Frank

The heater wires were twisted in a very tight pattern thanks to my cordless drill.

I only used 1/2 of each 12AY7 tube. Could this be causing any noise? should I parallel the sections of the 12AY7 together?

Joe

The heater wires were twisted in a very tight pattern thanks to my cordless drill.

I only used 1/2 of each 12AY7 tube. Could this be causing any noise? should I parallel the sections of the 12AY7 together?

Joe

HUM

Hi,

Shouldn't be a problem.

Assuming your heater voltage is 6.3VAC,did you connect pin #4 + 5 together on the 12AY7 and connect the heater wire to pins #9 +4 ?

Cheers,😉

Hi,

I only used 1/2 of each 12AY7 tube. Could this be causing any noise?

Shouldn't be a problem.

Assuming your heater voltage is 6.3VAC,did you connect pin #4 + 5 together on the 12AY7 and connect the heater wire to pins #9 +4 ?

Cheers,😉

Hi,

Actually, if only using half the tube, you coud, theroretically, only power the heater for that side.

If you did the channels mirror image, you could swap the tubes when worn out, and get another life!😀

Cheers,

Actually, if only using half the tube, you coud, theroretically, only power the heater for that side.

If you did the channels mirror image, you could swap the tubes when worn out, and get another life!😀

Cheers,

WIRING.

Hi,

That's a good idea John.

Here is the pin layout for the 12AY7A :

So if you use only section one on one channel you would use pins 1,2 and 3 and than 4+9 for the heaters.

The use section 2 of the twin triode using 6,7 and 8 and 5+9 for the heaters.

Cheers,😉

Hi,

That's a good idea John.

Here is the pin layout for the 12AY7A :

So if you use only section one on one channel you would use pins 1,2 and 3 and than 4+9 for the heaters.

The use section 2 of the twin triode using 6,7 and 8 and 5+9 for the heaters.

Cheers,😉

Attachments

Joe,

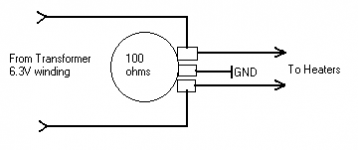

a) Did you center-tap, and then ground, the filament wires? This will elimanate a lot of fil. hum related issues. Get a 100 ohm pot, wire it across the filament winding with the wiper to ground.

b) If you have a scope, or a meter with frequency on it, can you tell if it's 60Hz, or 120Hz hum? That helps a lot in a diagnosis.

c) Other than the extra work and money, why'd you use two 12AY7's?? hehe

hehe

Joel

a) Did you center-tap, and then ground, the filament wires? This will elimanate a lot of fil. hum related issues. Get a 100 ohm pot, wire it across the filament winding with the wiper to ground.

b) If you have a scope, or a meter with frequency on it, can you tell if it's 60Hz, or 120Hz hum? That helps a lot in a diagnosis.

c) Other than the extra work and money, why'd you use two 12AY7's??

hehe

heheJoel

Well, I wired up the heaters wrong on the 12AY7's. I had the AC going to pins 4&5. I corrected that and now you can see life inside them. LOL

The hum is still there but I just turned the volume up slightly and enjoyed the music.

Joel

Please diagram the pot circuit so I don't make anymore mistakes.

I just plain liked the looks of two 12AY7's instead of one sitting on the chassis.

Note: This is hard for a SS guy to say but this lineamp beats both of my class A preamps. I'm hearing things I haven't heard before.

Joe

The hum is still there but I just turned the volume up slightly and enjoyed the music.

Joel

Please diagram the pot circuit so I don't make anymore mistakes.

I just plain liked the looks of two 12AY7's instead of one sitting on the chassis.

Note: This is hard for a SS guy to say but this lineamp beats both of my class A preamps. I'm hearing things I haven't heard before.

Joe

Note: This is hard for a SS guy to say but this lineamp beats both of my class A preamps. I'm hearing things I haven't heard before.

Another convert to thermionic emission! Amen!

Joel

I checked the heater voltage just for the heak of it and got 3.145 on one side to ground and about 3.4 on the other side to ground.

If I am following your thinking the uneven supply caused by an a poorly centered centertap is causing the hum.

Joe

I checked the heater voltage just for the heak of it and got 3.145 on one side to ground and about 3.4 on the other side to ground.

If I am following your thinking the uneven supply caused by an a poorly centered centertap is causing the hum.

Joe

CT

Hi,

Could be the CT on the xformer, but it could be caused by the heater of the tube as well.

If you use the trimpot you could balance it so you read the same voltages on either side of the heater.

Cheers,😉

Hi,

Could be the CT on the xformer, but it could be caused by the heater of the tube as well.

If you use the trimpot you could balance it so you read the same voltages on either side of the heater.

Cheers,😉

Splitting hairs..

Hi,

Cheers,

Hi,

But even then, the true hum "null point" could be slightly either side of centre volts.If you use the trimpot you could balance it so you read the same voltages on either side of the heater.

Cheers,

TRUE

Hi,

Indeed,so you best adjust it by ear for lowest hum.

Cheers,😉

Hi,

But even then, the true hum "null point" could be slightly either side of centre volts.

Indeed,so you best adjust it by ear for lowest hum.

Cheers,😉

HUMMING BIRD.

Hi Joe,

What's going on?

Have you tried different sources or a shorted input?

How severe is the humming anyway?

Cheers,😉

Hi Joe,

What's going on?

Have you tried different sources or a shorted input?

How severe is the humming anyway?

Cheers,😉

Frank

I tried my CD player and a FM tuner with the same amount of hum. I have also tried several poweramps (both SS) with the same result. I think its a power supply problem if I were to make a guess. Haven't shorted the input yet but do plan to see if my frequency counter will give me an idea what the frequency is. Checking with my digital meter I get about 6mv of DC offset on the output and about 3mv on the AC scale.

Joe

I tried my CD player and a FM tuner with the same amount of hum. I have also tried several poweramps (both SS) with the same result. I think its a power supply problem if I were to make a guess. Haven't shorted the input yet but do plan to see if my frequency counter will give me an idea what the frequency is. Checking with my digital meter I get about 6mv of DC offset on the output and about 3mv on the AC scale.

Joe

12AY7

Joe, this tube has a spiraled filament. You must make sure you wired one filament leg to the heater center tap, pin 9, and the other leg to both pins 4 & 5.

I would start with that. Then we can talk about your ground(s).

Joe, this tube has a spiraled filament. You must make sure you wired one filament leg to the heater center tap, pin 9, and the other leg to both pins 4 & 5.

I would start with that. Then we can talk about your ground(s).

HEATERS

Hi,

Connecting pins 4+5 would heat up both sections of the 12AY7A.

See also post #44.

Cheers,😉

Hi,

and the other leg to both pins 4 & 5.

Connecting pins 4+5 would heat up both sections of the 12AY7A.

See also post #44.

Cheers,😉

Frank

I // pin 4 to 5 and wired to 4 & 9 for the heaters. I also pulled the CT of this winding and installed a 100ohm pot as suggested. I am assuming that the noise must now be grounding issues. Will check tonight after work and measure frequency of noise after amplification. There is no noise when using a SS preamp or my other tube(Hong Kong) preamp.

Joe

I // pin 4 to 5 and wired to 4 & 9 for the heaters. I also pulled the CT of this winding and installed a 100ohm pot as suggested. I am assuming that the noise must now be grounding issues. Will check tonight after work and measure frequency of noise after amplification. There is no noise when using a SS preamp or my other tube(Hong Kong) preamp.

Joe

I good tip for heaters, if it has not been already mentioned, is not to ground the centre-tap (or wiper of the hum balance pot) but instead to sit it on +40V; this was used in old RCA designs. It turns off the "diode" created by the cathode and heater winding.

Another important mod is to AC ground each heater pin AT THE VALVE SOCKET* using 10nF ceramic capacitors. This will prevent any RF reaching the cathode via the heaters.

Proabably best to use DC in preamps though!

7N7

* I have used capitals because I cannot make the underline facility work

Another important mod is to AC ground each heater pin AT THE VALVE SOCKET* using 10nF ceramic capacitors. This will prevent any RF reaching the cathode via the heaters.

Proabably best to use DC in preamps though!

7N7

* I have used capitals because I cannot make the underline facility work

Paul, I find the software to do underlines italics etc awkward, so perhaps HTML or Markup would be easier. It's what I use, and I just type it in as I go.7N7 said:* I have used capitals because I cannot make the underline facility work

HTML

{b}all this will be bold{/b}

{i}and this will be italicised{/i}

{u}and this will be underlined{/u}

To directly link to an image from another site

{img src=image URL}

NOTE: I have used {} brackets where in reality you would use <> for HTML, but if I did, it wouldn't show it as examples, but actually bold, underlined etc in the finished post.

You can also use HTML at audioasylum.

Markup:

Similar to HTML, but uses [] for brackets instead of <>. I'll use {} again for examples so they're visible in the finished post. Notice the capitals.

{B}bold{/B}

{I}italicised{/I}

{U}underlined{/U}

{QUOTE}quoted text{/QUOTE}

{IMAGE}image URL here{/IMAGE}

To add a hyperlink into a sentence, eg

Another audio forum is {URL=http://www.audioasylum.com}Audioasylum{/URL}.

The word Audioasylum would show up in the finished post as a hyperlink, blue and underlined.

You can use both HTML and Markup in this forum in the same post, but you can't start a bold (for example) in html and finish it in markup. Start a function in one style, and you must finish it with the same.

You can also "nest" functions, eg in HTML (same idea with Markup too),

{i}813's are the {b}best{/b} tubes{/i}. The entire sentence would be in italics, with the word 'best' bold too.

HTH

Cheers

- Home

- Amplifiers

- Tubes / Valves

- The complete 6SN7 preamp