just one question more, in that spherical picture, why does he stop drawing lines there? he could have drawn a few more. have a look to the image, you´ll see it is half the spherical reflector used.

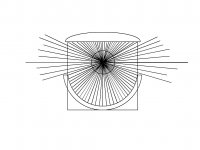

Hhehehe not sure you could always email them and ask them, imo yeah it is just a drawing for an idea, its not overly acurate. Ive drawn one of a system i designed a while back (see pic below).

The ellipsidal i bought cost me us$100, somewhat a very high quality commercial reflector.

Trev🙂

Attachments

very good picture yours. It is what i´ll do a swell. so no need to focus light to paralell output....

about that picture, i´ll tell you why 😀, if you draw one more, you wuld see it will not go paralell, it will bend down (drawing upside first), then you can draw next to it another one, it will bend more than the last, and finally the error will be inaceptable.

Now this error goes increasing in the way we go farther and goes decreasing in the why we go left(upside of sphere)), but always there will be this error, the only point where error is 0 is the ray that goes left orizontaly. is returned horizontaly, paralell .

all other rays will have error, (more or less, but always error)

need a pic?

about that picture, i´ll tell you why 😀, if you draw one more, you wuld see it will not go paralell, it will bend down (drawing upside first), then you can draw next to it another one, it will bend more than the last, and finally the error will be inaceptable.

Now this error goes increasing in the way we go farther and goes decreasing in the why we go left(upside of sphere)), but always there will be this error, the only point where error is 0 is the ray that goes left orizontaly. is returned horizontaly, paralell .

all other rays will have error, (more or less, but always error)

need a pic?

Na i dont need a pic because you can only get the paralelle light from a shperical in a shallow sphere, never in the one that i drew. Telescope mirrors you can for an example 😉, i get what your saying though and your right in a way.

My picture is only on a 1 way axis aswell so its not overly acurate in a 3d world, if i drew one in the otherway you would soon see how bad a spherical realy can be as the light wont go back to the center of the source due to our arcs being miles too big. The only way to have a spherical somewhat distortion free is the have a arc no bigger then 1mm, even then we will still have spherical abberations.

Trev🙂

My picture is only on a 1 way axis aswell so its not overly acurate in a 3d world, if i drew one in the otherway you would soon see how bad a spherical realy can be as the light wont go back to the center of the source due to our arcs being miles too big. The only way to have a spherical somewhat distortion free is the have a arc no bigger then 1mm, even then we will still have spherical abberations.

Trev🙂

ok, i don´t need to go further on these r/2 focusing on sphericals.

now, just having a look to your picture, i have masured the diameter and the focal lenth of your condnesor lens (i stated the bulb is 1 inch diameter circle). and found your lens is like; 70mm diameter and should have 4-5 cm focal.

do you have such a lens?

now, just having a look to your picture, i have masured the diameter and the focal lenth of your condnesor lens (i stated the bulb is 1 inch diameter circle). and found your lens is like; 70mm diameter and should have 4-5 cm focal.

do you have such a lens?

Your close the lens is 65mm dia and 80mm focal 😉

That pic isnt overly acurate, its just to give an idea on how much light i was utilising from the lamp, and even this is questionable as i havnt drawn in any reflections, that all comes under what type of coating used.

From memory the reflectors curvature is out too though its close.

Trev🙂

That pic isnt overly acurate, its just to give an idea on how much light i was utilising from the lamp, and even this is questionable as i havnt drawn in any reflections, that all comes under what type of coating used.

From memory the reflectors curvature is out too though its close.

Trev🙂

i´m very interested on your setup, could you tell me bulb lens separation, and tft size as well as back fresenll focal?

Hmm well i dont use that setup no more, the rear frensel was 220mm, the condenser now used (not me but for others) is about 80mm focal and is 80mm in dia, the bulb dia is 25mm and the reflector is 63mm dia.

I got quite a fair bit of my previous setup in my old thread which can be found here:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=21892

Alot of this stuff is outdated now by a long shot as i didnt post up any new stuff for a while, and alot of it ive held back due to time and copyright. Id rather spend more time in testing then posting, and alot of stuff isnt worth posting. Im one of these people who goes in leaps and bounds in R&D 😉, so i could post up a great idea one day and the next i could post up somthing 10x better. So thats why in one way i didnt bother posting all up.

Trev🙂

I got quite a fair bit of my previous setup in my old thread which can be found here:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=21892

Alot of this stuff is outdated now by a long shot as i didnt post up any new stuff for a while, and alot of it ive held back due to time and copyright. Id rather spend more time in testing then posting, and alot of stuff isnt worth posting. Im one of these people who goes in leaps and bounds in R&D 😉, so i could post up a great idea one day and the next i could post up somthing 10x better. So thats why in one way i didnt bother posting all up.

Trev🙂

ace3000_1 said:I dont use a condenser on my ellipsidal, why? cos all of the light is going to where i need it, its that simple. I can prove this if you want with a pic of my light on. Its clearly visible. From memory you even drew it out on paper just as i did before i bought it and it all matched up. Why condense the beam more if its spot on where it is? you will end up with a bright center on the projected image.

The only gain you would get with a condenser in this setup is the heh, roughly 5% of light you do loose, its that small its not worth the gain. Hell i hardly see any light on the table other then where it should go, and thats why its so bright, its going where i want it. And thats the key.

Trev🙂

didn't you have to hit the fresnel with the correct angle too?

i think the problem isn't only to get the light on the fresnel, but also to do this according to fresnel's focal length, or you will not have parallel light on the lcd.

i think that using a ellipsidal you have to use a condenser too to adjust the spot-fresnel distance according to focal length...i'm wrong?

ace uses a 7" LCD. the light beam will cover the whole LCD at fresnel's FL. for 15" you will need a condensor lens.

wow, ace is a lucky man! thank you it was my doubt18wheeler said:ace uses a 7" LCD. the light beam will cover the whole LCD at fresnel's FL.

It doesn't require luck

Ace just found an elliptical reflector and fresnel that matched his LCD size. If you are making your own elliptical reflector, then you can design it to match a particular fresnel for your LCD.

Lots of different shapes are possible, from curved saucer to deep dish, but it loses too much light if you make it too shallow. For any reasonable set of focal points, you just need to make it deep enough so the rays spreading from the second focal point will cover your condensor fresnel at its focal distance. I spent less than an hour just fooling around with some push pins, string, and ruler, and I came up with a perfect reflector design for a 15" LCD with a 330 mm fl condensor fresnel.

For anybody who doesn't know how to draw an ellipse: Tape a piece of paper to a soft board. Put two push pins or thumb tacks at the focal points you want. Make a loop of string that is larger than the length between the two pins, and put it around the two pins. Then you use the loop of string to guide your pencil to draw the ellipse. If you don't like the shape, change the pin distance or the size of the loop. Try it, it's fun! 😀

Ace just found an elliptical reflector and fresnel that matched his LCD size. If you are making your own elliptical reflector, then you can design it to match a particular fresnel for your LCD.

Lots of different shapes are possible, from curved saucer to deep dish, but it loses too much light if you make it too shallow. For any reasonable set of focal points, you just need to make it deep enough so the rays spreading from the second focal point will cover your condensor fresnel at its focal distance. I spent less than an hour just fooling around with some push pins, string, and ruler, and I came up with a perfect reflector design for a 15" LCD with a 330 mm fl condensor fresnel.

For anybody who doesn't know how to draw an ellipse: Tape a piece of paper to a soft board. Put two push pins or thumb tacks at the focal points you want. Make a loop of string that is larger than the length between the two pins, and put it around the two pins. Then you use the loop of string to guide your pencil to draw the ellipse. If you don't like the shape, change the pin distance or the size of the loop. Try it, it's fun! 😀

i can draw it but i have no idea about how build it...i was thinking to buy a professional one (18wheeler knows =).

how sis you build it? which material?

how sis you build it? which material?

yes, i also find this problem. I can draw 1000 of them but can´t do 1. 😀 any idea?

by the way, what do you think about doing a giant eliptical reflector? this way we can have a high precision eliptical reflector so the light efficiency would be the best.

And also if we design the reflector for our custom setup, there is no need of condenser, we can designe it with the output angle needed for our rear fresnell or lcd size.

Condensor lens does help when the solid angle of the rear fresnell is smaller than the solid angle the bulb is capable of outputing, but the bad side of using a condenser lens is that the arc would virtually look larger, then when fresnlls project it to the triplet, it can be as big as 5" arc lengh.

by the way, what do you think about doing a giant eliptical reflector? this way we can have a high precision eliptical reflector so the light efficiency would be the best.

And also if we design the reflector for our custom setup, there is no need of condenser, we can designe it with the output angle needed for our rear fresnell or lcd size.

Condensor lens does help when the solid angle of the rear fresnell is smaller than the solid angle the bulb is capable of outputing, but the bad side of using a condenser lens is that the arc would virtually look larger, then when fresnlls project it to the triplet, it can be as big as 5" arc lengh.

How did I build it?

I didn't, but I have looked into ways to do it inexpensively. There are two potential reflector surfaces, aluminum or silver. Silver is the very best reflector there is. (Only about 2% loss.) There are many places that will silver plate anything metal for you, so you could form the reflector from any metal and then get it plated to make it highly reflective.

Aluminum is also a very good reflector, (About 5-10% loss.) It is also easy to stamp, cast, or machine, and then polish. There is one thread here about machining a reflector out of a solid billet:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=50942&perpage=10&pagenumber=1

I have also seen some interest in making a stamping mold for a 1/8th section of a reflector. Then 8 identical pieces would include lips along the edges that you could rivit or bolt together to make the whole ellipse. Copper sheet might work better than aluminum, with silver plating after the stamping. (But much more expensive.)

I have done some sand casting, so that is what I would try: You make a prototype out of anything you can work to the right shape, then you use it to make a two-piece greensand mold. You pour molten aluminum into the assembled mold. Take the solid piece out and machine or grind it to the finished shape, followed by polishing. If you can make a prototype. there are many small local metal foundaries that can do the casting for you, along with any of the remaining steps. It is just a matter of how much to DIY versus how much to pay somebody else.

Anybody who wanted to go into mass production could get the cost down to just a few dollars each by using modern stamping or spin forming. The materials and forming are identical to the reflectors you see for light bulbs, and those cost less that $10 US at retail.

I didn't, but I have looked into ways to do it inexpensively. There are two potential reflector surfaces, aluminum or silver. Silver is the very best reflector there is. (Only about 2% loss.) There are many places that will silver plate anything metal for you, so you could form the reflector from any metal and then get it plated to make it highly reflective.

Aluminum is also a very good reflector, (About 5-10% loss.) It is also easy to stamp, cast, or machine, and then polish. There is one thread here about machining a reflector out of a solid billet:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=50942&perpage=10&pagenumber=1

I have also seen some interest in making a stamping mold for a 1/8th section of a reflector. Then 8 identical pieces would include lips along the edges that you could rivit or bolt together to make the whole ellipse. Copper sheet might work better than aluminum, with silver plating after the stamping. (But much more expensive.)

I have done some sand casting, so that is what I would try: You make a prototype out of anything you can work to the right shape, then you use it to make a two-piece greensand mold. You pour molten aluminum into the assembled mold. Take the solid piece out and machine or grind it to the finished shape, followed by polishing. If you can make a prototype. there are many small local metal foundaries that can do the casting for you, along with any of the remaining steps. It is just a matter of how much to DIY versus how much to pay somebody else.

Anybody who wanted to go into mass production could get the cost down to just a few dollars each by using modern stamping or spin forming. The materials and forming are identical to the reflectors you see for light bulbs, and those cost less that $10 US at retail.

Does anyone know roughly how much would it cost to silver-plate a stainless steel Ikea "Soare" napkin ring? It's about 5 inches wide and 20 square inches of inner surface area.

Of course, I only ask because I want to make my table-settings more elegant!

Of course, I only ask because I want to make my table-settings more elegant!

In that case ask Martha 😉

ask your local plater in the yellow pages. guess $10-15??

Is silver plating better than chrome plating? Chrome seems more mirror like.

ask your local plater in the yellow pages. guess $10-15??

Is silver plating better than chrome plating? Chrome seems more mirror like.

Before someone responds with the " but mirrors are made with silver so how could chrome plating be more mirror like?" question, look at your plated items.

The silver in a mirror is protected by glass and some black finish. Silver tarnishes. The rate of a chemical reaction is logarithmic. every 10degrees C doubles the reaction rate. This will be close to a very hot lamp. How often do you want to polish it?

I have a chrome racing bike that I got custom plated 20years ago and its still shiny like a mirror. Shiny car parts are chrome for the same reason - they stay shiny.

The silver in a mirror is protected by glass and some black finish. Silver tarnishes. The rate of a chemical reaction is logarithmic. every 10degrees C doubles the reaction rate. This will be close to a very hot lamp. How often do you want to polish it?

I have a chrome racing bike that I got custom plated 20years ago and its still shiny like a mirror. Shiny car parts are chrome for the same reason - they stay shiny.

chrome & silver

When something is chrome plated, the chrome layer is so thin it is transparent. What you are seeing is the nickel layer underneath the chrome. That combination is much less reflective than silver. Aluminum is a much better choice than chrome. Even with the naturally-formed transparent layer of aluminum oxide on the surface, it is better than 90% reflective.

Maybe you could get something silver plated and then chrome plated over that to protect it? Ask a plating company...

I actually studied silver plating quite a bit before I had my stainless steel reflector plated: Silver tarnishes by combining with atmospheric oxygen. If you heat lightly oxidized silver, it reduces the silver oxide coating back to metalic silver. I think a spherical reflector right next to a MH lamp, may be one of the few places you can use unprotected silver: Every time you use your projector it should get rid of any tarnish.

When I was shopping around, I saw prices from $20 to $48 for plating something the size of a saucer. Some platers have webpages. Shop around, but make sure you get good quotes by describing your reflector size and material: Some materials require multiple layers of other metals before the silver can go on.

When something is chrome plated, the chrome layer is so thin it is transparent. What you are seeing is the nickel layer underneath the chrome. That combination is much less reflective than silver. Aluminum is a much better choice than chrome. Even with the naturally-formed transparent layer of aluminum oxide on the surface, it is better than 90% reflective.

Maybe you could get something silver plated and then chrome plated over that to protect it? Ask a plating company...

I actually studied silver plating quite a bit before I had my stainless steel reflector plated: Silver tarnishes by combining with atmospheric oxygen. If you heat lightly oxidized silver, it reduces the silver oxide coating back to metalic silver. I think a spherical reflector right next to a MH lamp, may be one of the few places you can use unprotected silver: Every time you use your projector it should get rid of any tarnish.

When I was shopping around, I saw prices from $20 to $48 for plating something the size of a saucer. Some platers have webpages. Shop around, but make sure you get good quotes by describing your reflector size and material: Some materials require multiple layers of other metals before the silver can go on.

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- The Moving Image

- Lighting and OHP

- The Effects of Reflector Design and Lamp Orientation