Yeah, gorilla glue expands, makes for a fun cleanup and probably compromises its strength. I use PL Premium as it stays where you put it and I know it works.

There's probably an equivalent "No More Nails" or other branded product, but stores around here all carry PL so it's all I've ever bought.

There's probably an equivalent "No More Nails" or other branded product, but stores around here all carry PL so it's all I've ever bought.

I looked at that PL stuff and it seems to be just PVA like bog standard wood glue, unless I'm totally mistaken. Is it really that good? I'd be worried about just glue and no other means of fastening.

I'd be tempted to screw in some right angled metal brackets on the edges.

I'd be tempted to screw in some right angled metal brackets on the edges.

I normally use "Henkel Ponal Express". Glues in 5 minutes. The bonding is normally more solid than the wood itself. 🙂

http://www.amazon.co.uk/Henkel-Ponal-Express-PN10X-Wood/dp/B000S6CJMS/

http://www.amazon.co.uk/Henkel-Ponal-Express-PN10X-Wood/dp/B000S6CJMS/

Last edited:

Looks like another PVA. I'm amazed that there can be so many different varieties of PVA. I didn't know it was that good!

I'd be tempted to screw in some right angled metal brackets on the edges.

Completely unnecessary They'd do no good except emptying some coins from your wallet and add weight.

The thing is that when you're limited to basically 8-10mm screws because the baffle is 12mm they'll be much weaker than the glue joint. Naturally, if you went all the way and riveted the metal brackets in place they'll start to become a possible factor but I doubt that any force strong enough to break the glue joint won't also just snap the metal bracket clean through.

Well, you've had plenty of experience so I trust your opinion.

Personally, I've never made anything out of wood which is just held together with glue. I would expect it to break down over time and fail. But you say it's fine - that's good enough for me.

Personally, I've never made anything out of wood which is just held together with glue. I would expect it to break down over time and fail. But you say it's fine - that's good enough for me.

I plan on using West system Six10 epoxy to glue it all together, already got a few tubes and will be testing it on some scrap first to get the hang of it.

Dupe...

Dupe...

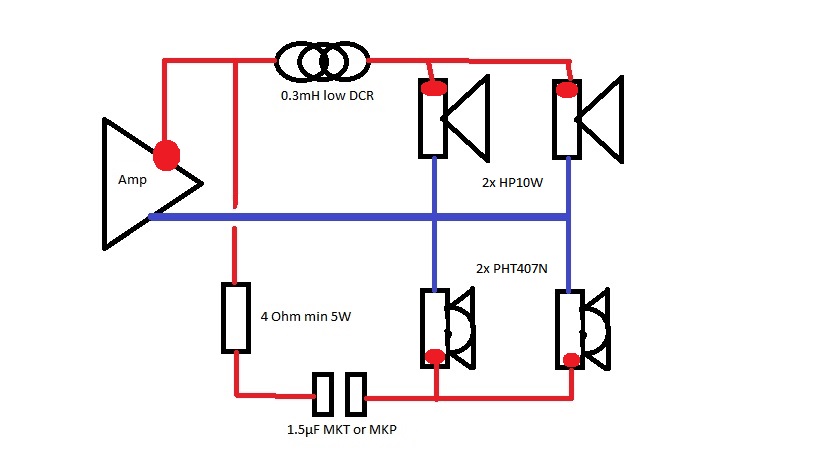

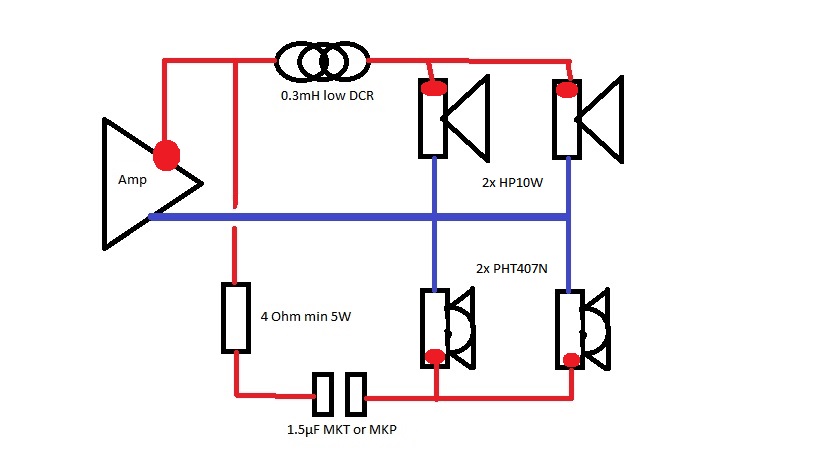

I'm building a half boominator (2xHP10W, 2xPHT407N) and planning to use a 2x50W tpa3116 amp on 24V. Is it possible to bi-amp this setup end still use this filter? Or is it better to put a dummy load on the other channel?

Will do, still not convinced, but cars and airplanes are stuck together with the stuff so it should be ok!

Cnc pack arrives tomorrow so we will see...

Dupe...

Cnc pack arrives tomorrow so we will see...

Dupe...

Trucie it's not possible to use the TPA3116 on 24V batteries. Consider using a TK2050 or STA508.

For bi-amping you need a MiniDSP, is that what you want?

For bi-amping you need a MiniDSP, is that what you want?

I'm building a half boominator (2xHP10W, 2xPHT407N) and planning to use a 2x50W tpa3116 amp on 24V. Is it possible to bi-amp this setup end still use this filter? Or is it better to put a dummy load on the other channel?

You can parallel the output channels. It won't give you more output power but at least energy is not wasted on a dummy load.

As mentioned by others the TPA3116 will not work on a "24V" battery. It has a hard voltage limit at 26V built in. Above that and the chip simply shuts down. If you have a dc-dc converter it will work on 24V though. Just note that it is generally regarded that the optimum supply voltage is no higher than 21V.

Wouldn't use epoxy at all for wood as is totally different joint, only wood glue.

This was my first thought, however its used to glue wooden airplanes together, boats, and the plywood itself. Its also used to repair wood in structural applications, its very universal and means I can use 1 glue for everything, attaching speakers and bonding magnet to the centre panel.

I can not find the post now, but sure Saturnus also suggested it?

Dupe...

I looked at that PL stuff and it seems to be just PVA like bog standard wood glue, unless I'm totally mistaken.

Not even close, its at least 3 times stronger, but the main benefit is that it is a lot more impact resistant, if you tap two panels with a hammer that have been glued together with PVA than they will come apart, not with this stuff, it dries hard but still behaves like rubber.

Not even close, its at least 3 times stronger, but the main benefit is that it is a lot more impact resistant, if you tap two panels with a hammer that have been glued together with PVA than they will come apart, not with this stuff, it dries hard but still behaves like rubber.

Interesting. My brief research indicates that there are three types of PVA - categorised mainly on the basis of how water resistant they are. Type 1 is the strongest and most water resistant(I expect the PL falls into this category). Joints must be tight and it's prone to creep under load.

Epoxy glues are better for gap filling (if the joint is too tight, it's weaker)and are waterproof, but more toxic and expensive.

I plan on using West system Six10 epoxy to glue it all together, already got a few tubes and will be testing it on some scrap first to get the hang of it.

Dupe...

If you use the phenolic coated ply, please don't. It won't stick.

Wow, lots of comments about glue today. Compatibility with materials is critical.

Saying epoxy is a bit like saying food. There are a lot of variations with varying qualities. Commonly available epoxy will be fine on bare ply wood. It holds up well and can have some modest gap filling properties too (e.g. the west systems stuff). It doesn't stick to polyester resins well, or at all. That's why it isn't good for the phenolic coated ply.

As for PL. I've used a lot of PL400 gluing ply to floor joists. It is amazing and I considered it for my builds but I am concerned it is too thick for the dado joints. They only have 0.01" (0.24mm) clearance in width and half again as much in depth. I'd really prefer to avoid a situation were the glue can't flow and I can't get the parts fully seated. Is there a thinner version?

As for Gorilla glue, this is the second time I've used it. It is just as awful as I remember. Just crap to work with, but I did some test glue ups and I'm confident it is strong enough, especially with the dados.

I suppose a bead of PL to the joint corners to add additional strength.

Saying epoxy is a bit like saying food. There are a lot of variations with varying qualities. Commonly available epoxy will be fine on bare ply wood. It holds up well and can have some modest gap filling properties too (e.g. the west systems stuff). It doesn't stick to polyester resins well, or at all. That's why it isn't good for the phenolic coated ply.

As for PL. I've used a lot of PL400 gluing ply to floor joists. It is amazing and I considered it for my builds but I am concerned it is too thick for the dado joints. They only have 0.01" (0.24mm) clearance in width and half again as much in depth. I'd really prefer to avoid a situation were the glue can't flow and I can't get the parts fully seated. Is there a thinner version?

As for Gorilla glue, this is the second time I've used it. It is just as awful as I remember. Just crap to work with, but I did some test glue ups and I'm confident it is strong enough, especially with the dados.

I suppose a bead of PL to the joint corners to add additional strength.

- Home

- Amplifiers

- Class D

- The Boominator - another stab at the ultimate party machine