Hi Joe,

is it worth considering getting these made out of plastic, I bet someone on this forum has the means? You have obviously got a good mould.

is it worth considering getting these made out of plastic, I bet someone on this forum has the means? You have obviously got a good mould.

North America wave guide GB

Joe,

Thanks for the wave guide information and pictures and also the future dimensions and drawings.

If everybody that responded earlier is still with us, including BHD and mantraxl, we have 7 in our group, assuming the final cost is acceptable to everybody. We shall appreciate it if you and Steve would let us know how to proceed the negotiations.

Thanks,

Francois

Hi Guys

Steve and I had a good discussion and we have made some decisions you guys might be interested in.

....

Of course Group Buys will be negotiated with Steve - at this stage have not yet decided on any details. But if they are all sent to the same address, say in the US, then the saving on Air freight alone will help.

...

Cheers, Joe R.

Joe,

Thanks for the wave guide information and pictures and also the future dimensions and drawings.

If everybody that responded earlier is still with us, including BHD and mantraxl, we have 7 in our group, assuming the final cost is acceptable to everybody. We shall appreciate it if you and Steve would let us know how to proceed the negotiations.

Thanks,

Francois

Gday All

My first post so be gentle with me.

First batch of waveguides will be sent to Joe next Monday.

Long time follower of this thread.

Elsinores has been my first effort in the DIY audio world and I am blown away with the results.

A couple of photos of my pair attached (I hope)

My first post so be gentle with me.

First batch of waveguides will be sent to Joe next Monday.

Long time follower of this thread.

Elsinores has been my first effort in the DIY audio world and I am blown away with the results.

A couple of photos of my pair attached (I hope)

Attachments

Greenpea, excellent photo. There gorgeous!

Thanks for working on the waveguides and looking forward to seeing the plans.

Thanks again, Joel

Thanks for working on the waveguides and looking forward to seeing the plans.

Thanks again, Joel

Hello

Just wondering if it matters if the drivers are installed, rotated by 90 degrees?

So the flats of the speaker sides are vertical with the side of the cabinet instead of horizontal.

Just for a different look thats all.

Well done greenpea looks great,the picture reminds me i still goto make the grille frame.Thanks for the waveguides.

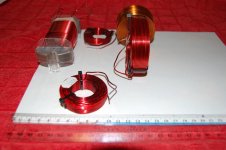

Currently trying to set out the coils on a4 paper for best orientation any suggestion appreciated.

I was looking at humbles website and he packs the stuff really close together, couldn't find one with five coils though.I did see his write up on coil placement but the five on one board got me.

Cheers Paul

Just wondering if it matters if the drivers are installed, rotated by 90 degrees?

So the flats of the speaker sides are vertical with the side of the cabinet instead of horizontal.

Just for a different look thats all.

Well done greenpea looks great,the picture reminds me i still goto make the grille frame.Thanks for the waveguides.

Currently trying to set out the coils on a4 paper for best orientation any suggestion appreciated.

I was looking at humbles website and he packs the stuff really close together, couldn't find one with five coils though.I did see his write up on coil placement but the five on one board got me.

Cheers Paul

Attachments

Pictures 2 and 3..

I,m thinking picture 2 as it keeps the coils relative to the wiring diagram.(V5)

Less chance of me stuffing it up.

I,m thinking picture 2 as it keeps the coils relative to the wiring diagram.(V5)

Less chance of me stuffing it up.

Attachments

Last edited:

Hello

Just wondering if it matters if the drivers are installed, rotated by 90 degrees?

So the flats of the speaker sides are vertical with the side of the cabinet instead of horizontal.

Just for a different look thats all.

<snip>

Currently trying to set out the coils on a4 paper for best orientation any suggestion appreciated.

I was looking at humbles website and he packs the stuff really close together, couldn't find one with five coils though.I did see his write up on coil placement but the five on one board got me.

Cheers Paul

Hi Paul,

Changing the driver orientation should make no difference, as long as you manage your wire connections.

My layout is most like your Pic 1.

Apparently lab measurements indicate that any crosstalk is very low after about 50 mm between coils I usually go or the greatest separation allowed by the dimensions of the mounting area (or box). Another rule of thumb says that when you look straight through the whole of a coil you should not see another coil behind it, especially not one with the same coil orientation. Pic 1 looks the best in this regard also.

My 2 cents. Good luck.

Francois

Gday All

My first post so be gentle with me.

First batch of waveguides will be sent to Joe next Monday.

Long time follower of this thread.

Elsinores has been my first effort in the DIY audio world and I am blown away with the results.

A couple of photos of my pair attached (I hope)

Good news about the waveguides and congrats with your superb looking Elsinores. They speak volumes about your craftsmanship.

As you know from earlier posts we have 7 people in the US that expressed interest in group buying 7 pairs of waveguides, pending the final cost. Would you and/or Joe prefer to proceed by private mail in our discussions?

Then please send PM to me.

Thanks,

Francois

GB list from North America

The 7 folks on the interest list (each with one pair) are:

BHD

ben-jam-in (representing Canada - Ben and Matt, 1 pair each)

donkt88

Francois G

Johngalt47

mantraxl

Apologies if I missed anyone who tried to contact me - please let me know. If there are more of you out there please send PM

Francois

As you know from earlier posts we have 7 people in the US that expressed interest in group buying 7 pairs of waveguides, pending the final cost.

Thanks,

Francois

The 7 folks on the interest list (each with one pair) are:

BHD

ben-jam-in (representing Canada - Ben and Matt, 1 pair each)

donkt88

Francois G

Johngalt47

mantraxl

Apologies if I missed anyone who tried to contact me - please let me know. If there are more of you out there please send PM

Francois

The 7 folks on the interest list (each with one pair) are:

BHD

ben-jam-in (representing Canada - Ben and Matt, 1 pair each)

donkt88

Francois G

Johngalt47

mantraxl

Apologies if I missed anyone who tried to contact me - please let me know. If there are more of you out there please send PM

Francois

Don G contacted me and might join in the waveguide GB if he could find someone to build the crossover for him at reasonable cost. Anyone?

Joe and Steve, we are now looking at a GB of 7 or 8 from North America.

Francois

Wave Guide

Hello BHD

I do not recall if I entered my name as part of you GB but count me in if not. I know a Machinist who makes the molds for such pressings for the automotive industry and he may be willing to mill from aluminum, the mold shape you will need for a plastic pressing/mold! Should I contact him in this regard? We/ Group will have to buy a slab of aluminum and he can mill per our spec's. He is also willing to Mill other things like baffle plates or anything imaginable really! Get back to me if this avenue is of interest!

Francis

Hello BHD

I do not recall if I entered my name as part of you GB but count me in if not. I know a Machinist who makes the molds for such pressings for the automotive industry and he may be willing to mill from aluminum, the mold shape you will need for a plastic pressing/mold! Should I contact him in this regard? We/ Group will have to buy a slab of aluminum and he can mill per our spec's. He is also willing to Mill other things like baffle plates or anything imaginable really! Get back to me if this avenue is of interest!

Francis

Hi Guys,

Would anyone in the states be willing to build the MK-5 crossover for me?

Preferably someone who has yet to build theirs.

I would send the funds to cover the cost of the parts, labor, and shipping.

My expertise is cabinet building, and the knowledge of knowing that if I screw up the crossover, just a little, I've ruined a perfectly good loudspeaker. Anyone interested?

Don

Would anyone in the states be willing to build the MK-5 crossover for me?

Preferably someone who has yet to build theirs.

I would send the funds to cover the cost of the parts, labor, and shipping.

My expertise is cabinet building, and the knowledge of knowing that if I screw up the crossover, just a little, I've ruined a perfectly good loudspeaker. Anyone interested?

Don

Hi Guys,

Would anyone in the states be willing to build the MK-5 crossover for me?

Preferably someone who has yet to build theirs.

I would send the funds to cover the cost of the parts, labor, and shipping.

My expertise is cabinet building, and the knowledge of knowing that if I screw up the crossover, just a little, I've ruined a perfectly good loudspeaker. Anyone interested?

Don

Following a cross over wiring diagram isn't very difficult, worse case someone should be able to post a picture of an assembled cross over.

Can't be much more complex/difficult than soldering a couple of wires together. Even a inexpensive radio shack iron should do.

Just practice on a few wires and you should "get the hang of it".

If you are really worried about mucking it up, you could use jumper wires to assemble it and try it with your speakers. Once your satisfied that it works you can then solder it together.

If you can master the skills needed to assemble a set of cabinets a cross over really is simple (in my opinion).

I've been watching this thread since it first started, this new version has piqued my interest.

I've been looking for speakers to run with a set of Dynaco MK3s.

Has anyone recently priced out the total parts prices? (drivers and cross overs) I understand that the waveguide is TBD.

Wave Guide proto T

Hello Joe, in regards to the wave guide and respectful of your friend & assoc. Steve and his hard work, I like the way the problem to solve the flare of the tweeter's FLANGE has been approached. (Post #698 illustration) However may I suggest another maybe simpler approach? Remove the flange and model it's shape as part of the Wave Guide substrate (MDF) and mount the dome and motor section direct to the guide eliminating the flange but incorporating the flare at the mouth (inlet) into the MDF as part of the initial shape. In this way you may have better control of the thickness and proximity to the dome you can be. Your views?

Francis

Hello Joe, in regards to the wave guide and respectful of your friend & assoc. Steve and his hard work, I like the way the problem to solve the flare of the tweeter's FLANGE has been approached. (Post #698 illustration) However may I suggest another maybe simpler approach? Remove the flange and model it's shape as part of the Wave Guide substrate (MDF) and mount the dome and motor section direct to the guide eliminating the flange but incorporating the flare at the mouth (inlet) into the MDF as part of the initial shape. In this way you may have better control of the thickness and proximity to the dome you can be. Your views?

Francis

Gday Kingfisher

I think I know what you mean- mount the driver sans flatplate directly to the back of the MDF panel-? We did contemplate this method but Joe was reluctant to have the driver mounted to the WG, as he would rather have the driver mounted directly to the front panel structure of the Elisnores to ensure it is very "solid", and then just have the WG mounted seperately "in-front", forming no structural purpose. Joe might want to confirm the theory/reasoning.

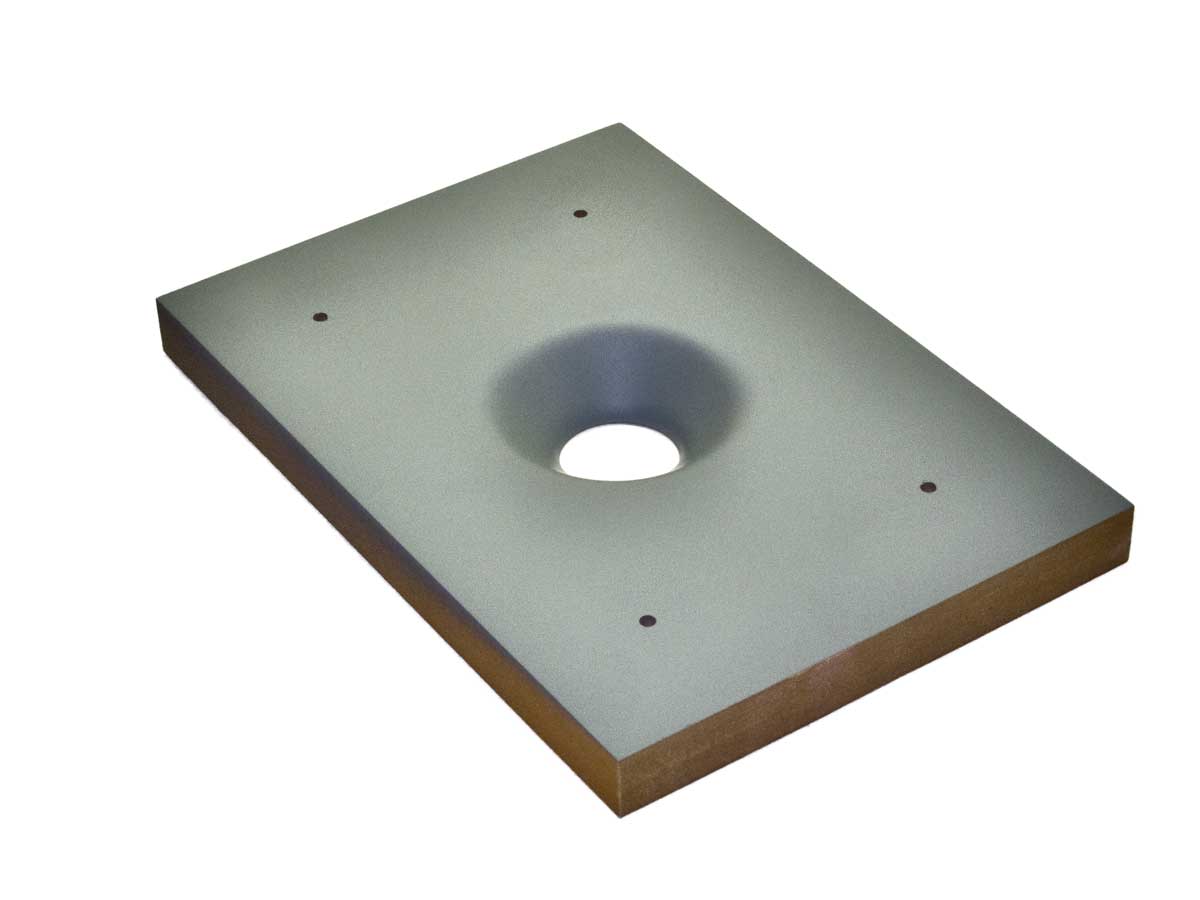

Below is a photo of the prototype WG in my pair- I had the luxury of fitting the WG panel very neatly into the "cavity" (where the felt used to be), but it took a bit of fiddling around trimming the edges to match "my" cavity exactly. It all depends on how accuratley (centered) your tweeter is mounted in the cavity, and the size of the cavity itself. That it is why we suggest having a small gap around the perimeter of the WG and to your cavity, trimmed to have it even, to make up for the differences in tolerance between each and every Elsinore fabrication

I think I know what you mean- mount the driver sans flatplate directly to the back of the MDF panel-? We did contemplate this method but Joe was reluctant to have the driver mounted to the WG, as he would rather have the driver mounted directly to the front panel structure of the Elisnores to ensure it is very "solid", and then just have the WG mounted seperately "in-front", forming no structural purpose. Joe might want to confirm the theory/reasoning.

Below is a photo of the prototype WG in my pair- I had the luxury of fitting the WG panel very neatly into the "cavity" (where the felt used to be), but it took a bit of fiddling around trimming the edges to match "my" cavity exactly. It all depends on how accuratley (centered) your tweeter is mounted in the cavity, and the size of the cavity itself. That it is why we suggest having a small gap around the perimeter of the WG and to your cavity, trimmed to have it even, to make up for the differences in tolerance between each and every Elsinore fabrication

Attachments

Hi Guys

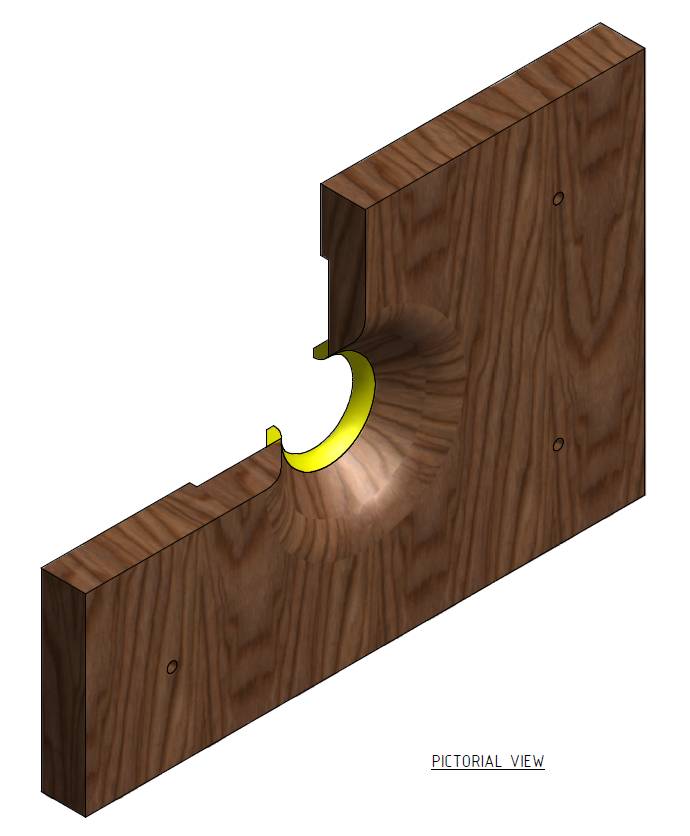

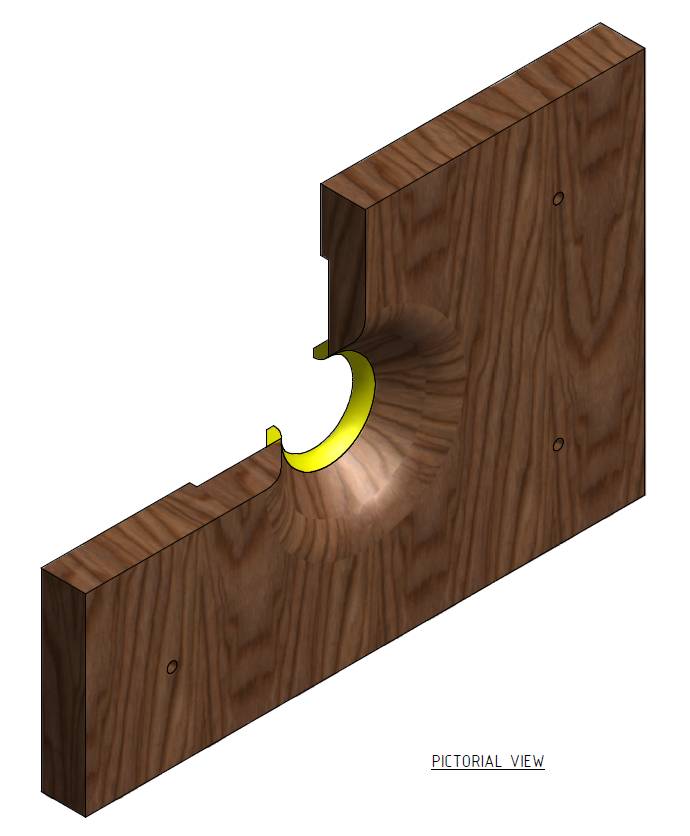

Steve has taken my rough drawings and come up with more detailed drawings, so I have decided to post them here:

OVERALL:

CLOSEUP:

For those inclined to make their own, go for it. But for the rest of us, we can appreciate Steve's efforts and the take advantage of his efforts.

Cheers, Joe

Steve has taken my rough drawings and come up with more detailed drawings, so I have decided to post them here:

OVERALL:

CLOSEUP:

For those inclined to make their own, go for it. But for the rest of us, we can appreciate Steve's efforts and the take advantage of his efforts.

Cheers, Joe

If you have access to a fancy CNC machine and wanted to make it look out of this world, Steve did this on his computer - nice 3D modelling:

But it also gives a good idea of the Waveguide parts.

Cheers, Joe

But it also gives a good idea of the Waveguide parts.

Cheers, Joe

Hi Guys

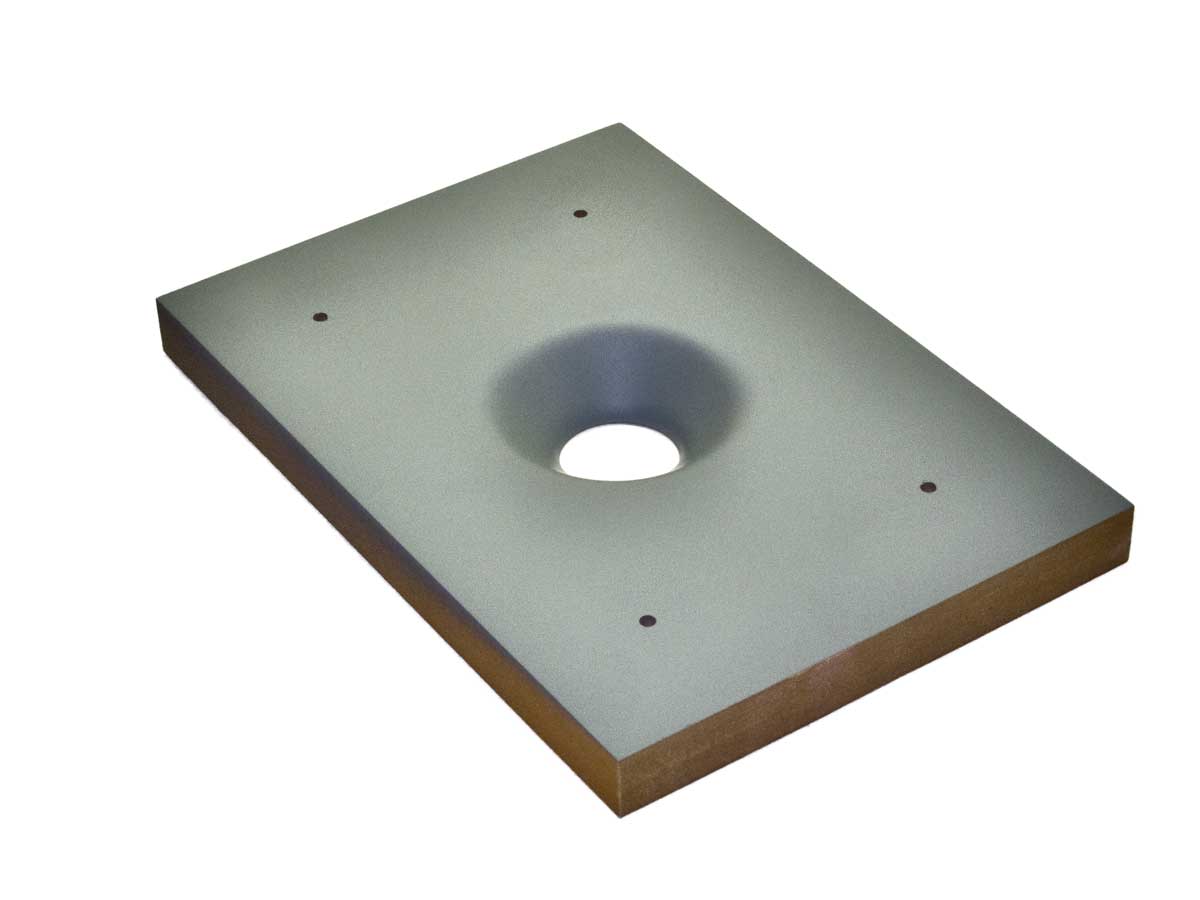

Received the first batch of waveguides from Steve "greenpea" today.

I've got to say that he has done a beautiful job and after talking today with him on the phone, may I simply say that the hours he spends making these... well, he is not making much for the time he puts in.

If these could be made with a CNC machine and cut down the time... ? But these are hand-made.

The first pair was posted to "spoonted" this arvo (that's Oz for afternoon - mustn't forget the international audience). 😀

The MDF is completely sealed from effects to moisture. The Front of the Waveguide is grey undercoat and very smooth. The Rear is also an undercoated, but this is a kinda rusty yellow.

Cheers, Joe

FRONT:

REAR:

Received the first batch of waveguides from Steve "greenpea" today.

I've got to say that he has done a beautiful job and after talking today with him on the phone, may I simply say that the hours he spends making these... well, he is not making much for the time he puts in.

If these could be made with a CNC machine and cut down the time... ? But these are hand-made.

The first pair was posted to "spoonted" this arvo (that's Oz for afternoon - mustn't forget the international audience). 😀

The MDF is completely sealed from effects to moisture. The Front of the Waveguide is grey undercoat and very smooth. The Rear is also an undercoated, but this is a kinda rusty yellow.

Cheers, Joe

FRONT:

REAR:

Last edited:

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread