store. He had made the complete mechanical part of the recorder himself, including the capstan. The motor was a bicycle dynamo. He made the electronics from valves that were available at dump stores.

I've seen measurements of it and it worked remarkably well for a 1950's recorder. At start-up, one had to give the dynamo a little push to make it rotate in the correct direction.

Member

Joined 2009

Paid Member

If you want to escape from all this narcissistic whining check out some of the stuff here:

https://hackaday.com/tag/projects/

Here’s one showing a home made atomic force microscope

https://hackaday.com/2014/04/29/a-diy-atomic-force-microscope/

https://hackaday.com/tag/projects/

Here’s one showing a home made atomic force microscope

https://hackaday.com/2014/04/29/a-diy-atomic-force-microscope/

". Maybe your USB scopes sit in that hole?"

Yes I sell between £25-£30. The slowest one is 3.3 mega samples/second and is about 100KHz bandwidth.

They are both dual channel.

The faster one is 17 mega samples/second and bandwidth just over 1MHz.

It has scope and spectrum analyser software for the PC.

It also has a data logger and captures data say overnight and you read it back next morning.

Sold about 30 in last few months.

They work OK for audio.

I also found them useful for debugging model railway 10KHz DCC signals.

Yes I sell between £25-£30. The slowest one is 3.3 mega samples/second and is about 100KHz bandwidth.

They are both dual channel.

The faster one is 17 mega samples/second and bandwidth just over 1MHz.

It has scope and spectrum analyser software for the PC.

It also has a data logger and captures data say overnight and you read it back next morning.

Sold about 30 in last few months.

They work OK for audio.

I also found them useful for debugging model railway 10KHz DCC signals.

I admit that I played the guitar from age 6 and was fed years of guitar lessons. I stuck with it because I had the dream. Fortunately, there were two incidents in my teen years that killed that dream for good........ people still hanging on to dreams of being rich and famous via music. Some had been hanging onto that same dream for many decades, but still couldn't let it go.

I played popular surf music in a garage band for a couple years around age 14. The other guitar player had a nice Hagstrom Guitar and lots of goodies, but he was one of those undermotivated kids. His older brother was in a real band. My mother like the Monkees because of their horrible TV show. She kept trying to get me to play their music. She even offered to buy us tickets to their upcoming concert. We laughed. When the older brother heard about the offer, he jumped at it and even volunteered to take us to the show. He had a car. Surprisingly my mom went for it. So why would a 17 year old high school kid be willing to take his younger brother and a tag along to a concert? Apparently the opening act was a young superstar guitar player. His name was Jimi Hendrix. That show convinced all three of us that we would never be rock stars. Layne, my band mate would lose interest in playing the guitar within a year. His mother sold me the Hagstrom. I kept playing off and on for years.

Around age 17 through 20 I hung around a third rate recording studio. I didn't get paid, but I fixed stuff in exchange for free access to play with all the toys. There I met a few real rock stars. Most were not happy people. The group that I became friends with were a local band called Fantasy that had an instrumental top 10 radio hit, Stoned Cowboy in 1970. They got screwed over royally by the record company. They bankrupted all the players, made it impossible to fulfil their contract, fired all the musicians except for the young female singer. They wanted her to front Big Brother and the Holding Company after Janis Joplin died. That didn't work out and Lydia Janene Miller died at age 45.

Shortly after Fantasy was dissolved I quit hanging out at the studio and the University of Miami music lab and took a job 40 miles north of Miami at Motorola.

One aspect which has taken away most of the fun I used to have designing and building my electronic equipment, is the sad fact, that PCB design and creation has become extremely cumbersome and inconvenient. In the old gone days of my youth, I used to use PCB transfers which were quick to use and produced very professionally looking PCBs in a matter of two or three hours. These days, PCB design requires the use of unnecessarily bloated and complicated software, which is often intended to be used by professionals with long years of training as opposed to enthusiasts. After the great hassle of having to use cryptic software packages to design a PCB, the latter's design files have to be sent to some company to do the actual PCB production with a cost per square centimetre. I consider all this a huge regression. The enthusiast benefited greatly using legacy methods, but without ready made transfers, this is impossible.

I tried the toner transfer method which worked to successfully transfer the toner, but the latter, remained stuck to the paper it was printed upon no matter how long it was immersed in water! Paper is very difficult to dissolve in water. So, I am stuck with ugly unprofesssionally looking PCBs and have to be contented by telling myself that the most important thing about a PCB, is that it works!

I tried the toner transfer method which worked to successfully transfer the toner, but the latter, remained stuck to the paper it was printed upon no matter how long it was immersed in water! Paper is very difficult to dissolve in water. So, I am stuck with ugly unprofesssionally looking PCBs and have to be contented by telling myself that the most important thing about a PCB, is that it works!

I do not agree. Eagle is very easy to learn and the 80 x 100mm 2-layer limited version is still for freeOne aspect which has taken away most of the fun I used to have designing and building my electronic equipment, is the sad fact, that PCB design and creation has become extremely cumbersome and inconvenient. In the old gone days of my youth, I used to use PCB transfers which were quick to use and produced very professionally looking PCBs in a matter of two or three hours. These days, PCB design requires the use of unnecessarily bloated and complicated software, which is often intended to be used by professionals with long years of training as opposed to enthusiasts. After the great hassle of having to use cryptic software packages to design a PCB, the latter's design files have to be sent to some company to do the actual PCB production with a cost per square centimetre. I consider all this a huge regression. The enthusiast benefited greatly using legacy methods, but without ready made transfers, this is impossible.

https://www.autodesk.com/products/eagle/free-download

and there are of course another software products usable for amateurs.

There are numerous PCB production companies that will make a PCB from Eagle output production files, like this one:

https://www.pcbway.com/

And it is not expensive. We just may not be lazy and must be willing to learn. I have stopped using nest-wired samples or amateurish production of PCBs more than 20 years ago - the time spent and the results of amateurish attempts were just not worth it.

It is all about personal attitude and willingness to learn during our whole life.

I tried gEDA PCB, a free to use and distribute open sourced program. However, the PCB makers I found googling, need other formats and I had to convert the native gEDA format into some weird, unknown to me format: that discouraged me completely. There are far too many unknowns for something I used to do in a matter of a few hours cheaply and with very good results.

Regarding using the proprietary software Eagle, the imposed size limitation of 8cm*10cm is a hurdle for amateurs as these usually make things bigger for themselves to handle more easily. A more logical restriction would have been a restriction on complexity and device use: that would have affected any commercial user of the software by professionals, instead of hitting amateurs.

Regarding using the proprietary software Eagle, the imposed size limitation of 8cm*10cm is a hurdle for amateurs as these usually make things bigger for themselves to handle more easily. A more logical restriction would have been a restriction on complexity and device use: that would have affected any commercial user of the software by professionals, instead of hitting amateurs.

Last edited:

For me, fun and thrill is still there with every new project. What I find different is that never ending chain of depressing world events is influencing my desire to start a new project. I have fresh PCBs and Mouser component boxes laying in the corner for weeks.

These days, for an enthusiast hobbyist, nothing beats KiCad. It’s free software with no limitations as Eagle, suitable for most demanding professional needs, and still very easy to learn.

KiCad

After only a day or two of poking around, you will be able to prepare first simple PCB.

As a kid, I was making PCB designs with tools for technical drawing (Rotring ink pens on semitransparent paper) and photosensitive coating, UV lamp and etching chemicals. 🙂In the old gone days of my youth, I used to use PCB transfers which were quick to use and produced very professionally looking PCBs in a matter of two or three hours. These days, PCB design requires the use of unnecessarily bloated and complicated software, which is often intended to be used by professionals with long years of training as opposed to enthusiasts.

These days, for an enthusiast hobbyist, nothing beats KiCad. It’s free software with no limitations as Eagle, suitable for most demanding professional needs, and still very easy to learn.

KiCad

After only a day or two of poking around, you will be able to prepare first simple PCB.

I tried KiCad but have to give up due to its complexity and unnecessary tests in my case. I also remember it crashing while using it thrashing my time and effort. I have it installed under Devuan (Linux) and read a tutorial, but it was all in vain: too many programmatic errors lead to the program being killed by the kernel (crashing). The reported error was, if I remember well: "segmentation fault" or "access violation" in Windows.

Was it a reasonably up to date KiCad? Devuan is a fork of Debian and the Debian package manager installs very old versions of everything.

I manually installed KiCad on my Debian computer and it works fine as long as I don't try to open two PCB calculators simultaneously.

I manually installed KiCad on my Debian computer and it works fine as long as I don't try to open two PCB calculators simultaneously.

Thank you for mentioning KiCad, I have just installed it and it seems to be a good PCB SW tool.These days, for an enthusiast hobbyist, nothing beats KiCad. It’s free software with no limitations as Eagle, suitable for most demanding professional needs, and still very easy to learn.

KiCad

After only a day or two of poking around, you will be able to prepare first simple PCB.

Which version?MarcelvdG said:I manually installed KiCad on my Debian computer and it works fine...

I remember myself trying to learn Borland Delphi in vain until I found a book on Amazon, purchased it and read/studied a few chapters. Unless I do that again, it is all in vain. Books are essential for me.

Last edited:

My 16 year old grandson spends far too much time playing video games. He has a YouTube channel that is mostly him playing video games. He has been zapped a few times by YouTube for using copyrighted music in his videos, and has been asking me how to avoid this. I have explained how to make his own music with a DAW and a PC and he is slowly gaining interest. I have been slowly collecting stuff to make him a rudimentary "music construction set" for his upcoming birthday. We have dragged all 4 grandkids to several live music concerts at a local high school which were performed by kids their age. Some of these were very good. Last night at a large show (over 100 kids on stage) he heard something that clicked in his head, and he asked me, "how can I make something like that?"My son got into video games when he was young and we worried about that becoming his sole pursuit in life. I felt much better the day I came home and him and his friend had hooked up the motion sensor from his Xbox to a Lego Mindstorms robot and programmed it so they could control the robot using hand gestures. His fun now frequently involves a soldering iron followed by programming.

One aspect which has taken away most of the fun I used to have designing and building my electronic equipment, is the sad fact, that PCB design and creation has become extremely cumbersome and inconvenient.

I tried the toner transfer method which worked to successfully transfer the toner, but the latter, remained stuck to the paper it was printed upon no matter how long it was immersed in water! Paper is very difficult to dissolve in water. So, I am stuck with ugly unprofesssionally looking PCBs and have to be contented by telling myself that the most important thing about a PCB, is that it works!

For a quick and ugly PCB, you can still draw the design directly on copper clad board with a fresh Sharpie and etch it. You can also use masking tape directly on the board for resist. Use wide tape to cover the whole board. Rub it down good with the butt end of a screwdriver or a spoon, then cut and peel away the areas you want etched. Some people claim that this step can be done with a Cricut machine, but I never tried it.I do not agree. Eagle is very easy to learn and the 80 x 100mm 2-layer limited version is still for free

https://www.autodesk.com/products/eagle/free-download

There are numerous PCB production companies that will make a PCB from Eagle output production files, like this one:

Eagle has its quirks, but I started with DOS version 2.5 and still use V 5.11 today. The free version is virtually useless for vacuum tube amps due to its size limitation. I have created all the necessary libraries I'll ever need for vacuum tube amps, so Eagle 5.11 is fine for those boards. The toner transfer process works for me if I use real toner transfer paper from Mouser. Some magazine pages work OK too, but some don't. For anything that involves making more than two boards, I send the files off to China and get nice boards back in a couple weeks, often cheaper than making my own boards.

https://www.mouser.com/ProductDetail/Pulsar/TONER-TRANFER-PAPER-50-1102?qs=KM10vAbi7NgEjO92RWGifA==

I am now at the point where I need to make some music synthesizer boards that are mostly, or all SMD. My 15 year old Eagle libraries are not sufficient as most of the newer SMD parts are not in them. I have downloaded KiCad and Design Spark and played with both a bit. Both have released new versions since I last spent any time with them, so I need to repeat the process. So far I'm leaning towards KiCad as Design Spark could easily slip down the Eagle path to expensiveware.

Anyone out there have any experience comparing these two, or KiCad and any other popular freeware or cheapware package. I'm looking at medium density SMD on 2 or 4 layer boards and vacuum tube stuff on 2 layer boards with a board size of up to 8 X 12 inches (200 X 300 mm).

I am sorry, but no way. I always start with a 2-sided PCBs even for prototypes, can't imagine drawing this by hand. I know what I speak about, 40 years ago I made my proto boards by hand. Depends what we want to do and what we expect to get. Too many variables 😉.For a quick and ugly PCB, you can still draw the design directly on copper clad board with a fresh Sharpie and etch it. You can also use masking tape directly on the board for resist. Use wide tape to cover the whole board. Rub it down good with the butt end of a screwdriver or a spoon, then cut and peel away the areas you want etched.

I use a version similar to Autocad (mechanical CAD software) to draw my PCBs.

Mostly double layer (SMD or TH), but have done 4-layer before.

Have also etched many 2-layer boards that way, down to 0.3mm traces.

It is half way between by hand, or using a PCB design software, I guess.

Cheers,

Patrick

Mostly double layer (SMD or TH), but have done 4-layer before.

Have also etched many 2-layer boards that way, down to 0.3mm traces.

It is half way between by hand, or using a PCB design software, I guess.

Cheers,

Patrick

EasyEDA: Simple version should do: https://easyeda.com/editorAnyone out there have any experience comparing these two, or KiCad and any other popular freeware or cheapware package. I'm looking at medium density SMD on 2 or 4 layer boards and vacuum tube stuff on 2 layer boards with a board size of up to 8 X 12 inches (200 X 300 mm).

I've done two and four layer with it, and you can even have the SMT stuff populated for you. You can even have them order the parts from Mouser etc instead of LCSC.

Pro version if you need a more complicated board: https://pro.easyeda.com/editor

We or at least I realize how fortunate we are to have low cost pcb mfg in Asia. I use jlcpcb as my supplier these days. I certainly would not waste a dime or time trying to fab my own pcb. I am still running orcad 16 although I have to run capture on the win 7 machine. One day I know I have to switch old orcad off and move on but for now it works like a charm.

I have tried diptrace and easyeda, limited, lame is the best way to describe them without being rude.

A good amount of time has to be invested in libraries to make them work for your design process. Being able to minimize the time spent on documentation loading boms into mouser project manager etc all count as part of the design process

I have tried diptrace and easyeda, limited, lame is the best way to describe them without being rude.

A good amount of time has to be invested in libraries to make them work for your design process. Being able to minimize the time spent on documentation loading boms into mouser project manager etc all count as part of the design process

Last edited:

Anyone out there have any experience comparing these two, or KiCad and any other popular freeware or cheapware package. I'm looking at medium density SMD on 2 or 4 layer boards and vacuum tube stuff on 2 layer boards with a board size of up to 8 X 12 inches (200 X 300 mm).

My suggestion is to go Kicad, you'll have a large community to draw from and it has an incredibly large library of parts. Most other PCB packages are either crippleware or a variation of a cloud based software package. What happens if the cloud service is withdrawn, you may loose all your schematics and pcb files.

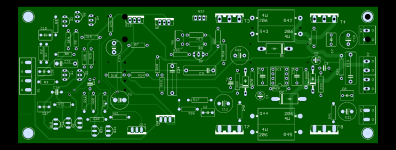

Here's my first attempt (albeit a work in progress) at a 2 layer pcb board layout in Kicad (to give some scale the flooded copper area is 60mm x 70mm) :

Last edited:

I think there's still a lot of the fun left to DIY when you're designing, and/or building out a new circuit, trying new ideas. Basically that part where you explore and discover with no obligations other than your own pursuits. This can be very rewarding. Discussing and sharing ideas with like-minded people on forums such as here can also be enjoyable when it's constructive conversation..and most members here are very helpful and polite. I've tried to keep to DIY audio as a hobby, although I've built and sold some finished products, and done servicing on existing gear (mostly musical instrument audio and pro audio) locally. Would I want to turn this into a full time working gig? I don't charge a lot for bench fees (and people have told me I don't charge nearly enough), but that's OK by me. My day job is in industrial controls and automation, so there's a real risk of DIY audio feeling like my "job" if I started to pursue it as a "business". The service rates for industrial electronics are about six times what I would charge out to a friend who wanted me to service a guitar amp. So I do it because it's still fun to get the amp back into shape, get to meet and chat with musicians about gear, and sometimes they'll gift me with a bottle of wine or something as a token of appreciation. That's worth more to me than trying to make a profit from it.

I remember buying Visual Studio on 26 floppies in around 1995.I remember myself trying to learn Borland Delphi in vain until I found a book on Amazon, purchased it and read/studied a few chapters. Unless I do that again, it is all in vain. Books are essential for me.

It was very hard to use.

I got Delphi 2.0 free on a magazine cover.

Tried it and it was 100 times better than Visual Studio.

I converted a 300,000 line assembly language program to Delphi quite quickly.

- Home

- Member Areas

- The Lounge

- The fun has gone out of DIY audio ?